Full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration

A technology for LED light strips and production equipment, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low efficiency, more production, affecting production efficiency and production quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0174] Gap divider 8, the input shaft continuously rotates one week and the output shaft can be used as a mechanism for stopping and rotating. The desired action can be completed during the stop period.

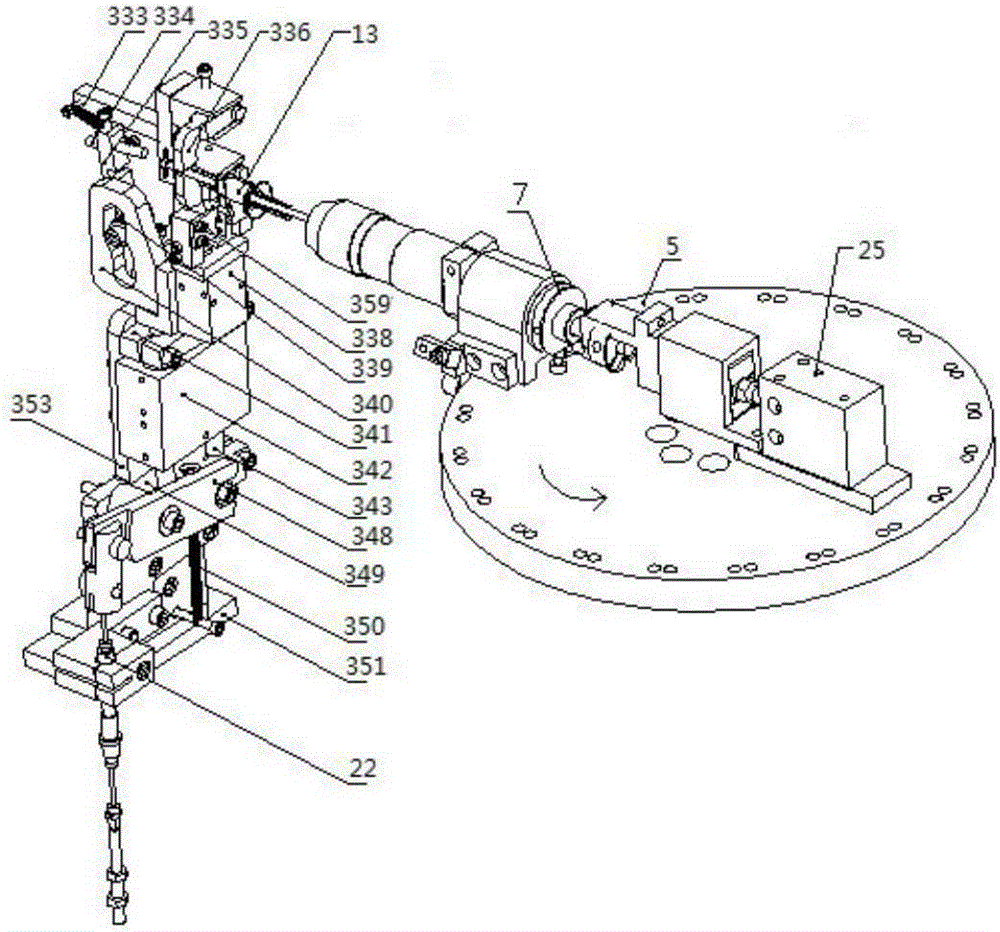

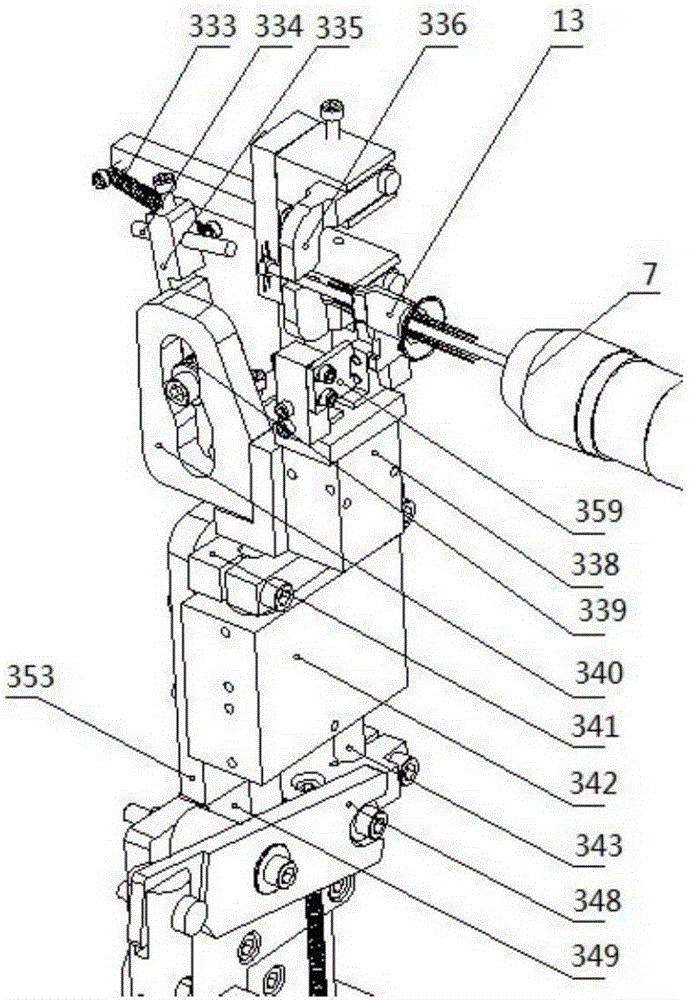

[0175] The indexing disc 5 has been reduced for the convenience of display, and the indexing disc 5 is fixed on the output shaft end of the divider, the gap divider 8, the long-legged 45-degree assembly mechanism (in the rectangular frame A) and the stem left and right The positioning mechanisms (in the rectangular frame B) are all fixed on a platen 3 .

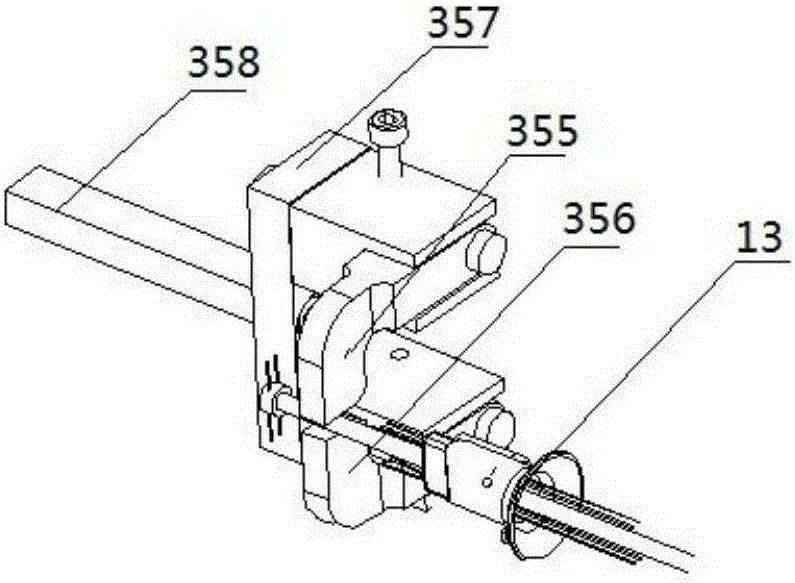

[0176] The bottom slide rail seat 718 is used to straighten the long feet and is rotated by the motor through the belt, the reducer 10, the station main shaft 9, and the gear, and the jaw cylinder is pushed upward by the lever 12 and the connecting rod. When pushed upward, the jaw cylinder The action is to clamp the horn front end plane of the stem 13 through the positioning chuck 703 connected with the jaws, so that the ki...

Embodiment 2

[0189] like figure 1 As shown, the short leg of the LED light bar automatically dials the 45-degree device, which is used to dial the four short metal legs connected to the stem 13 to make about 90 degrees to each other, including the connection on the indexing disc 5 in sequence. The stem clamp 7, the gap divider 8, the stem positioning device, and the toggle device; the stem positioning device and the toggle device are respectively connected to the same transmission shaft through a positioning and transmission cam 839, wherein: the core Column positioning device: including the positioning chuck 802 concentric with the core column clamp 7, the cylinder seat 831 for the shifting foot, the guide rail seat, the cylinder 832 for the shifting foot, the positioning guide post 830, the positioning slider 805, the guide rail seat cam 806, the shifting foot The rocker arm 808, the thick pull rope 22, the cylinder 832 for the shifting foot are connected in the cylinder seat 831 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com