Mechanical degluing method and device of phloem fiber

A technology of bast fiber and degumming method, which is applied in the directions of fiber mechanical separation, mechanical treatment, fiber treatment, etc., can solve the problems of large alkali consumption, environmental pollution, high energy consumption, etc., to reduce the amount of consumption, facilitate penetration, and reduce energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

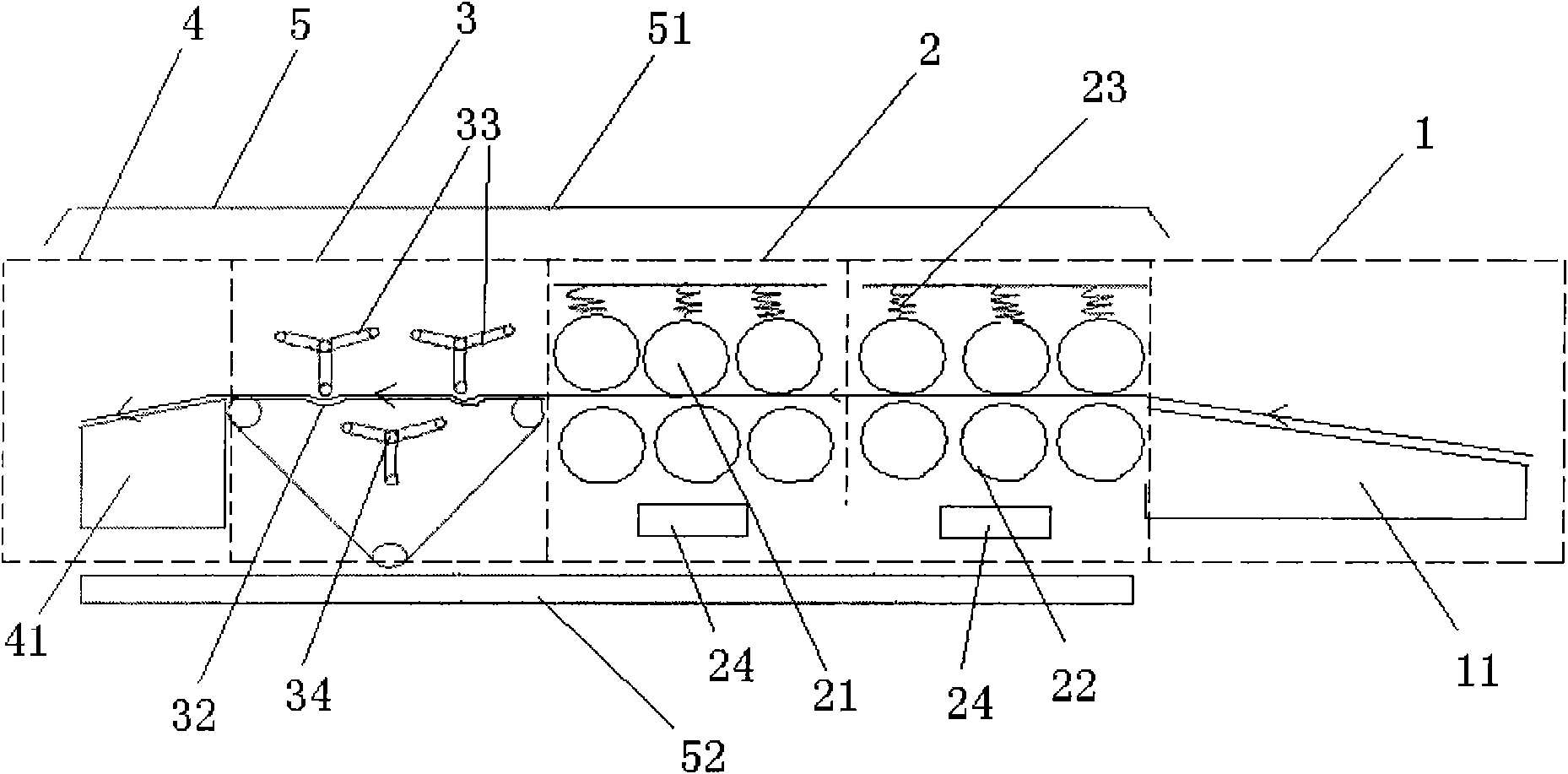

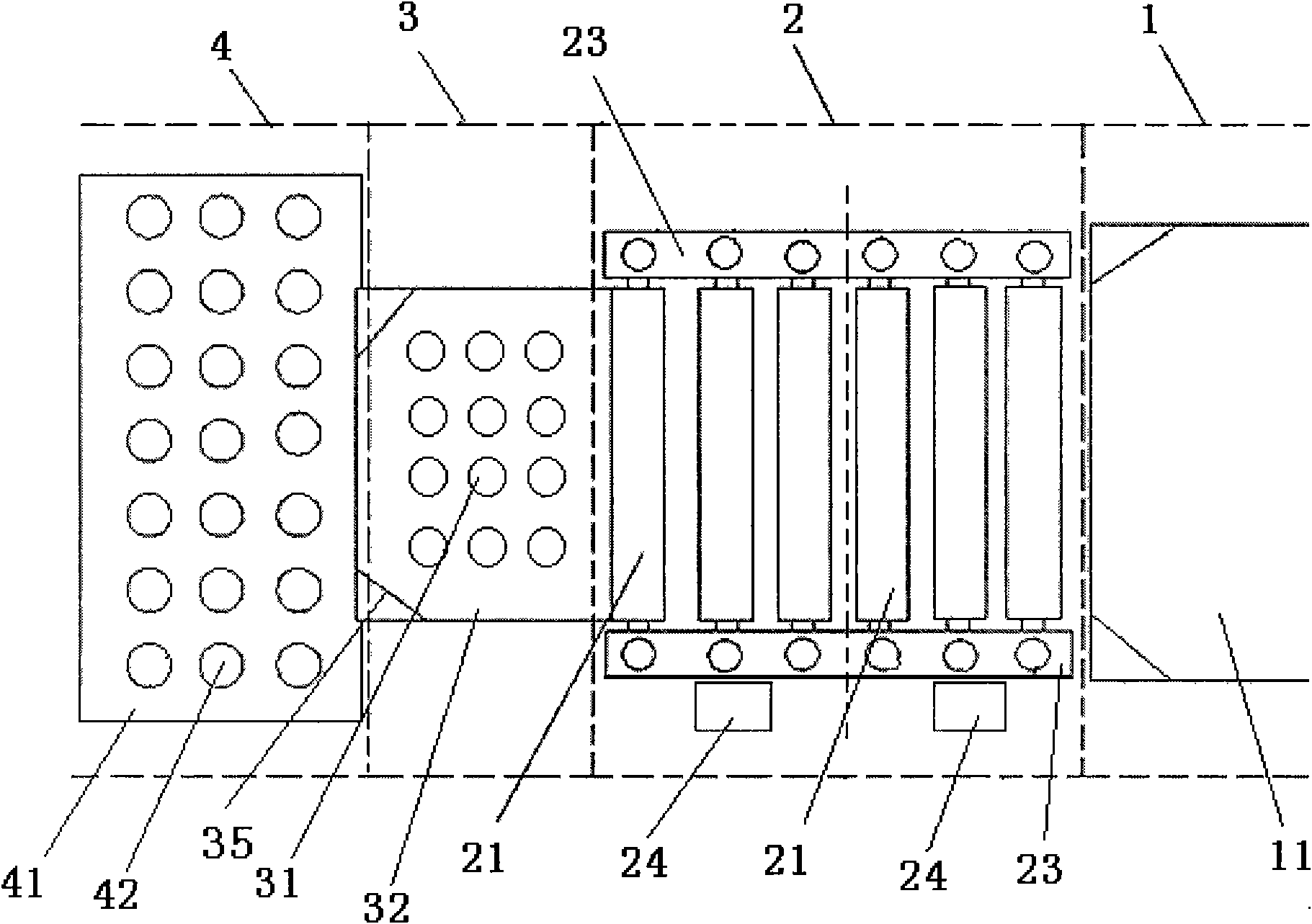

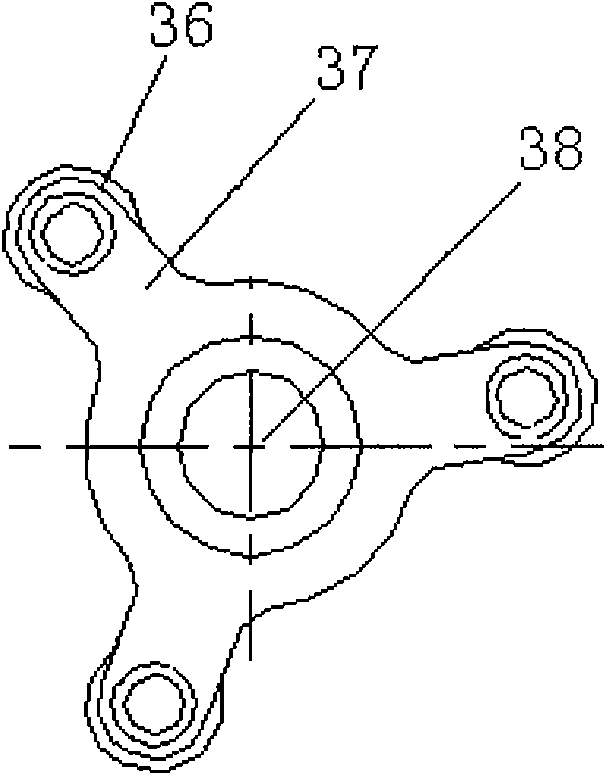

[0018] Such as figure 1 , figure 2 Shown, the present invention comprises a feeding area 1, and feeding area 1 connects a mechanical kneading area 2, and mechanical kneading area 2 connects a beat impurity removal area 3, beats the impurity removal area 3 and connects a discharge area 4, and is arranged on The impurity removal devices 5 in the upper and lower parts of the above-mentioned regions.

[0019] The feeding zone 1 of the present invention includes a feeding platform 11, and the bast fibers sorted out in the early stage are spread out on the feeding platform 11 and sent into the mechanical kneading zone 2.

[0020] The mechanical kneading zone 2 of the present invention includes two rows of upper and lower grooved rollers 21, 22 arranged in pairs. The tops of the two ends of the upper grooved roller 21 are respectively provided with pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com