Production method of carbon fiber

A production method, carbon fiber technology, applied in fiber chemical characteristics, wet spinning, textiles and papermaking, etc., can solve problems such as low apparent viscosity, low strength, and strict production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

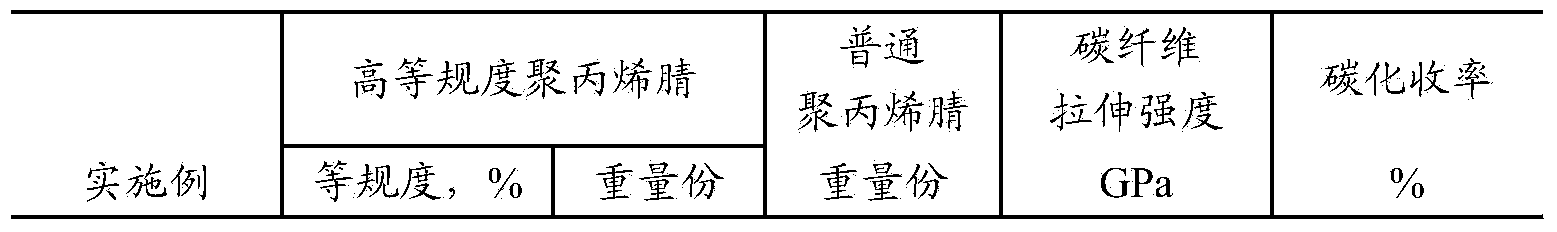

[0105] Example 1: Production of carbon fibers

[0106] The implementation steps of this embodiment are as follows: The equipment used in this embodiment is the same as that of Embodiment 1.

[0107] A. Preparation of spinning solution

[0108] Let 17 parts by weight of high isotacticity polyacrylonitrile resin of 38% and 95 parts by weight of ordinary polyacrylonitrile resin in a high-speed mixer sold by German IKA company under the trade name LR-2.ST reactor at a rotating speed of 2800rpm. Pulverize and mix for 0.8 min under the conditions, then add 355 parts by weight of solvent dimethyl sulfoxide to the mixed resin, stir and mix, then swell for 6 hours at a temperature of 60 ° C, and then heat up to 70 ° C, dissolve at this temperature for 10 hours , then a mixed resin solution is obtained, and its solid content is 22% by the total weight of the mixed resin solution;

[0109] Next, use the defoaming kettle sold by Yangzhou Hengderong Equipment Manufacturing Co., Ltd. unde...

Embodiment 2

[0125] Example 2: Production of carbon fibers

[0126] The implementation steps of this embodiment are as follows:

[0127] The equipment used in this example is the same as that used in Example 1.

[0128] A. Preparation of spinning solution

[0129] 10 parts by weight of high isotacticity polyacrylonitrile resin with 38% isotacticity and 90 parts by weight of ordinary polyacrylonitrile resin were pulverized and mixed for 1.0min in a high-speed mixer at a speed of 3200rpm, and then 400 parts by weight were added to the mixed resin. 2 parts of solvent dimethyl sulfoxide, stirred and mixed, then swollen for 8 hours at a temperature of 52 °C, then heated to 68 °C, and dissolved for 8 hours at this temperature, so a mixed resin solution was obtained, and its solid content was mixed. The total weight of the resin solution is 20%;

[0130] Next, use a defoaming kettle to deaerate the mixed resin solution under a pressure of 3.2 kPa, and then use a candle wick filter to filter, a...

Embodiment 3

[0146] Example 3: Production of carbon fibers

[0147] The implementation steps of this embodiment are as follows:

[0148] The equipment used in this example is the same as that used in Example 1.

[0149] A. Preparation of spinning solution

[0150] 17 parts by weight of high isotacticity polyacrylonitrile resin with 38% isotacticity and 83 parts by weight of ordinary polyacrylonitrile resin were pulverized and mixed for 1.2min in a high-speed mixer at a speed of 3000rpm, and then 335 parts by weight were added to the mixed resin. 2 parts of solvent dimethyl sulfoxide, stirred and mixed, then swollen for 6 hours at a temperature of 56°C, then heated to 72°C, and dissolved at this temperature for 6 hours, thus obtaining a mixed resin solution, the solid content of which was based on the mixed resin. The total weight of the solution is 23%;

[0151] Next, use a defoaming kettle to deaerate the mixed resin solution under a pressure of 3.4kPa, and then use a candle wick filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com