Gas-barrier material with excellent blocking resistance and process for producing the same

A gas-barrier material and gas-barrier layer technology, applied in chemical instruments and methods, layered products, thin material processing, etc., can solve the problems of gas-barrier properties dependent on humidity, reduced gas-barrier properties, poor adhesion, etc., to achieve Reduced production time, high productivity, and the effect of imparting steam resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0168] A solution thereof was obtained by dissolving polyester polyol (Byron 200, manufactured by Toyo Boseki Co.) in a mixed solvent of ethyl acetate / MEK (65 / 35 by weight) at a concentration of 14% by weight. To this solution, polyisocyanate (Sumijule N3300, manufactured by Sumika-Bayer Urethane Co., an iso cyanurates) and di-n-butyltin dilaurate (manufactured by Wako Junyaku Co.), the mixture was diluted with the above-mentioned mixed solvent in such a manner that the total solid content became 14% by weight, thereby obtaining Coating solution.

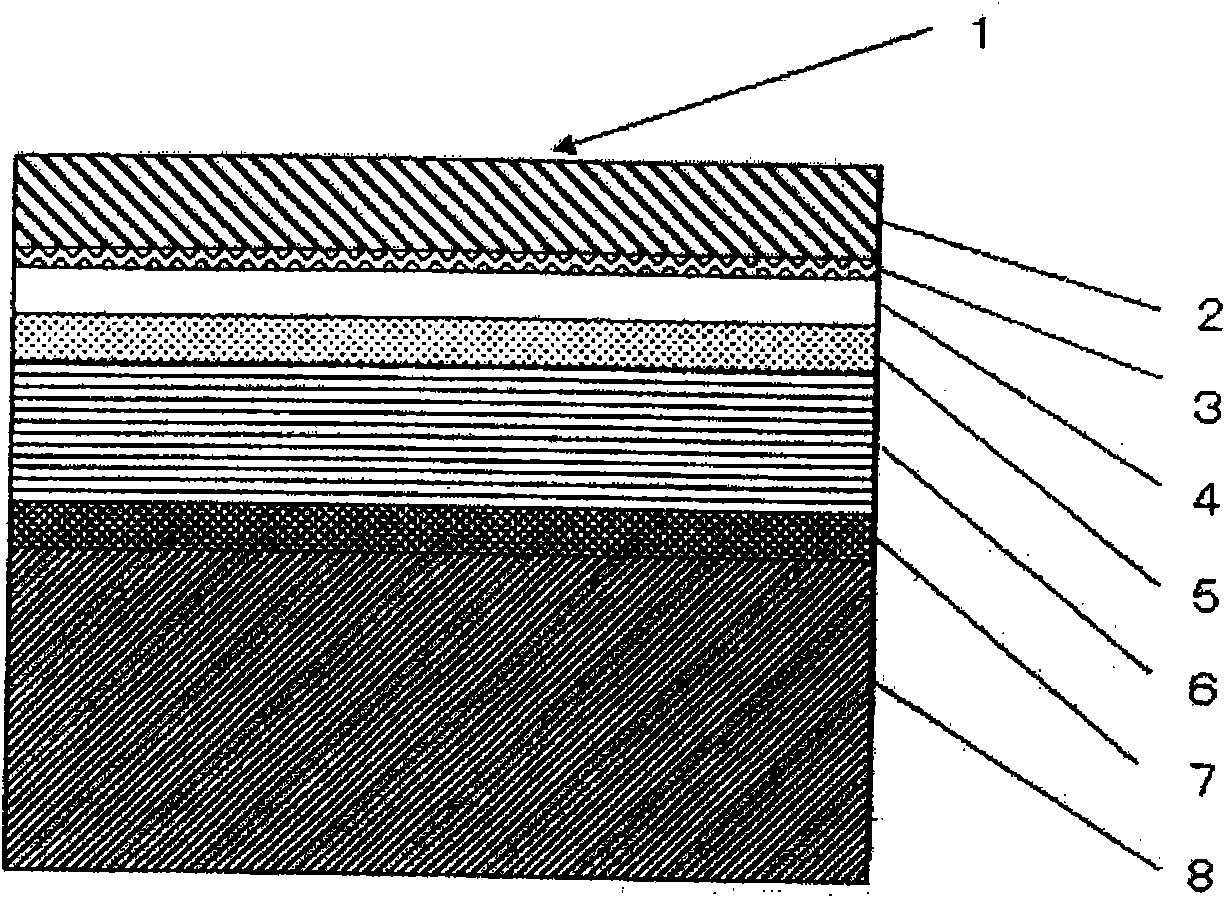

[0169] By using a bar coater, the above-mentioned coating solution was applied to a biaxially stretched polyethylene terephthalate film 2 having a thickness of 12 μm in a box-type electric oven at a preset temperature of 70° C. Heat treatment was performed for 2 minutes under conditions to obtain a polyethylene terephthalate film having an anchor layer, that is, an isocyanate compound-containing layer 3 having a thickness of 0.3 μm...

Embodiment 2

[0177] A laminated member was obtained by the same method as in Example 1 except that the amount of polyisocyanate added to the anchor layer-forming coating liquid was changed to 30% by weight relative to the polyester polyol.

Embodiment 3

[0179] A laminated member was obtained by the same method as in Example 1, except that the conditions for heat-treating the anchor layer in an electric box oven were changed to a preset temperature of 120° C. and a treatment time of 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com