Workbin handling AGV, handling method and automatic docking system for SMT production line

A production line and material box technology, applied in general control systems, control/regulation systems, motor vehicles, etc., can solve the problems of inflexible operation of AGV, inflexible operation, lengthened vehicle body, etc., to achieve compact size, flexible movement and rotation, The effect of compact body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

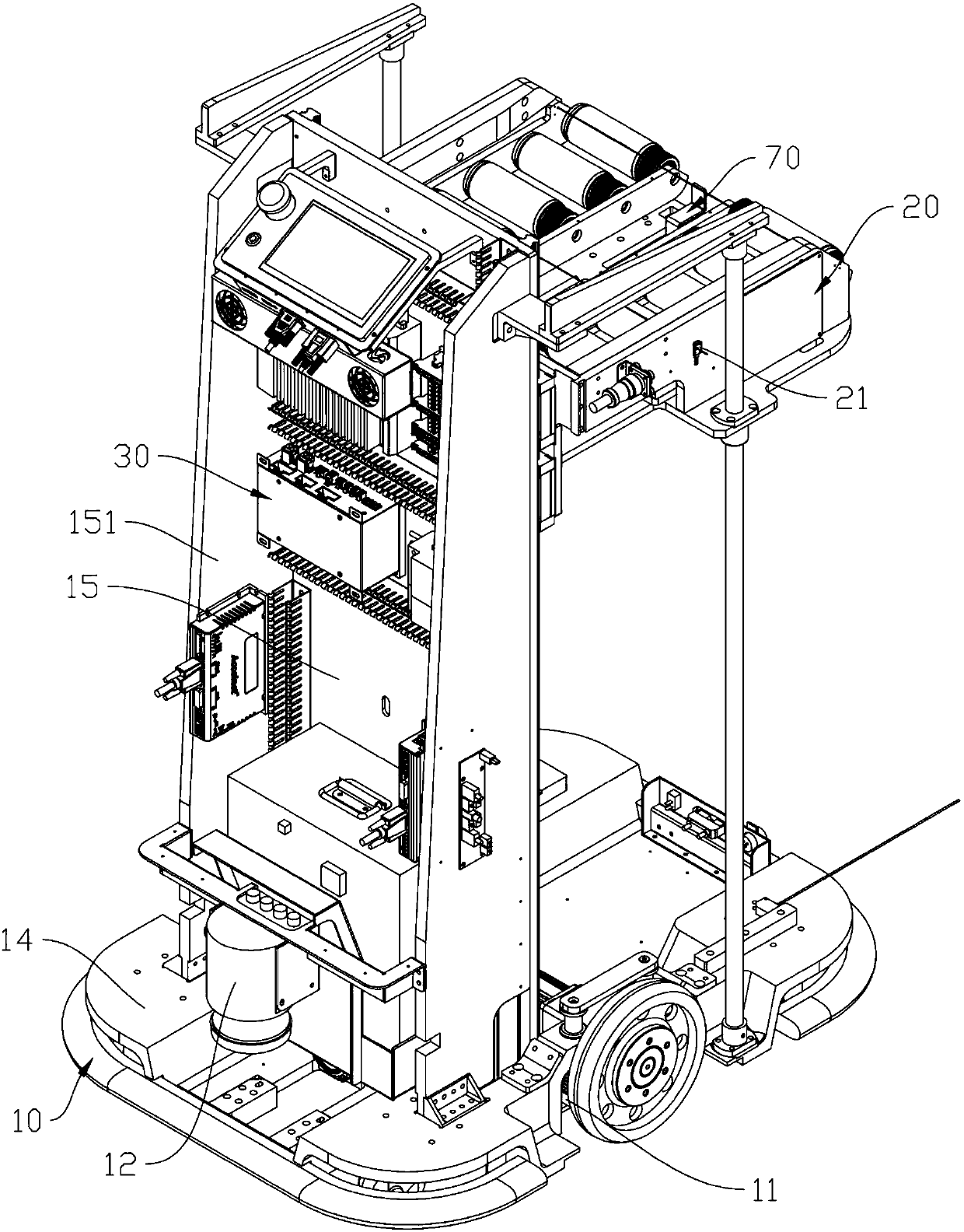

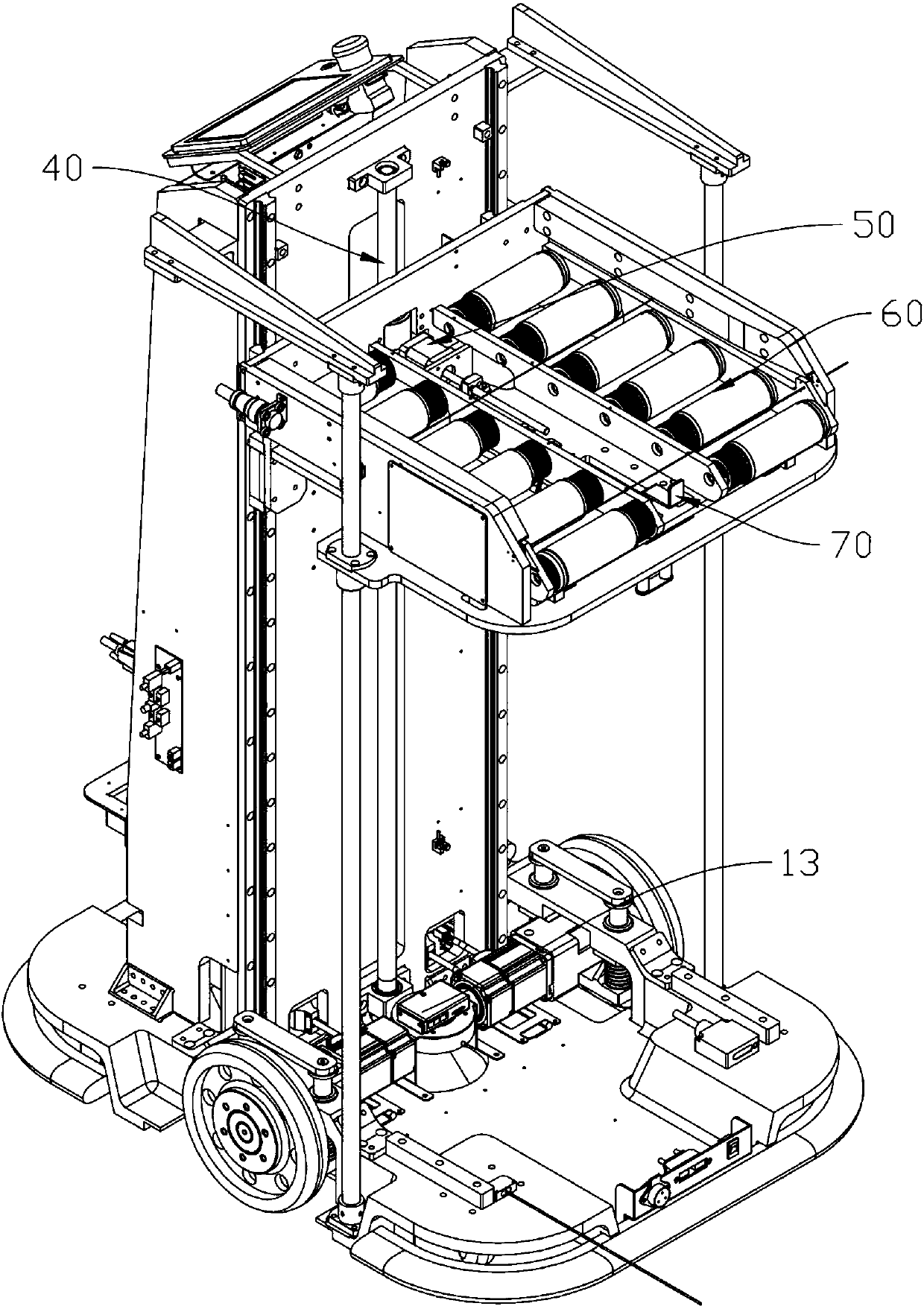

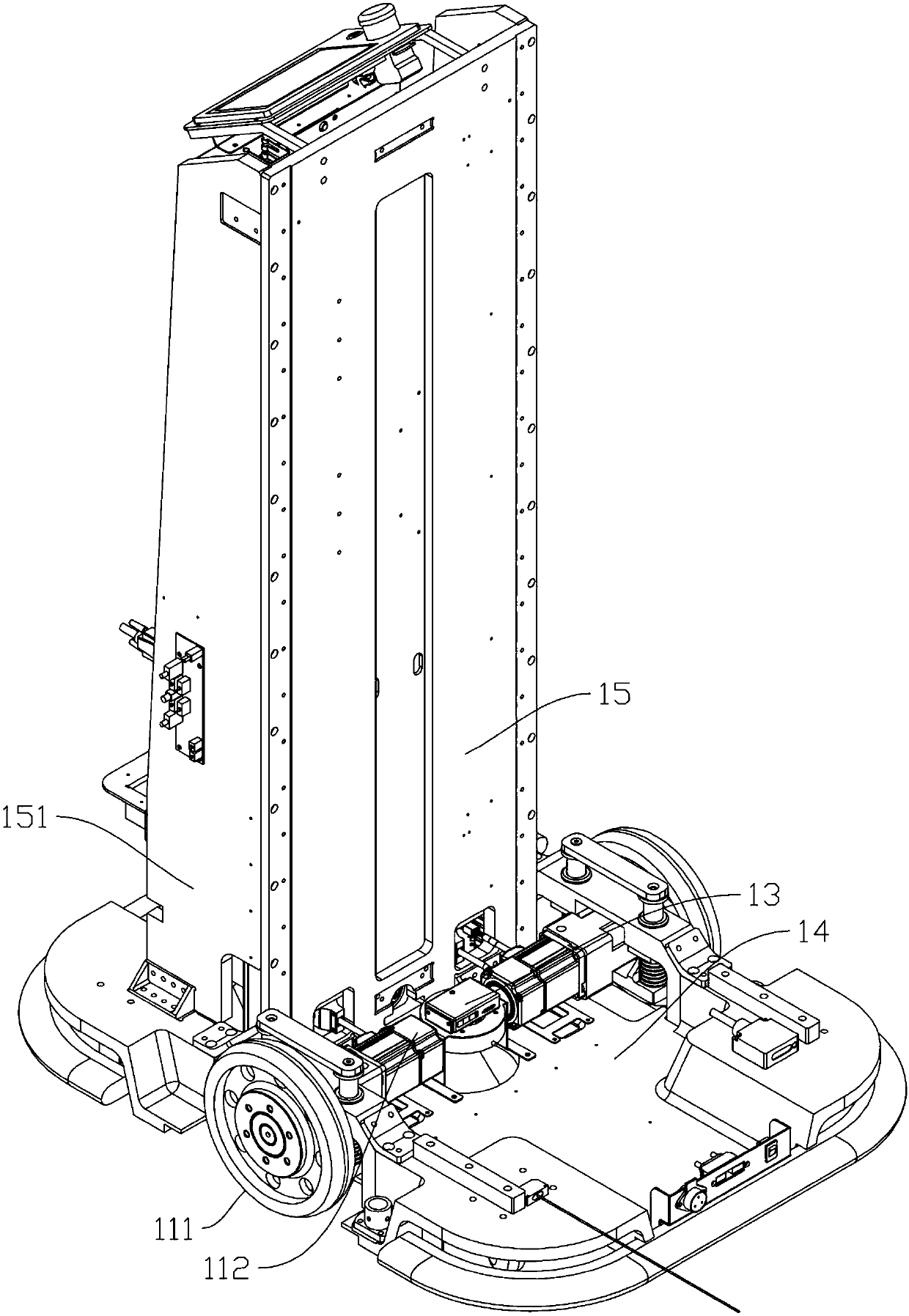

[0040] Such as figure 1 , figure 2As shown, a material box handling AGV includes a car body 10, a material box loading and unloading device 20 arranged on the car body 10, and a control center 30. The material box loading and unloading device 20 is arranged behind the car body 10, and the material box loading and unloading device 20 includes a material box conveying mechanism for receiving and conveying material boxes, and the direction of receiving and conveying material boxes of the material box conveying mechanism is parallel to the running direction of the car body 10 .

[0041] Through the control center, the various mechanisms of the AGV for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com