Efficient pentahedron vertical and horizontal integrated machining center

A machining center and pentahedron technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unreasonable design, low environmental protection performance, inability to remove dust and purification, etc., and achieve reasonable design and high environmental protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

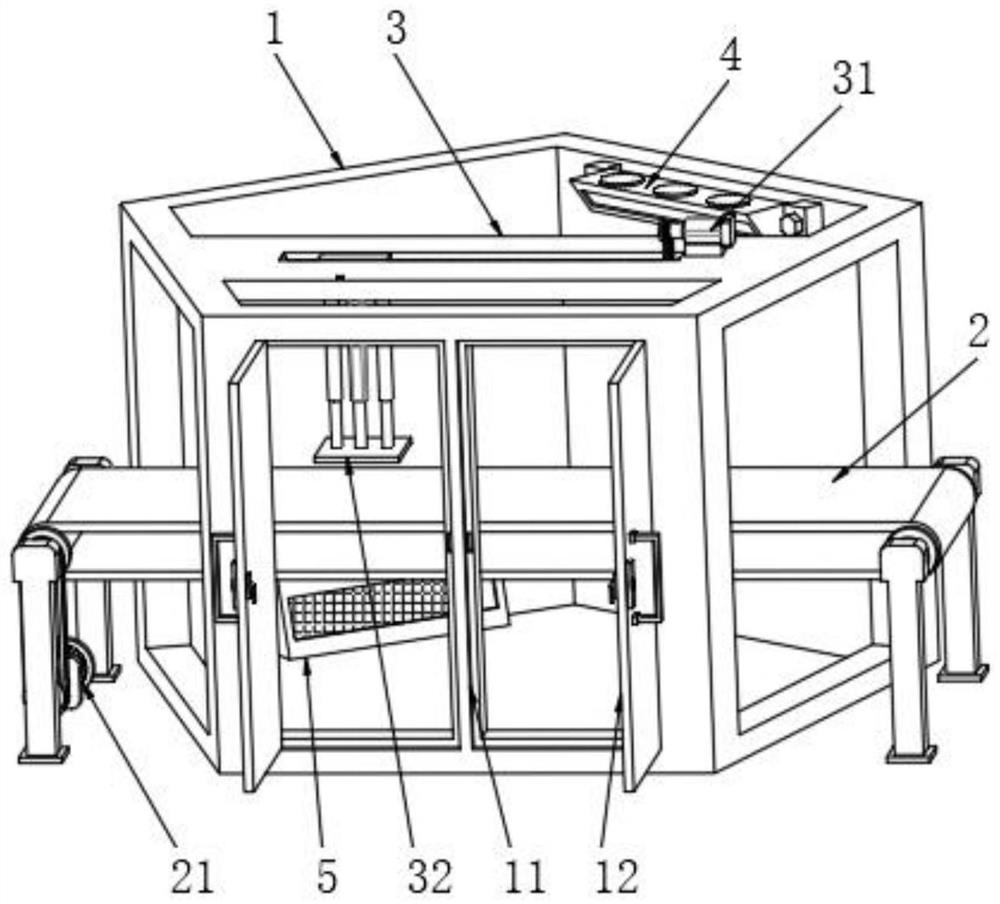

[0032]The embodiment of the present invention provides a technical solution: a high-efficiency pentahedron vertical and horizontal integrated machining center, a door frame 11 is fixed in the middle of the front part of the integrated processing frame 1, and the front part of the integrated processing frame 1 is connected to the door frame. The inner end of the front part of the door frame 11 is provided with a groove; the middle end of the door frame 11 is provided with a positioning hole; The outside of the positioning pin is provided with a safety lock plate, and the outer middle of the cabinet door panel 12 is provided with a pulling device, which is convenient for opening and closing operations.

example 2

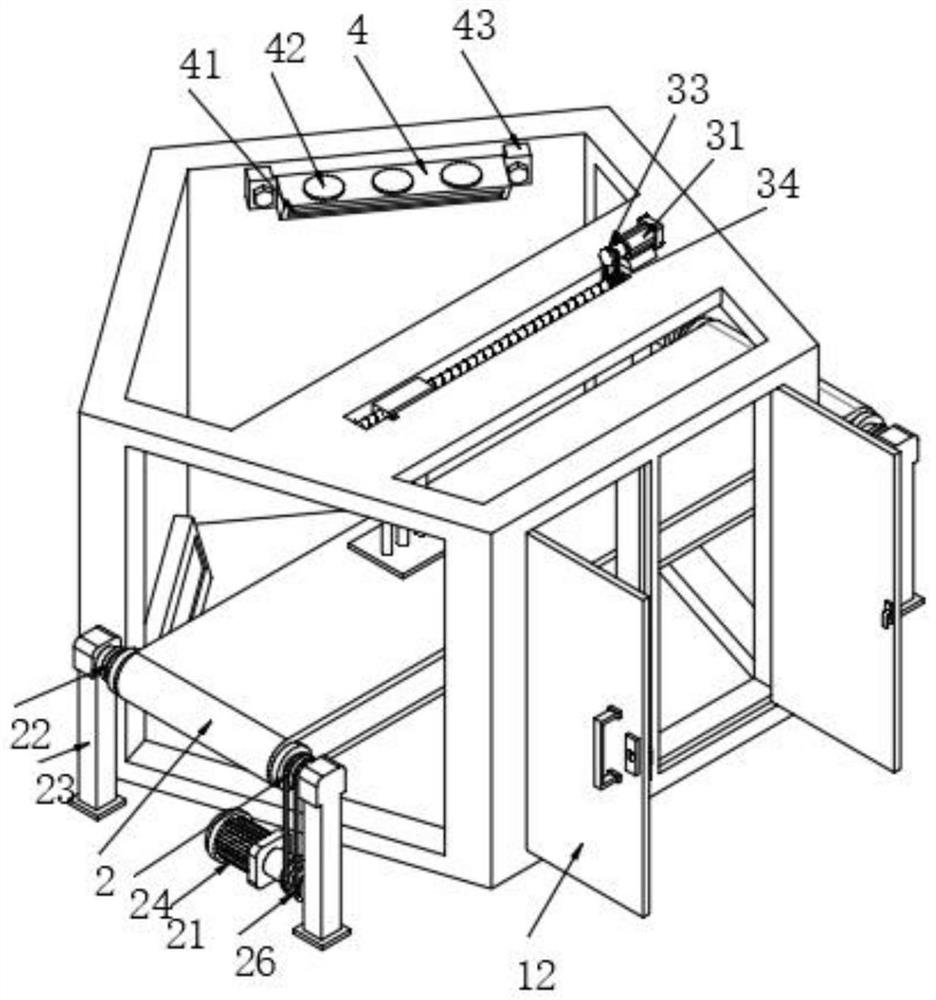

[0034] The embodiment of the present invention provides a technical solution: a high-efficiency pentahedron vertical and horizontal integrated machining center, the conveying device 2 is arranged through the interior of the integrated machining frame 1, and the inner ends of the conveying device 2 are provided with rotating shafts The rod 22, the front and rear ends of the rotating shaft rod 22 are connected with support legs 23, the left front end of the conveying device 2 is connected with a first driven gear 24, and the bottom of the first driven gear 24 is connected with a first driven gear 24 through a belt. The drive motor 21 is connected to the rear end of the first drive gear 26; the bottom of the drive motor 21 is fixedly provided with a backing plate 25, and the bottom of the backing plate 25 is bonded with a rubber pad. A limit plate is fixed between the driven gear 24 and the first driving gear 26 to stabilize the limit belt chain. The front end of the first driving...

example 3

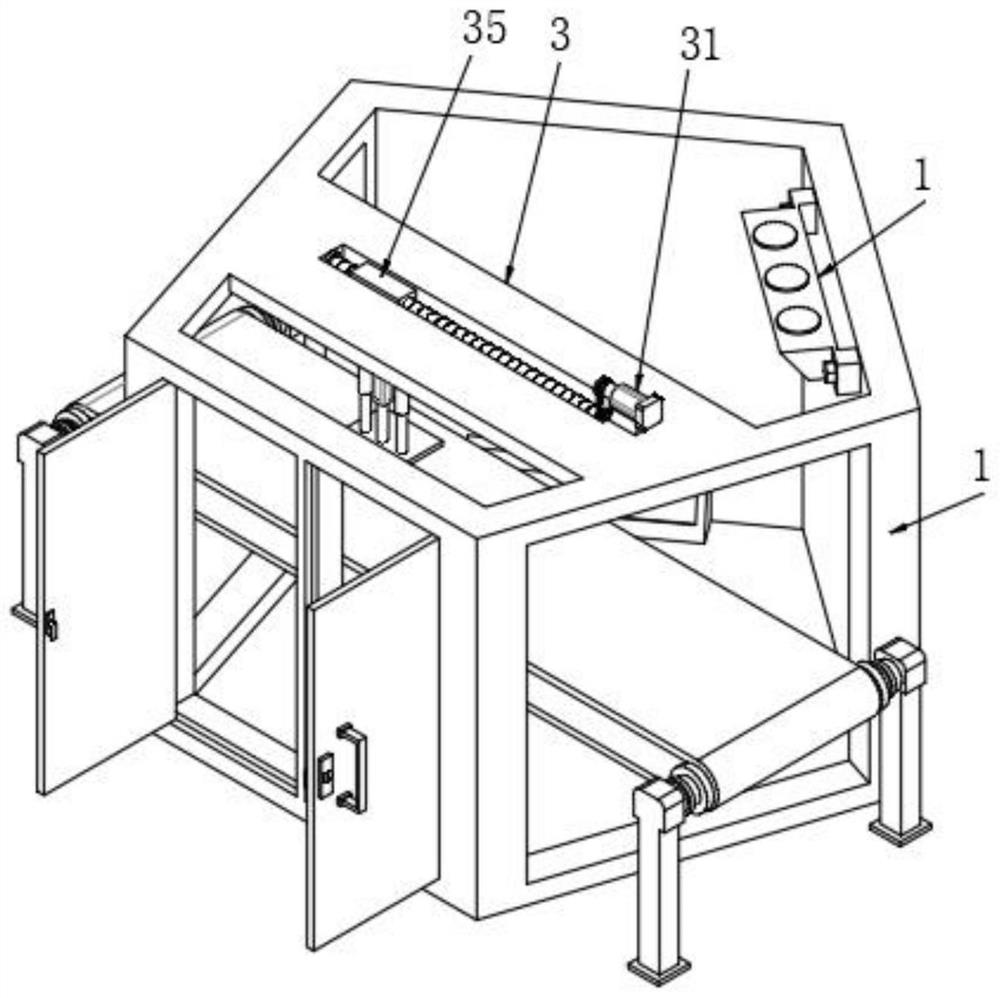

[0036] The embodiment of the present invention provides a technical solution: a high-efficiency pentahedron vertical and horizontal integrated machining center, the fixing plate 3 is fixedly arranged on the top middle of the integrated processing frame 1 near the front end, and the middle of the fixing plate 3 is provided with The drive slot 39, the inside of the drive slot 39 is provided with a screw rod 391, the right end of the screw rod 391 is provided with a second driven gear 34, and the upper end of the second driven gear 34 is connected with a second drive through a belt. Gear 33, the outer end of the second driving gear 33 is connected to the motor 31, the outside of the screw rod 391 is provided with a sliding plate 35, and the bottom of the sliding plate 35 is provided with an electric push rod device 36 in the middle. The bottom of the push rod device 36 is connected to the processing plate 32 through the push rod, the bottom ends of the sliding plate 35 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com