An oiling device for gear production

An oiling device and oiling technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of single function, rigid structure, and inability to automatically apply oil to gears, so as to achieve a simple and flexible structure and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

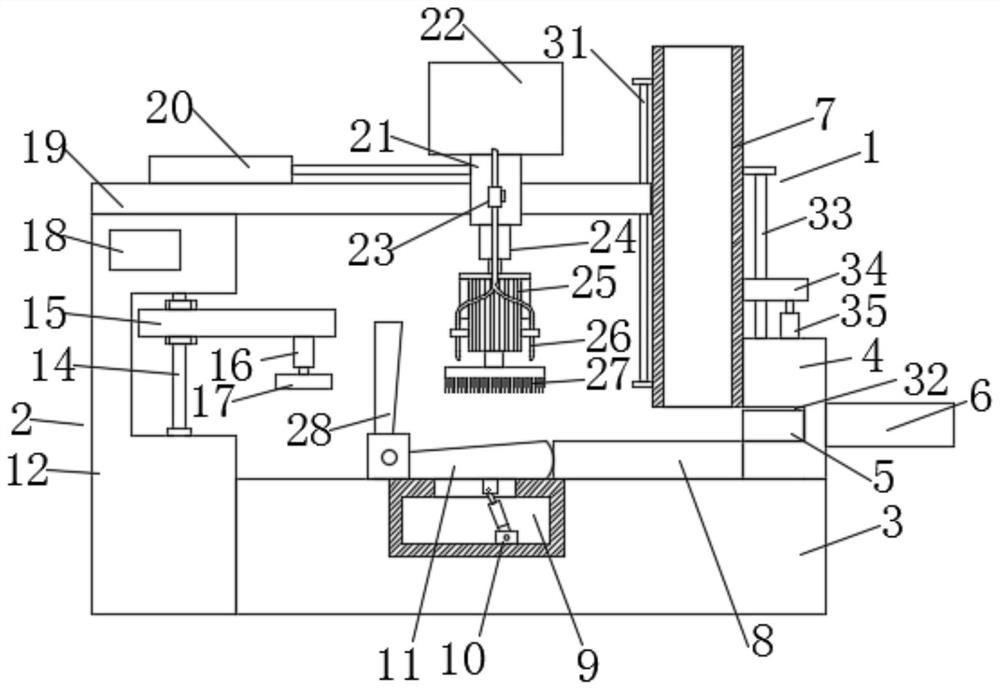

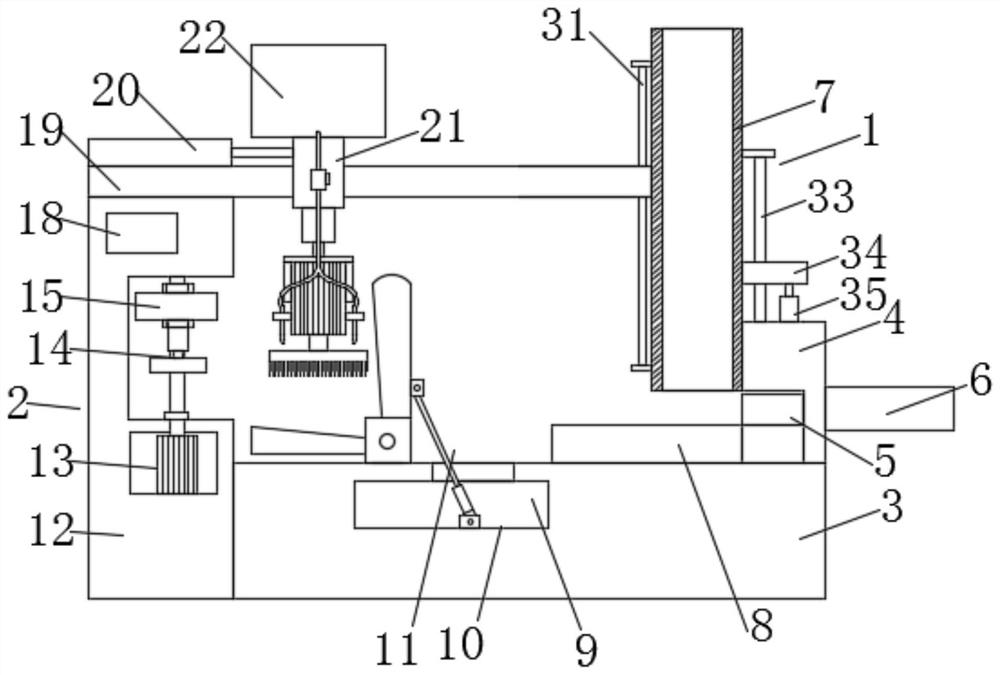

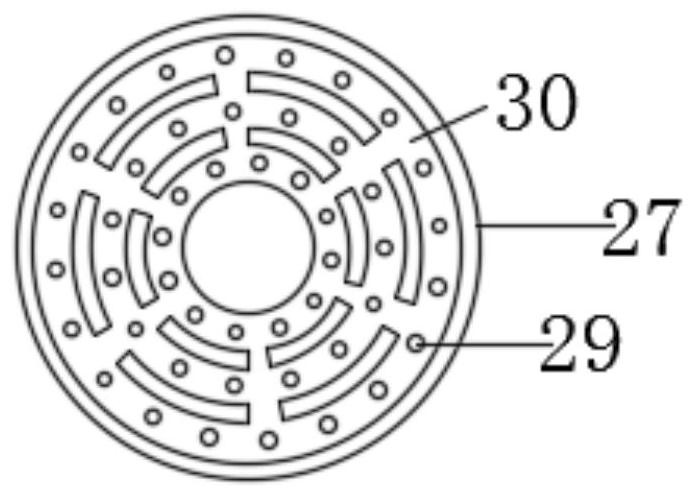

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: an oiling device for gear production, including an automatic feeding mechanism 1 and an oiling mechanism 2, and the automatic feeding mechanism 1 is fixed by an oiling workbench 3 and a feeding mechanism. Block 4, feeding push block 5, feeding cylinder 6, material storage pipe 7, feeding support plate 8, vertical slide bar 31, groove 32, distance adjusting slide bar 33, lifting slide plate 34 and distance adjusting cylinder 35 One end of the top of the oiling workbench 3 is fixedly connected with a feeding fixing block 4, and one side of the feeding fixing block 4 is provided with a groove 32, and the inside of the groove 32 is slidably connected with a feeding push block 5. The side of the feeding fixed block 4 away from the feeding push block 5 is fixedly connected with a feeding cylinder 6, the output end of the feeding cylinder 6 is fixedly connected with the feeding pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com