Brick conveying device for building construction

A technology of building construction and slide rails, which is applied in the direction of transportation and packaging, conveyor objects, etc., and can solve problems such as large manpower consumption, long time consumption, and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

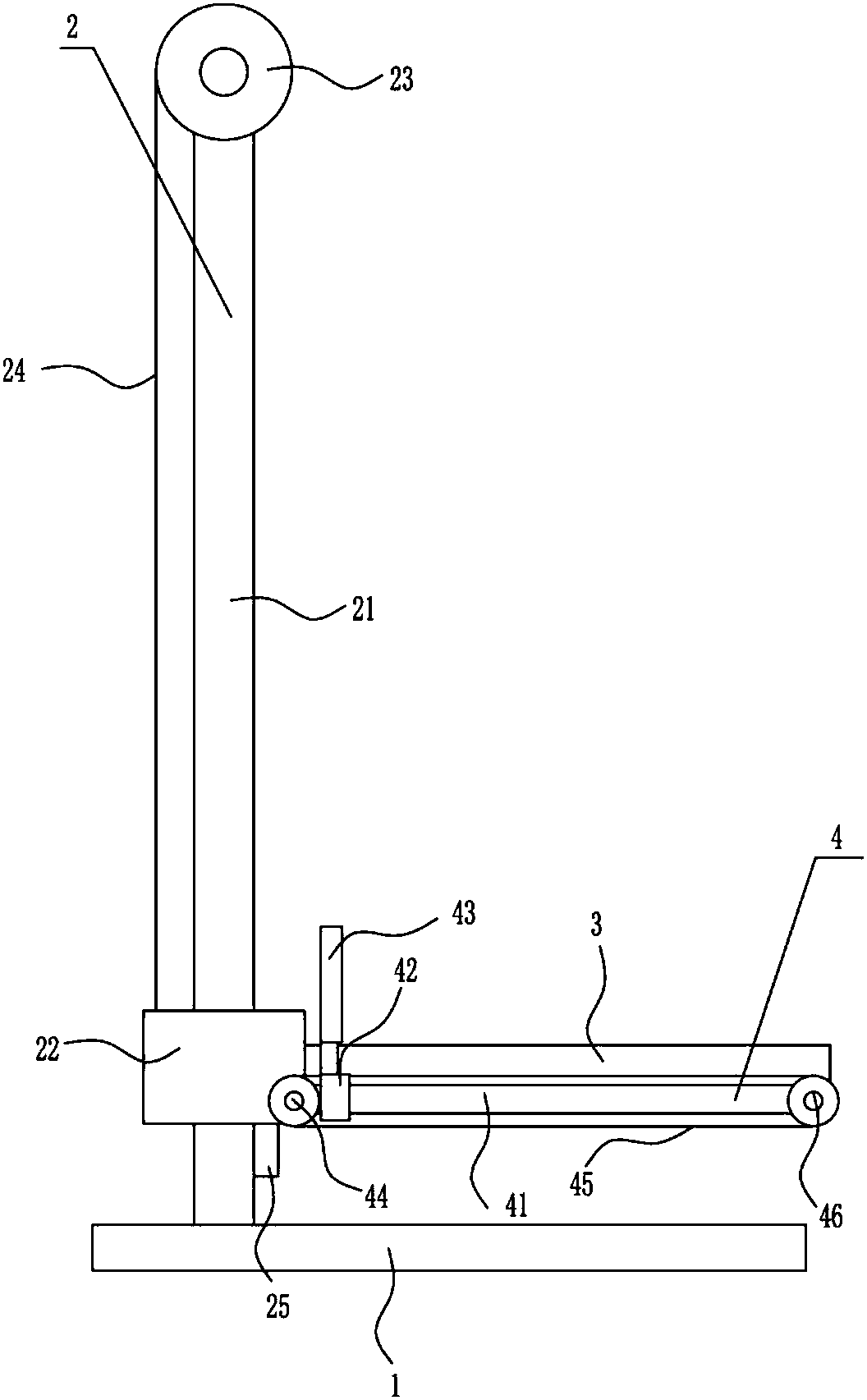

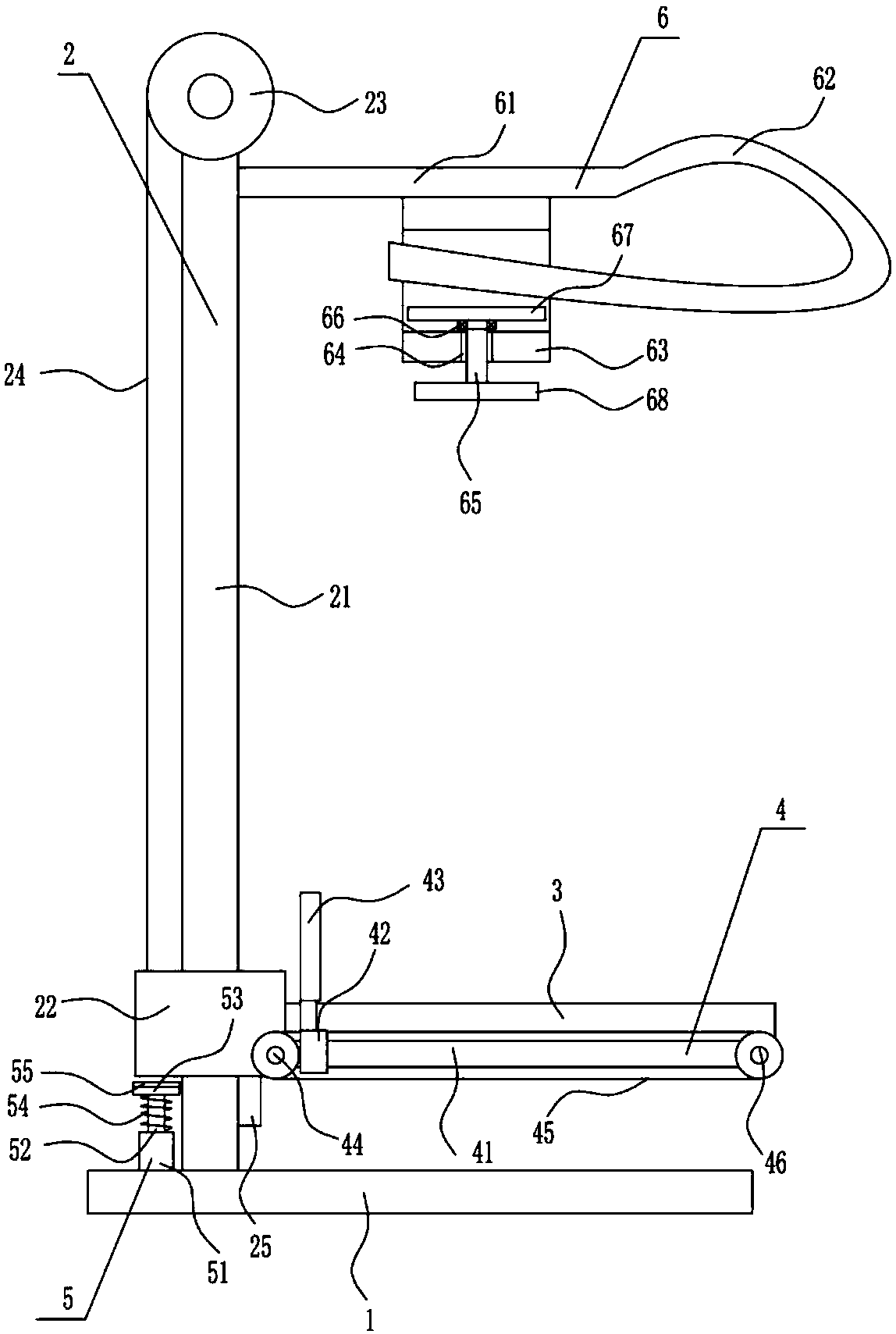

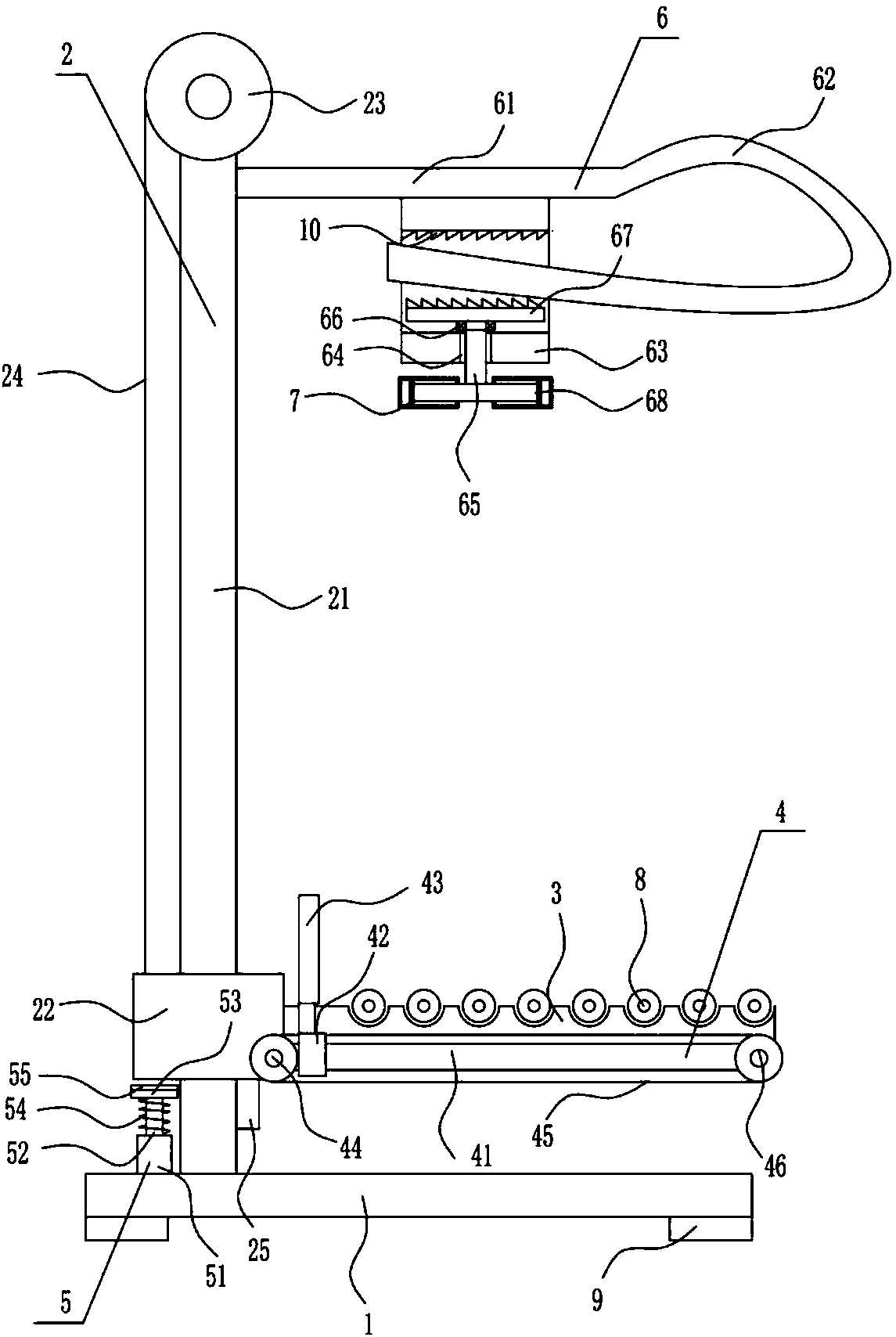

[0033] A brick moving device for building construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a lifting mechanism 2, an operating platform 3 and a pushing mechanism 4. The lifting mechanism 2 is installed on the top of the bottom plate 1, and an operating platform 3 is arranged on the moving parts of the lifting mechanism 2. The front side of the operating platform 3 is installed There is a driving mechanism4.

Embodiment 2

[0035] A brick moving device for building construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a lifting mechanism 2, an operating platform 3 and a pushing mechanism 4. The lifting mechanism 2 is installed on the top of the bottom plate 1, and an operating platform 3 is arranged on the moving parts of the lifting mechanism 2. The front side of the operating platform 3 is installed There is a driving mechanism4.

[0036]The lifting mechanism 2 includes a first slide rail 21, a first slide block 22, a first electric reel 23, a first pull wire 24 and a limit block 25, and the middle left position on the top of the bottom plate 1 is vertically connected with a first slide rail. rail 21, the first sliding block 22 is slidably arranged on the first sliding rail 21, the first electric reel 23 is installed on the top of the first sliding rail 21, and the first pull wire 24 is wound on the first electric reel 23 , the tail end of the first pull wire 24 is connecte...

Embodiment 3

[0038] A brick moving device for building construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a lifting mechanism 2, an operating platform 3 and a pushing mechanism 4. The lifting mechanism 2 is installed on the top of the bottom plate 1, and an operating platform 3 is arranged on the moving parts of the lifting mechanism 2. The front side of the operating platform 3 is installed There is a driving mechanism4.

[0039] The lifting mechanism 2 includes a first slide rail 21, a first slide block 22, a first electric reel 23, a first pull wire 24 and a limit block 25, and the middle left position on the top of the bottom plate 1 is vertically connected with a first slide rail. rail 21, the first sliding block 22 is slidably arranged on the first sliding rail 21, the first electric reel 23 is installed on the top of the first sliding rail 21, and the first pull wire 24 is wound on the first electric reel 23 , the tail end of the first pull wire 24 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com