Buffer storing and conveying system and method

A conveying system and caching technology, which is applied in the field of caching and conveying systems, and can solve problems such as inability to realize item caching and product delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

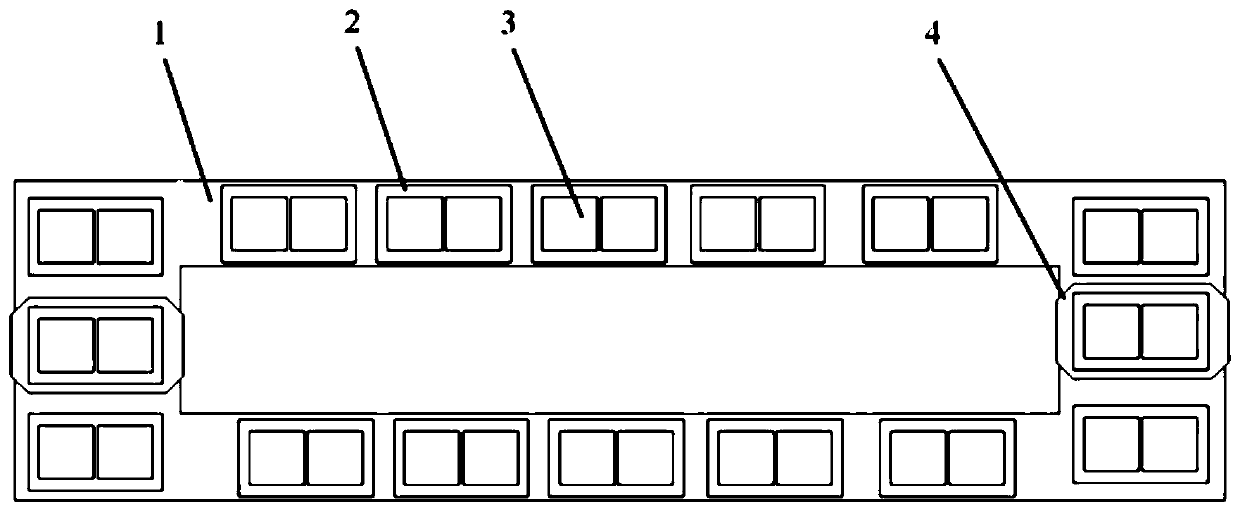

[0085] In the system of the present invention, the conveying line is in a plane closed-loop circulation layout, and the standard section is composed of a deceleration motor, a station stopper, a station switch, a wire body, a leg, a stick road protective cover, and the like. Equipped with turntables at the corners. According to the actual demand, multiple transfer trays are circulated online at the same time, the trays are circulated in the buffer line, and the stopper is set on the line. According to the program instructions, the trays either pass directly or touch the stopper to stop. At the grasping station of the manipulator, a set of lifting and positioning mechanism is set up. After the tray stops, the tray can be accurately positioned, which is convenient for the manipulator and the robot to grasp the parts.

[0086] A flexible buffering and conveying system, through the operation of the system, realizes the transfer of various parts and components of a product between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com