Toner binder and toner

A technology of toner and adhesive, applied in the direction of developer, instrument, electrography, etc., can solve the problems of insufficiency, etc., and achieve the effect of excellent caking resistance and low temperature fixability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

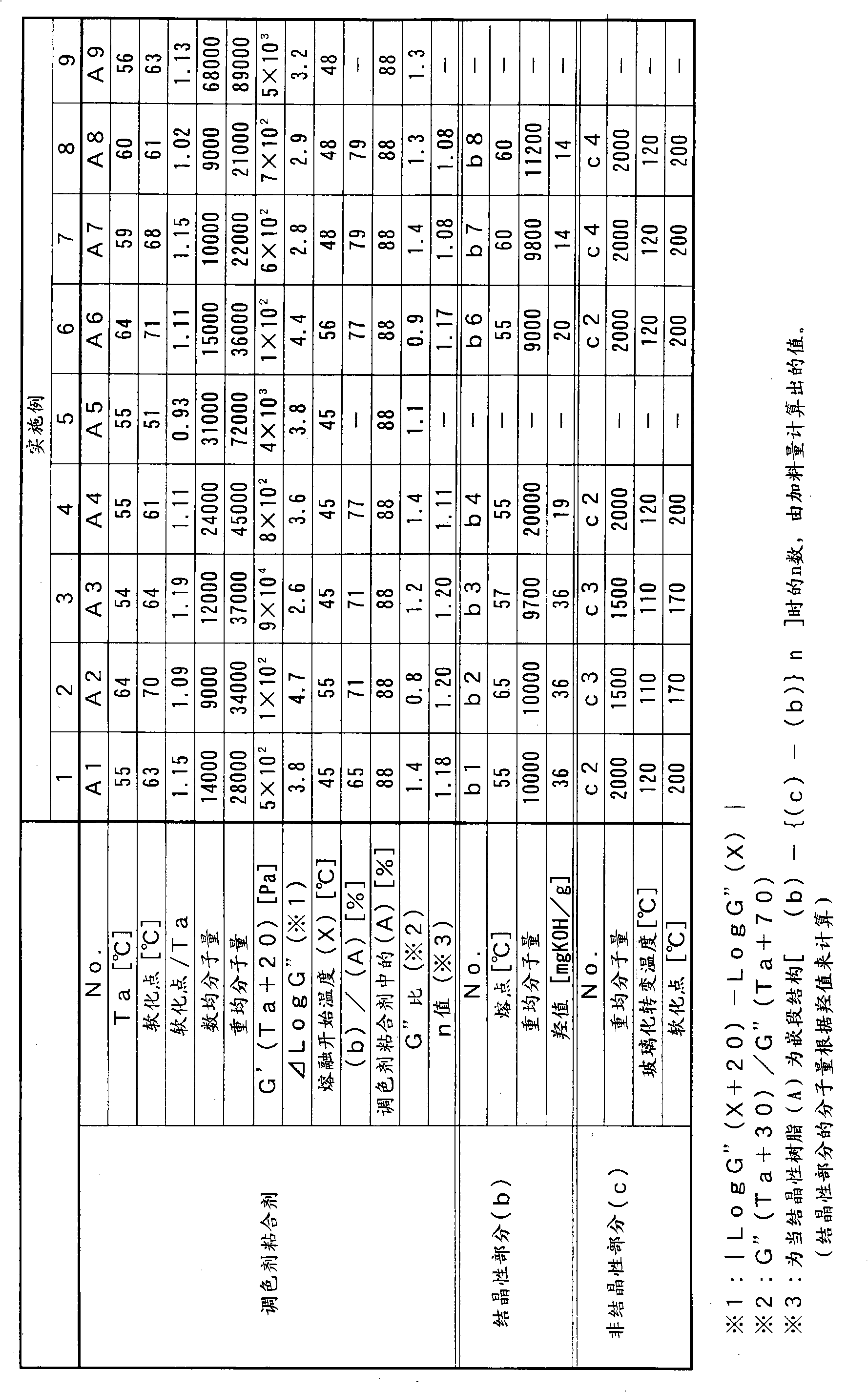

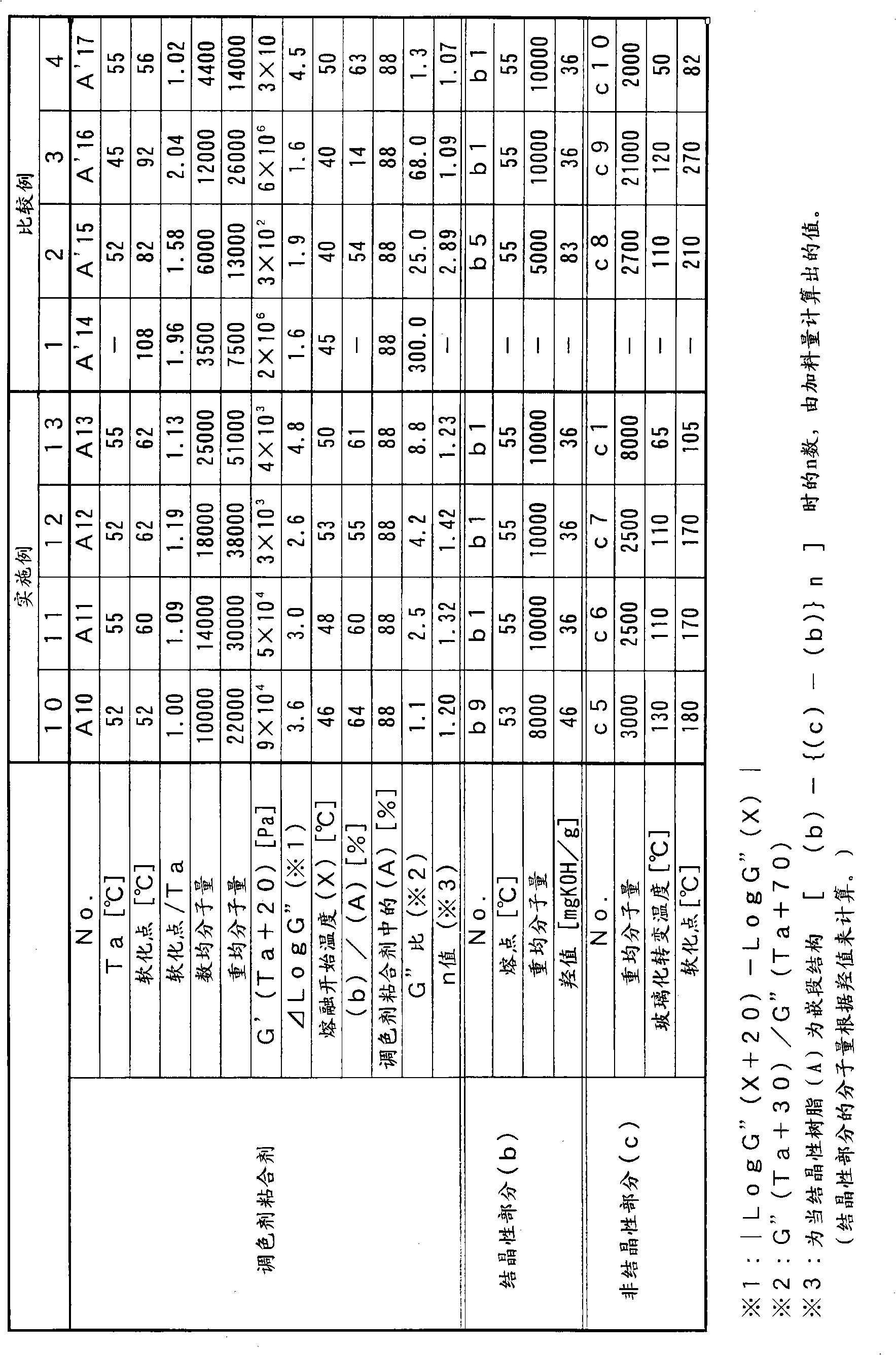

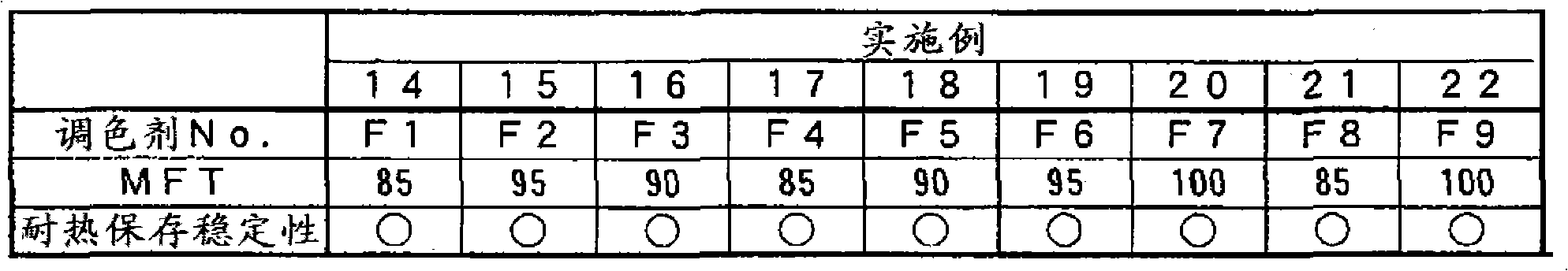

Examples

manufacture example 1

[0177] Production example 1 (production of crystalline part b)

[0178] Into the reaction tank with cooling pipe, mixer and nitrogen inlet pipe, add 159 parts of sebacic acid, 28 parts of adipic acid and 124 parts of 1,4-butanediol and dihydroxybis(triethanolamine) as a condensation catalyst One part of titanium was reacted at 180°C for 8 hours in a nitrogen stream while distilling off generated water. Next, while slowly raising the temperature to 220° C., the generated water and 1,4-butanediol were distilled off in a nitrogen stream, and reacted for 4 hours, and then reacted under a reduced pressure of 5 to 20 mmHg. When the Mw reached 10,000, the its taken out. After cooling the taken-out resin to room temperature, it was pulverized into particles to obtain a crystalline polycondensation polyester resin [crystalline fraction b1]. [Crystalline fraction b1] had a melting point of 55° C., a Mw of 10,000, and a hydroxyl value of 36.

manufacture example 2

[0179] Production example 2 (production of crystalline part b)

[0180] In the reaction tank with cooling pipe, stirrer and nitrogen inlet pipe, add 286 parts of dodecanedioic acid and 159 parts of 1,6-hexanediol and 1 part of dihydroxy bis(triethanolamine) titanium as condensation catalyst, The reaction was carried out at 170°C for 8 hours in a nitrogen stream while distilling off generated water. Next, while slowly raising the temperature to 220° C., the generated water was distilled off in a nitrogen stream, and the reaction was carried out for 4 hours, and the reaction was further carried out under a reduced pressure of 5 to 20 mmHg, and it was taken out when the Mw reached 10,000. After cooling the taken-out resin to room temperature, it was pulverized into particles to obtain a crystalline polycondensation polyester resin [crystalline fraction b2]. [Crystalline fraction b2] had a melting point of 65° C., a Mw of 10,000, and a hydroxyl value of 36.

manufacture example 3

[0181] Production example 3 (production of crystalline part b)

[0182] Into a reaction container equipped with a stirring bar and a thermometer, 66 parts of 1,4-butanediol, 86 parts of 1,6-hexanediol, and 40 parts of methyl ethyl ketone (hereinafter referred to as MEK) were added. 248 parts of hexamethylene diisocyanate (HDI) was added to this solution, and it was made to react at 80 degreeC for 5 hours, and the MEK solution of the crystalline polyurethane resin [crystalline part b3] was obtained. [Crystalline fraction b3] after removing the solvent had a melting point of 57° C., a Mw of 9700, and a hydroxyl value of 36.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com