Anti-static colored glaze mixed ink for ceramic ink-jet printing and preparation method thereof

A ceramic inkjet and hybrid technology, applied in the field of ceramic tile decoration, can solve the problems of unsuitable anti-static ceramic products and no electrostatic protection effect, achieve good anti-static effect, enhance suspension stability, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

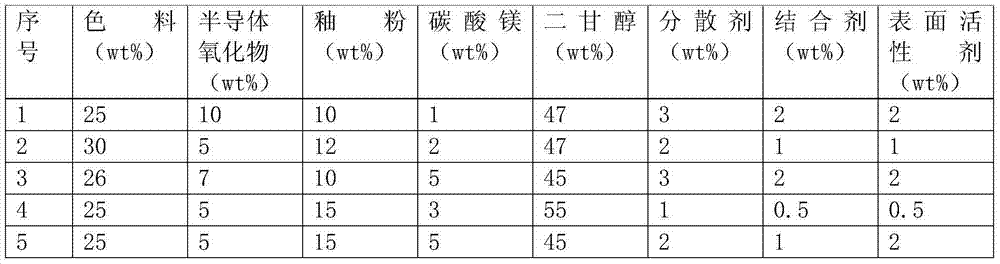

[0032] The composition formula of the colored glaze mixed ink for inkjet printing of ceramics provided in Examples 1-5 is shown in Table 1 below.

[0033] Table 1

[0034]

Embodiment 1

[0035]The pigment used in Example 1 is praseodymium yellow, and the prepared ink is yellow in color. The semiconductor oxide is a mixture of tin oxide and zinc oxide, and the mass ratio of tin oxide and zinc oxide is 8:2. The mass percentage of the chemical composition of the glaze powder is: silicon dioxide: 45% to 50%; aluminum oxide 18% to 22%, ferric oxide: ≤0.2%; titanium dioxide: ≤0.3%; calcium oxide 8% to 12% ;Magnesia 4%~5%; Potassium oxide: 2%~5%; Sodium oxide: 3%~5%; Barium oxide: 2%~4%; Zirconia: 1%~2%; Loss on ignition: ≤ 1%; water: ≤0.5%. Through the mass percentages of the above chemical components, those skilled in the art can calculate the dosage of the formula through the chemical analysis results of the Segel formula and the common mineral or frit raw materials used in ceramic production. Therefore, only the chemical composition requirements of the glaze powder are given here. For raw materials from different origins or frits with different chemical compone...

Embodiment 2

[0052] For the formula, see the mass ratio of each component given in Table 1. In this example, the pigments used are cobalt blue and spinel-based black pigments mixed at a mass ratio of 1:2. The ratio of the two can be matched according to the ink color required in actual use. , And if necessary, other pigments can also be added, such as: praseodymium yellow, red brown, orange and so on. The semiconductor oxide is selected as a mixture of titanium oxide and tin oxide, and the mass ratio of the two is 1:2.

[0053] In this example, the preparation method is basically the same as that in Example 1, except that the raw materials of the colorant used in this example are pre-calcined before use. Specifically: the cobalt blue and spinel black pigments are calcined at a temperature of 700-850 ° C, and the particle size reaches 325 mesh. The standard analysis sieve residue ≤ 0.05%, and the water content ≤ 0.5% can be used as the raw material of the color material. .

[0054] The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com