Cotton stalk skin-core mechanical separation method and special equipment

A technology of mechanical separation and cotton stalk skinning, which is applied in fiber mechanical separation, mechanical processing, textiles and papermaking, etc., can solve the problems of low labor efficiency, high labor intensity, poor toughness and strength of cotton stalk skins, etc., and achieve smooth waste removal Chip removal, simple structure of the transmission mechanism, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A kind of mechanical separation method of cotton stalk bark and rod core, its production steps are:

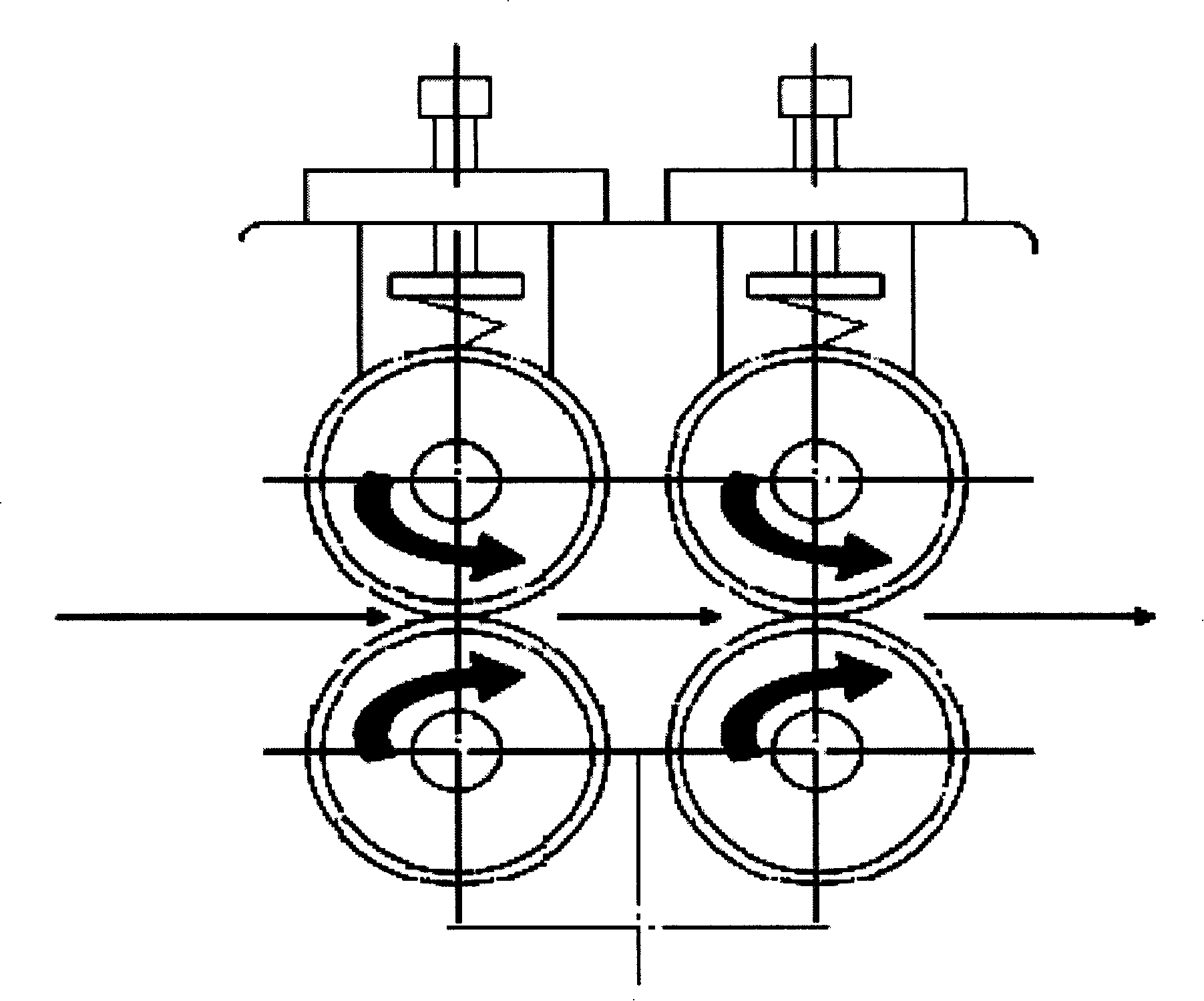

[0030] Step 1: Squeeze the cross-section of the cotton stem into a flat shape so that it is in a continuous shape in the longitudinal direction;

[0031] Step 2: Push the flat-cracked cotton stalk horizontally, and apply striking force at intervals of 2mm to make it bend 85°-90° quickly. The bark is separated and the bark of the cotton stalk is still in the continuous range of bands;

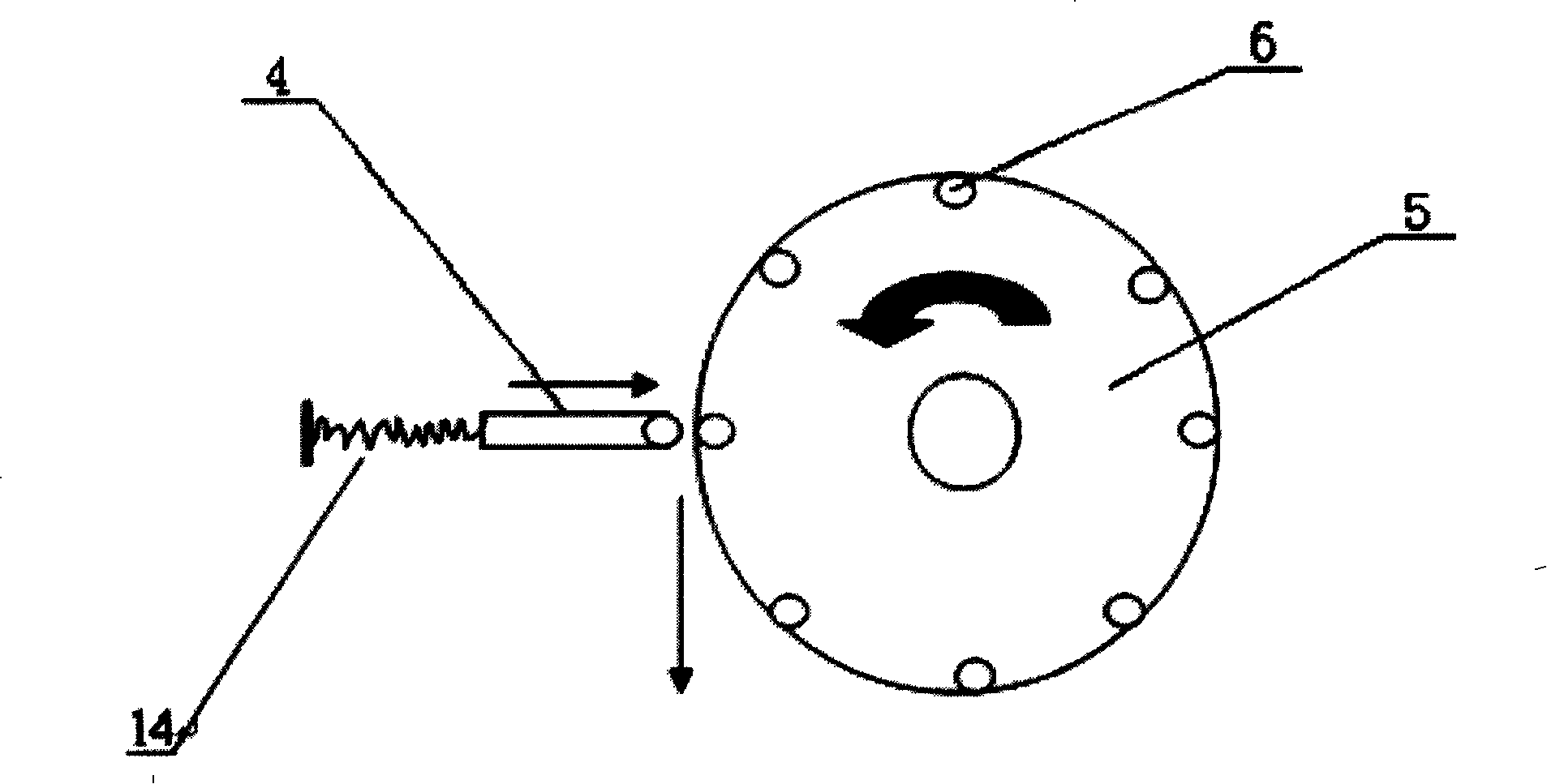

[0032] Step 3: Freely pluck the ribbon-shaped cotton stalk bark at a high frequency of 160 times per second to remove the residues and broken cores attached to the cotton stalk bark;

[0033] Step 4: Cross-free plucking with a plucking frequency higher than Step 3, to effectively remove debris still attached to the cotton stalk husk, and obtain qualified cotton stalk husks.

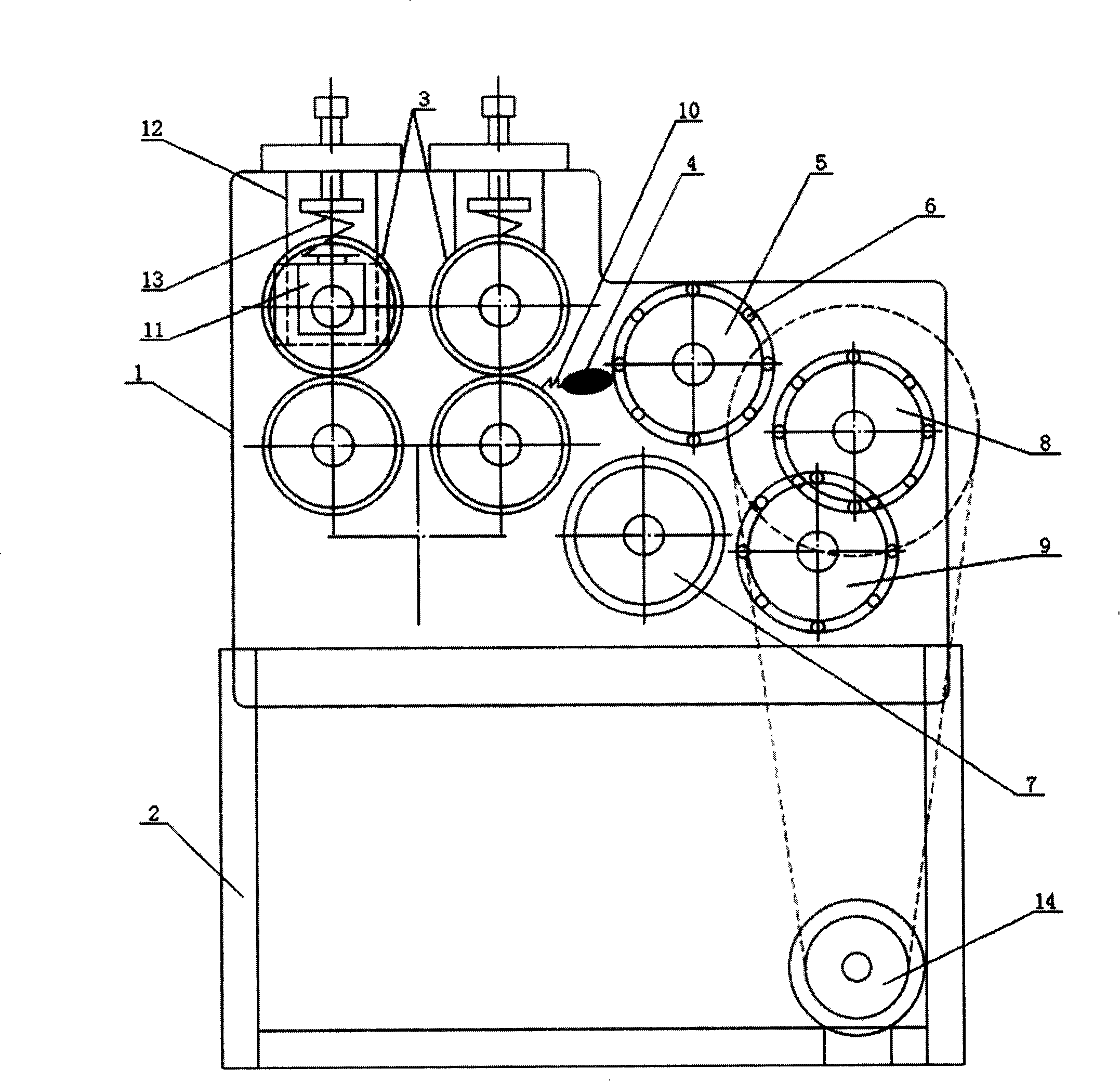

[0034] A cotton stalk core separator that implements the above-mentioned mechanical separation met...

Embodiment 2

[0036] Embodiment 2: A kind of mechanical separation method of cotton stalk bark and rod core, its production steps are:

[0037] Step 1: Squeeze the cross-section of the cotton stem into a flat shape so that it is in a continuous shape in the longitudinal direction;

[0038] Step 2: Push the flat-cracked cotton stalk horizontally, and apply striking force at intervals of 6mm to make it bend quickly by 85°-90°. The bark is separated and the bark of the cotton stalk is still in the continuous range of bands;

[0039] Step 3: Freely pluck the strip-shaped cotton stalk skin at a frequency of 70 times per second to remove the residue and broken cores attached to the cotton stalk skin;

[0040] Step 4: Cross-free plucking with a plucking frequency higher than step 4, to effectively remove the debris still attached to the cotton stalk husk, and obtain a qualified cotton stalk husk.

[0041] A cotton stalk core separator that implements the above-mentioned mechanical separation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com