Combined circuit board chemical treatment line equipment and treatment method thereof

A technology of chemical treatment and treatment method, which is applied in the field of combined circuit board chemical treatment line equipment and its treatment, which can solve the problems of unfavorable integration and utilization of the same process, large footprint of single line body, product oxidation, etc., and achieve convenient automatic treatment operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

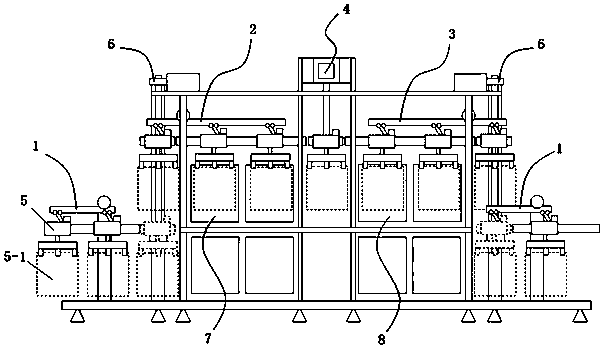

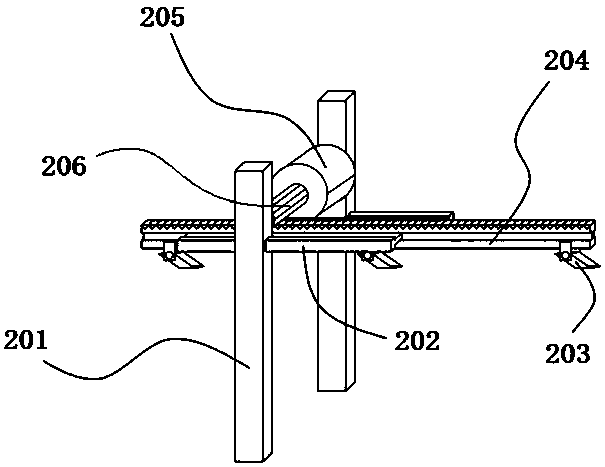

[0040] Example 1, please refer to Figure 1~4 A combined circuit board chemical processing line equipment, including a frame, the frame is provided with a left-right symmetrical front processing groove 7 and a rear processing groove 8, between the front processing groove 7 and the rear processing groove 8 A transfer mechanism 4 is provided, and the frame is provided with a front processing transport mechanism 2 corresponding to the front section processing tank 7, and the frame is provided with a plate entry transport mechanism 1 corresponding to the front processing transport mechanism 2, and the plate entry transport mechanism 1 is arranged at the bottom of the frame. A plate lifting mechanism is set between the plate-in transport mechanism 1 and the front-processing transport mechanism 2, and the post-processing transport mechanism 3 is provided on the frame corresponding to the rear processing tank 8, and the plate-out transport mechanism is provided on the frame correspond...

Embodiment 2

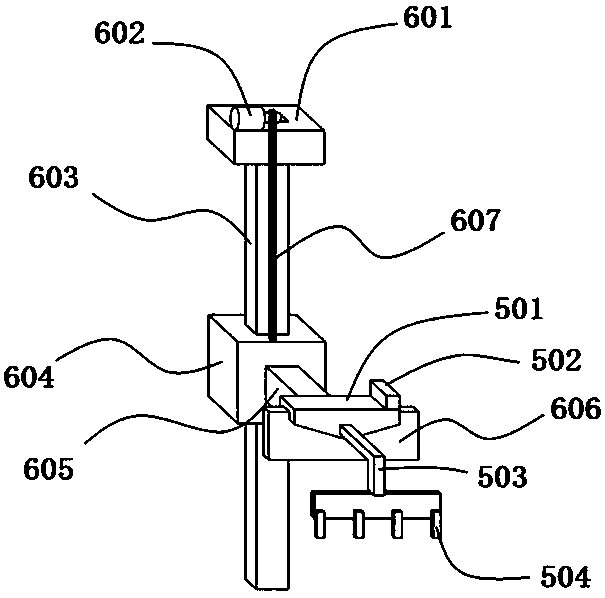

[0046] Embodiment two, refer to Figure 5 , the present embodiment adds the following technical features on the basis of Embodiment 1: the lifting fixture mechanism 6 also includes vertical support beams 608 symmetrically arranged left and right on the frame, the top platform 601 is arranged on the top of the two vertical support beams 608, and the two A horizontal support beam 609 is arranged between the bottoms of the vertical support beams 608. There are two sliding rods 603 arranged symmetrically along the horizontal support beams 609. Set in the middle of the top platform 601, the suspension motor 602 is a double-head motor, and the two ends are connected with the sliding sleeve 604 through the suspension chain 607.

Embodiment 3

[0047] Embodiment three, refer to Image 6 , the difference between this embodiment and Embodiment 1 is:

[0048] Wherein, the transfer moving mechanism is a belt vehicle-mounted mobile mechanism, including a vehicle-mounted beam 412 arranged on the frame, and fixed frames 411 are symmetrically arranged at both ends of the vehicle-mounted beam 412, and the vehicle-mounted beam 412 is suspended and installed on the frame through the fixed frame 411 , the two ends of the vehicle-mounted beam 412 are fitted with a belt shaft 414, the belt shaft 414 is equipped with a transmission belt 410, the vehicle-mounted beam 412 is slidably fixed with a vehicle-mounted seat 413, the vehicle-mounted seat 413 is fixedly connected with the transmission belt 410, and the top of the connecting rod 404 It is fixed on the lower side of the vehicle seat 413, and the belt shaft 414 on one side is connected with a relay stepping motor 401.

[0049] see Figure 7-8 , Embodiment 1 to Embodiment 3: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com