circuit breaker

A circuit breaker and circuit technology, applied in the direction of electromagnetic release switch, protection switch operation/release mechanism, etc., can solve the problems of increasing the tripping load of the abutment plate, difficult operation, unstable tripping action, etc., and achieve the effect of reducing the tripping load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

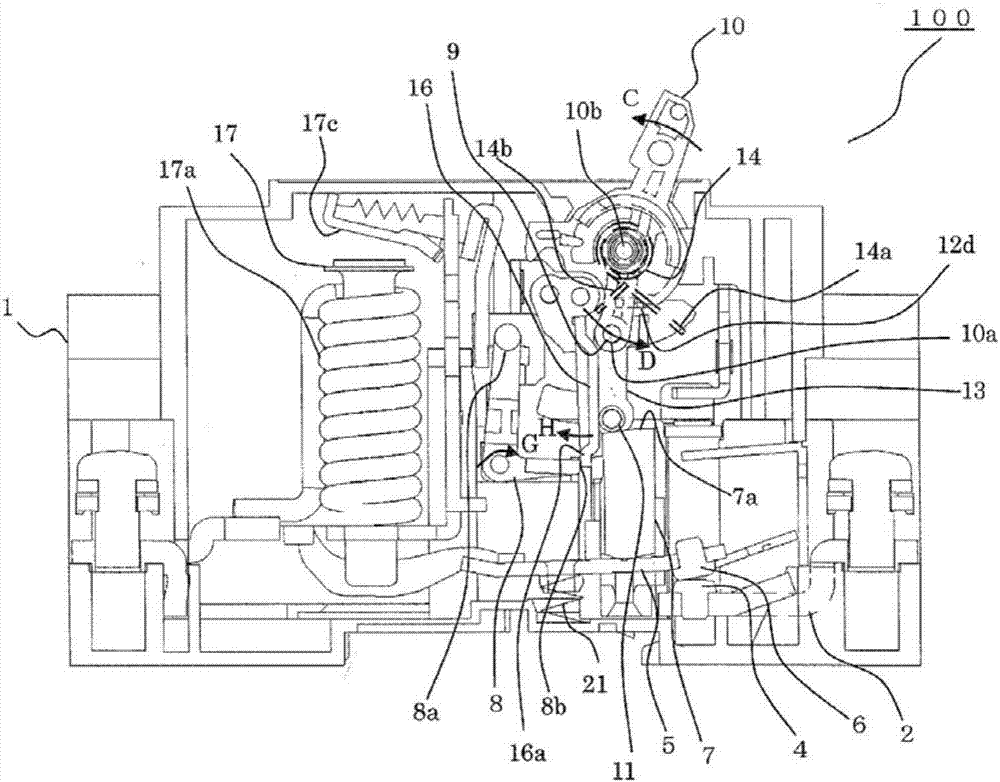

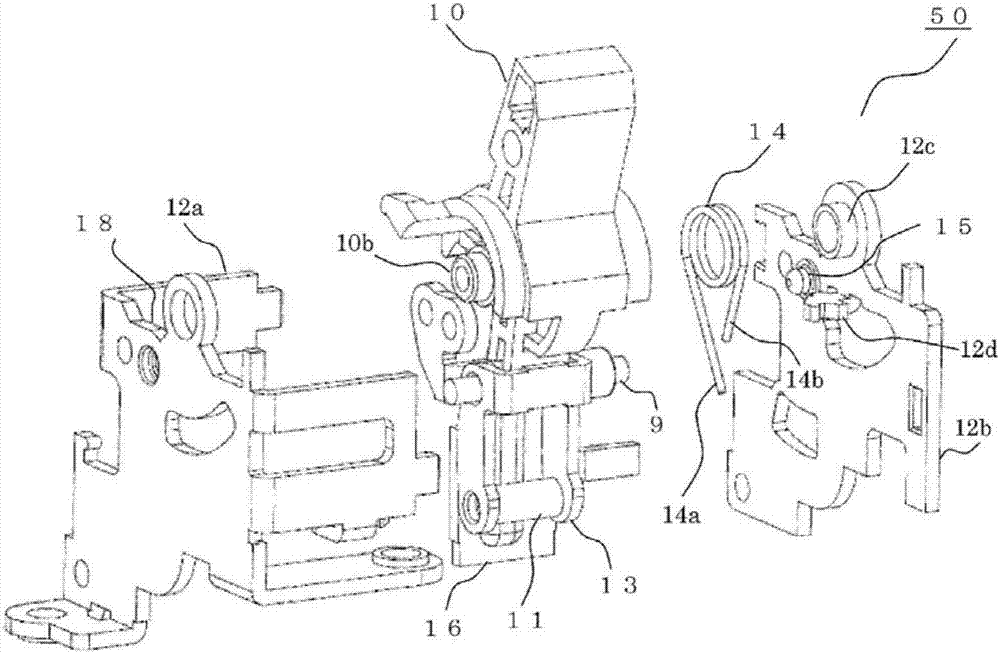

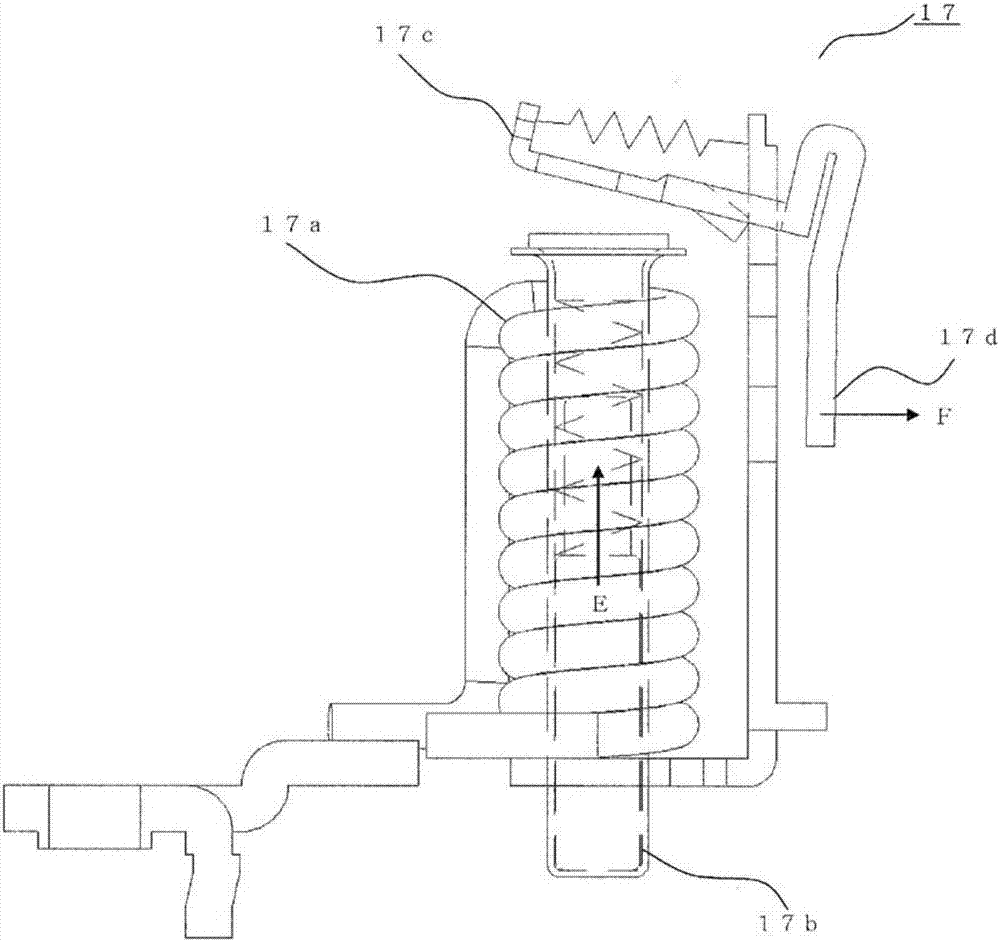

[0021] Figure 1 ~ Figure 7 Is a diagram showing a circuit breaker in Embodiment 1 of the present invention, in figure 1 , figure 2 In this case, the circuit breaker 100 is composed of a housing 1 made of an insulating material, and the following components respectively contained in the housing 1, and other components. That is, the components respectively contained in the housing 1 are: The externally operated manual handle 10; the fixed contact conductor 2 provided with the fixed contact 4; the movable contact conductor 5 provided with the movable contact 6 contacting / separating from the fixed contact 4; and the above-mentioned fixed contact 4 The opening / closing mechanism part 50 for making and breaking operations with the movable contact 6.

[0022] The opening and closing mechanism section 50 has: a pressing plate 7, which is made of an insulating material, and extends along the not-shown groove of the frame 1 while maintaining the engagement with the movable contact conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com