Rough out of the residue padding agency

A hopper and barium salt technology, which is applied in the field of hopper lifting devices, can solve the problems of high working noise, high labor intensity of workers, insensitive movements, etc., and achieve the effects of reducing the degree of participation, shortening the production cycle, and smoothing the action process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

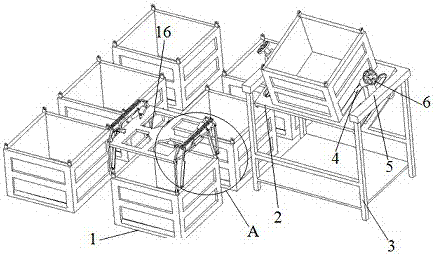

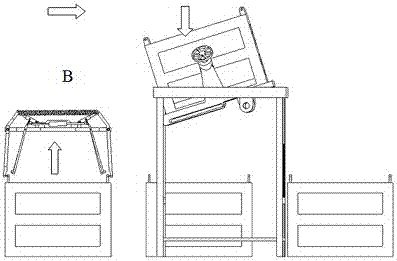

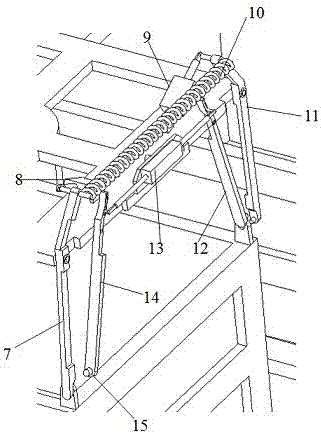

[0016] control Figure 1 to Figure 3 To illustrate, due to the harsh working environment, before the device works, it is necessary to focus on checking the connection between the left hanging rod driving cylinder 8 and the right hanging rod driving cylinder 9, as well as the two-way cylinder 13 and the bucket suspension 16. The components are reliably connected to avoid safety accidents, and then the turning table 2 is placed in a horizontal state, and the compression hand wheel 6 is rotated at the same time to make the distal end of the locking screw 4 close to the force frame 5, thereby avoiding the placement of the fired barium salt hopper 1 When it interferes with it, the device completes the preparation work so far.

[0017] After the calcined barium salt mineral raw material in the calcined barium salt hopper 1 is soaked in water, if necessary, the calcined barium salt hopper 1 is transported to the upper side of the turning table 2, and the bucket suspension 16 moves to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com