Production system for door leaf of plain batten door

A production system and flat door technology, applied in the direction of cooperative devices, instruments, wood processing equipment, etc., can solve the problems of many employees, high error rate, high labor cost, etc., achieve energy saving and environmental protection layout, strong controllability, The effect of reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

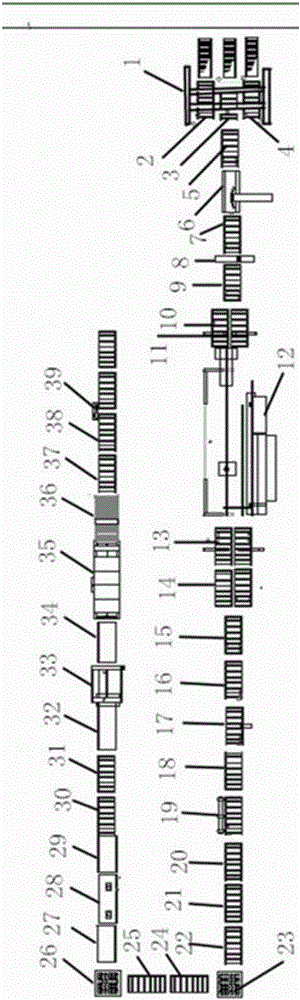

[0023] The present invention provides a production system for flat door leaves. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] The specific implementation of the production system of flat door leaf is as follows:

[0025] When the material supply personnel push the door leaf to half of the left lifting platform 2, press the lifting control switch, the door leaf is automatically pushed to the designated photoelectric sensing position, the photoelectric sensor detects the door leaf, and the left lifting platform 2 automatically rises to a certain height and stops. Then when the door leaf is pushed to the half of the right lifting platform 4, press the lifting control switch, the door leaf is automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com