Herringbone retainer

A technology of fixers and robots, applied in multidisciplinary fields, can solve problems such as costing time and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

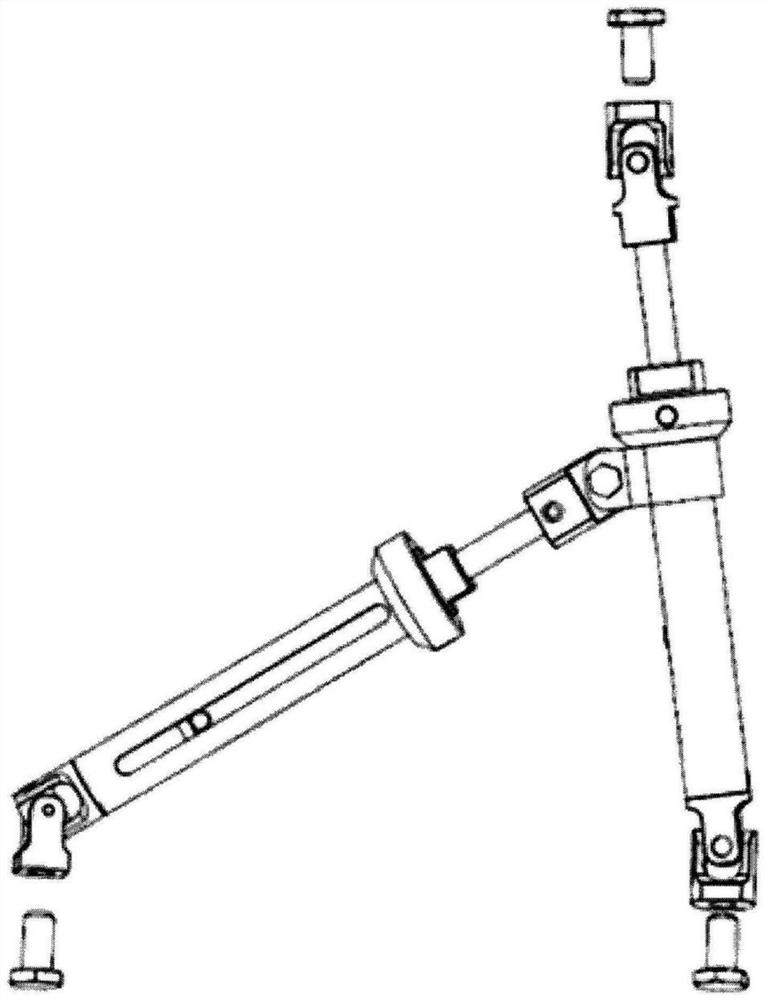

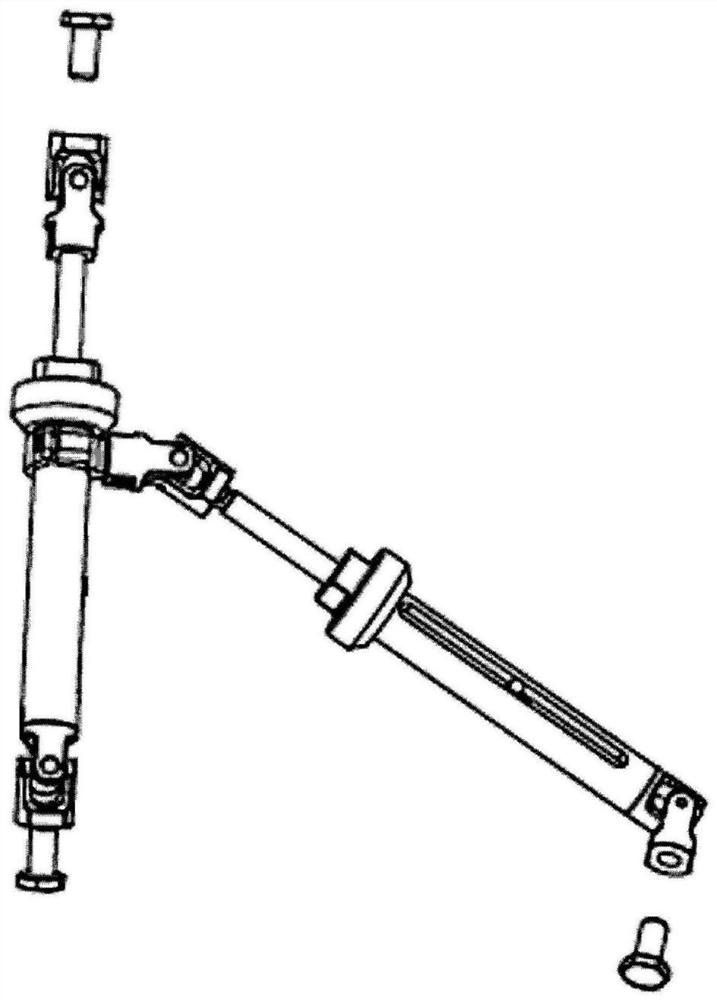

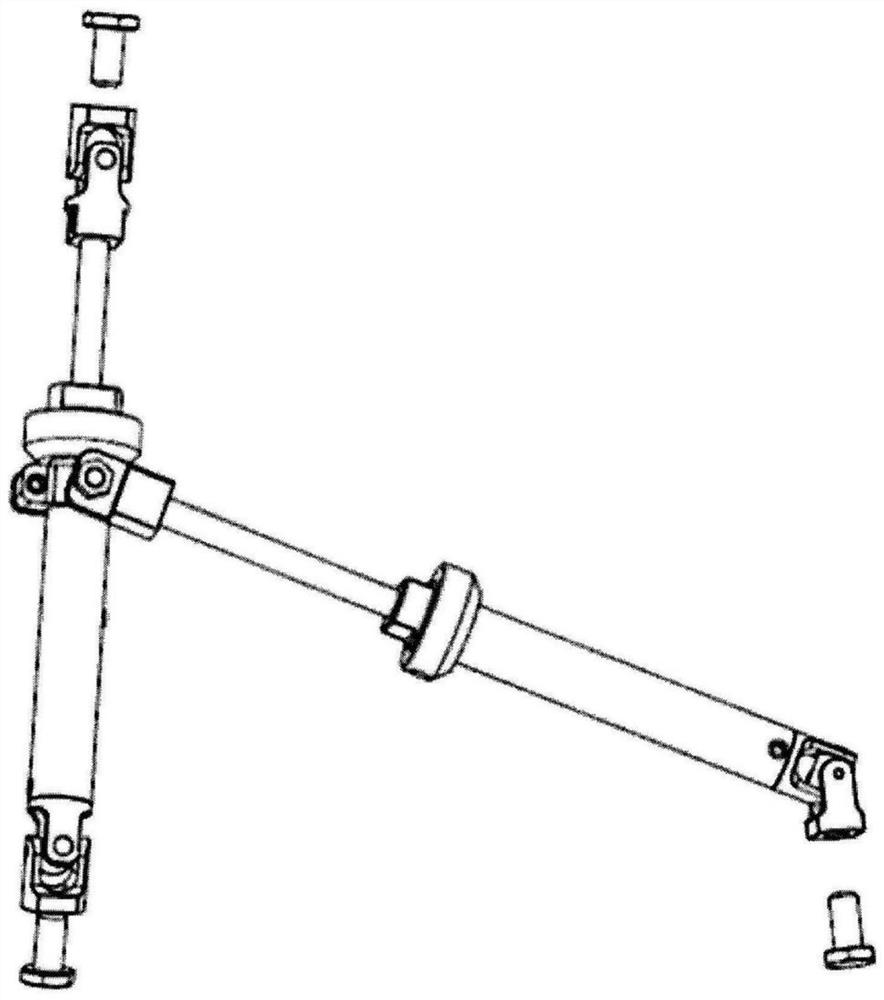

[0074] In the robotic arrangement of external fixators, the first basic lambda module type ( figure 1 ) can be used with rings having a single row of holes; this is because the short and long legs of the lambda modules, together with their axes, lie in a single plane perpendicular to the axis of rotation of the swivel joints connecting them. The presence of short feet and long feet on the same plane may introduce small constraints on the length of the short feet and the number of changes in this length. able to pass image 3 The second class of first basic lambda modules seen in overcomes this situation. By making the axis of rotation of the swivel joint pass through a point on the axis of the long leg, the condition for making the short leg to take a greater length is fulfilled by this second category ( image 3 ). In this case, the axes of the short and long legs of the lambda modules lie in two separate planes that are parallel to each other and at the same time perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com