Supporting device for measuring instrument

A technology for supporting devices and measuring instruments, applied in the field of measuring tools, can solve problems such as inaccurate measurement results, and achieve the effect of preventing measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

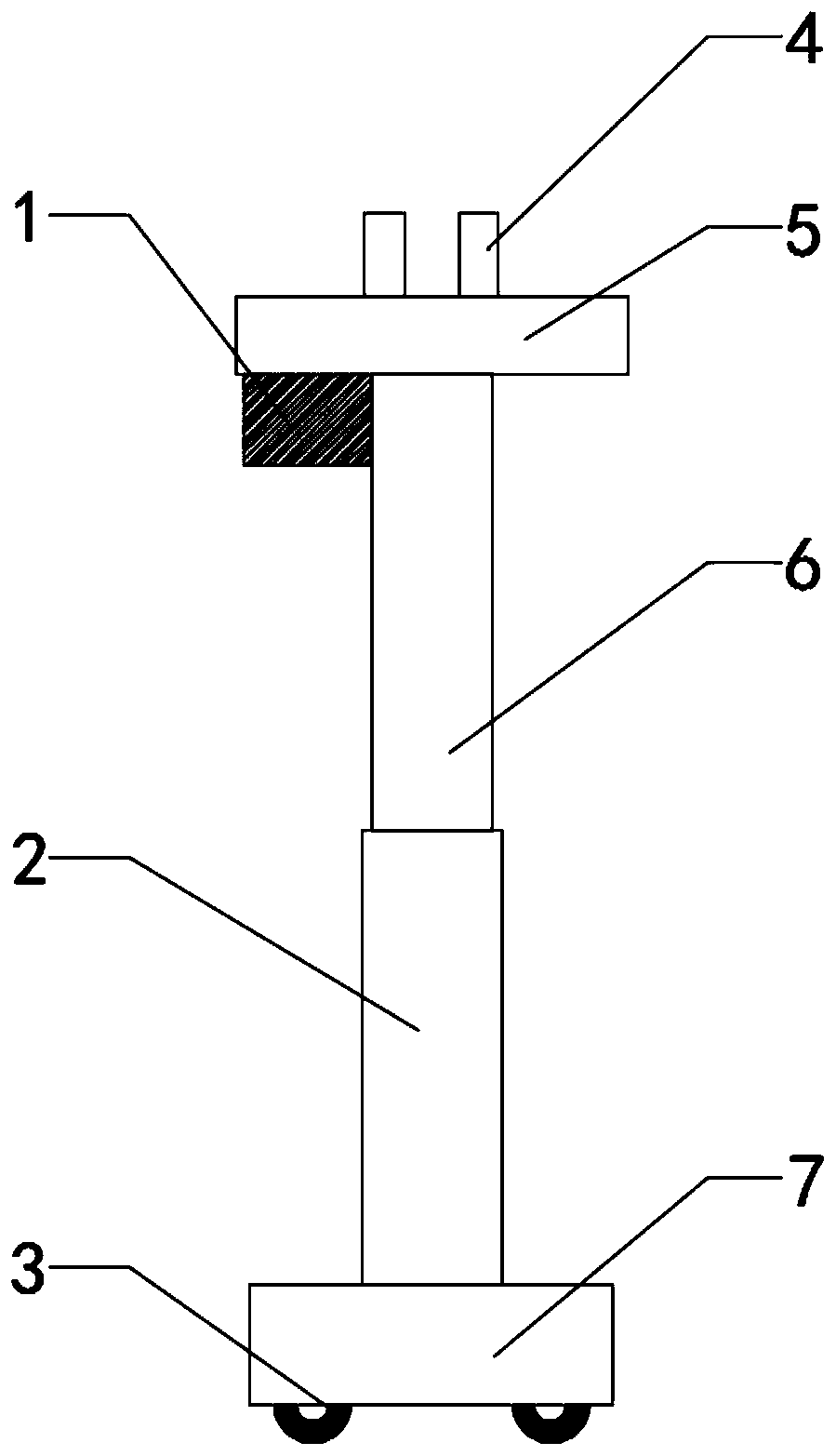

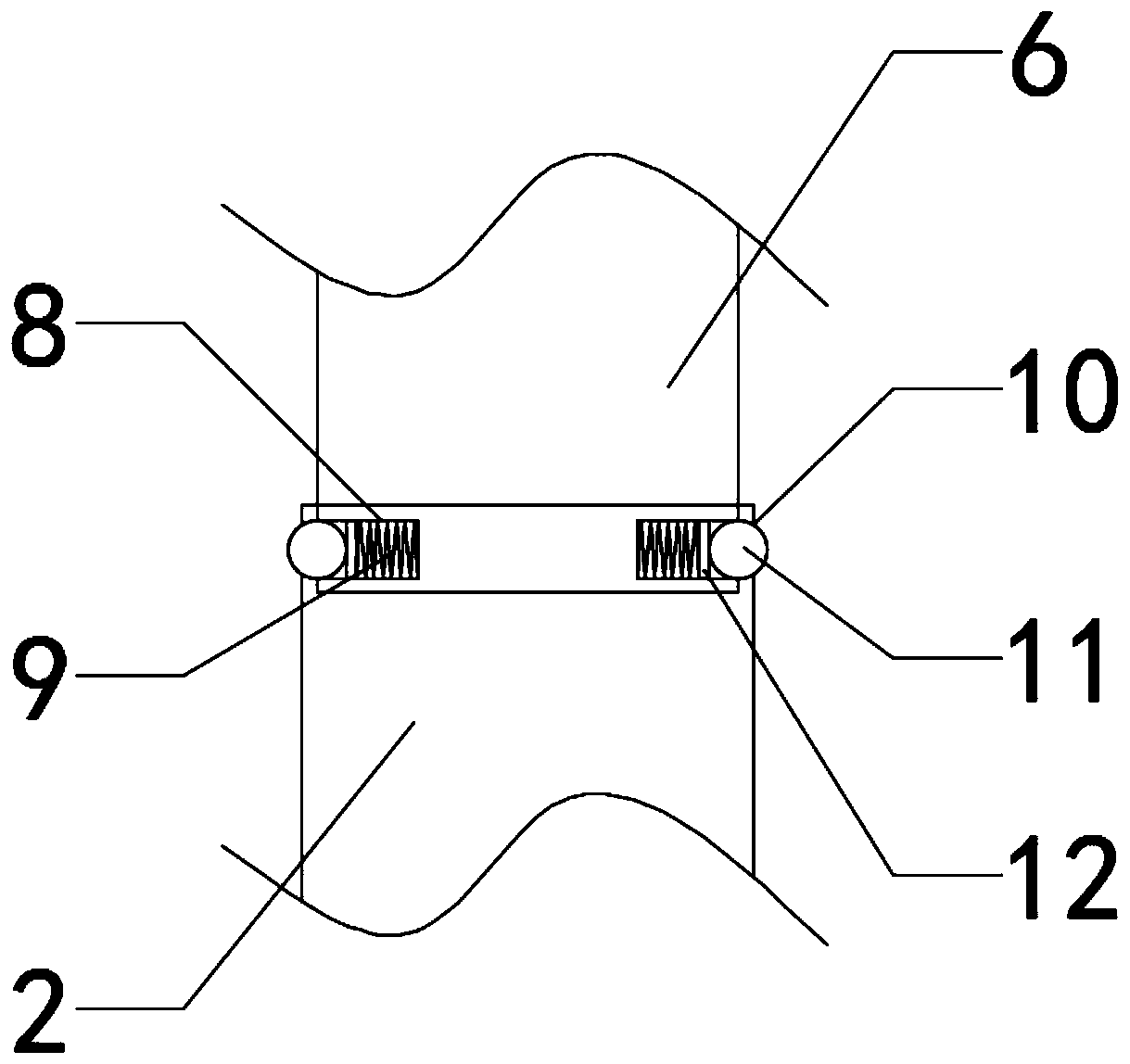

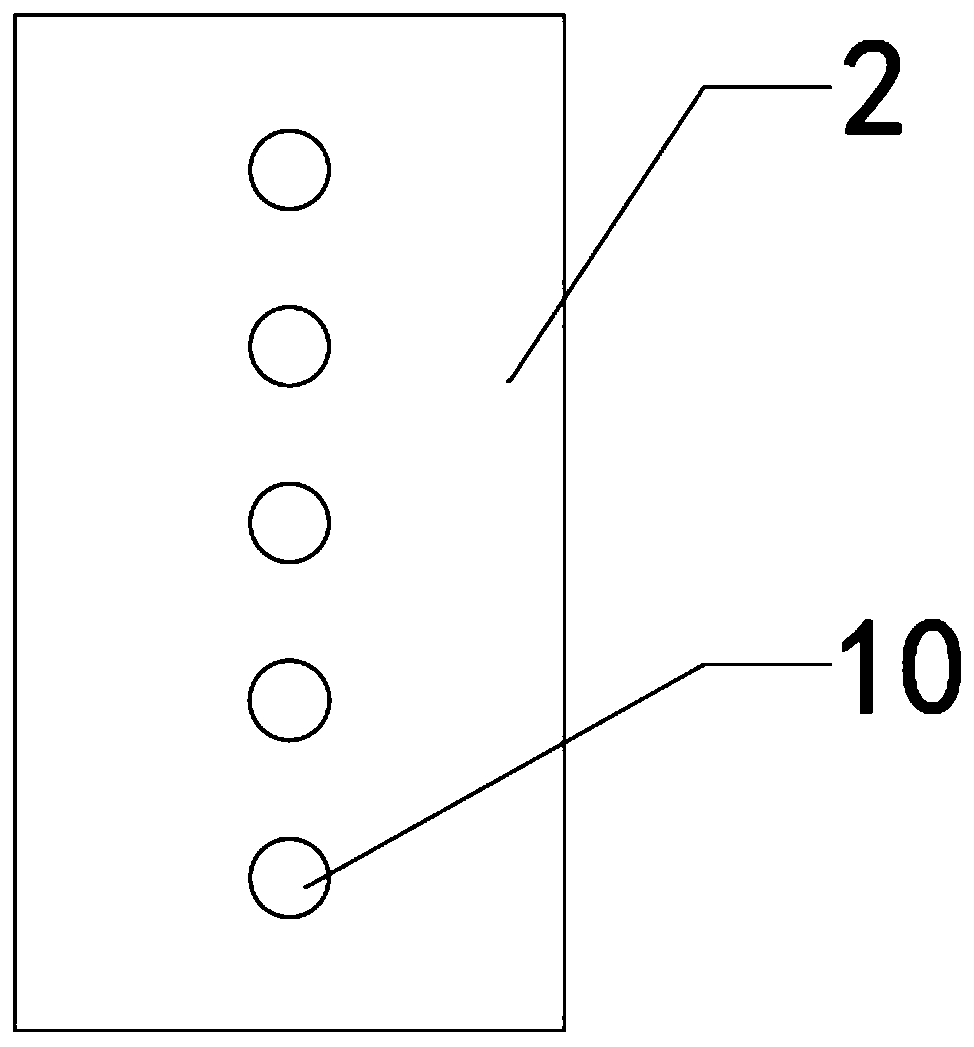

[0030] see Figure 1-11 , a supporting device for measuring instruments, comprising a support base 7, a plurality of moving wheels 3 are arranged at the lower end of the supporting base 7, in this embodiment, preferably, the number of the moving wheels 3 is four and is evenly distributed on The lower end of the support base 7, the user can push the supporting device for the measuring instrument through the moving wheel 3, the upper end of the support base 7 is connected with the support assembly, the upper end of the support assembly is fixedly connected with the placement seat 5, and the placement seat 5 is fixed. A dust-proof mechanism is provided, and the specific form of the dust-proof mechanism is not limited. In this embodiment, preferably, the dust-proof mechanism includes a dust-proof main body 1, and the dust-proof main body 1 is fixedly connected with the placement seat 5. A dust-proof motor 16 is arranged inside the dust-proof main body 1, and the dust-proof motor 1...

Embodiment 2

[0035] This embodiment is improved on the basis of Embodiment 1. The specific improvement is that: the dust-proof main body 1 is provided with an air extraction device 18, and the specific form of the air extraction device 18 is not limited. This embodiment Among them, preferably, the air extraction device 18 is an air extraction pump, the air is sucked in by the air extraction device 18 and then released through the passage groove 19 and the passage hole 21, which can also effectively prevent dust from affecting the measurement accuracy of the measuring instrument.

[0036] The working principle of this embodiment is: the dustproof main body 1 is provided with an air extraction device 18, the air extraction device 18 is an air extraction pump, the air is sucked in by the air extraction device 18 and then the air is released through the passage groove 19 and the passage hole 21, It can also effectively prevent dust from affecting the measurement accuracy of the measuring instru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com