Enamelling copper flat wire paint-dipping process

The technology of copper flat wire and enameled copper is applied in the field of dipping paint process of enameled copper flat wire, which can solve the problems of incomplete heat treatment and poor dipping effect, and achieve the effect of good quality and effect.

Active Publication Date: 2008-10-15

WUXI XIZHOU MAGNET WIRES

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, most of the current heat treatment uses one heat treatment, and the heat treatment is not complete, and the process needs to be further improved.

Dip paint effect is not good

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

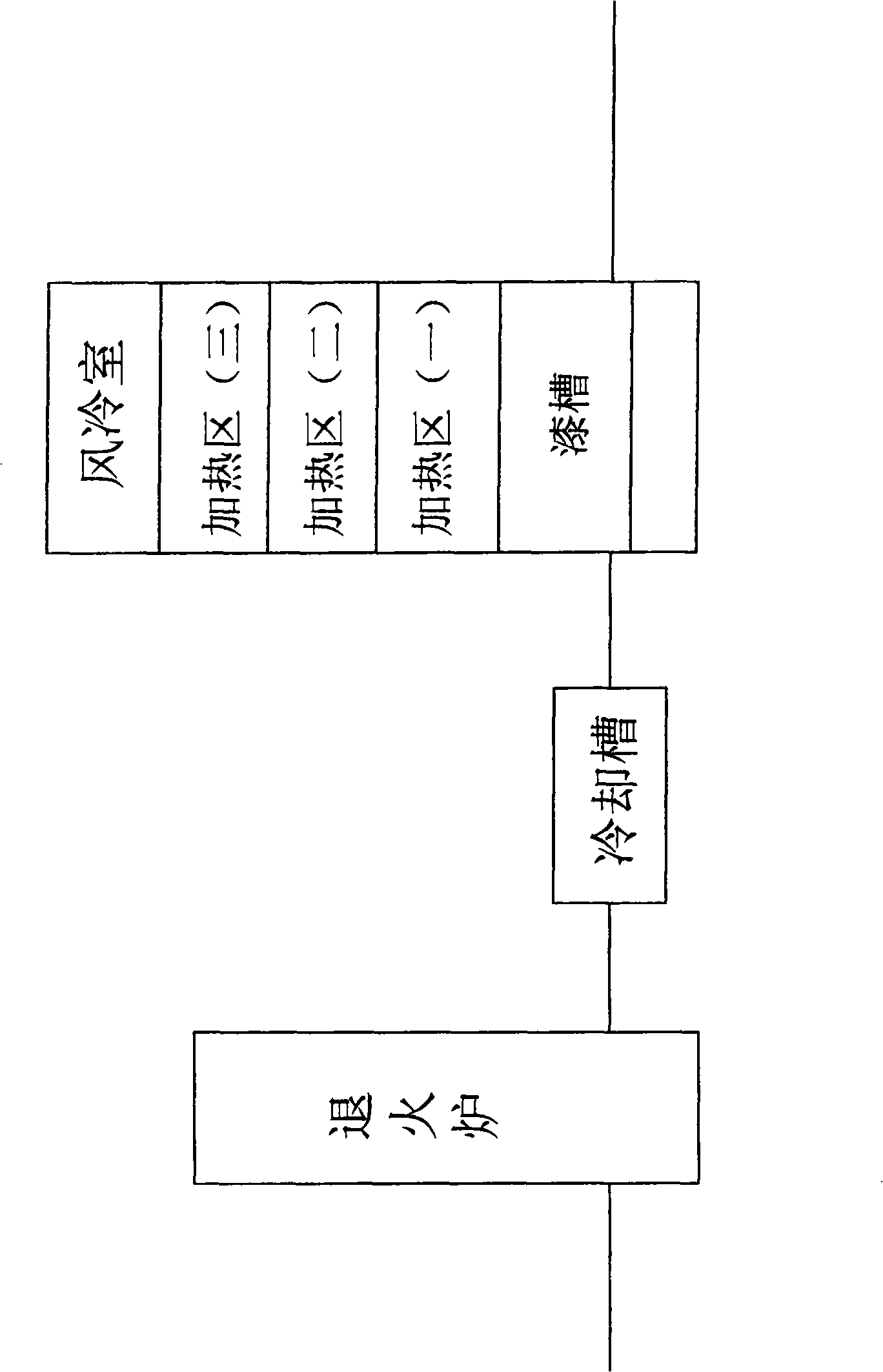

The invention discloses a lacquer dipping technique of a lacquer-covering copper strap wire, relates to the lacquer dipping techniques of the lacquer-covering copper strap wire, and comprises following steps: a copper strap wire is transmitted into an annealing furnace at the speed of 6 to 8 meters per minute, the temperature of the annealing furnace is controlled between 480 and 520 DEG C, and heating stroke lasts for 8 to 10 meters; then the copper strap wire is cooled to the temperature of 20 to 40 DEG C; the lacquer dipping of the copper strap wire is implemented at the speed of 6 to 8 meters per minute; then the copper strap wire is heated, a heating device with three levels of heaters is provided, the temperature of the three levels of heaters are respectively controlled at 160 to 200 DEG C, 230 to 270 DEG C and 300 to 350 DEG C, and the copper strap wire orderly passes through the three temperature regions and then through a cooling device that is arranged at an upper part of the heating furnace; finally the copper strap wire is cooled naturally and then stored. The lacquer dipping steps are repeated for 6 to 10 times. The heating furnace of the invention has three levels of heaters and the temperature gradually is raised, the copper strap wire orderly passes the three heating regions and then is cooled, consequently, the copper strap wire that is thermally processed by the lacquer dipping technique has good quality effect.

Description

Enamelled Copper Flat Wire Impregnation Process technical field The invention relates to a process for impregnating enamelled copper flat wires. Background technique Impregnation is an important process in the processing of enamelled copper flat wire, which includes the previous annealing process and the subsequent varnish immersion process. Annealing can improve the plasticity and toughness of copper flat wire, improve mechanical properties, and remove residual stress. However, most of the current heat treatment uses one-time heat treatment, and the heat treatment is not complete, and the process needs further improvement. The effect of dipping paint is not good. Contents of the invention In view of the above defects, the present invention aims to provide an enamelled copper flat wire impregnation process that can overcome the above defects, has a good heat treatment effect, and has a firm paint coating. Technical scheme of the present invention is: it comprises th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B13/16

Inventor 卢之云周志云

Owner WUXI XIZHOU MAGNET WIRES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com