Efficient extending posture adjusting movable trestle

A mobile trestle and state-adjusting technology, applied to bridges, bridge forms, pedestrian bridges, etc., can solve problems such as narrow tunnel space, troublesome retreat, and inability to adapt to single-lane tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

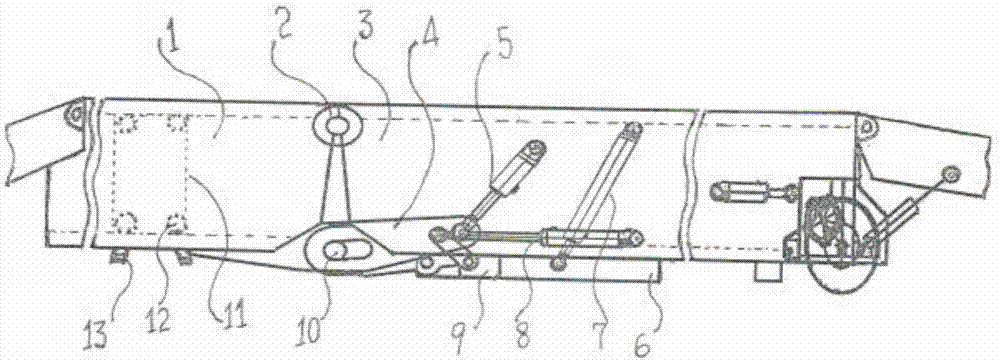

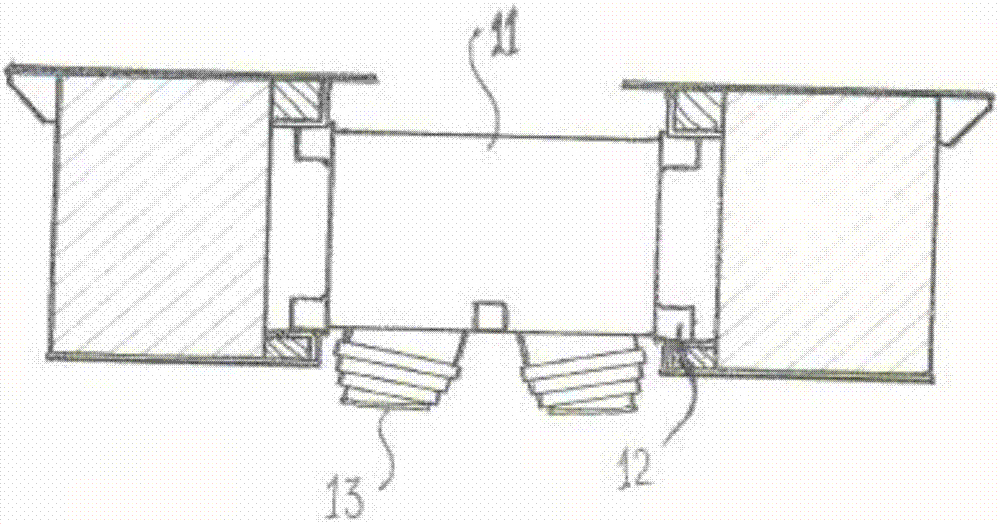

[0026] Such as figure 1 , 2 As shown, the high-efficiency extended adjustable state mobile trestle bridge includes two rows of main bridges arranged at intervals, and each row of main bridges includes the front section 1 of the main bridge and the rear section 3 of the main bridge, and the front section 1 of the main bridge and the rear section 3 of the main bridge The active connection is formed by the main bridge connecting mechanism 2 (such as pin joint pin), and the main bridge connecting mechanism 2 is arranged on the upper part of the connection between the front section 1 of the main bridge and the rear section 3 of the main bridge. State arm 4, this state control arm 4 is connected with arm oil cylinder 5.

[0027] The adjustment arm 4 is connected with the main bridge front section 1 and the arm oil cylinder 5 respectively, and the arm oil cylinder 5 is installed on the main bridge rear section 3, and a limit pin 10 is arranged at the main bridge rear section, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com