A hardware recovery device for in-mold injection products

A recycling device and in-mold injection technology, applied in the coating and other directions, can solve the problems of increasing the difficulty of separation, inconvenience in centralized collection of hardware, inconvenience in automatic transportation and heating of workpieces, etc., to improve work efficiency, simple and flexible structure, and reduce separation. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

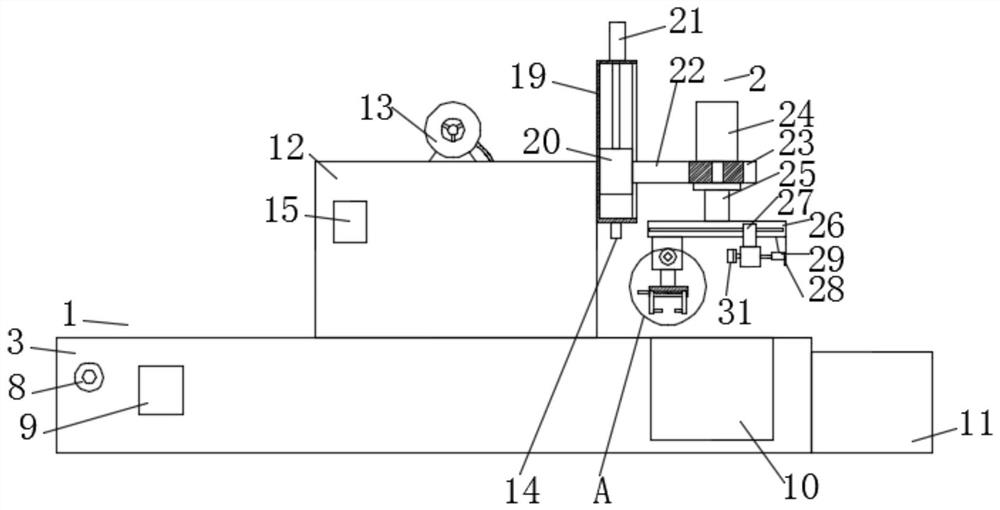

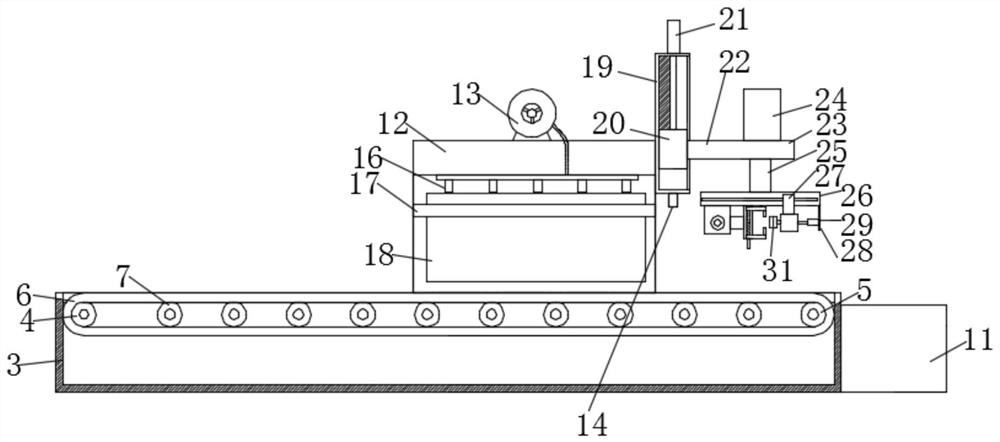

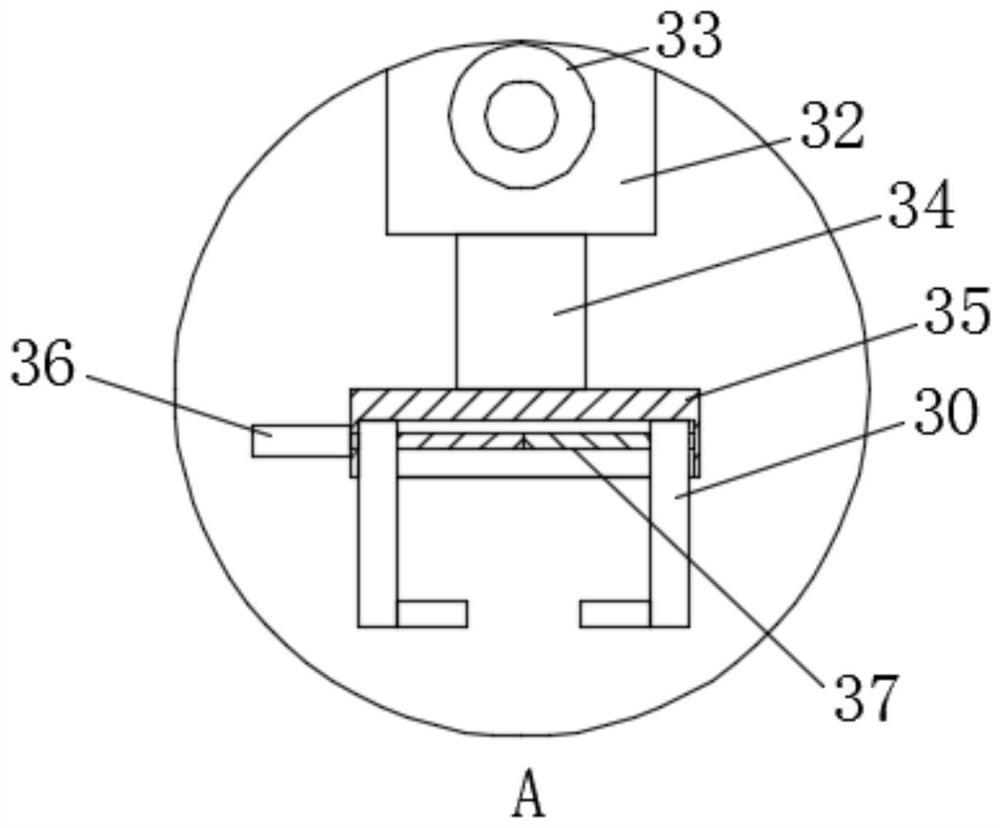

[0019] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a hardware recycling device for in-mold injection molding products, including a conveying mechanism 1 and a recycling mechanism 2, and the conveying mechanism 1 is composed of a conveying box 3, a driving roller 4, and a driven roller 5 , transmission belt 6, auxiliary roller 7, drive motor 8, control panel 9, first material receiving box 10 and second material receiving box 11, and the internal rotation of said delivery box 3 is connected with driving roller 4, and said delivery box The inner side of 3 is rotatably connected to the driven roller 5 at one end away from the driving roller 4, and a transmission belt 6 is set between the outer side of the driven roller 5 and the outer side of the driving roller 4, and the outer side of the delivery box 3 is close to the driving roller. One end of 4 is fixedly connected with a drive motor 8, the output end of the drive motor 8 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com