Civil ammonium nitrate modifier

A technology of modifying agent and ammonium nitrate, which is applied in the direction of non-explosive/non-thermal agent components, offensive equipment, explosives, etc., can solve the problems of inability to obtain comprehensive effects, achieve scientific and reasonable formula composition, prevent secondary agglomeration, The effect of increasing explosion temperature and explosive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

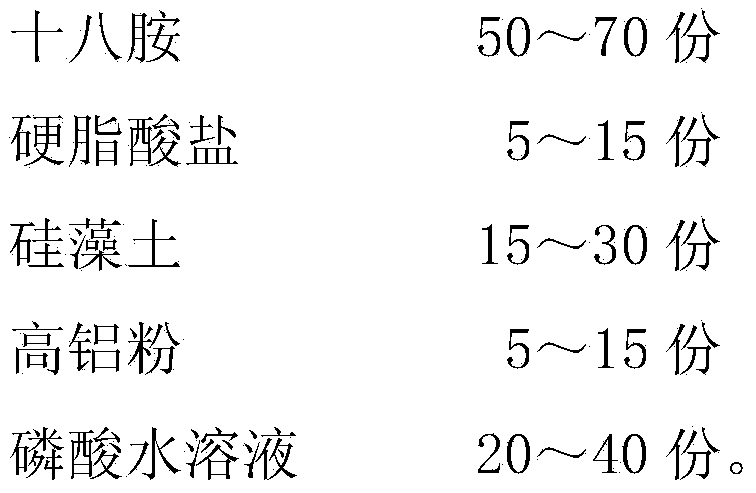

[0018] A kind of civil ammonium nitrate modifier, the parts by weight of each component are as follows:

[0019]

[0020] The above-mentioned modifying agent is a solid particle with a particle diameter not greater than 2.5mm.

[0021] The present invention is an ammonium nitrate modifier for civilian use: take the above-mentioned components and carry out a chemical reaction at 85° C. After the reaction, first dehydrate, then dry, and finally grind into powder.

[0022] The civil ammonium nitrate modifier prepared in this example was tested for hygroscopicity and caking performance, and the results showed that the ammonium nitrate with a water content of 0.15% and the ammonium nitrate modifier was exposed to the air for one month, and the ammonium nitrate was detected The water content is 0.17%. And there is no obvious caking phenomenon.

Embodiment 2

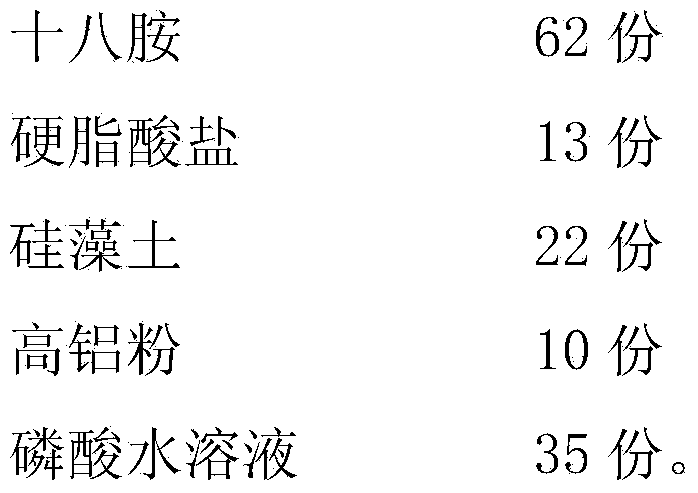

[0024] A kind of civil ammonium nitrate modifier, the parts by weight of each component are as follows:

[0025]

[0026] The above-mentioned modifying agent is a solid particle with a particle diameter not greater than 2.5mm.

[0027] The present invention is an ammonium nitrate modifier for civilian use: take the above-mentioned components and carry out a chemical reaction at 85° C. After the reaction, first dehydrate, then dry, and finally grind into powder.

[0028] The civil ammonium nitrate modifier prepared in this example was tested for hygroscopicity and caking performance, and the results showed that the ammonium nitrate with a water content of 0.15% and the ammonium nitrate modifier was exposed to the air for one month, and the ammonium nitrate was detected The water content is 0.18%. And there is no obvious caking phenomenon.

Embodiment 3

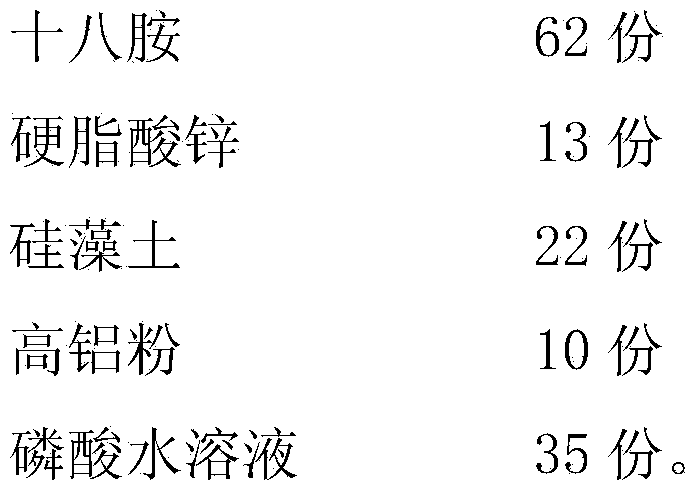

[0030] A kind of civil ammonium nitrate modifier, the parts by weight of each component are as follows:

[0031]

[0032] The above-mentioned modifying agent is a solid particle with a particle diameter not greater than 2.5mm.

[0033] The present invention is an ammonium nitrate modifier for civilian use: take the above-mentioned components and carry out a chemical reaction at 85° C. After the reaction, first dehydrate, then dry, and finally grind into powder.

[0034] The civil ammonium nitrate modifier prepared in this example was tested for hygroscopicity and caking performance, and the results showed that the ammonium nitrate with a water content of 0.15% and the ammonium nitrate modifier was exposed to the air for one month, and the ammonium nitrate was detected The water content is 0.19%. And there is no obvious caking phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com