Short-foot automatic sealing method and device for screw type fluorescent lamp tube

A fluorescent tube and automatic sealing technology, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve problems such as tube bursting, low degree of automation, and strong glass stress, so as to achieve good product appearance and improve product quality. Quality, yield, and productivity improvement effects

Inactive Publication Date: 2010-12-01

HANGZHOU YUZHONG GAOHONG LIGHTING ELECTRICAL

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

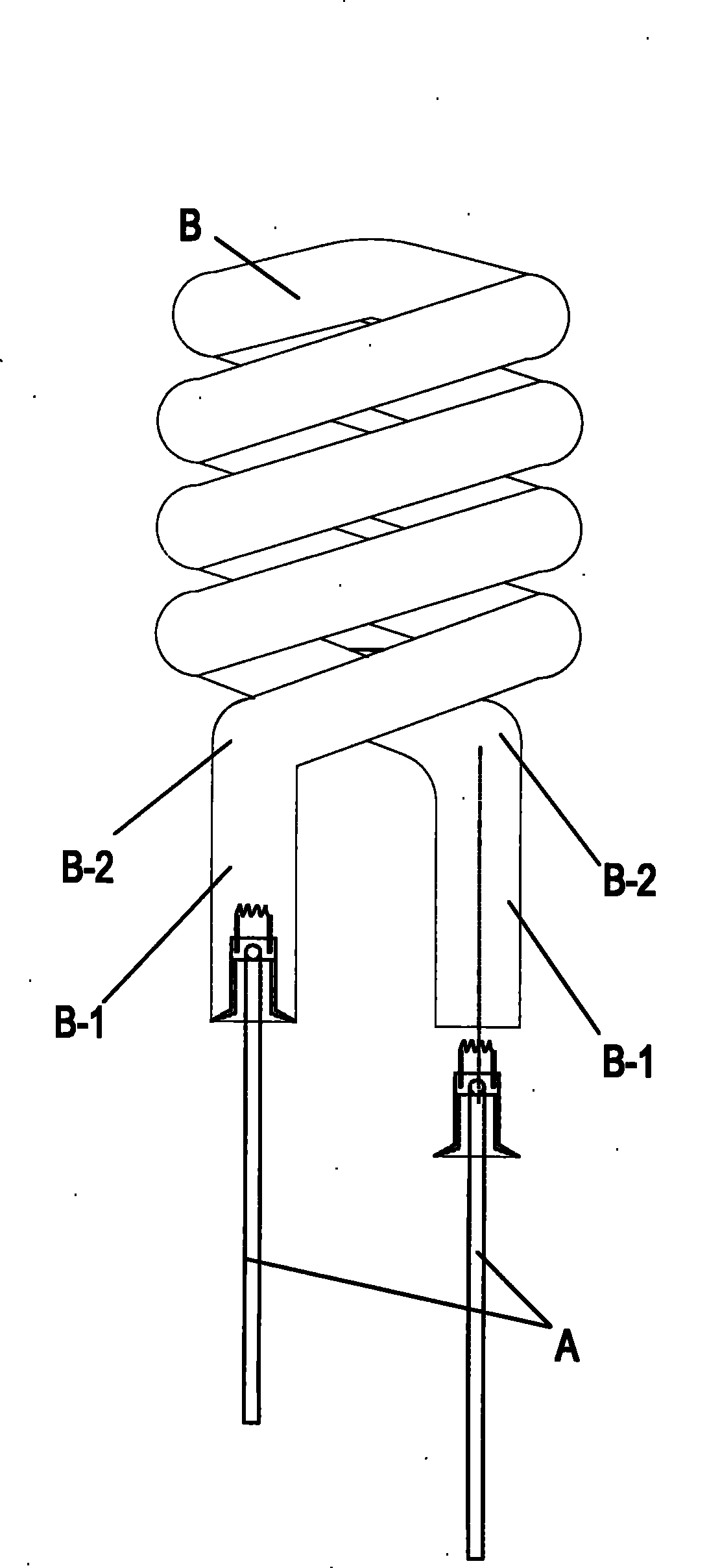

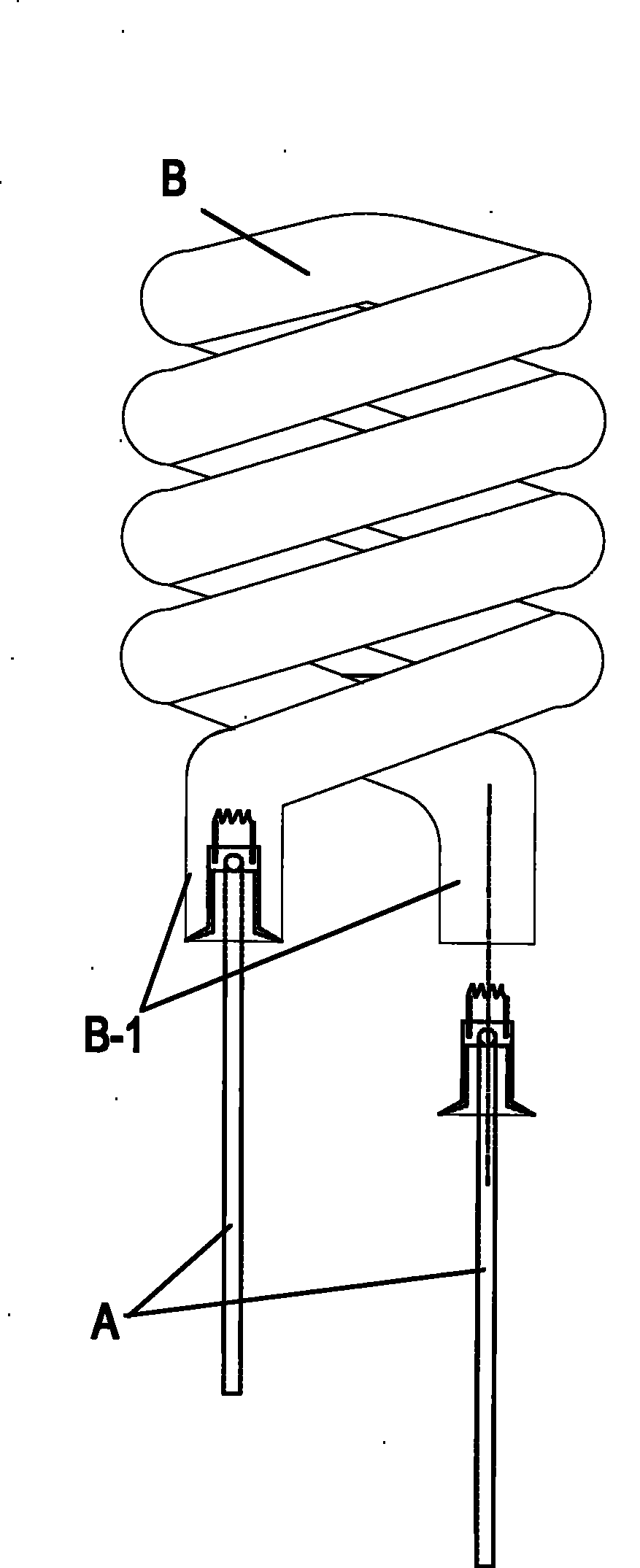

This sealing method needs to use a long-legged spiral lamp tube, combined with manual mechanical sealing, the degree of automation is low, and the pins of the sealed lamp tube are high (as shown in Figure 1, the pin B-1 of the lamp tube is longer), after assembly The appearance of energy-saving lamps is relatively poor, and the installation of lamps is not compact

If the spiral lamp tube with short legs of this equipment is used for sealing, since the sintered part is very close to the clamping part of the tube clamp, the temperature difference between the sintered part of the lamp tube and the tube clamp part is very large, and the glass tube is easily heated unevenly. Strong glass stress is generated, causing the lamp tube to burst, so the yield is not high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

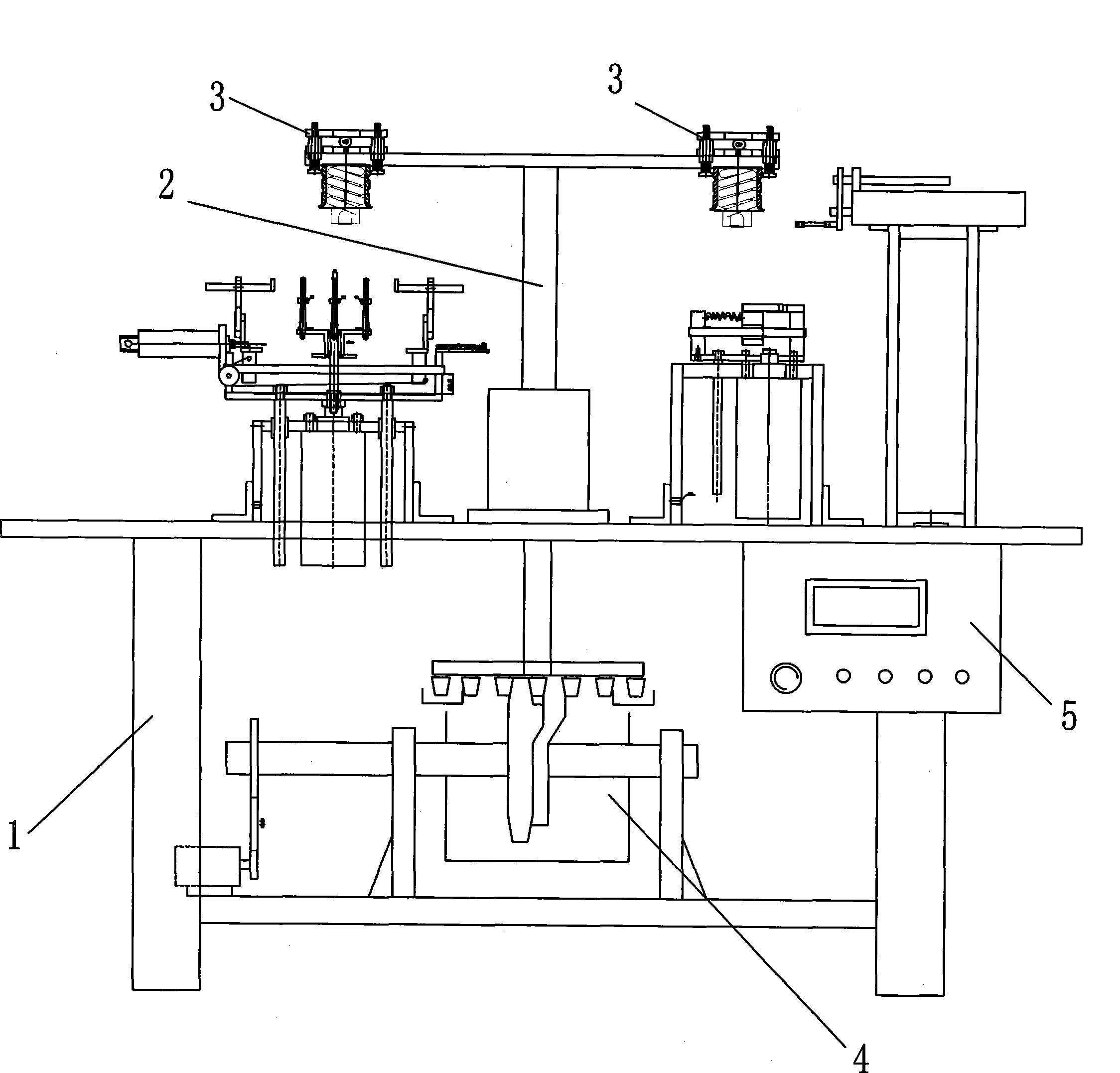

The invention relates to an automatic sealing method for spiral fluorescent lamp tube root and equipment thereof, aiming at providing a method and equipment thereof to produce short root lamp tubes and have high production rate, good quality and high automatization. The technical proposal is of an automatic sealing method for short tube root of the spiral fluorescent lamp tube. The method is divided into the steps: 1. prelocating the tube root; 2. taking the spiral peripheral part of the lamp tube as a handle part when sintering; 3. locating the space position of the lamp tube root to be sintered; 4. preheating; 5. locating a core column in the tube root; 6. sintering; 7. repeating the processes to process a second tube root. The automatic sealing equipment for short tube root of the spiral fluorescent lamp tube comprises a frame with a plurality of working stations. The frame is equipped with a main shaft, the upper end of which is fixed with a plurality of an externally grabbing-typed sealing clamper. The main shaft is driven by a driving mechanism and is provided with a control device. The working stations comprise tubes of material feeding location, preheating and sintering and each station is configured with a corresponding operation device.

Description

Automatic sealing method and equipment for short legs of spiral fluorescent tubes technical field The invention relates to a sealing method and equipment for fluorescent lamp tubes, in particular to an automatic sealing method and equipment for the pins of spiral fluorescent lamp tubes. Background technique Due to the advantages of high luminous efficiency and energy saving, energy-saving lamps are in line with the trend of energy saving and environmental protection in today's society, and have been vigorously promoted and applied at present. As one of the series of energy-saving lamps, the spiral fluorescent lamp has also expanded its application range unprecedentedly. Since the tubes of spiral fluorescent lamps currently produced in China are basically bent by hand, it is difficult to maintain the spiral shape of the tubes within a certain tolerance range, which brings great obstacles to the subsequent automatic production of the tube sealing process. The sealing proce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01J9/24C03B23/057

CPCY02P40/57

Inventor 张林夫项荣华

Owner HANGZHOU YUZHONG GAOHONG LIGHTING ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com