Powder material collecting cabin

A technology for collecting silos and powders, which is applied in the field of silos, can solve the problems of unfavorable control of production and the inability to accurately obtain the amount of powders, etc., and achieve the effects of easy control of production, uniform force, and reduced dust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

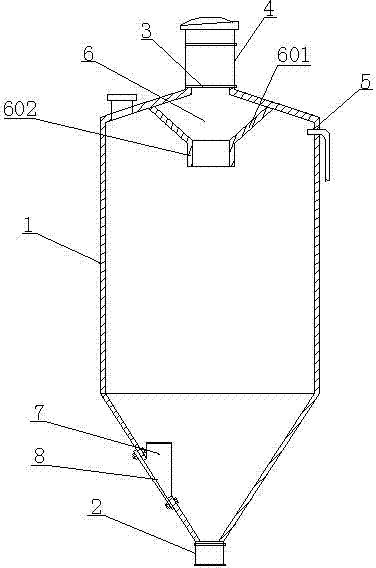

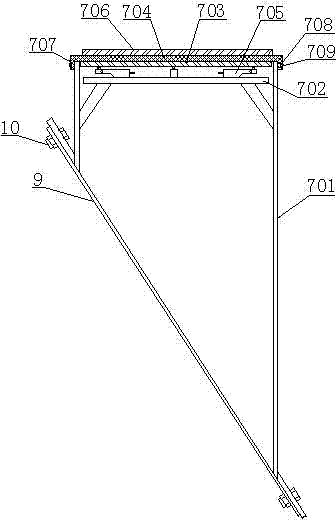

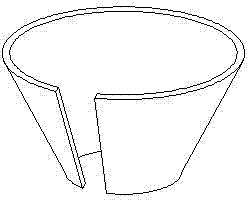

[0018] As shown in the figure, a powder collection bin includes a bin body 1. The lower part of the bin body 1 is funnel-shaped, and the bottom end is provided with a discharge port 2, and the upper end of the bin body 1 is provided with an air outlet 3. The air outlet 3 is provided with a dust filter 4 . Dust filtering device 4 can adopt strainer type filter or other conventional solid dust filtering device. The side wall of the bin body 1 is provided with a feeding pipe 5 , and a dust removal device 6 and a weighing device 7 are also arranged in the bin body 1 . The dust removal device 6 includes a conical guide tube 601 and a cylindrical guide tube 602 . The conical guide tube 601 is a truncated conical shape with a closed circumference or a truncated conical shape with an opening on the circumference. The opening is set in the following manner: image 3 shown. It is preferably set in the shape of a truncated cone with a closed circumference. The diameter of the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com