Tea processing system and method

A processing system and processing method technology, applied in the field of tea, can solve the problems of poor controllability, inconvenient adjustment, manual processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

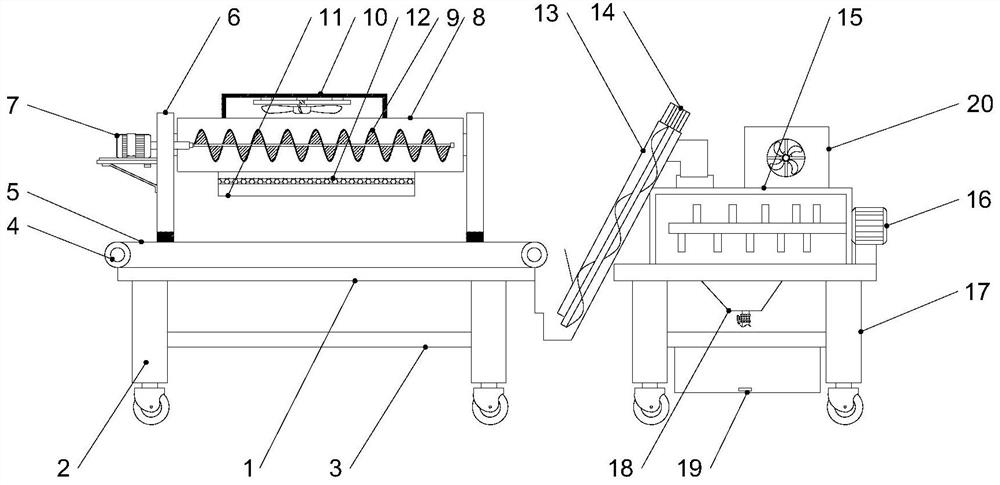

[0023] Example: such as Figure 1-3 As shown, a tea processing system of the present invention includes a base 1, a green fixing machine 8 and a drying box 15, the bottom of the base 1 is fixedly welded with a support leg 2, and the bottom of the support leg 2 is provided with a roller, and the roller has a wheel brake The inner side of the supporting leg 2 is fixedly welded with a connecting rod 3, the top of the base 1 is provided with a transmission wheel 4, and the outer side of the transmission wheel 4 is connected with a conveyor belt 5, and the top of the conveyor belt 5 is far away from the top of the conveyor belt 5. Two mutually symmetrical Fixed plate 6, the left side of fixed plate 6 is connected with the first driving motor 7 by the connecting frame bolt connecting frame bolt, the inboard of the first driving motor 7 is provided with killing machine 8, and the inside of fixing machine 8 is provided with stirring wheel 9, and It is fixedly connected with the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com