Device with weighing and automatic blanking functions

An automatic unloading and functional technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of affecting work efficiency, no weighing function, and high work intensity of operators, so as to avoid losses due to transshipment and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

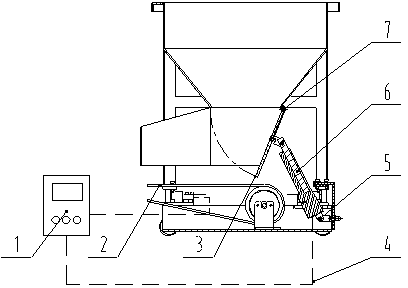

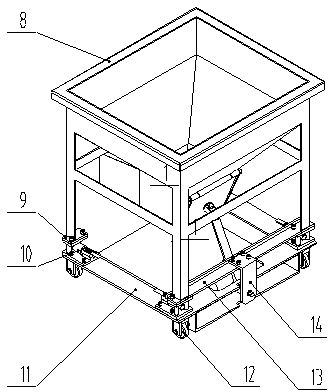

[0009] Such as figure 1 and figure 2 As shown, the present invention includes a control device 1, a conveying device 2, a discharge door 3, a communication line 4, a push rod hinge part 5, an electric push rod 6, a door hinge 7, a bucket 8, a short foot plate 9, a load cell 10, Bucket seat 11, castor 12, long foot plate 13, connecting plate 14. The bottom of the bucket 8 is provided with a short foot plate 9 and a long foot plate 13, a load cell 10 is connected under the short foot plate 9 and the long foot plate 13, the load cell 10 is connected to the bucket seat 11, and the long foot plate 13 is provided with a connecting plate 14. The plate 14 is not in contact with the bucket seat 11, the bucket seat 11 is provided with casters 12, the bucket 8 is connected to the unloading door 3 through the door hinge 7, the unloading door 3 is connected to the electric push rod 6 through the push rod hinge part 5, and the electric push rod 6 passes through the push rod The rod hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com