On-line quality and mass center measurement platform for assembly butt-joint scene

A technology for measuring platform and centroid, which is applied in the field of measuring platform and can solve problems such as the movable centroid measuring platform that has not yet been realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

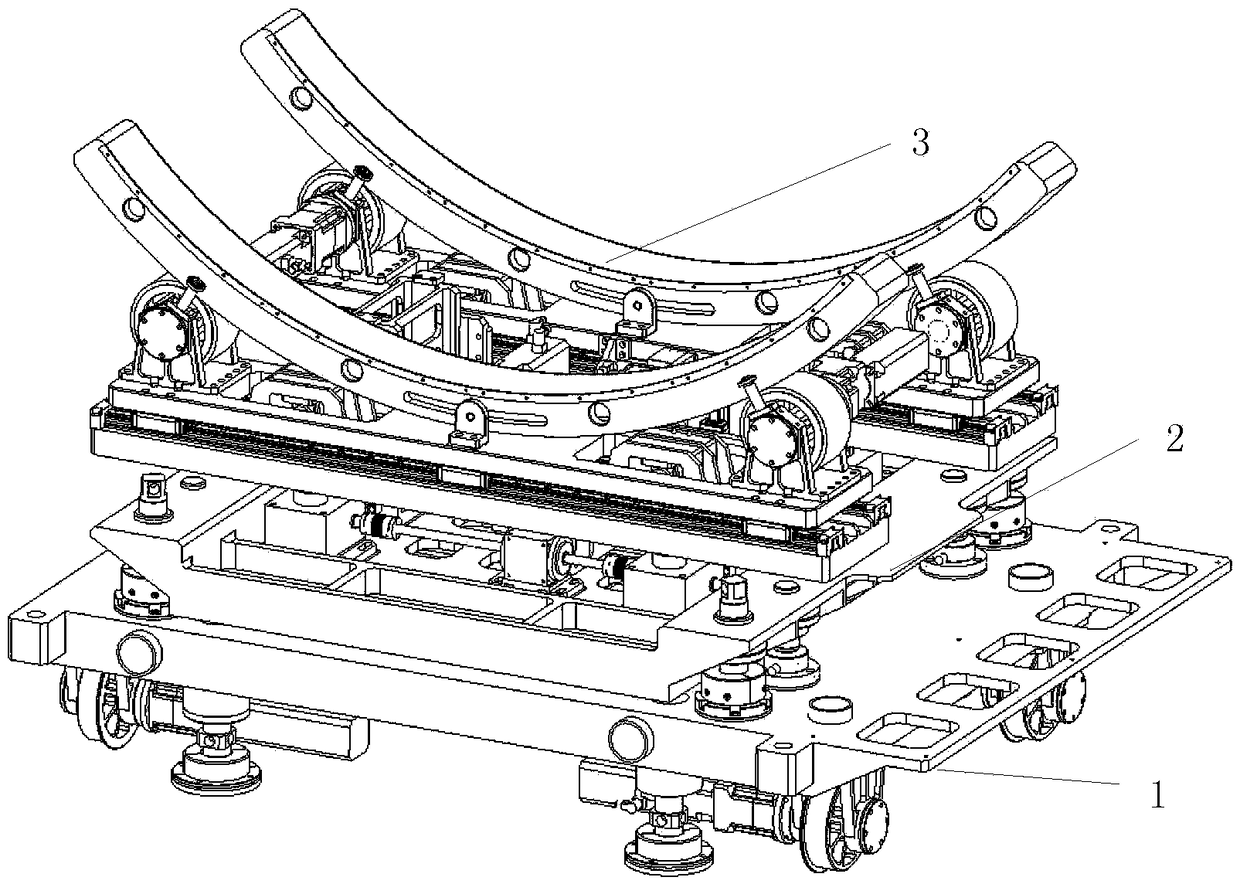

[0036] An assembly and docking on-site online mass centroid measurement platform includes a chassis component 1, a mass centroid measurement component 2, and an attitude adjustment component 3. The attitude adjustment component 3 is installed on the mass centroid measurement component 2 , and the mass centroid measurement component 2 is installed on the chassis 1 . It can realize attitude adjustment docking and mass centroid measurement functions.

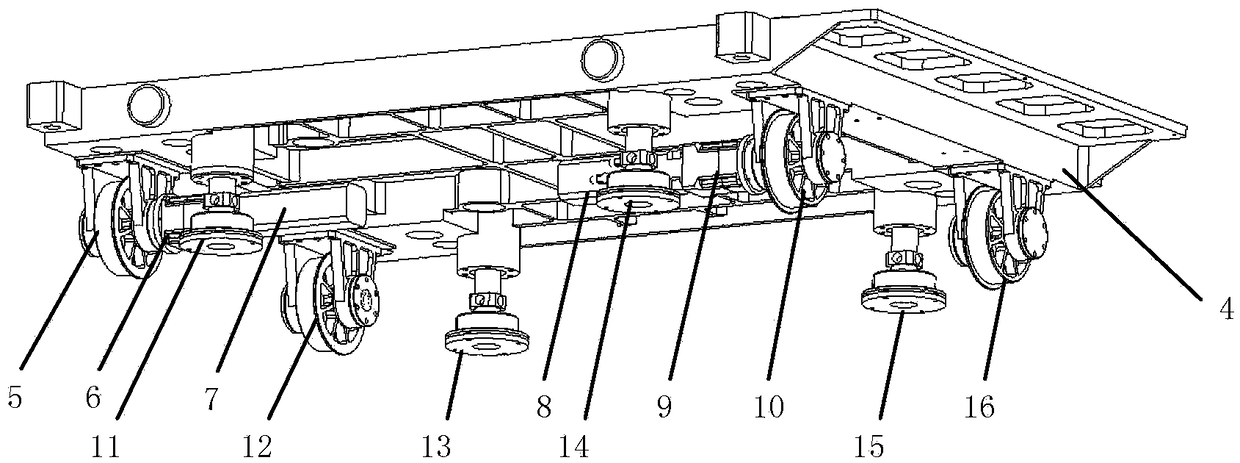

[0037] The chassis assembly 1 can drive the platform to move back and forth, or provide a horizontal reference for the measurement of the center of mass.

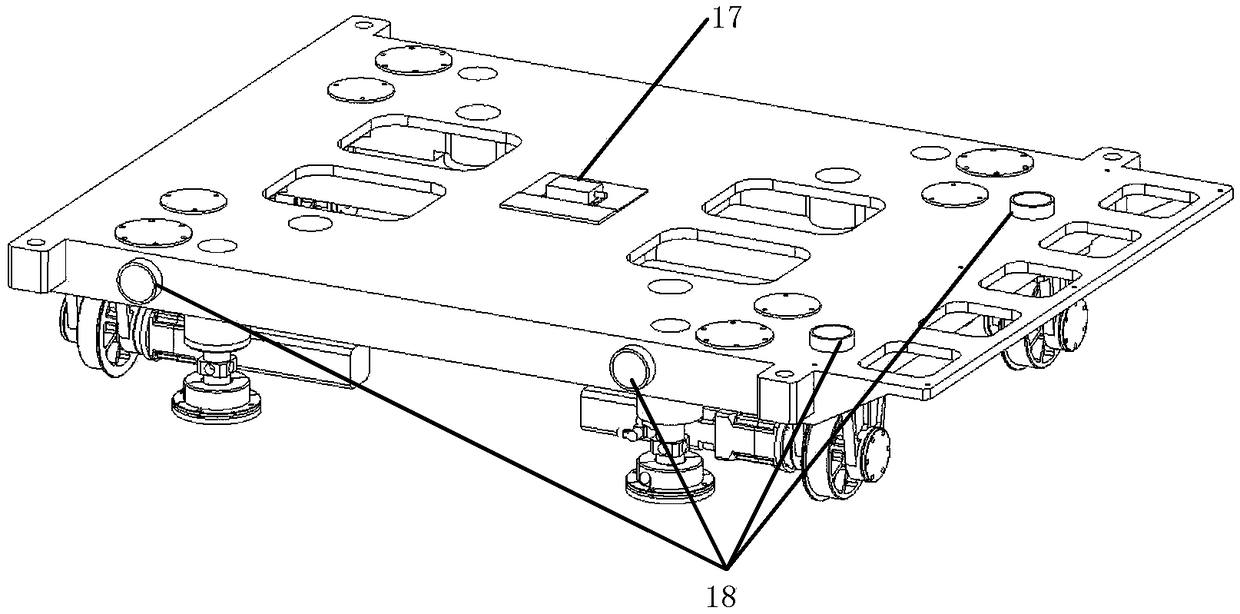

[0038] Chassis assembly 1 includes motor A7, reducer 6, steel wheel A5, motor B8, reducer 9, steel wheel B10, lifting and separating mechanism A11, steel wheel C12, lifting and separating mechanism B13, lifting and separating mechanism C14, lifting and separating mechanism D15, Steel wheel D16, level sensor 17, laser tracker ball seat 18 are all installed on the chassis support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com