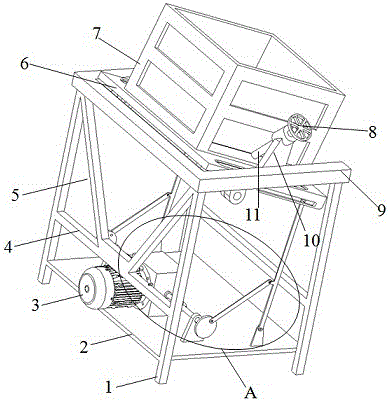

Coarse barium slag discharge overturning table based on crank-link mechanism

A technology of crank linkage mechanism and turning table, which is applied in the direction of conveyor, emptying container, loading/unloading, etc. It can solve the problems of unadjustable efficiency and large amount of dust, and achieve shortened production cycle, less dust amount and lower cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

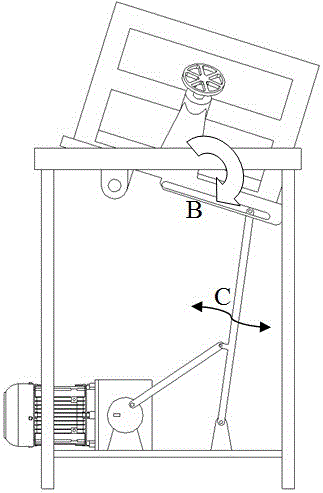

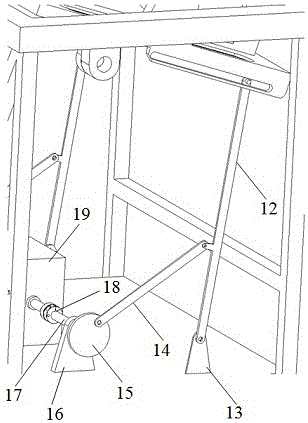

[0018] control figure 1 —3. Due to the harsh working environment, it is important to check the connection between the turning motor 3 and the turning table 6 before the device works, and at the same time ensure that the parts are connected reliably to avoid safety accidents, and then burn the barium salt The hopper 7 is placed on the overturning table 6, and the fired barium salt hopper 7 is fixed by rotating and compressing the hand wheel 8 and the locking screw 11, and the turning motor 3 is started for trial operation, and whether the actions of the biaxial reducer 19 and the overturning table 6 are Normal, finally make the turning table 6 in a horizontal state, and rotate the compression hand wheel 8 at the same time to make the distal end of the locking screw 11 close to the force frame 10, so as to avoid interference with the fired barium salt hopper 7 when placed, and the device has completed the preparation work so far .

[0019] After the calcined barium salt mineral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com