12 strand composite rope of nylon monofilament

A nylon and monofilament technology, applied in the field of cables, can solve the problems of large gaps in cable sections, poor stability and low safety, and achieve the effects of improving utilization, long service life and strong wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

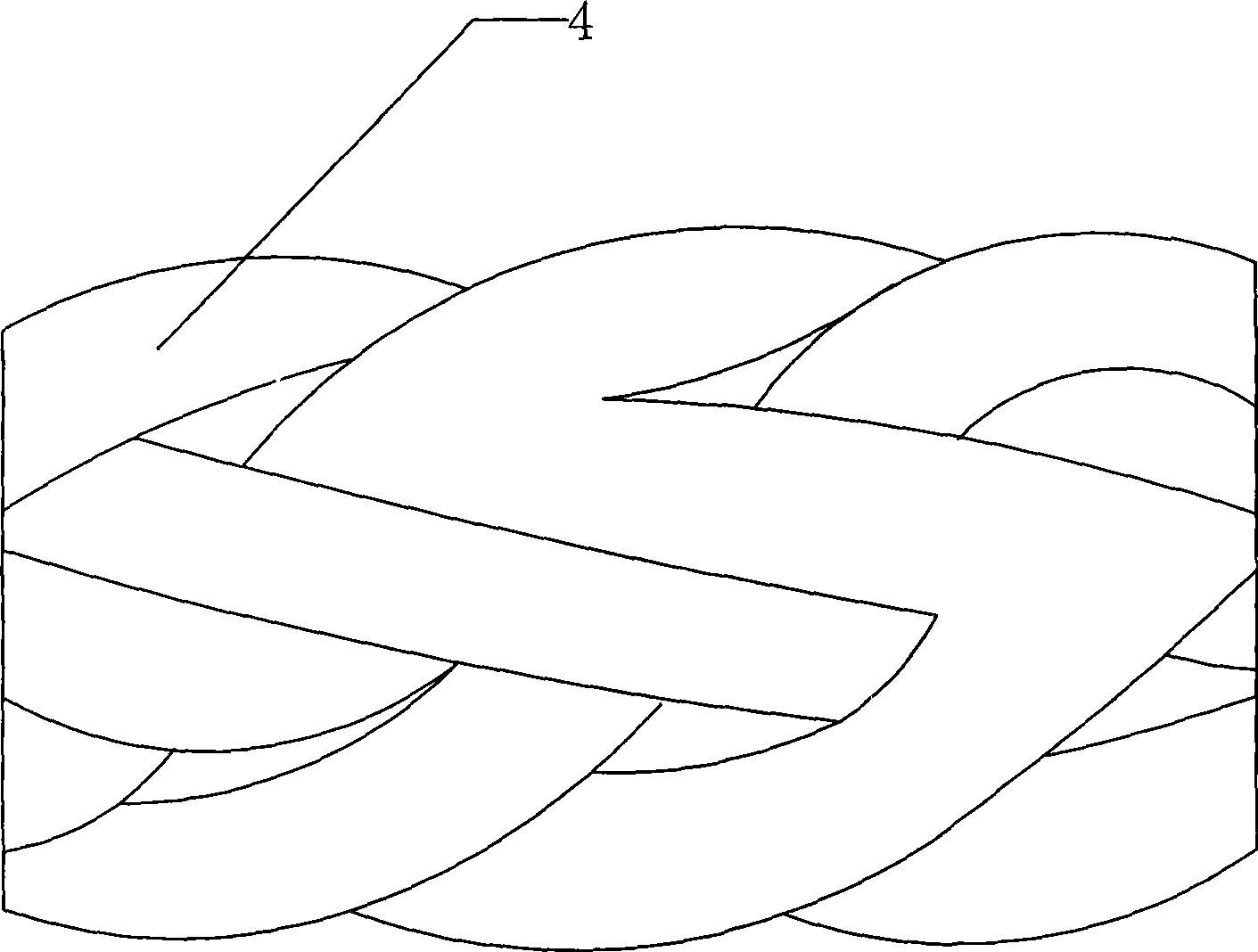

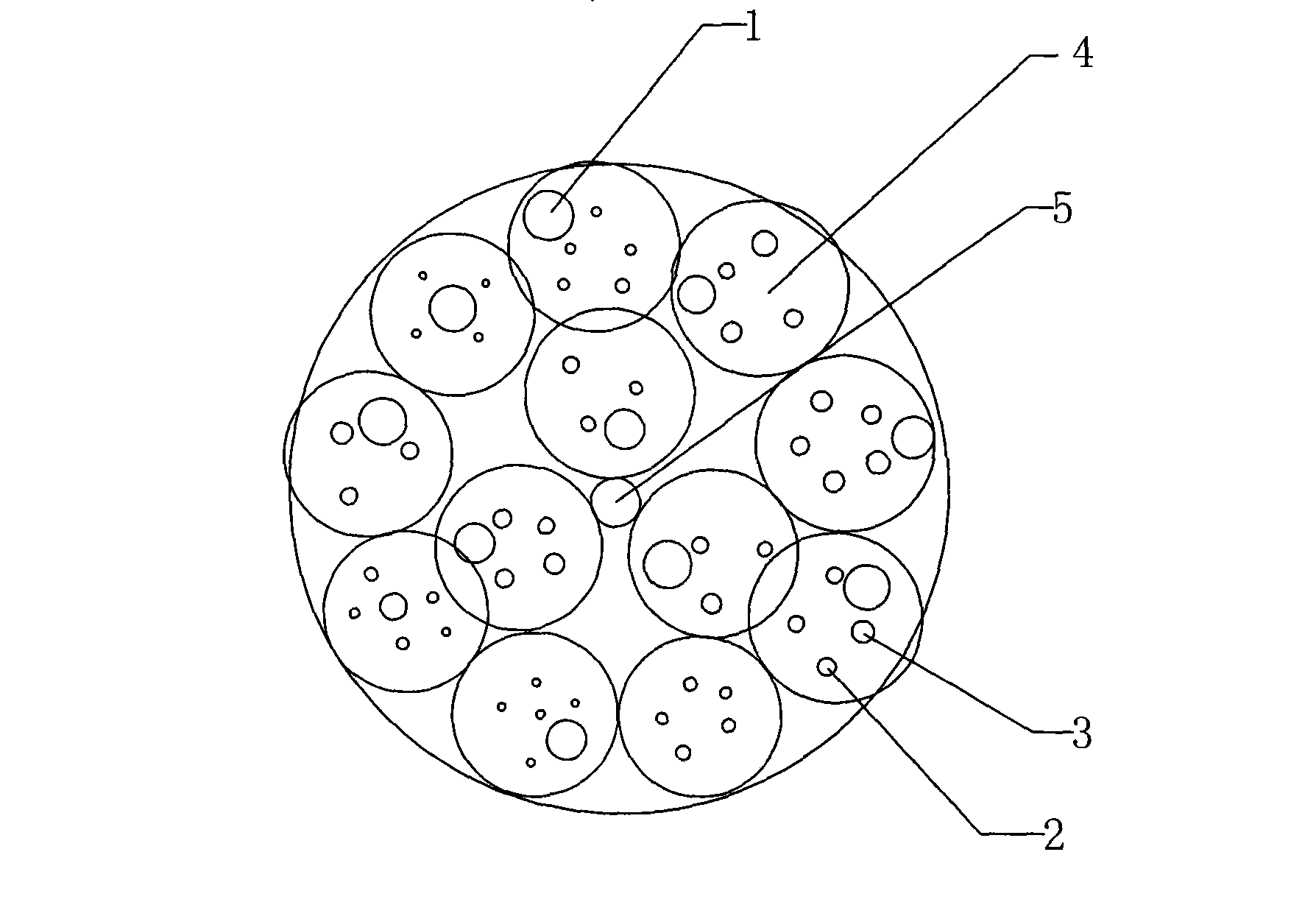

[0017] like Figure 1-2 As described above, a nylon monofilament twelve-strand composite cable described in the embodiment of the present invention includes nylon main shaft strands 5 and twelve strands 4 braided into one, and the nylon main shaft strands 5 are arranged on twelve strands. The center of the strand rope, the twelve strands are braided by six left-twisted strands 4 and six right-twisted strands 4; the strands 4 include nylon monofilament 1 and nylon multifilament 2 twisted into one and rope yarn3.

[0018] The preparation process of nylon monofilament twelve-strand composite cable of the present invention comprises the following steps:

[0019] 1) Select raw materials: the selected raw materials are nylon monofilament and nylon multifilament; the diameter of nylon monofilament is 2.5mm-4.5mm, and the density of nylon multifilament is 1000d-3000d;

[0020] 2) Twisting: First twisting and then re-twisting. During the initial twisting and re-twisting, the tension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com