Blackening-treated steel plate

A steel plate, black technology, applied in the field of black steel plate, can solve discoloration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

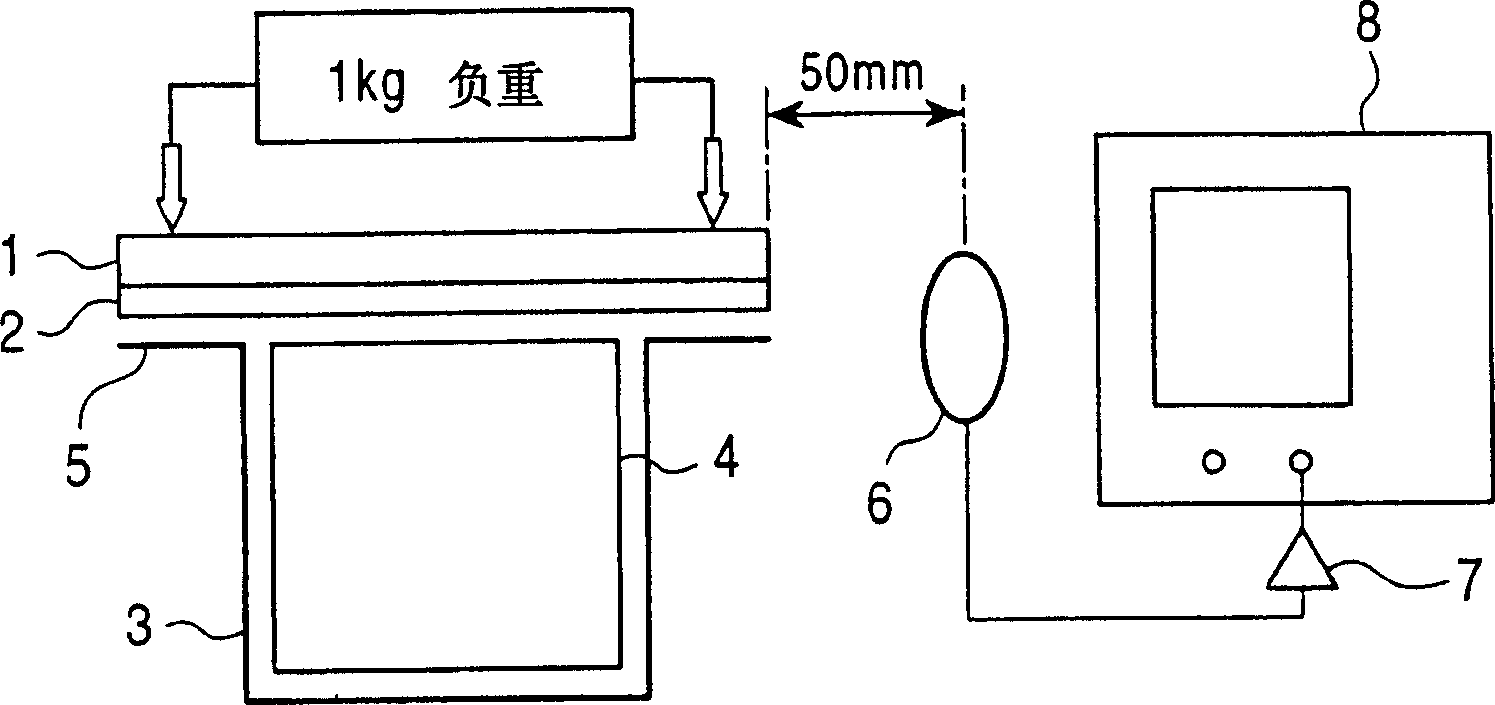

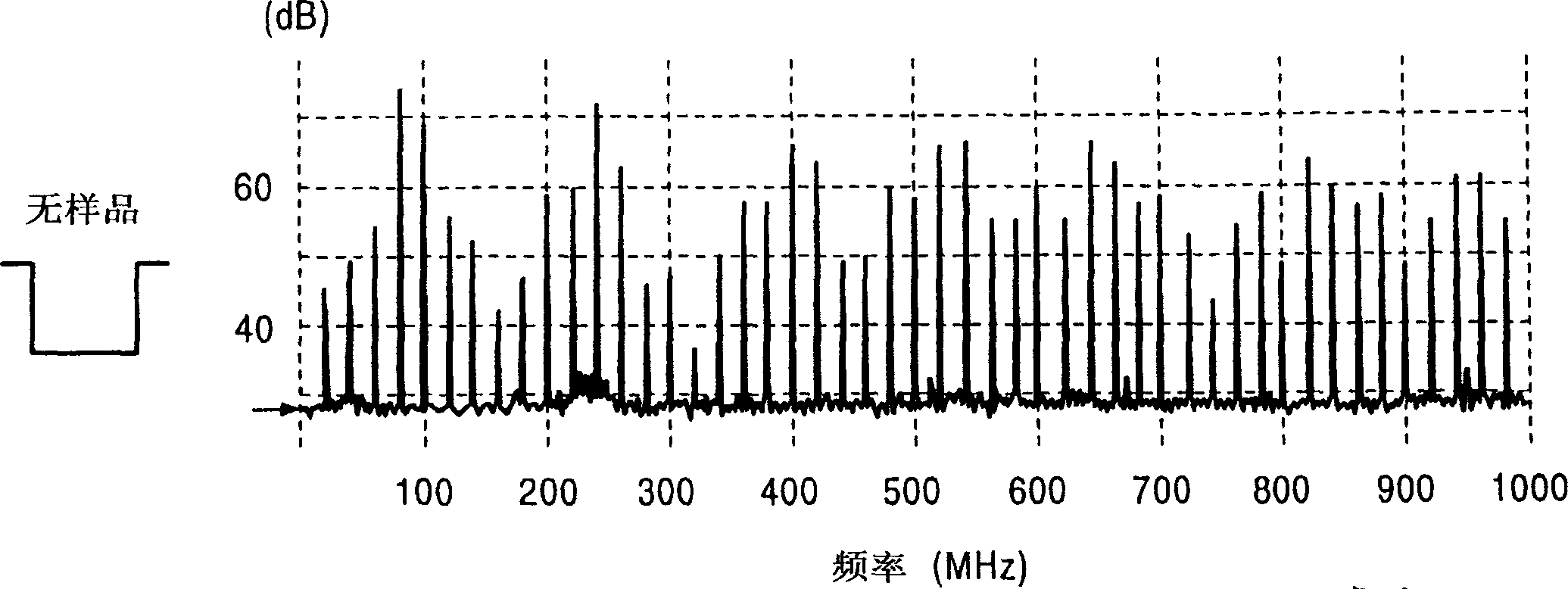

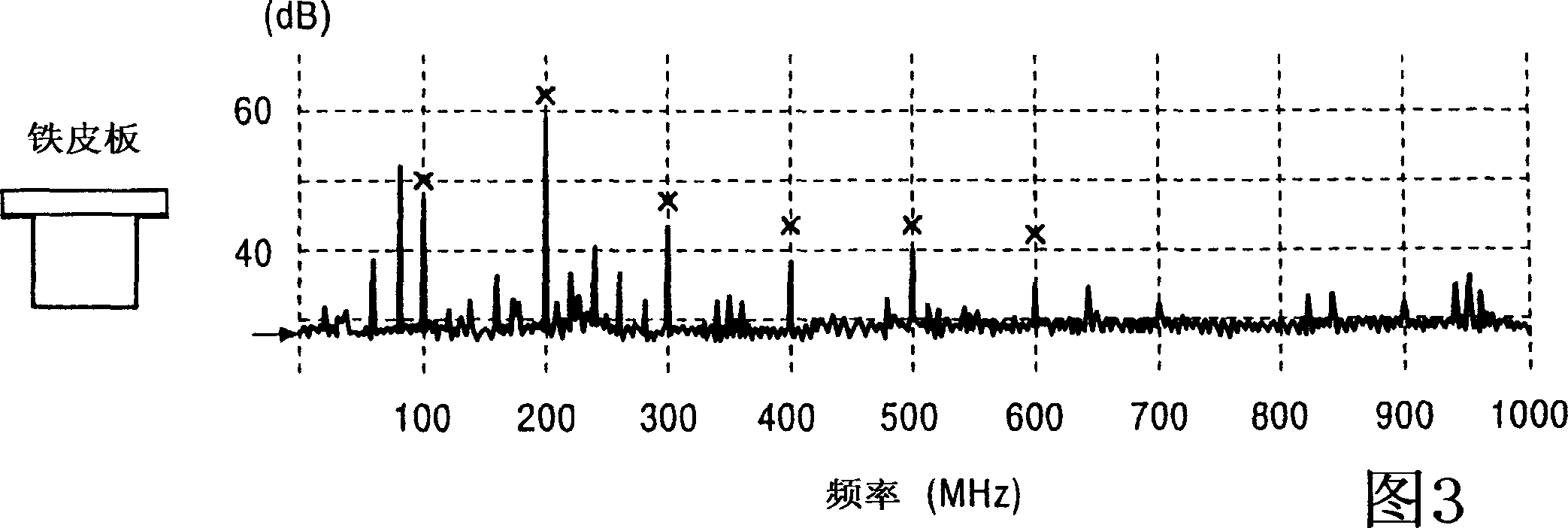

Method used

Image

Examples

Embodiment

[0071] The present invention will be described in detail below by way of examples.

example 1~29

[0073] On the following steel plates A~C of carrying out blackening treatment to the Zn-Ni plated steel plate, the following water-based paint composition is coated with a roll coater, and the water-based paint composition is obtained by adding the following water-soluble organic resin A ~D, 5 metal salts (metal ion types A~I), acids A~E, organic acids A~C, water-dispersible organic resins A~C and glycoluril resins A~D are added according to the ratio shown in Table 1 It was mixed with deionized water (total concentration of 20% by mass), heated for 15 seconds to bring the temperature of the steel plate to 170° C., dried and solidified to form a coating film with a predetermined film thickness, and made into a test piece of a black steel plate.

[0074] Black steel plates A~C:

[0075] Plate A: Anodized electrolytically treated steel plate (plate thickness: 0.7mm)

[0076] Plate B: Cathodic treatment steel plate (plate thickness: 0.7mm)

[0077] Plate C: alternately electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com