Production technology of edible salt

A production process and a technology for edible salt, applied in the field of salt processing technology, can solve the problems that potassium ferrocyanide is not allowed to be added, increase the chance of crystal collision, uneven particle size, etc., so as to improve anti-caking ability and increase anti-caking resistance. Block capacity, mass reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

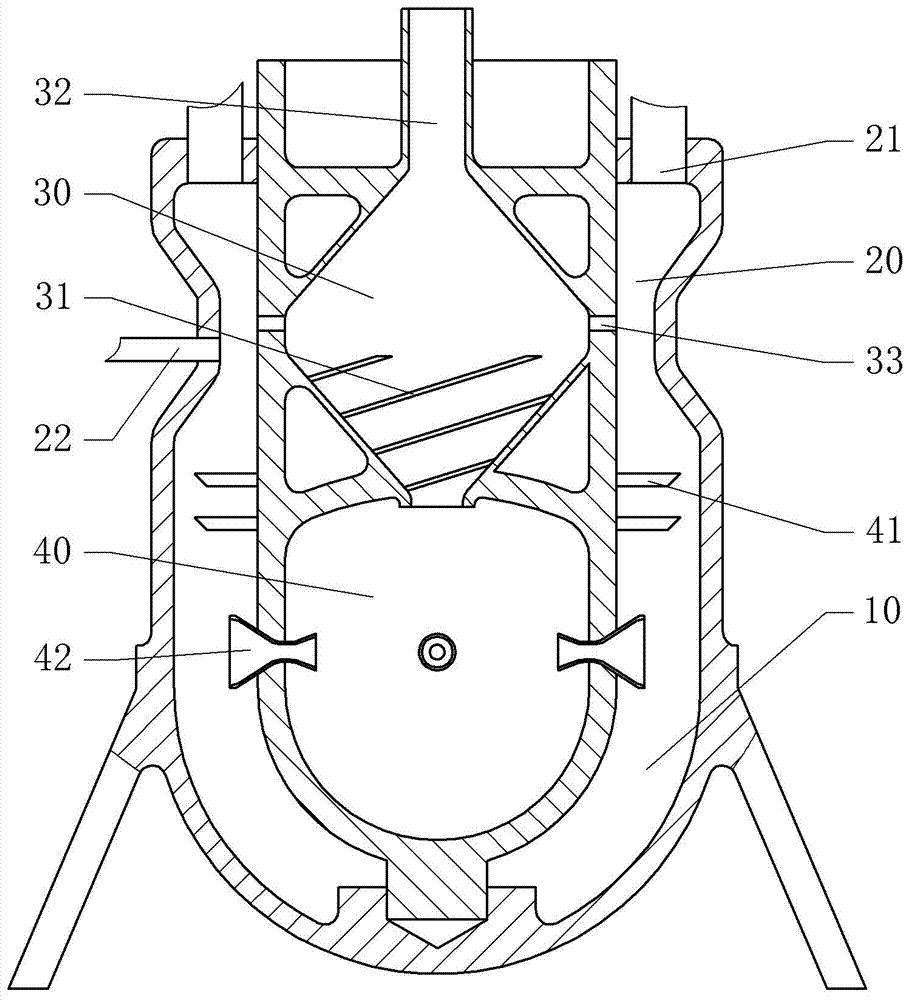

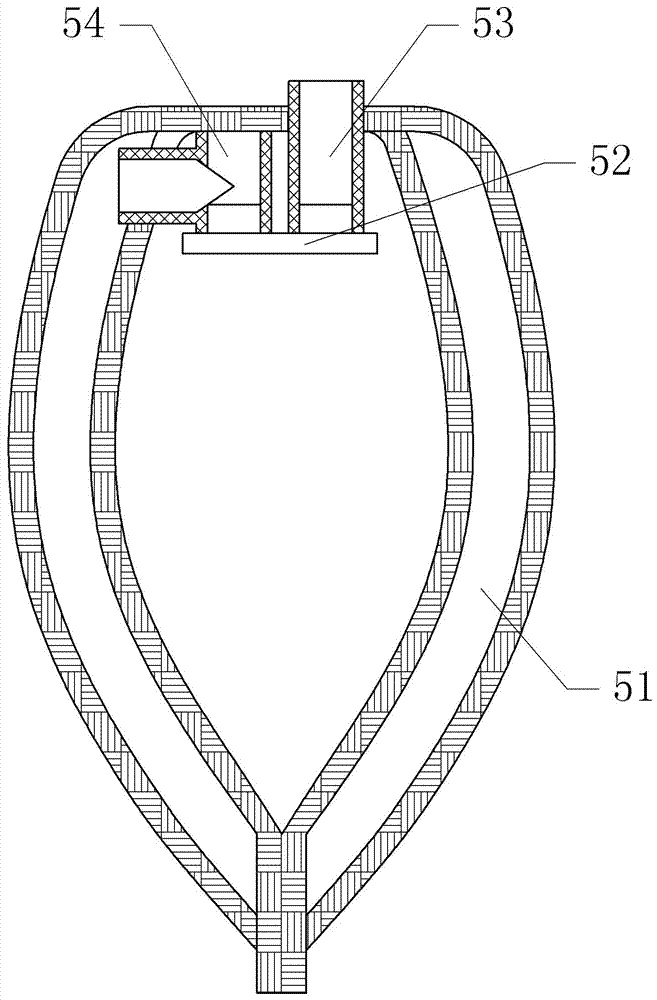

[0033]The reference signs in the drawings of the description include: pressure cylinder 10, venturi tube 20, compressed air inlet 21, feed pipe 22, discharge pipe 30, spiral blade 31, discharge port 32, screening hole 33, crushing cylinder Body 40, booster blade 41, Rafal nozzle 42, nitrogen layer 51, plug 52, first pipeline 53, second pipeline 54.

[0034] The production process of edible salt in this embodiment adopts a jet mill to grind the salt; the jet mill includes a body and a driving device, and the driving device in this embodiment is a motor. A pressure cylinder 10 is fixedly connected to the machine body, and a crushing cylinder 40 is rotatably connected inside the pressure cylinder 10. The side wall of the crushing cylinder 40 is oppositely provided with a Rafal nozzle 42 connecting the pressure cylinder 10 and the crushing cylinder 40 , There are two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com