Zeolite controlled-release fertilizer and manufacturing method for same

A slow and controlled release fertilizer and zeolite technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of destroying soil structure, not being environmentally friendly, and resin coating cannot be degraded, so as to improve performance, increase density, and improve anti-caking The effect of block power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

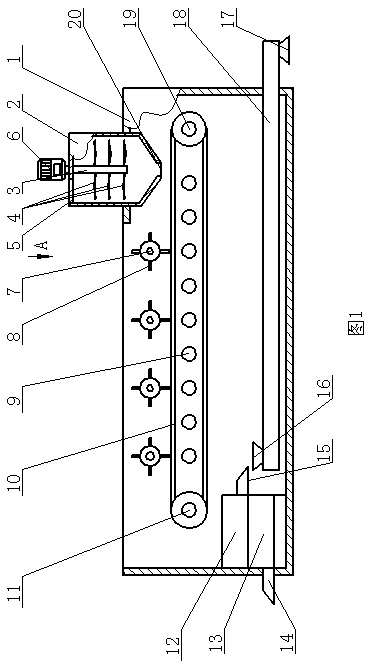

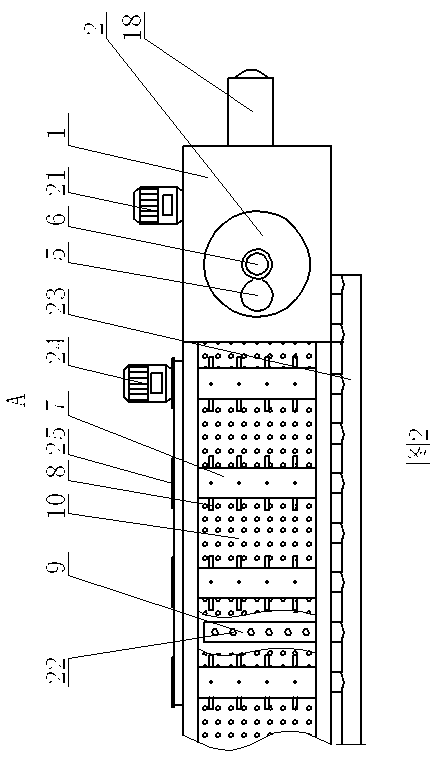

Method used

Image

Examples

Embodiment 1

[0014] A zeolite slow-release fertilizer, comprising the following raw materials in parts by weight: 5 parts of biochemical potassium fulvic acid, 15 parts of urea, 10 parts of monoammonium phosphate, 40 parts of potassium sulfate, 1 part of magnesium sulfate, 3 parts of calcium nitrate, sulfuric acid 4 parts of zinc, 30 parts of modified zeolite, 2 parts of ferric ammonium citrate, 4 parts of acid clay and 2 parts of calcium sulfate.

[0015] The test shows that: at 25°C, the nutrient release rate in the fertilizer is 5% within 24 hours; the nutrient release rate is 45% within 28 days; and the nutrient release rate is 65% within 60 days. The present invention is tested on spinach, and when the nutrient amount is reduced by 1 / 2 compared with the control group, there is a 22.30% increase in production.

Embodiment 2

[0017] A zeolite slow-release fertilizer, comprising the following raw materials in parts by weight: 15 parts of biochemical potassium fulvic acid, 50 parts of urea, 25 parts of monoammonium phosphate, 30 parts of potassium sulfate, 3 parts of magnesium sulfate, 4 parts of calcium nitrate, sulfuric acid 1 part of zinc, 10 parts of modified zeolite, 4 parts of ferric ammonium citrate, 2 parts of acid clay and 1 part of calcium sulfate.

[0018] The test shows that: at 25°C, the nutrient release rate in the fertilizer is 7% within 24 hours; the nutrient release rate is 55% within 28 days; and the nutrient release rate is 70% within 60 days. The invention is tested on spinach, and compared with the control group, the nutrient content is reduced by 1 / 2, and the yield is increased by 23.40%.

Embodiment 3

[0020] A zeolite slow-release fertilizer, comprising the following raw materials in parts by weight: 18 parts of biochemical potassium fulvic acid, 40 parts of urea, 40 parts of monoammonium phosphate, 15 parts of potassium chloride, 4 parts of magnesium sulfate, 1 part of calcium nitrate, 2 parts of zinc sulfate, 20 parts of modified zeolite, 5 parts of ferric ammonium citrate, 5 parts of acid clay and 4 parts of calcium sulfate.

[0021] The test shows that: at 25°C, the nutrient release rate in the fertilizer is 10% within 24 hours; the nutrient release rate is 50% within 28 days; and the nutrient release rate is 68% within 60 days. The present invention is tested on spinach, and compared with the control group, the nutrient content is reduced by 1 / 2, and the yield is increased by 24.50%.

[0022] The modified zeolite is obtained through the following steps: ① The zeolite raw material, paraffin, N-dodecanoyl-N-methyl-1-amino-1-deoxy-D glucitol and ether are in a weight rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com