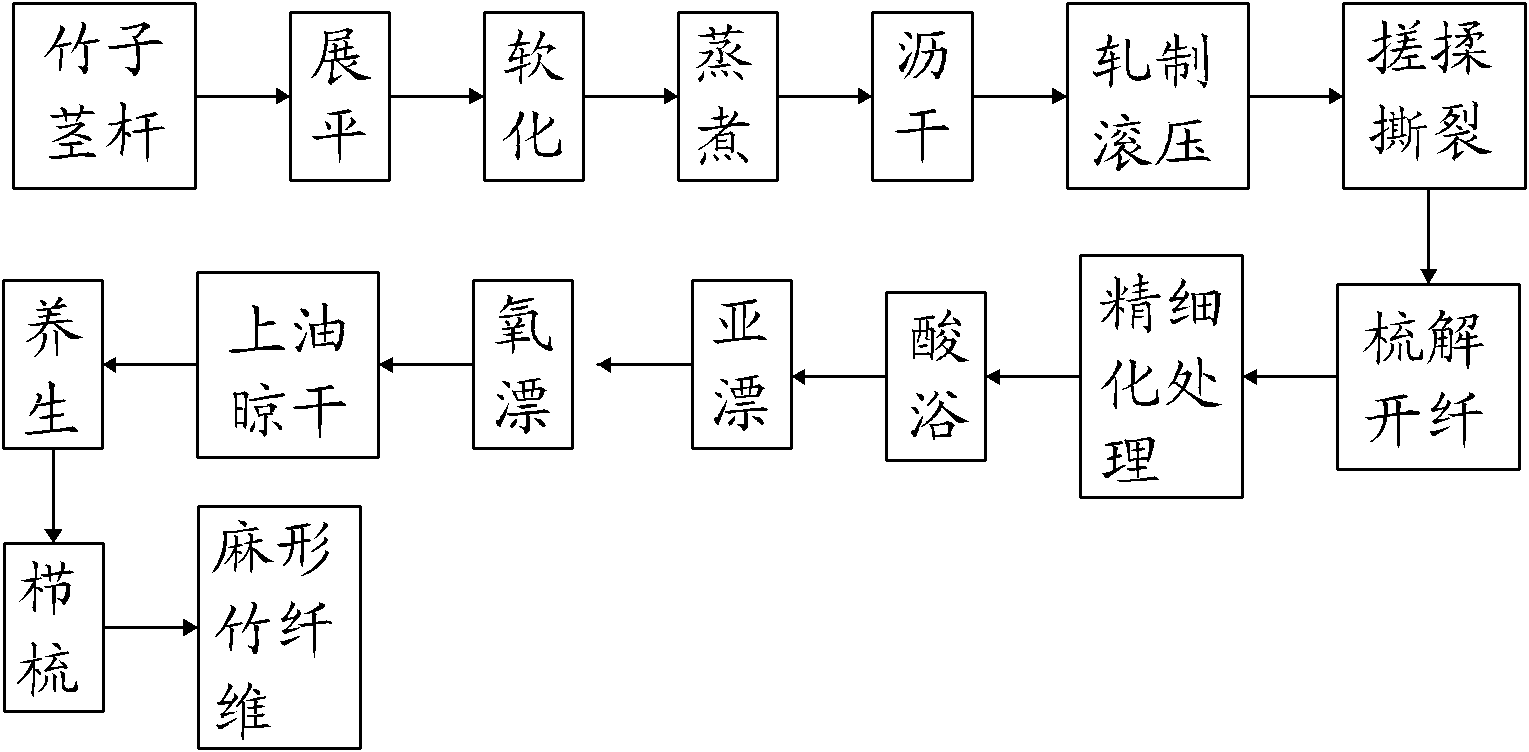

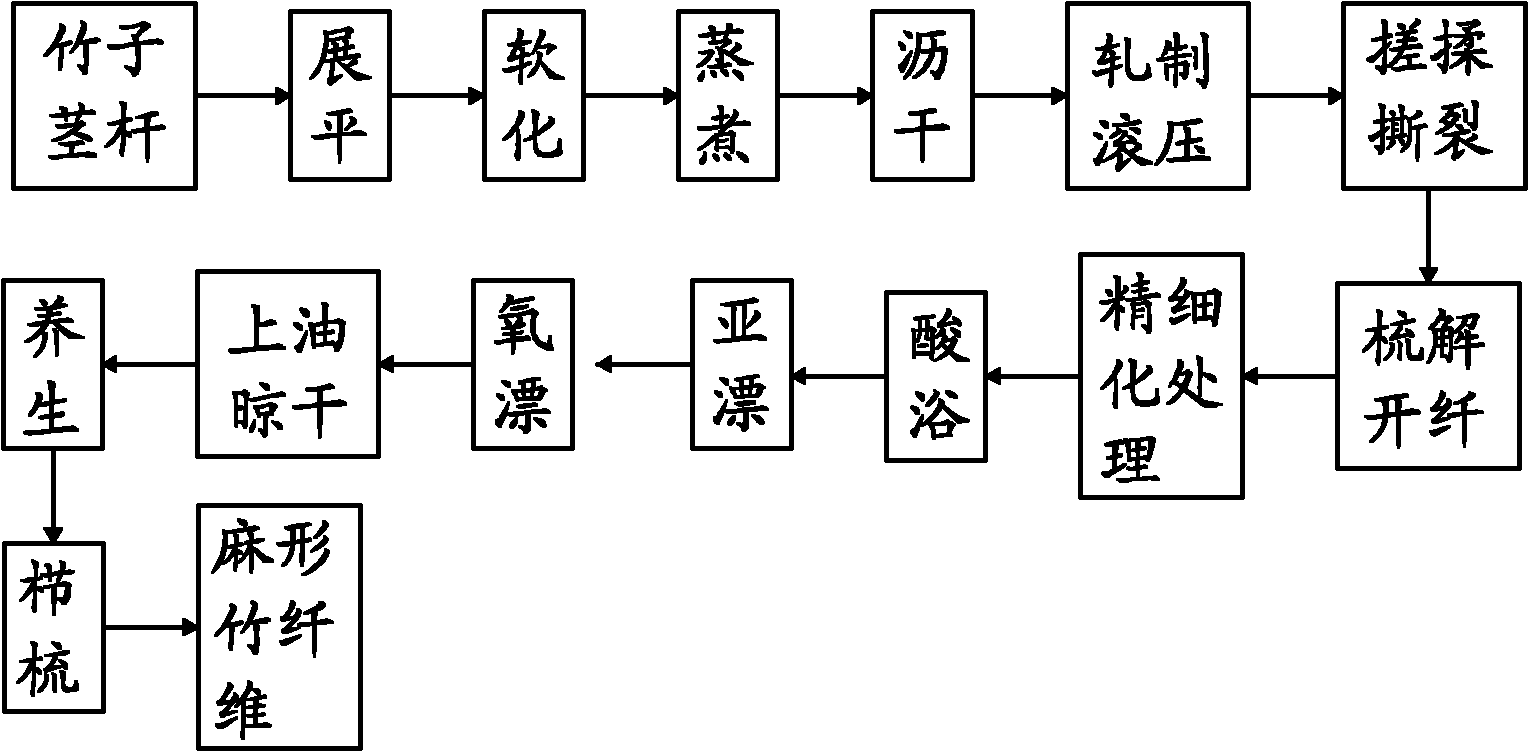

Process for producing hemp-like bamboo fibers

A production process, bamboo fiber technology, applied in the chemical post-processing of fibers, fiber treatment, fiber mechanical separation, etc., can solve the problems of low fiber yield, large consumption of raw materials, large pollution, etc., and achieve uniform fiber separation and integrity. good, flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] Take the 10-month-old Cizhu, saw it into 4-5 meters in length, and use a flattening machine to roll and flatten the cylindrical bamboo for the next process;

[0031] Soaking at room temperature: put the flattened bamboo into the softening pool for warm soaking. Bath ratio: 1:10, temperature: 75°C, softening solution formula: sodium hydroxide: 3%, anthraquinone: 0.2%. Soaking time: 3 hours;

[0032] Draining: take the softened bamboo out of the soaking pool, and after 3 hours, let the natural water drain;

[0033] A pair or more than one pair of rollers with grooves are used to apply a gradually increasing rolling force to the bamboo, and then the bamboo is sent to the impurity rolling machine to squeeze and crack the bamboo. The bamboo is rolled under the pressure of multiple pairs of rollers. , realize the splitting;

[0034] Rollers are used to repeatedly roll and squeeze the cracked bamboo, and the cracked bamboo is repeatedly kneaded and torn under the action of ...

no. 2 example

[0044] Take a one-year-old yellow bamboo, cut it into 2-3 meters in length, and use a flattening machine to roll and flatten the cylindrical bamboo for the next process;

[0045] High-temperature and high-pressure steaming: put the flattened bamboo into a pressure cooker for steaming. Bath ratio: 1:10, temperature: 140-150°C, pressure: 2kg / cm2, softening solution formula: sodium hydroxide: 5%, anthraquinone: 0.5%. Cooking time: 15 minutes;

[0046]Drain: take the softened bamboo out of the soaking pool, and wait for the natural water to drain after 6 hours;

[0047] Rolling and rolling: use a pair or more than one pair of rollers with grooves to apply a gradually increasing rolling force to the bamboo, and then send the bamboo to the impurity rolling machine to squeeze and crack the bamboo. Under the operation of rolling pressure, the filaments can be separated;

[0048] Kneading and tearing: the cracked bamboo is repeatedly rolled and squeezed by rollers, and the cracked b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com