Patents

Literature

46results about How to "Magnetic homogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of continuous casting non-oriented electrical steel strip

InactiveUS20040016530A1Great resistanceImproved mechanical propertyMagnetic materialsElectric machineryMagnetic core

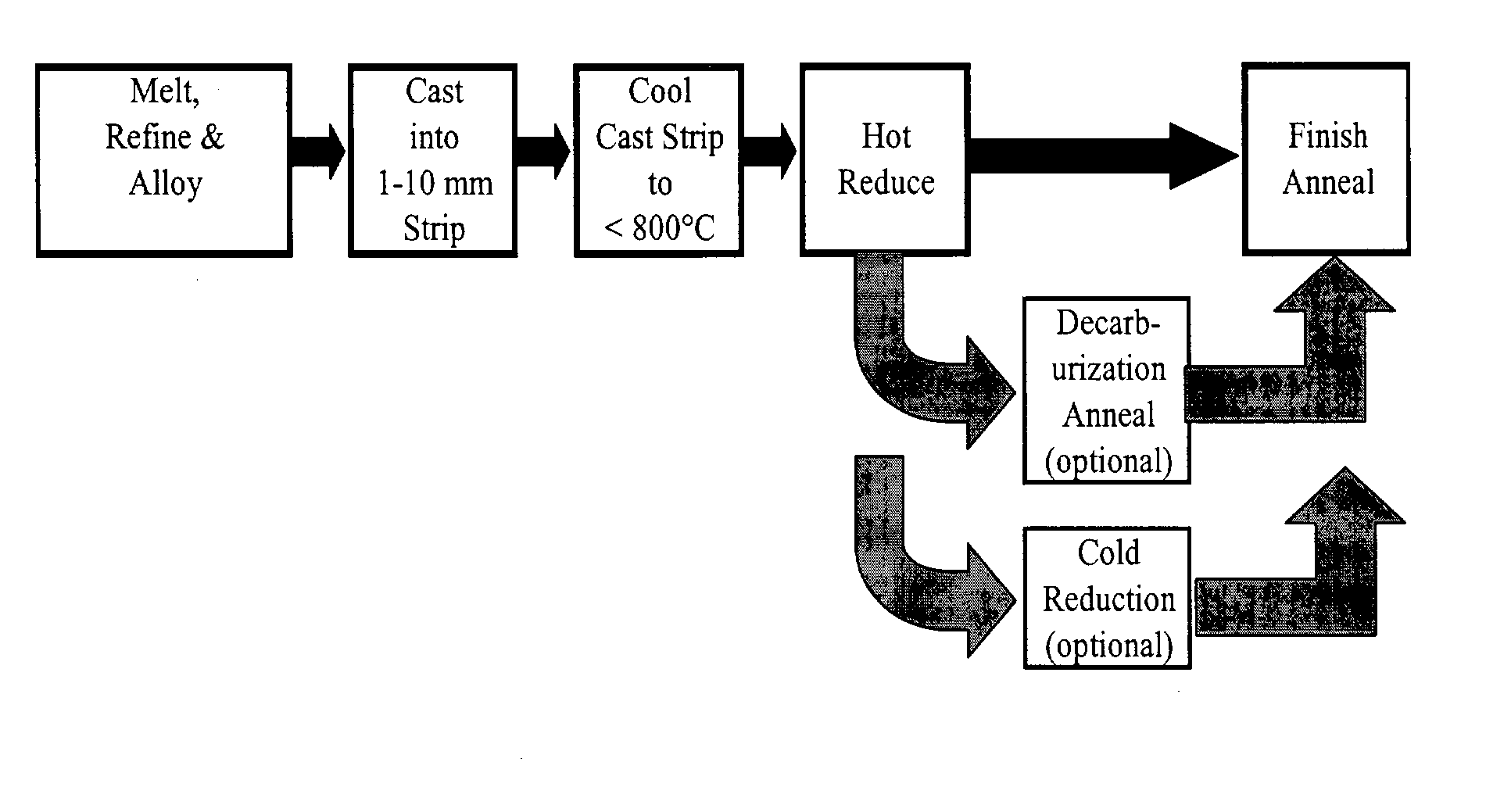

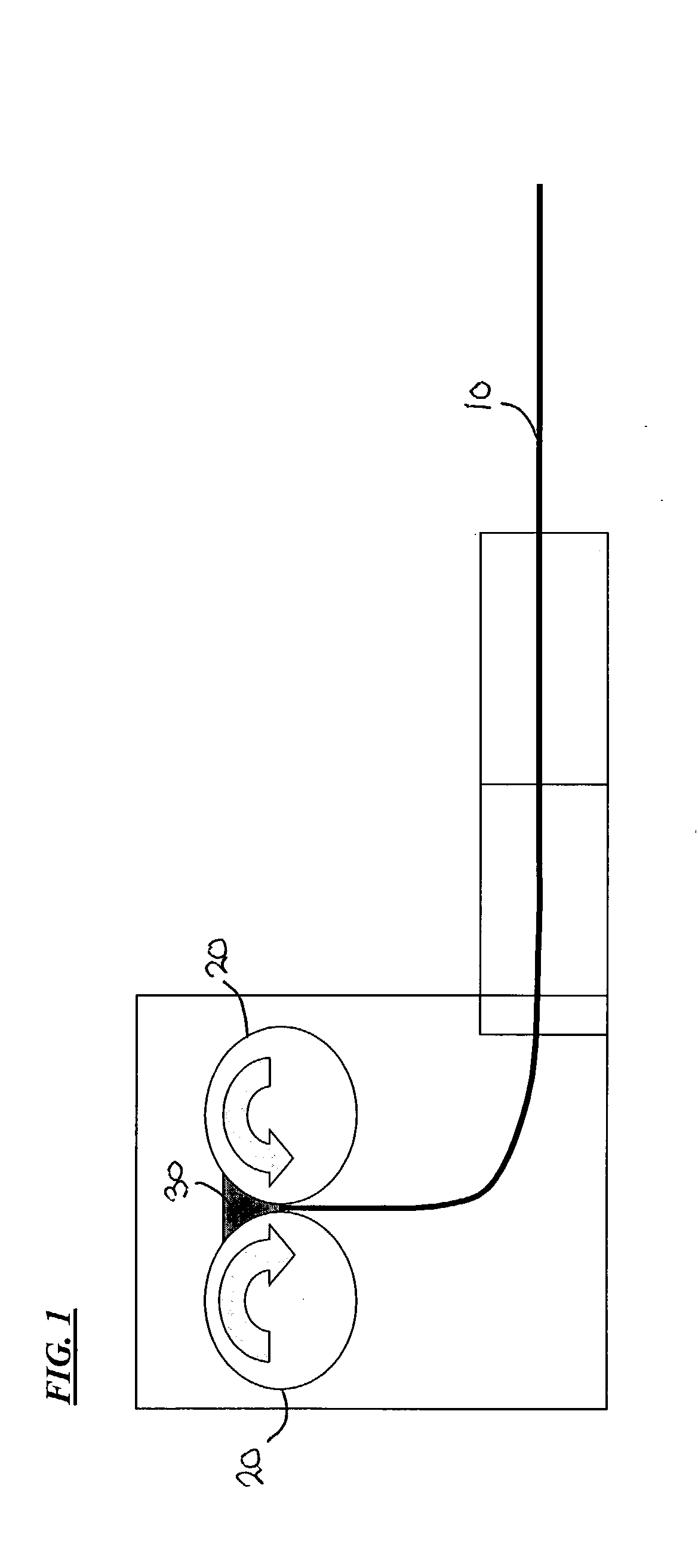

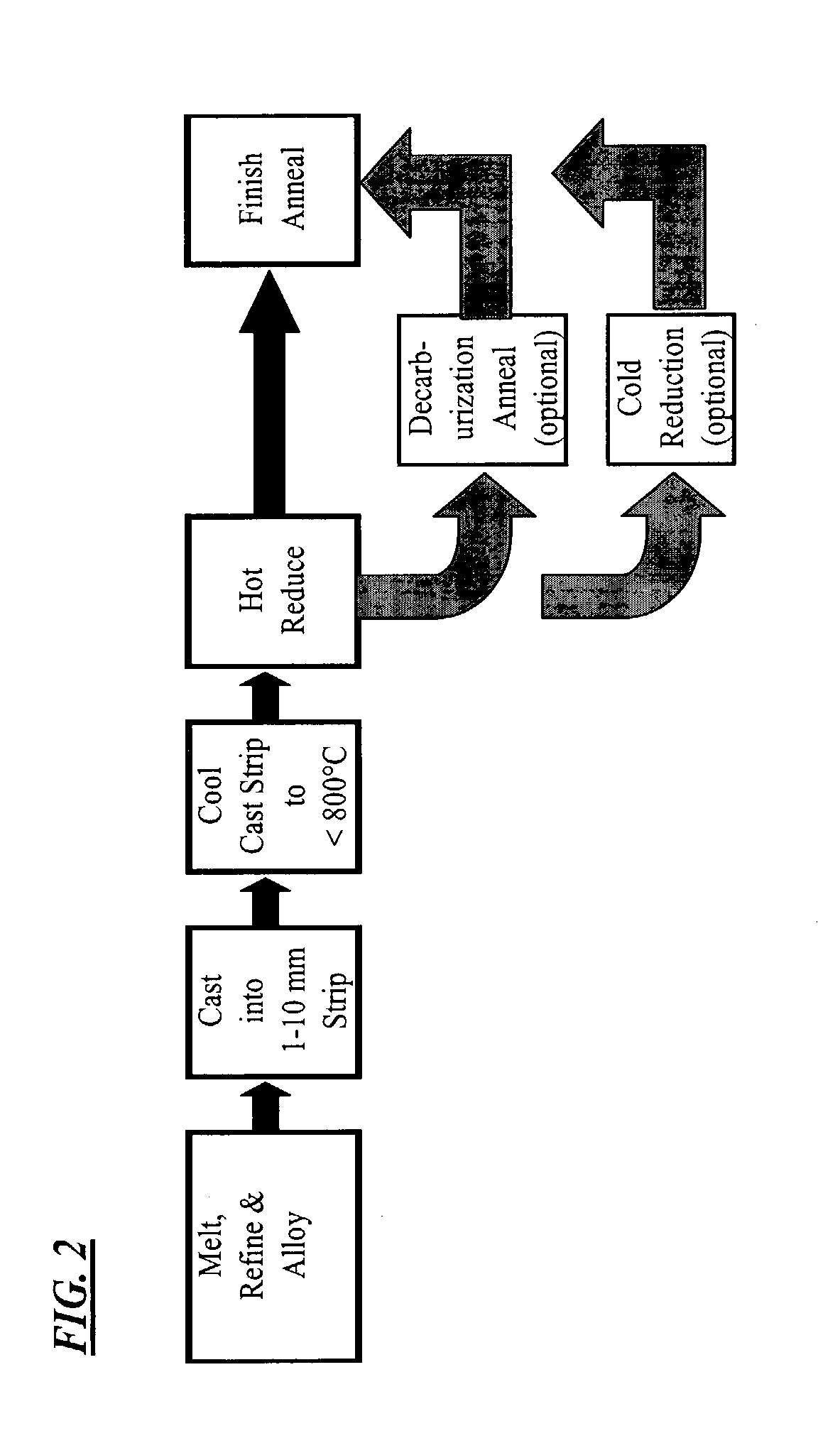

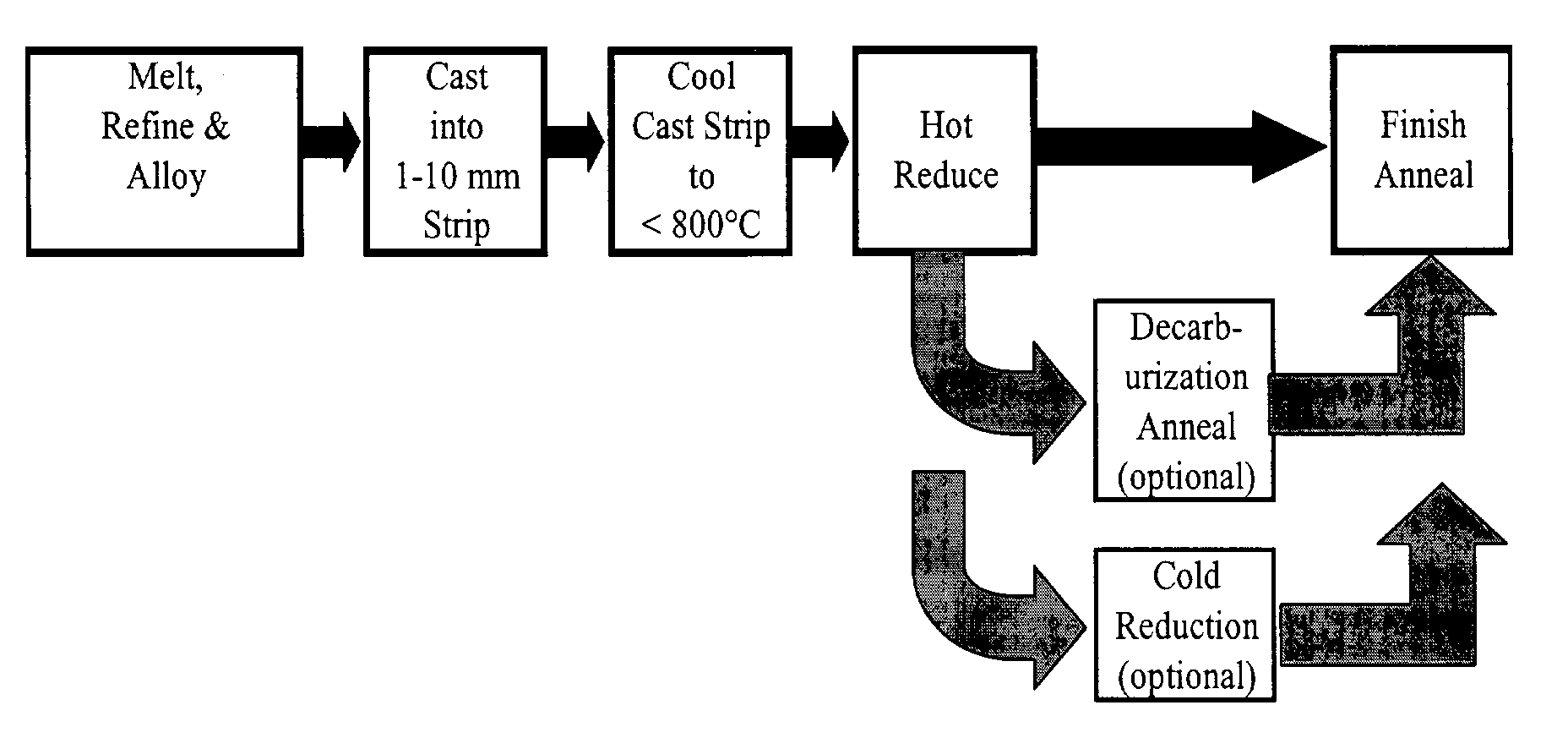

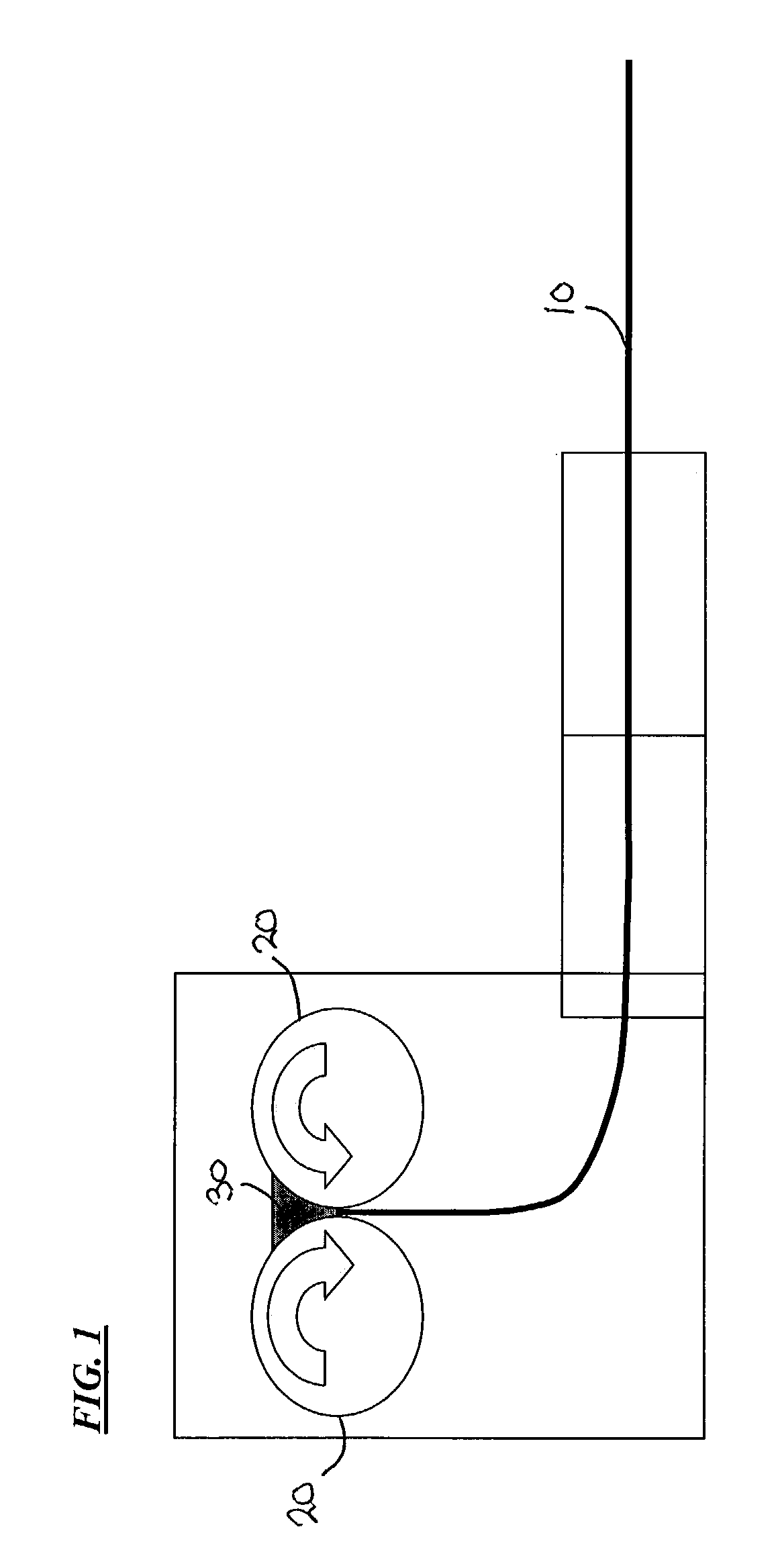

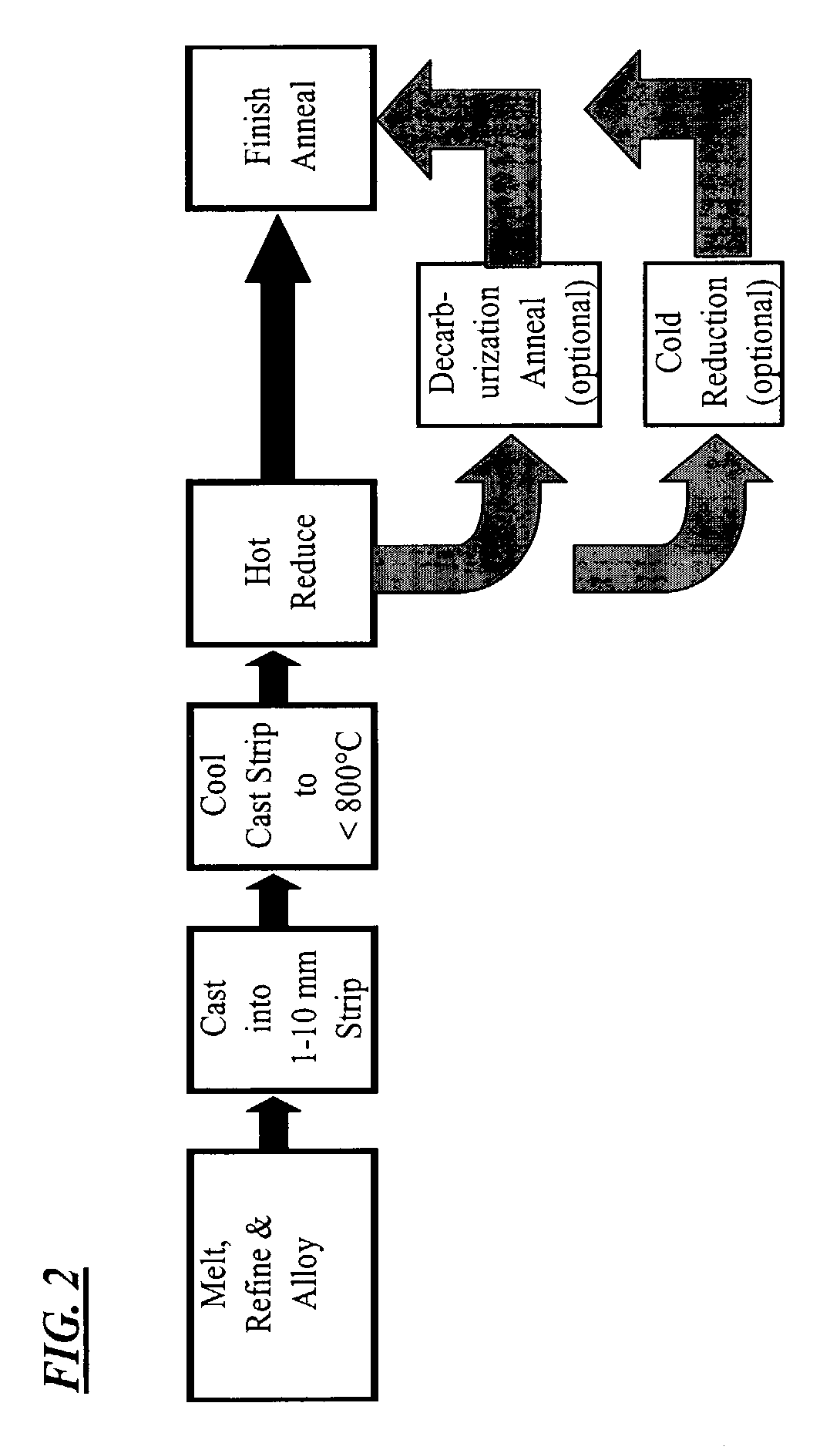

Non-oriented electrical steels are widely used as the magnetic core material in a variety of electrical machinery and devices, particularly in motors where low core loss and high magnetic permeability in all directions of the strip are desired. The present invention relates to a method for producing a non-oriented electrical steel with low core loss and high magnetic permeability whereby the steel is produced from a steel melt which is cast as a thin strip or sheet, cooled, hot rolled and / or cold rolled into a finished strip. The finished strip is further subjected to at least one annealing treatment wherein the magnetic properties are developed, making the steel strip of the present invention suitable for use in electrical machinery such as motors or transformers.

Owner:CLEVELAND CLIFFS STEEL PROPERTIES INC

Magnetic recording media with enhanced writability and thermal stability

ActiveUS20100209737A1Improved writabilityReduce defectsDifferent record carrier formsRecord information storageCouplingThermal stability

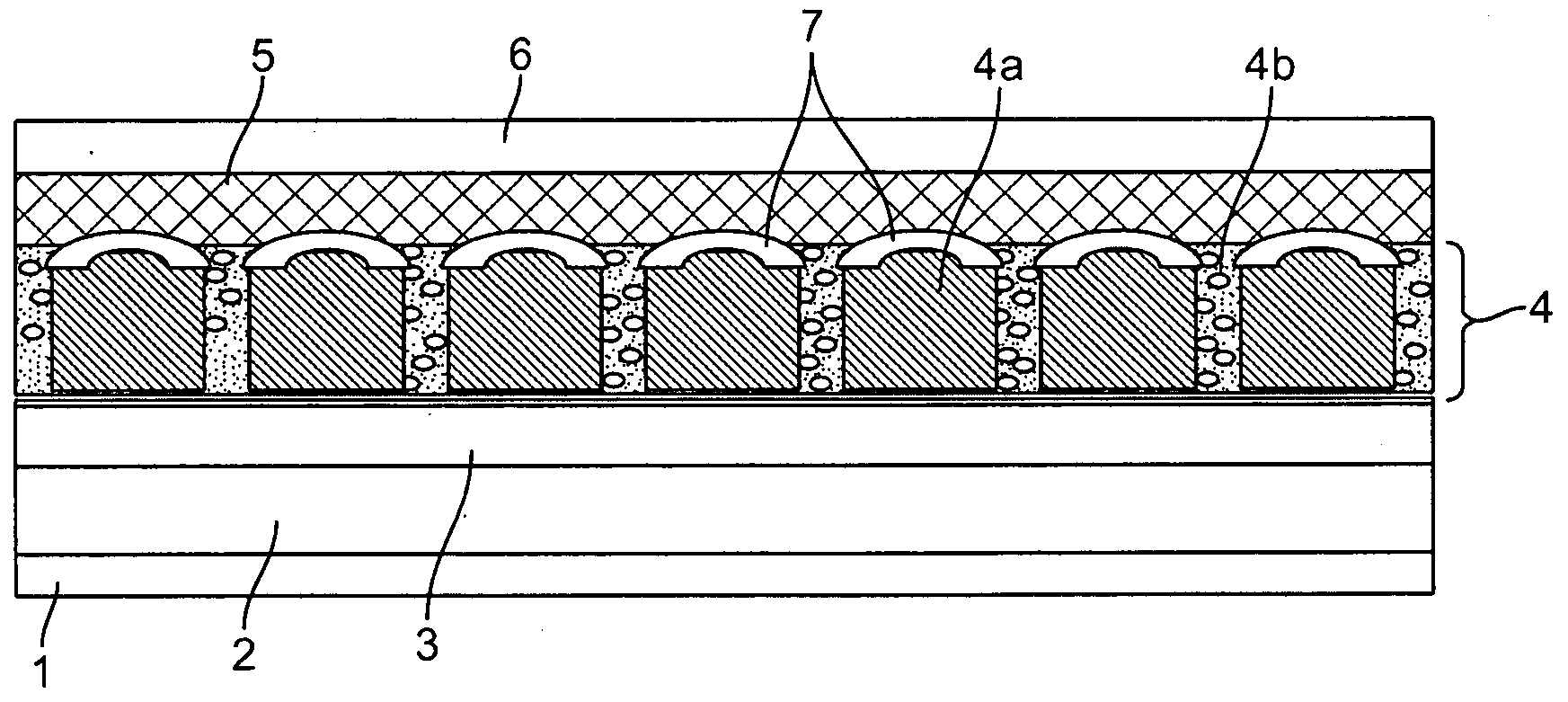

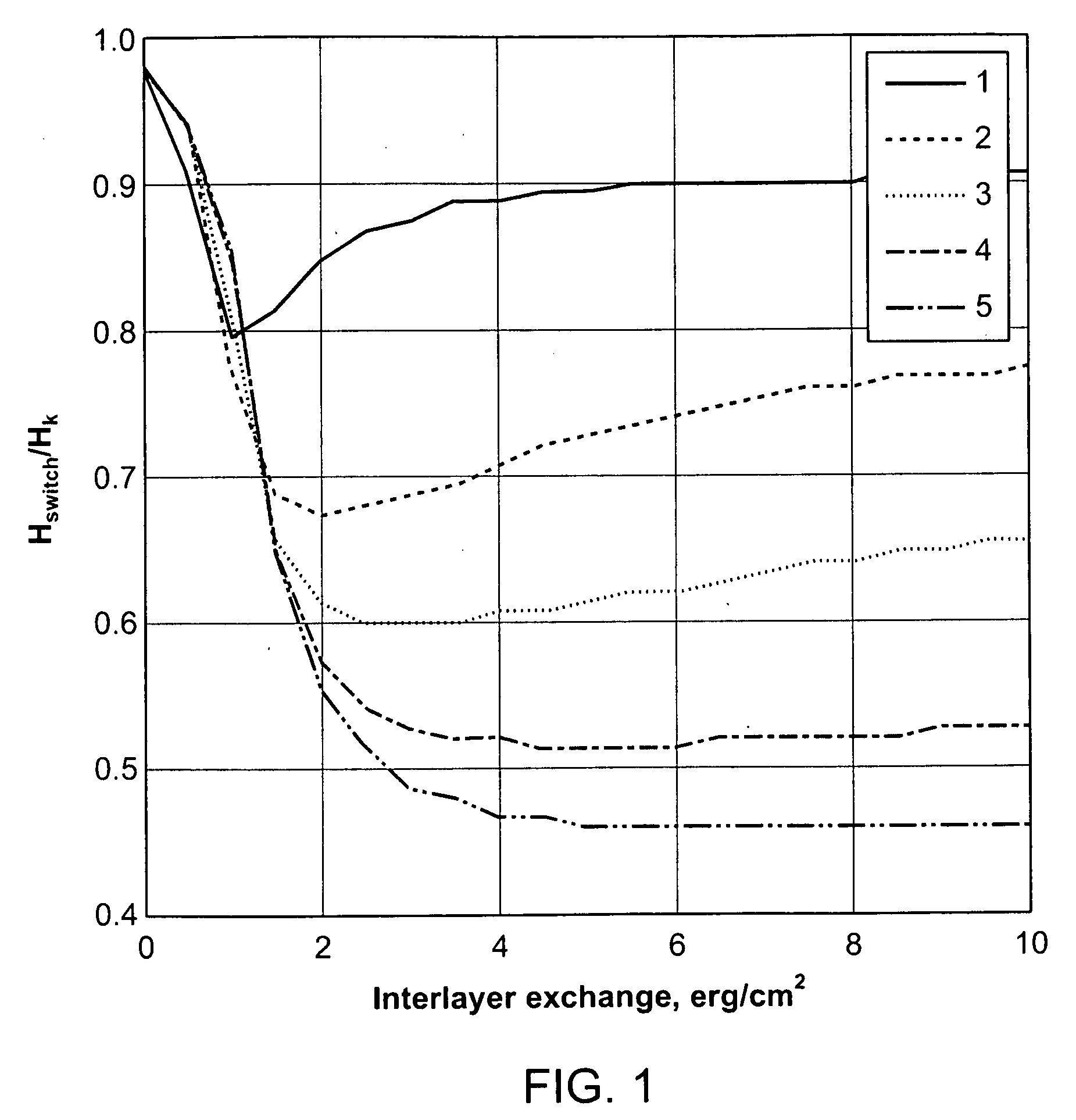

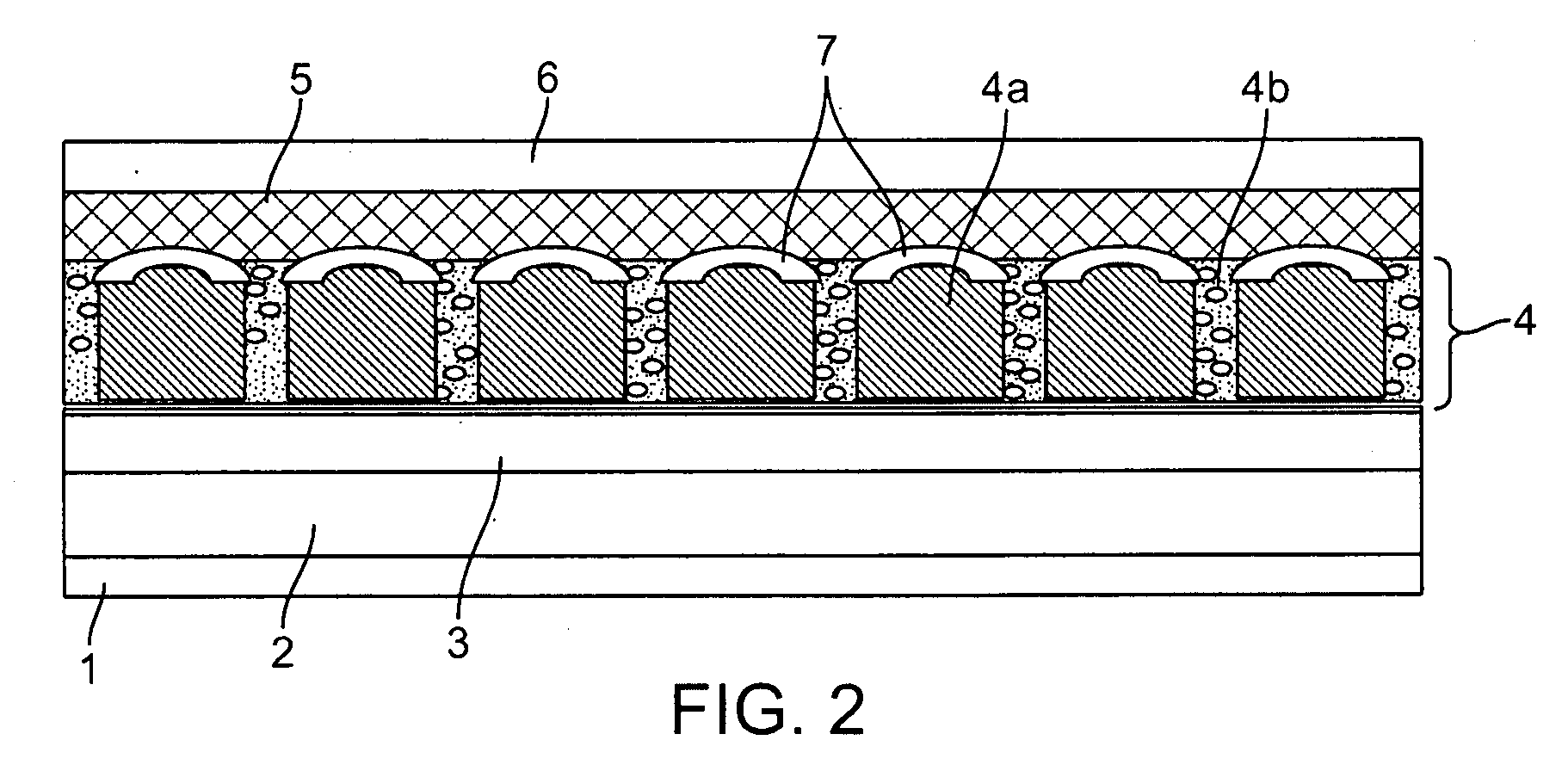

Aspects are directed to recording media with enhanced magnetic properties for improved writability. Examples can be included or related to methods, systems and components that allow for improved writability while reducing defects so as to obtain uniform magnetic properties such as uniformly high anisotropy and narrow switching field distribution. Some examples include a recording medium with an exchange tuning layer inserted between the hard layer and the soft, semi-soft or thin semi-hard layer so as to maximize the writability improvement of the media. Preferably, the exchange tuning layer is granular and reduces or optimizes the vertical coupling between the hard layer and the soft, semi-soft or semi-hard layer of a magnetic recording or storing device.

Owner:SEAGATE TECH LLC

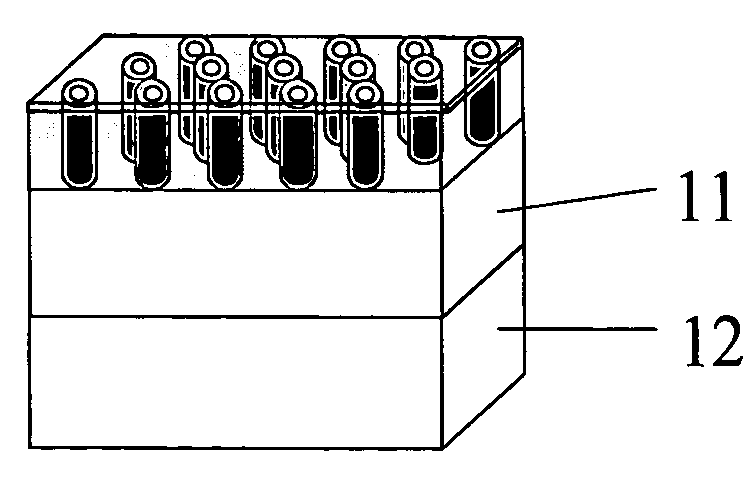

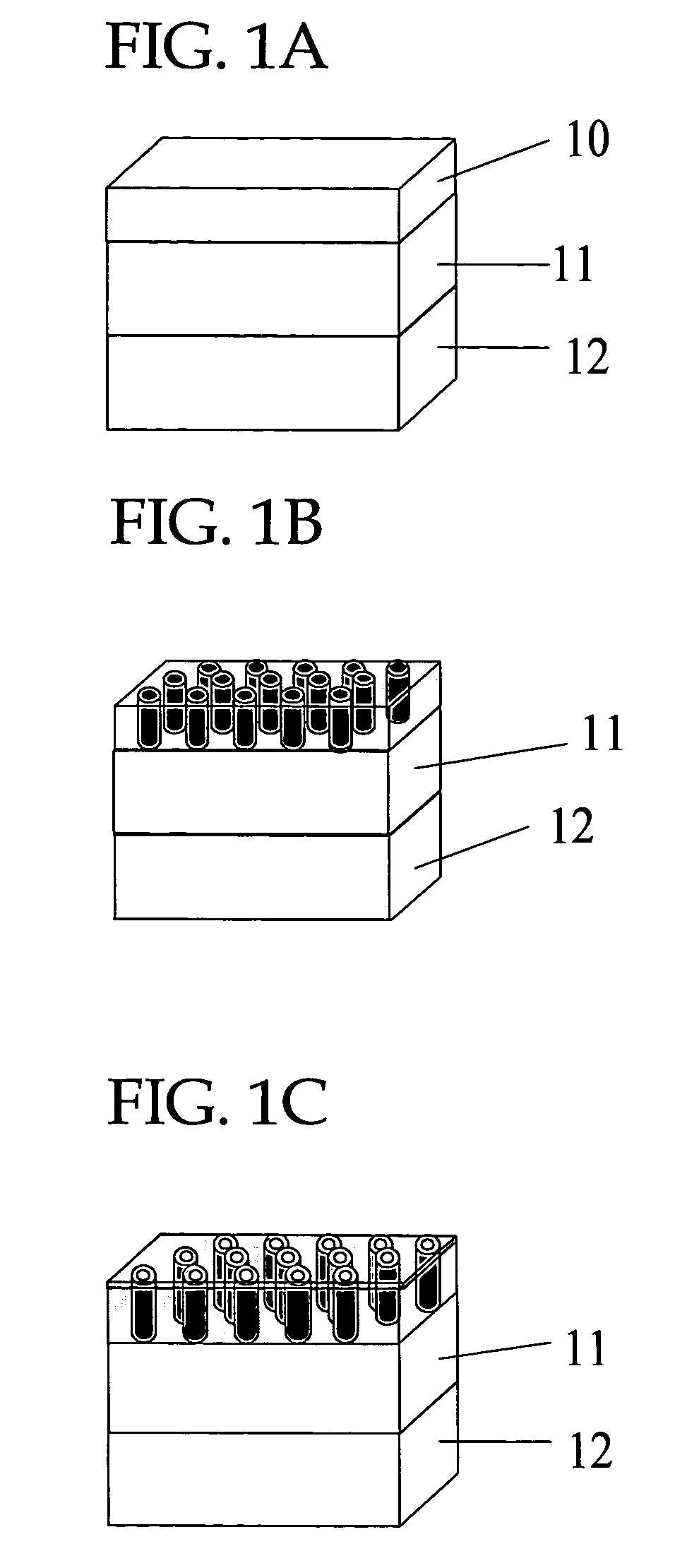

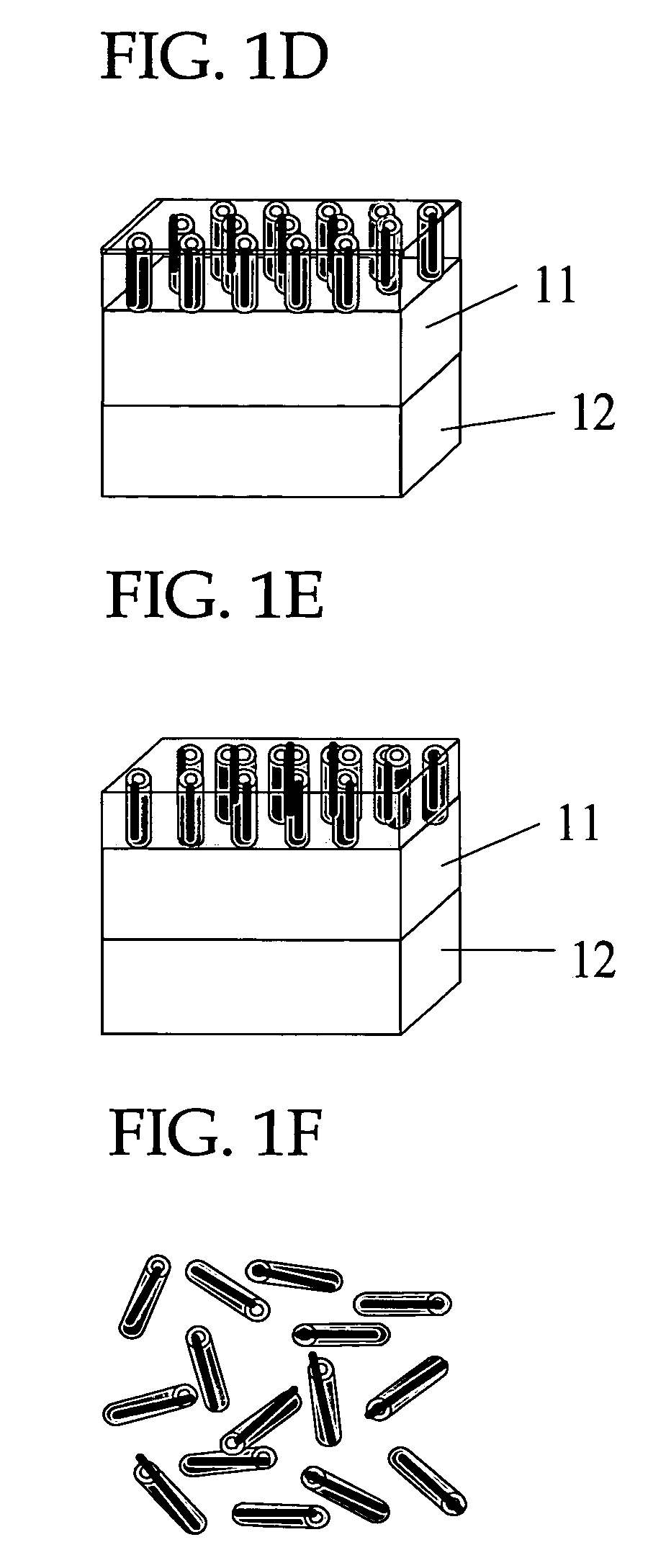

Carbon nanotube composite material comprising a continuous metal coating in the inner surface, magnetic material and production thereof

InactiveUS7335408B2Well controlled short lengthUniform and excellent physical propertyCarbon compoundsNanoinformaticsMetal coatingCarbon nanotube

A carbon nanotube composite material contains a carbon nanotube and a continuous layer of a metal covering the inner surface of the carbon nanotube. It is produced by forming a metallic matrix layer and treating the metallic matrix layer to form plural nanoholes in the metallic matrix layer to thereby form a nanohole structure, the nanoholes extending in a direction substantially perpendicular to the plane of the metallic matrix layer; forming carbon nanotubes inside the nanoholes; and covering inner surfaces of the carbon nanotubes with a continuous layer of a metal. It has a well controlled small size, has excellent and uniform physical properties, is resistant to oxidation of the metal with time, is highly chemically stable, has good durability enabling repetitive use, has good coatability, high wettability and dispersibility with other materials, is easily chemically modified, is easily handled and is useful in various fields.

Owner:FUJITSU LTD +1

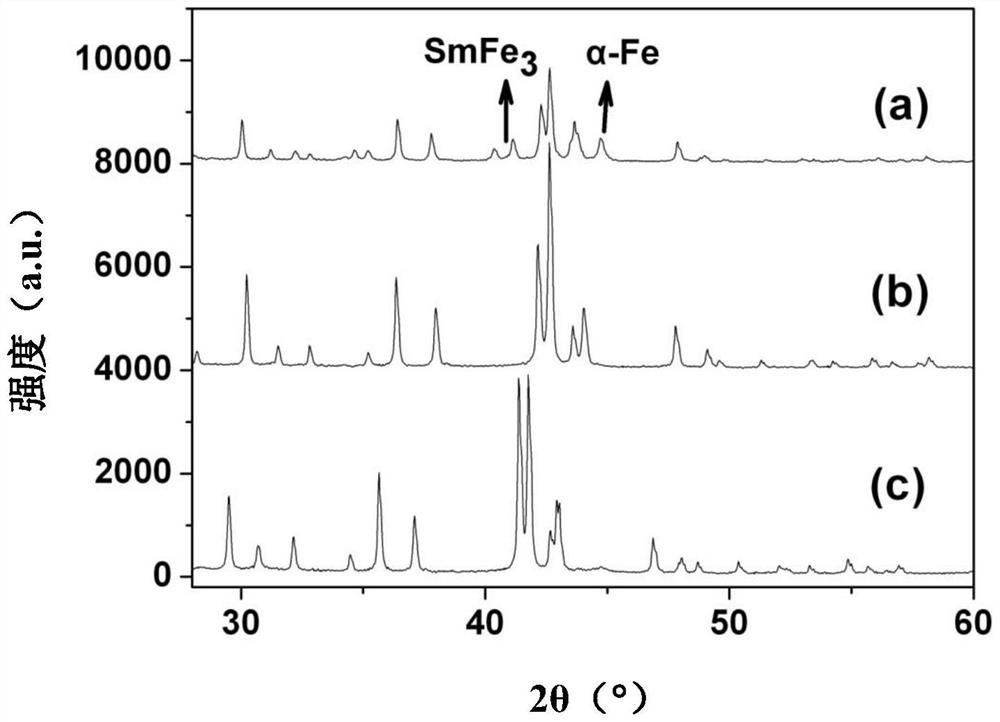

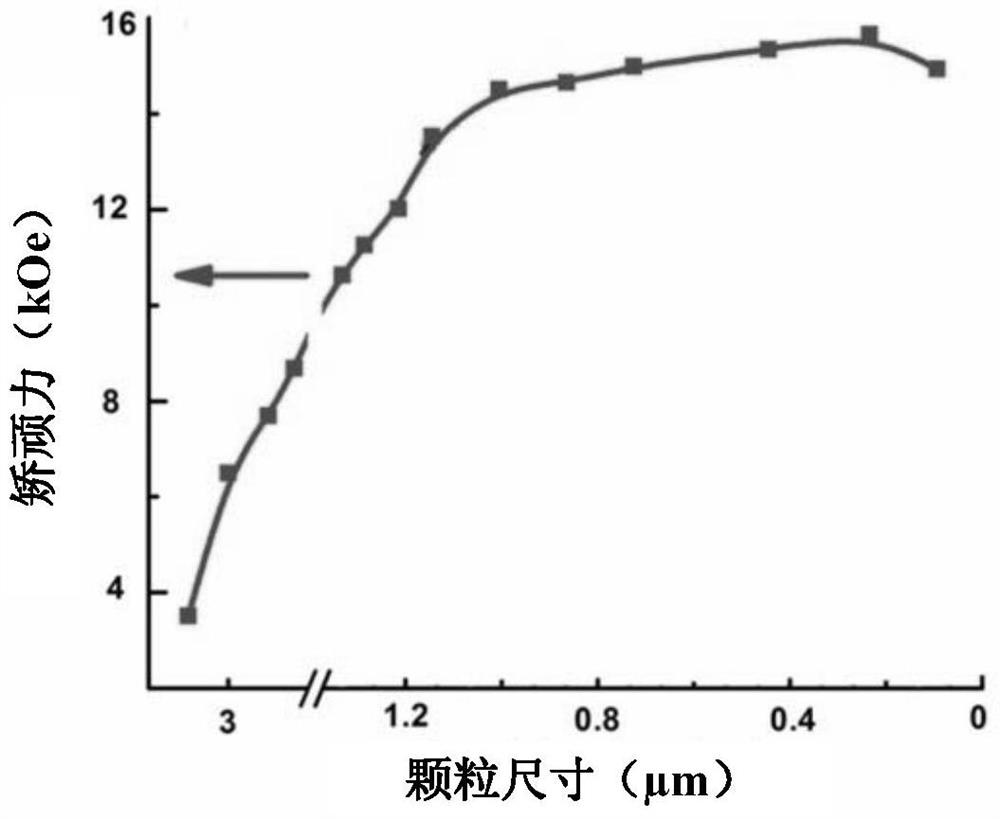

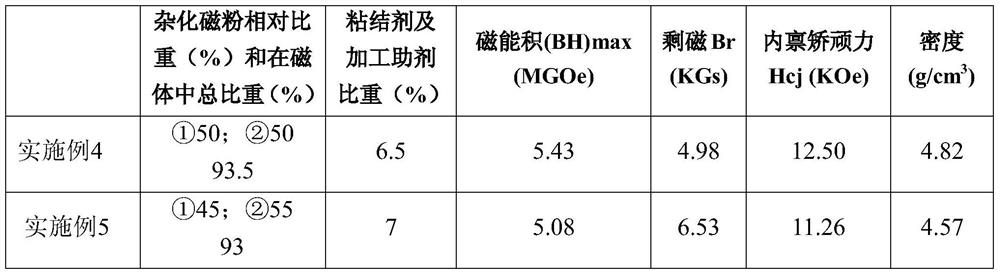

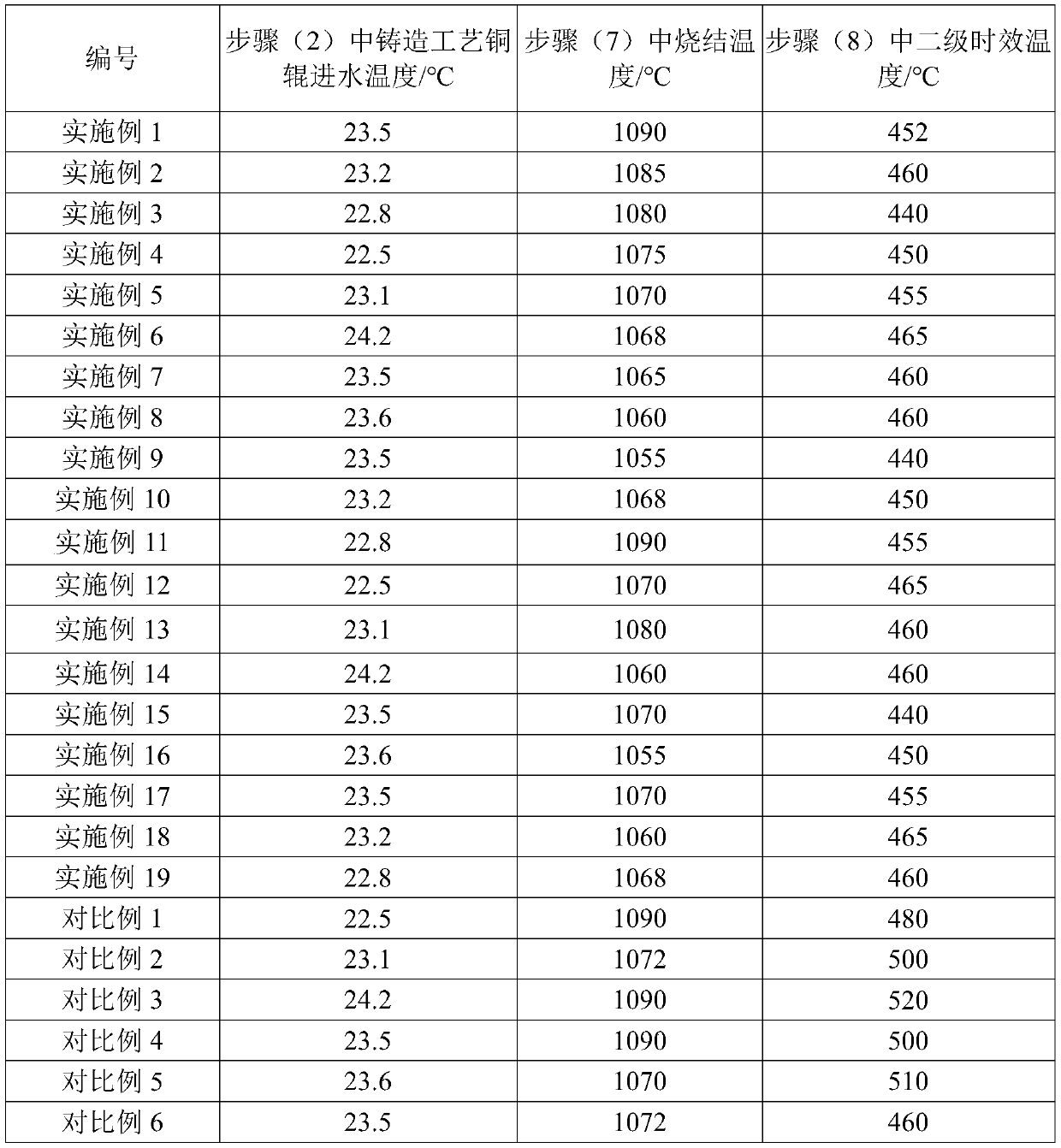

A submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom

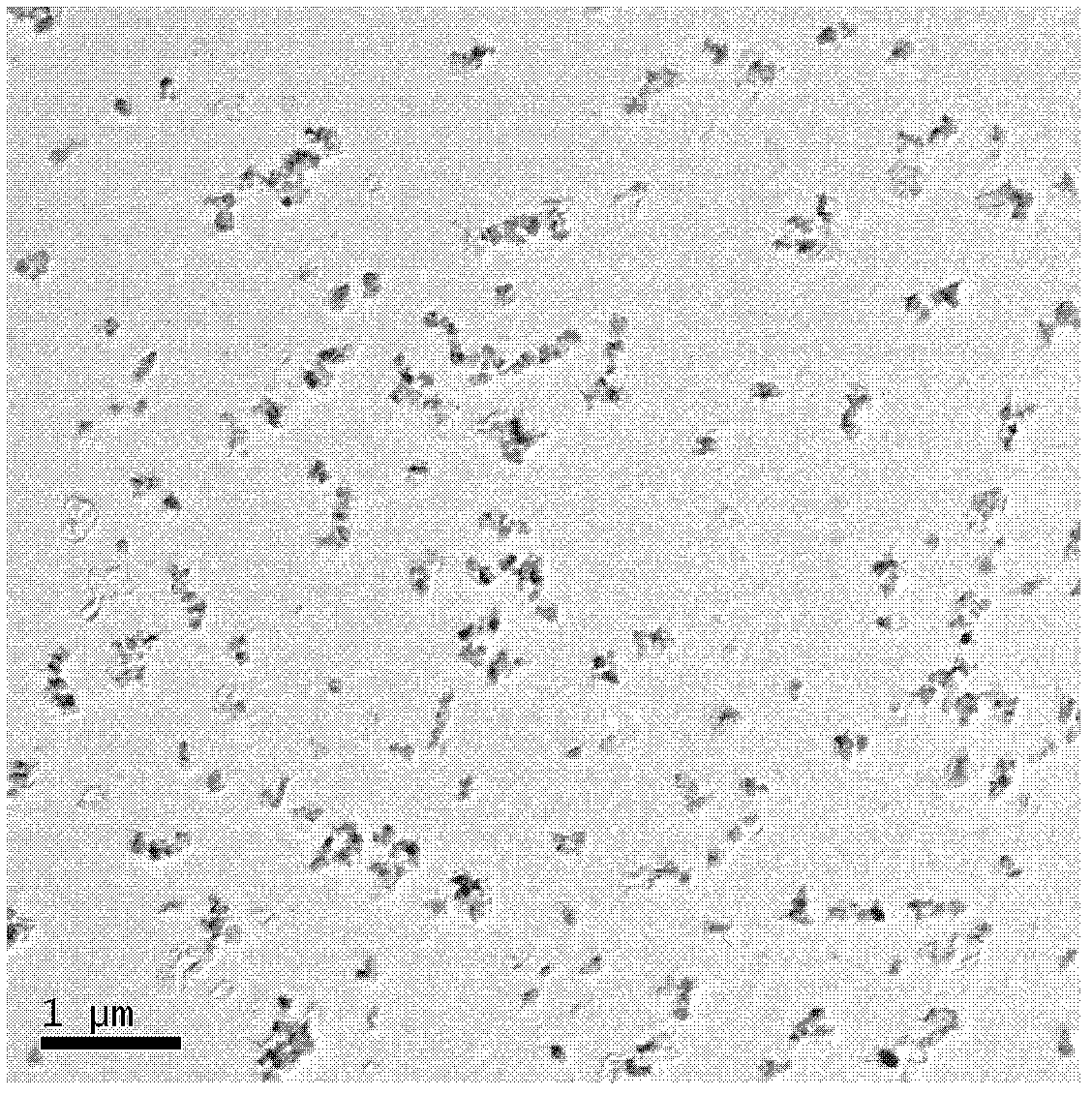

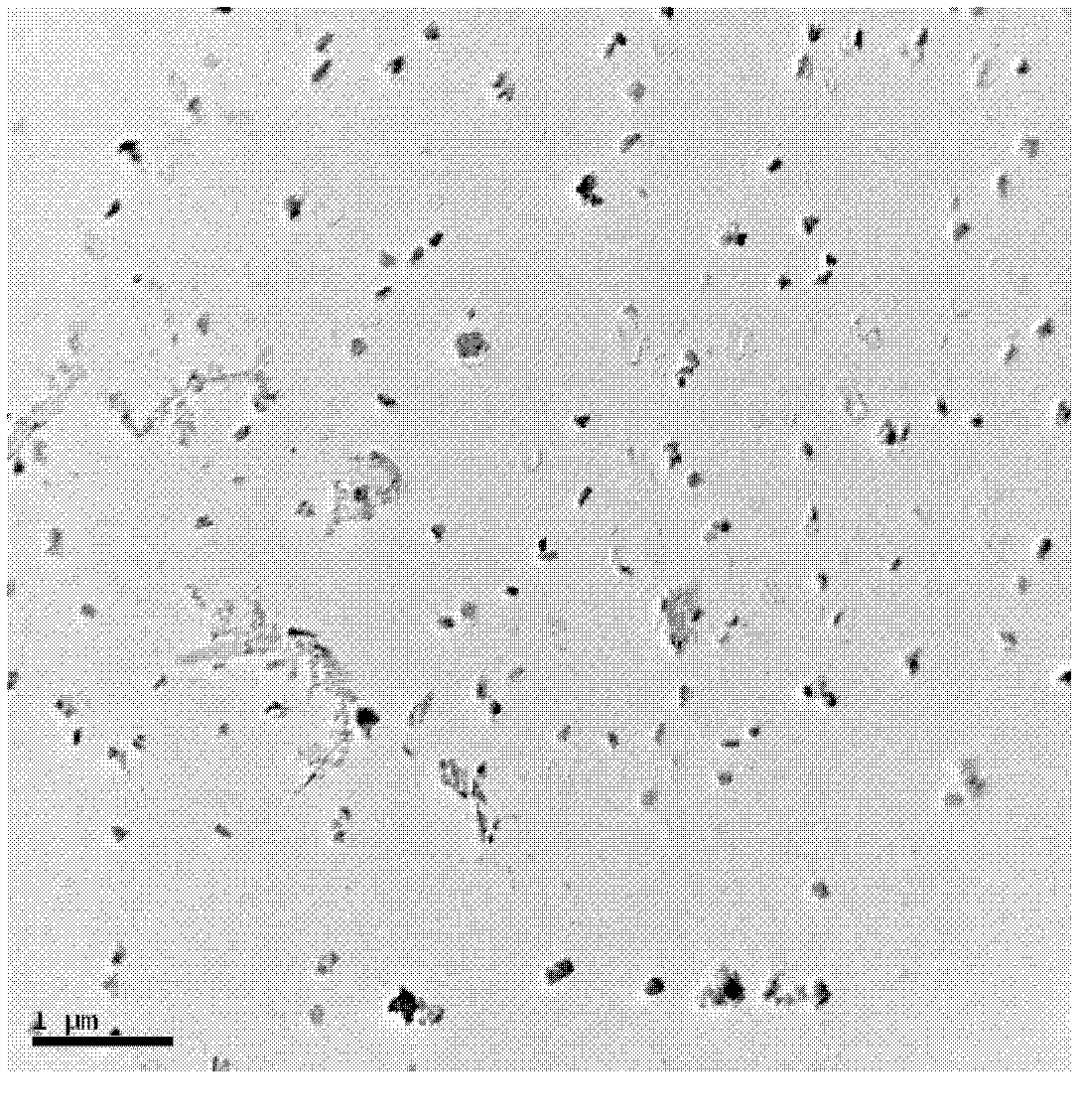

ActiveCN106312077AHigh energy productImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsAdditive ingredientSingle crystal

The invention provides a submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom. Samarium-iron alloy is prepared by using a quick setting sheet technology; the samarium-iron alloy is made to perform gas-solid phase reaction in nitrogen or mixed gas of nitrogen and hydrogen to form samarium-iron-nitrogen alloy; then airflow milling and / or ball milling is performed to obtain anisotropic samarium iron nitrogen single-crystal particle magnet powder with a particle size of 0.01-3 [mu]m. Further, the samarium iron nitrogen single-crystal particle magnet powder, as a first ingredient, is mixed with a second ingredient consisting of permanent magnetic ferrite, rapid quenching isotropic neodymium iron boron, anisotropic neodymium iron boron, samarium cobalt and / or neodymium iron nitrogen to form hybrid magnetic powder; processing agents are added; a hybrid bonded magnet is prepared by using a rolling, mould pressing, extrusion or injection method. The prepared samarium iron nitrogen magnet powder are high in magnetic energy product, residual magnetism and intrinsic coercive force, is low in cost and small in particle size; the corresponding hybrid bonded magnet exploits the advantages of different magnetic powder ingredients, is high in shaping degree and mechanical strength and is good in temperature performance.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

Method of continuous casting non-oriented electrical steel strip

InactiveUS7011139B2Magnetic homogeneityMinimize recrystallizationMagnetic materialsElectrical steelTransformer

Non-oriented electrical steels are widely used as the magnetic core material in a variety of electrical machinery and devices, particularly in motors where low core loss and high magnetic permeability in all directions of the strip are desired. A method for producing a non-oriented electrical steel with low core loss and high magnetic permeability provides a steel that is produced from a steel melt which is cast as a thin strip or sheet, cooled, hot rolled and / or cold rolled into a finished strip. The finished strip is further subjected to at least one annealing treatment wherein the magnetic properties are developed, making the steel strip suitable for use in electrical machinery such as motors or transformers.

Owner:CLEVELAND CLIFFS STEEL PROPERTIES INC

Magnetic plastic composite material and preparation method thereof

ActiveCN103258610AHigh strengthEvenly distributedInorganic material magnetismMaterials preparationNylon 6

The invention discloses a magnetic plastic composite material. The magnetic plastic composite material includes the following components, by mass, 4-8 % of nylon 6 powder, 90-95% of neodymium iron boron magnetic powder, 0-5% of caprolactam, 0.5-1.5% of lubricant and 0.3-1% of silane coupling agent. The invention further discloses a magnetic plastic composite material preparation method. The magnetic plastic composite material is good in strength due to the fact that content of the neodymium iron boron magnetic powder reaches 90-95%. Through fully mixing of the neodymium iron boron magnetic powder and the nylon 6 powder, the neodymium iron boron magnetic powder is even in distribution and magnetism. Therefore, the magnetic plastic composite material can be more stable in quality.

Owner:XIAMEN RUNNER IND CORP

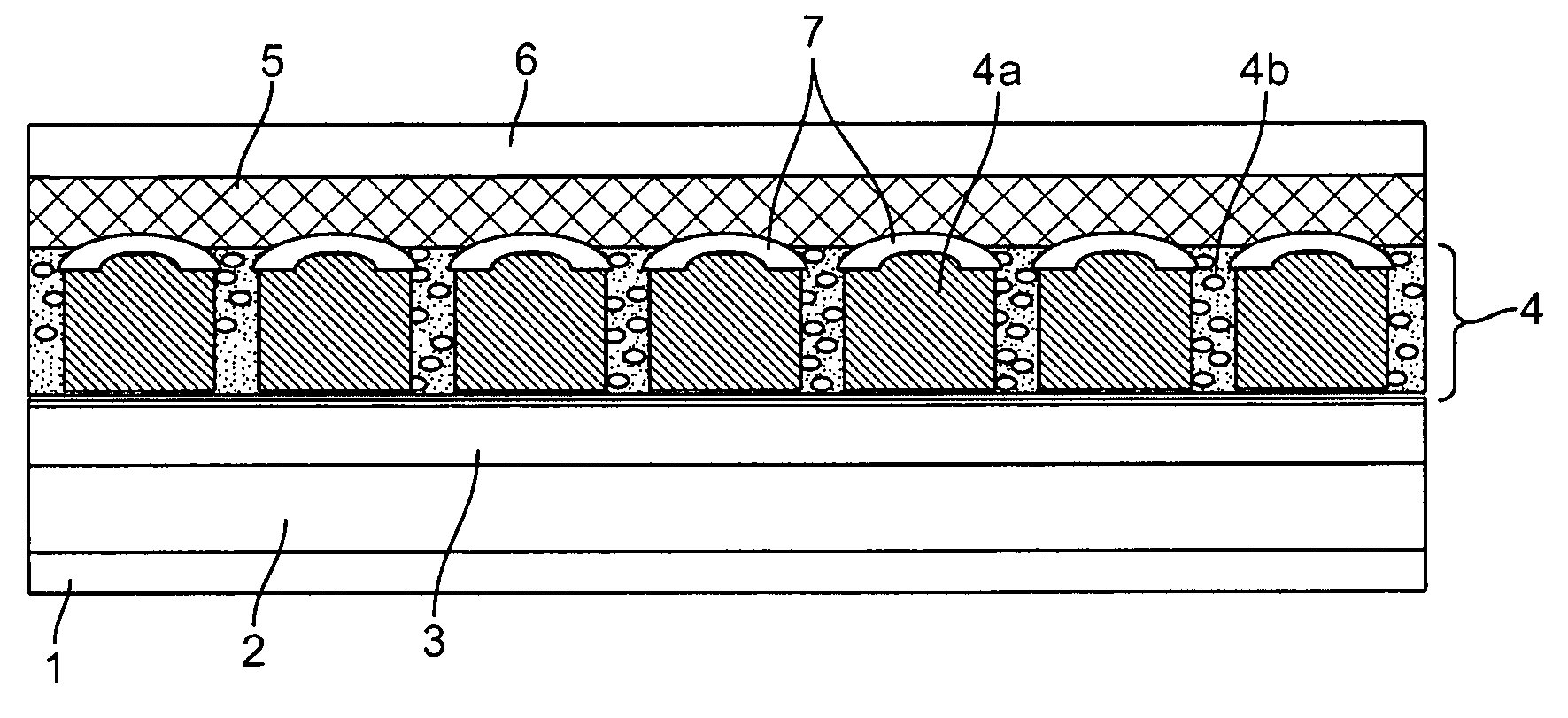

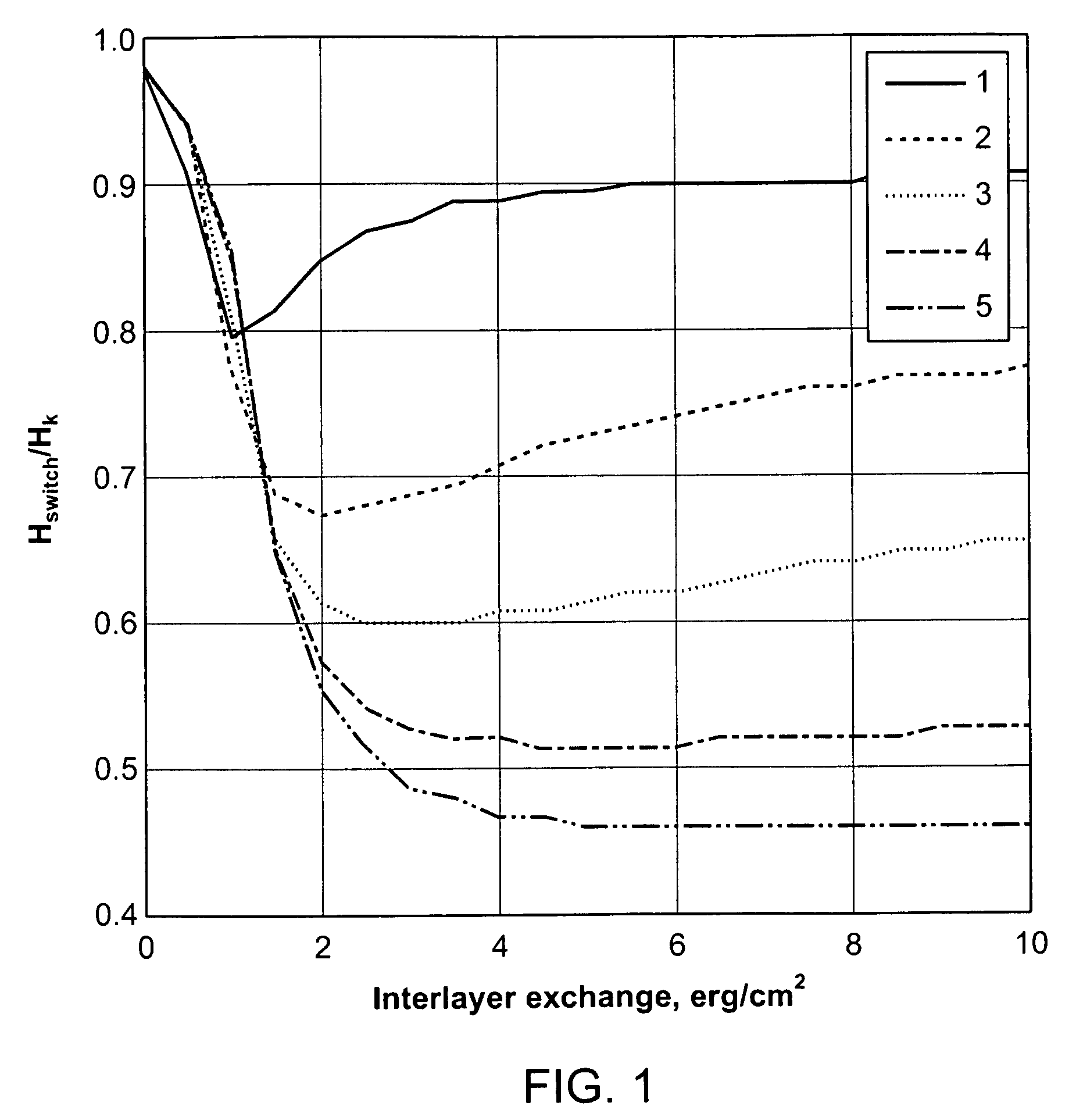

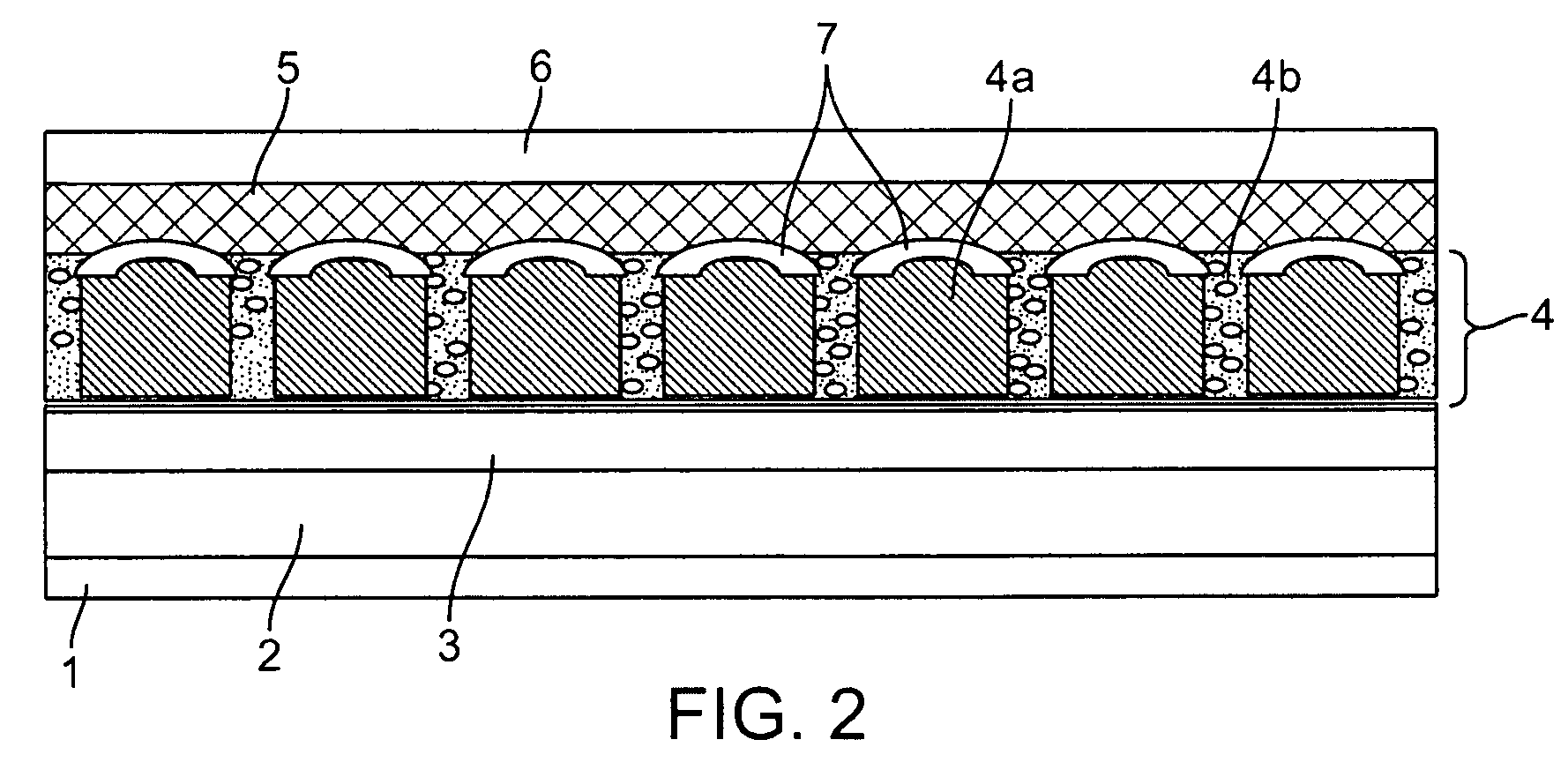

Magnetic recording media with enhanced writability and thermal stability

ActiveUS8685547B2Improved writabilityReduce defectsDifferent record carrier formsRecord information storageCouplingThermal stability

Aspects are directed to recording media with enhanced magnetic properties for improved writability. Examples can be included or related to methods, systems and components that allow for improved writability while reducing defects so as to obtain uniform magnetic properties such as uniformly high anisotropy and narrow switching field distribution. Some examples include a recording medium with an exchange tuning layer inserted between the hard layer and the soft, semi-soft or thin semi-hard layer so as to maximize the writability improvement of the media. Preferably, the exchange tuning layer is granular and reduces or optimizes the vertical coupling between the hard layer and the soft, semi-soft or semi-hard layer of a magnetic recording or storing device.

Owner:SEAGATE TECH LLC

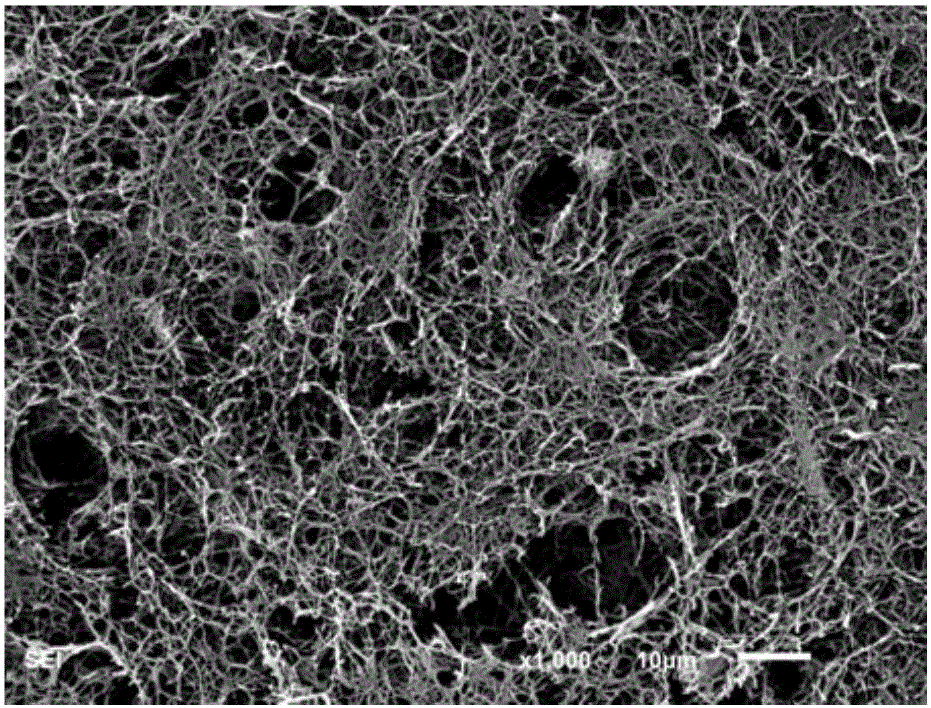

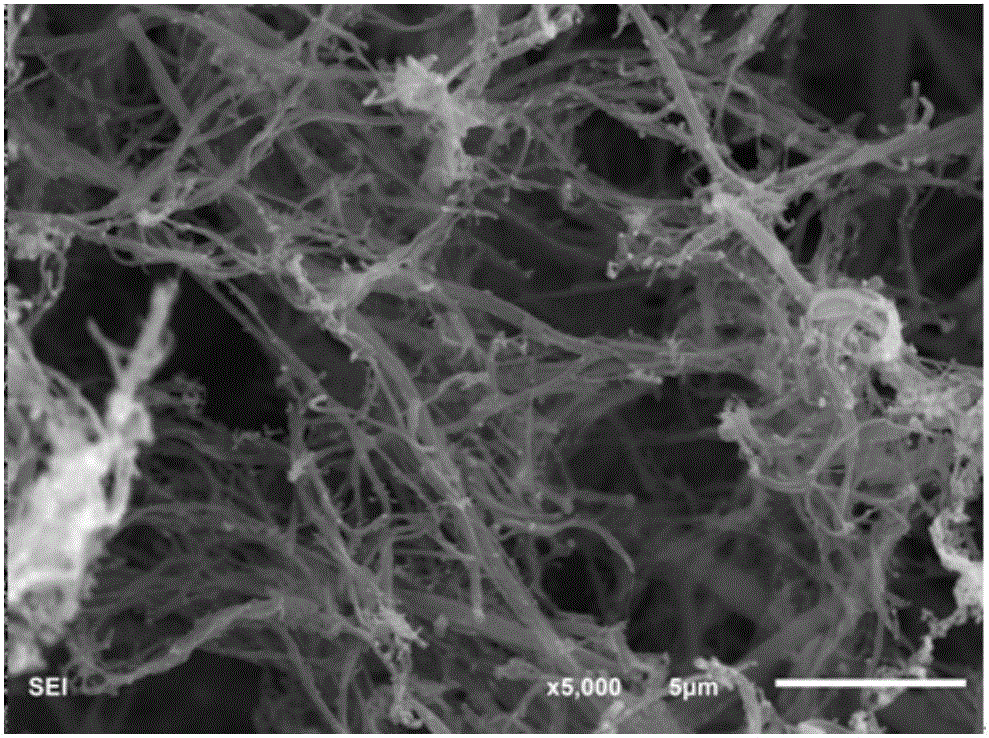

Preparation method of nanofiber aerogel material with hard magnetism

ActiveCN106334538AImprove mechanical propertiesGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesFiberAir filtration

The invention discloses a preparation method of a nanofiber aerogel material with hard magnetism, and belongs to the field of nanofiber functional materials. The preparation method comprises the following steps: 1) preparing demagnetized composite particles; 2) blending the demagnetized composite material and cellulose acetate butyrate, performing melting extrusion and extracting to prepare composite nanofiber; 3) dissolving the composite nanofiber by using a solvent, mixing with a bonding agent, freezing and drying to prepare a composite nanofiber aerogel; 4) magnetizing the composite nanofiber aerogel. The preparation method is simple in process and pollution-free, and is suitable for industrial production; the prepared hard-magnetism aerogel has the advantages of superparamagnetism and relatively high strength, has the characteristics of a high specific surface area, high porosity, low heat conductivity and the like, and can be widely applied to the fields of air filtration, electromagnetic shielding, energy absorption and the like.

Owner:WUHAN TEXTILE UNIV +1

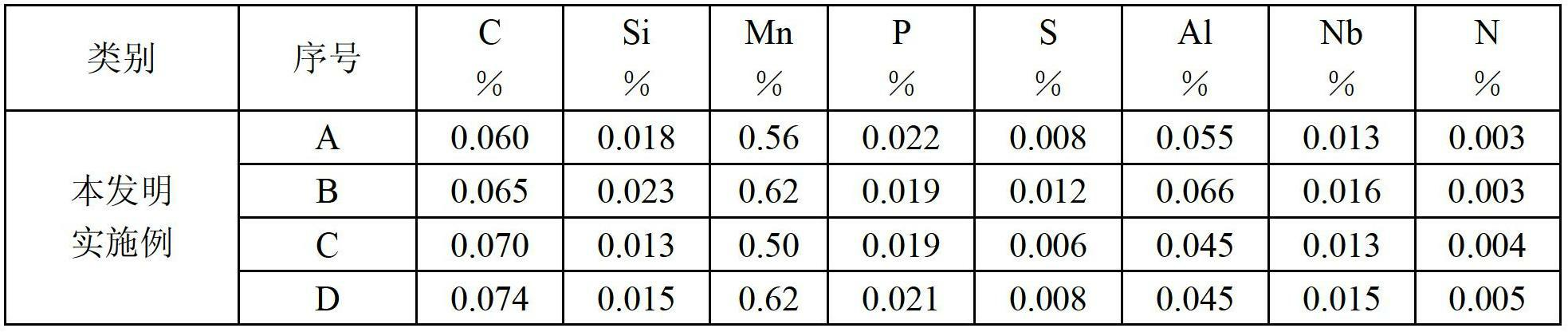

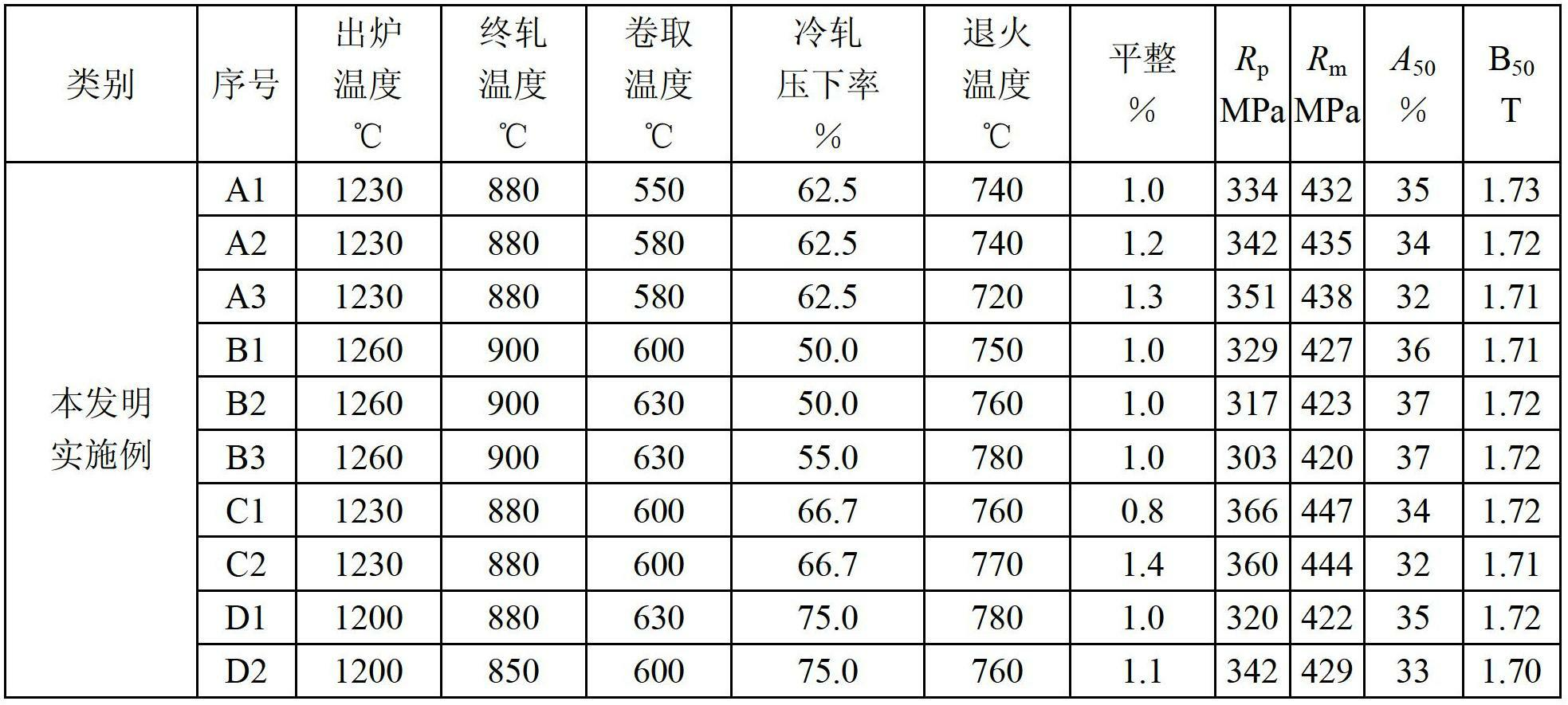

Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

ActiveCN102650016AFully exert the strengthening effectImprove shape qualityRoll mill control devicesMetal rolling arrangementsReduction rateHeating time

The invention discloses a manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel. The manufacturing method comprises the steps as follows: heating a plate blank to be 1200-1260 DEG C and insulating; hotly rolling, wherein the final rolling temperature is 850-900 DEG C, the coiling temperature is 550-630 DEG C and a jet water cooling way is adopted as a cooling way; cooling to be 60-80 DEG C for acid washing, wherein an air cooling way is adopted as the cooling way; coldly rolling, wherein the cold rolling reduction rate is 50-75%; continuously annealing, wherein the temperature of an uniform heating section is 720-780 DEG C and the uniform heating time is 60-200 s; and flattening by a flattening elongation rate of 0.8-1.4% to prepare the 250 MPa cold-rolled magnetic pole steel. The produced magnetic pole steel has lower yield strength ReL of more than 250 MPa and magnetic induction strength B50 of more than 1.70 T, and is suitable for manufacturing a magnetic pole iron core of a rotor body of a large water-wheel generator.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnetic Film of Oxide-Containing Cobalt Base Alloy, Oxide-Containing Cobalt Base Alloy Target, and Manufacturing Method Thereof

InactiveUS20080181810A1Reduce the differenceSmall coercivity differenceVacuum evaporation coatingSputtering coatingIngotMagnetic films

A magnetic film of an oxide-containing cobalt base alloy has a smaller coercivity difference than conventional magnetic films. A target material and a sputtering target of the invention are capable of forming the magnetic film. A manufacturing method of the target material is also disclosed.The magnetic film of an oxide-containing cobalt base alloy and the oxide-containing cobalt base alloy target material each have a Fe content of 100 ppm or less. The sputtering target includes the target material bonded to a backing plate. The manufacturing method of the oxide-containing cobalt base alloy target material includes preparing a Co—Cr alloy by melting Cr ingot and at least one Co source selected from Co ingot and Co powder, preparing Co—Cr alloy powder by atomizing the Co—Cr alloy, preparing a mixed powder by mixing the Co—Cr alloy powder, Pt powder and oxide powder, and sintering the mixed powder after forming or simultaneously with forming.

Owner:MITSUI MINING & SMELTING CO LTD

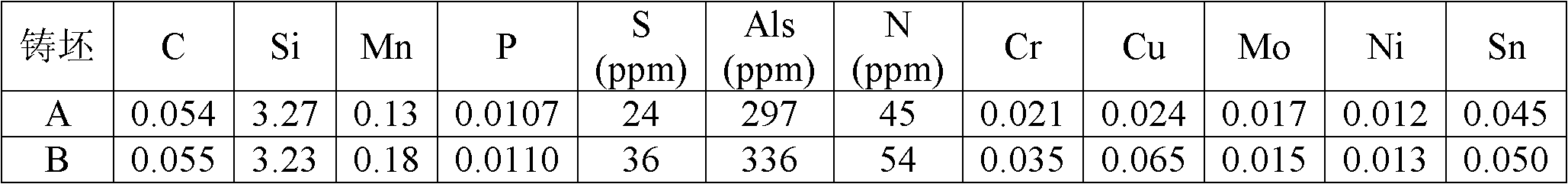

Method for producing high-magnetic-induction oriented silicon steel by continuous casting and rolling of thin slab

The invention relates to a method for producing high-magnetic-induction oriented silicon steel by continuous casting and rolling of a thin slab. The method comprises the following steps of: smelting and performing continuous casting and rolling of the thin slab; dephosphorizing the casting blank by using high-pressure water for the first time; performing soaking; dephosphorizing for the second time; performing finish rolling; normalizing and then cooling to below 100 DEG C; performing cold rolling to reach the thickness of finished products; continuously decarburizing and annealing; permeating N2; coating a magnesium oxide parting agent and annealing at high temperature; and stretching flatly and coating an insulating layer. By the method, manufacturing cost is low; the defects that the surface of a steel plate is mixed with impurities and overlapped with skin and the like can be overcome; magnetic performance is stable; and the continuous casting process is loose.

Owner:武汉钢铁有限公司

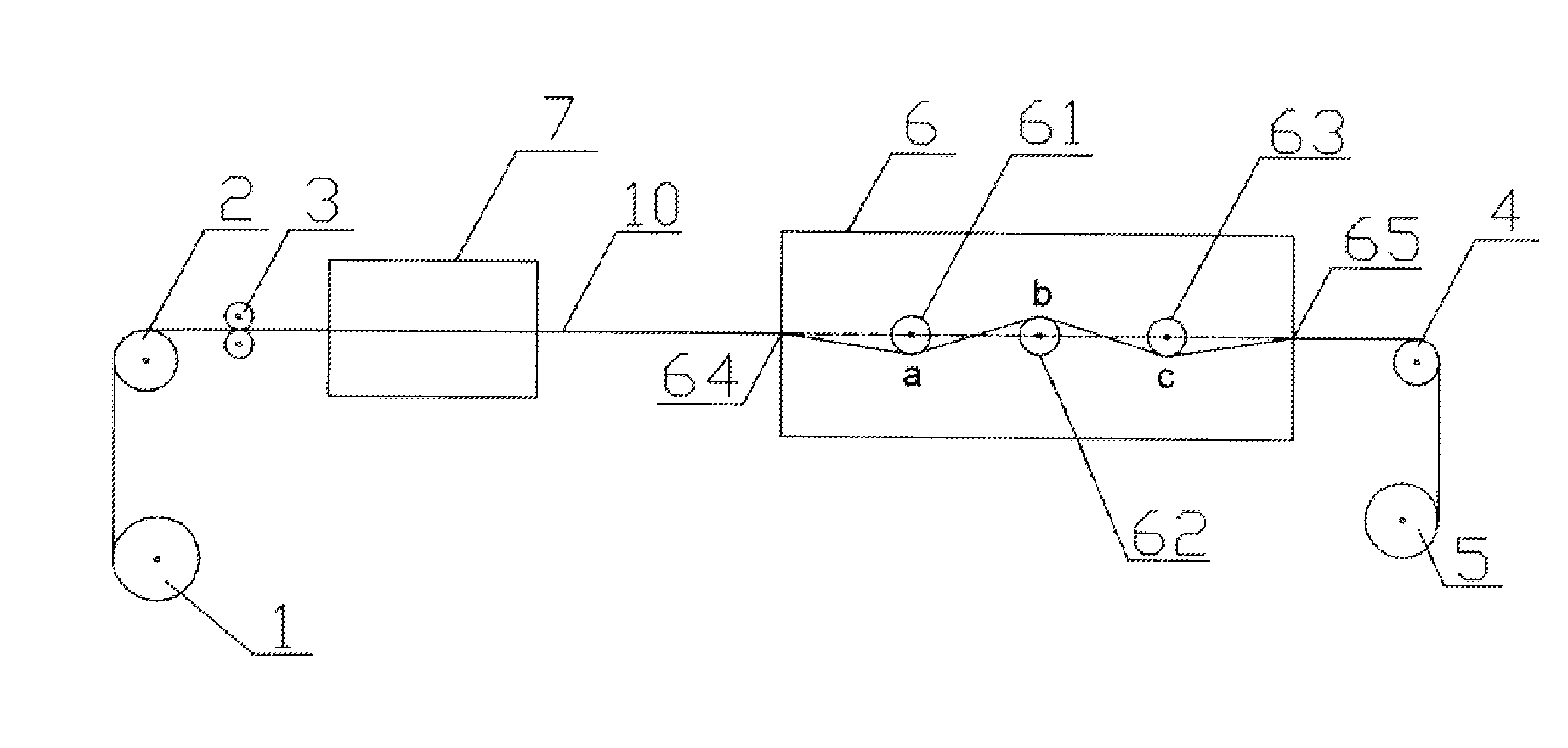

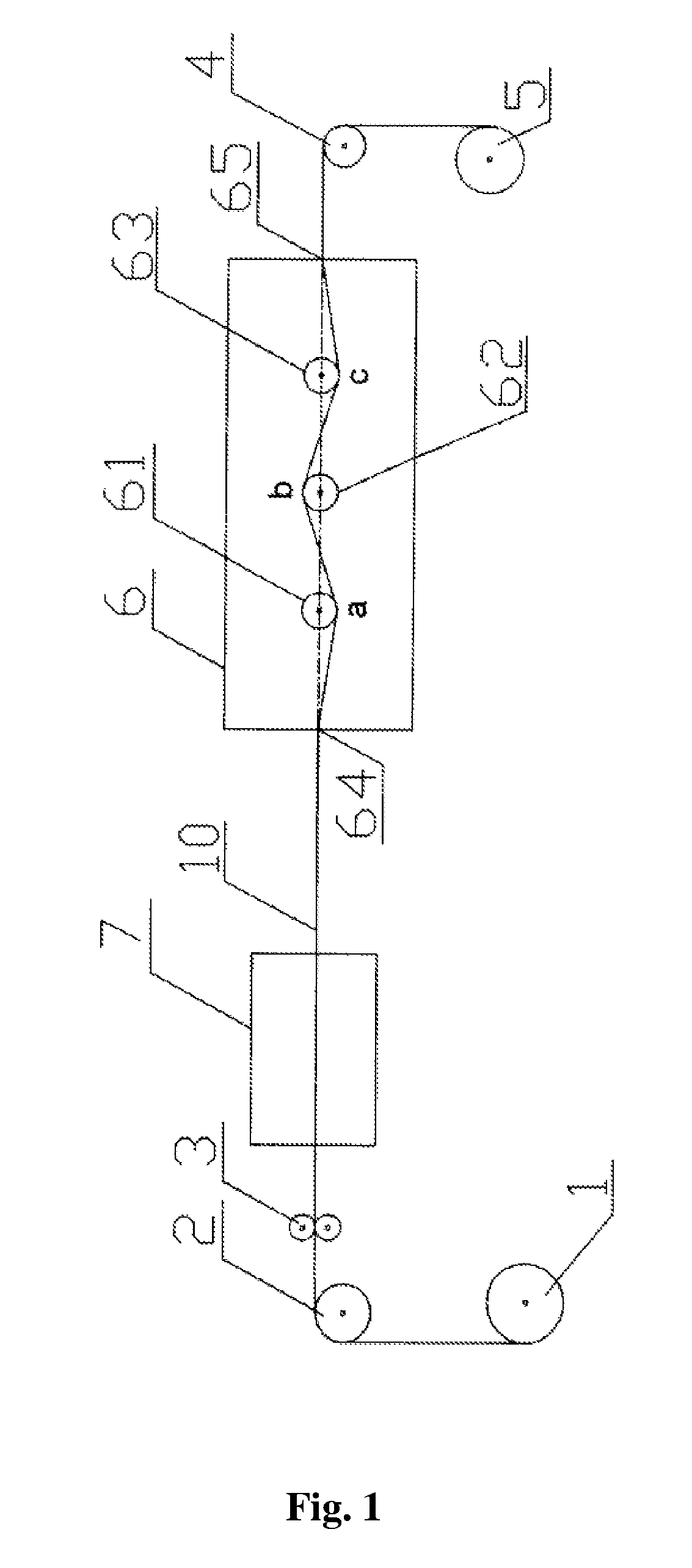

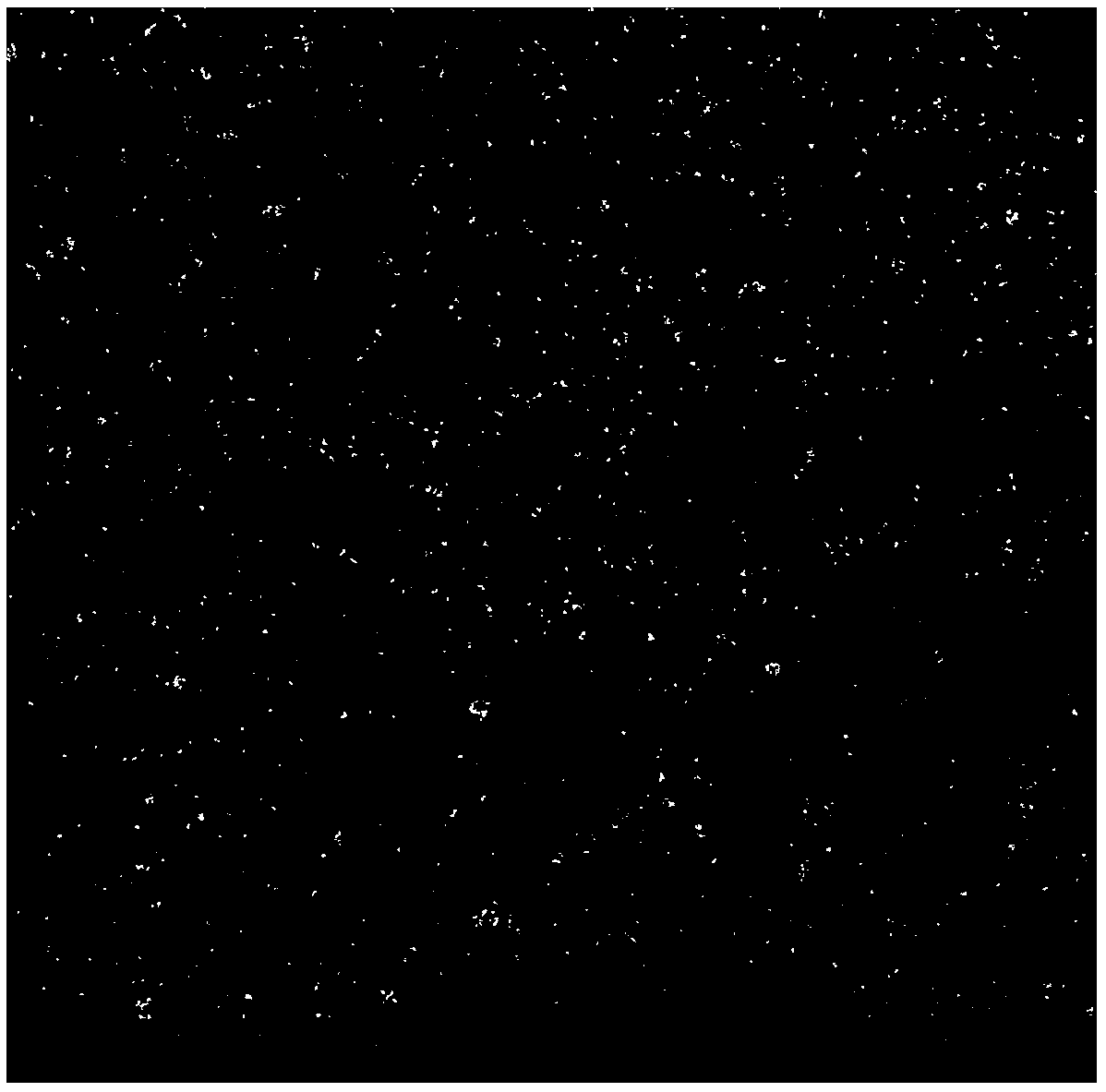

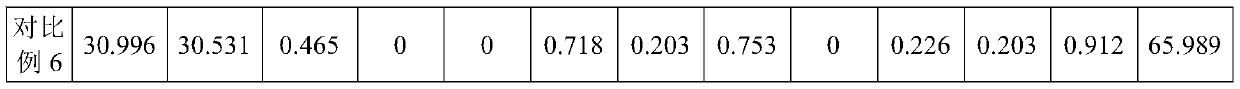

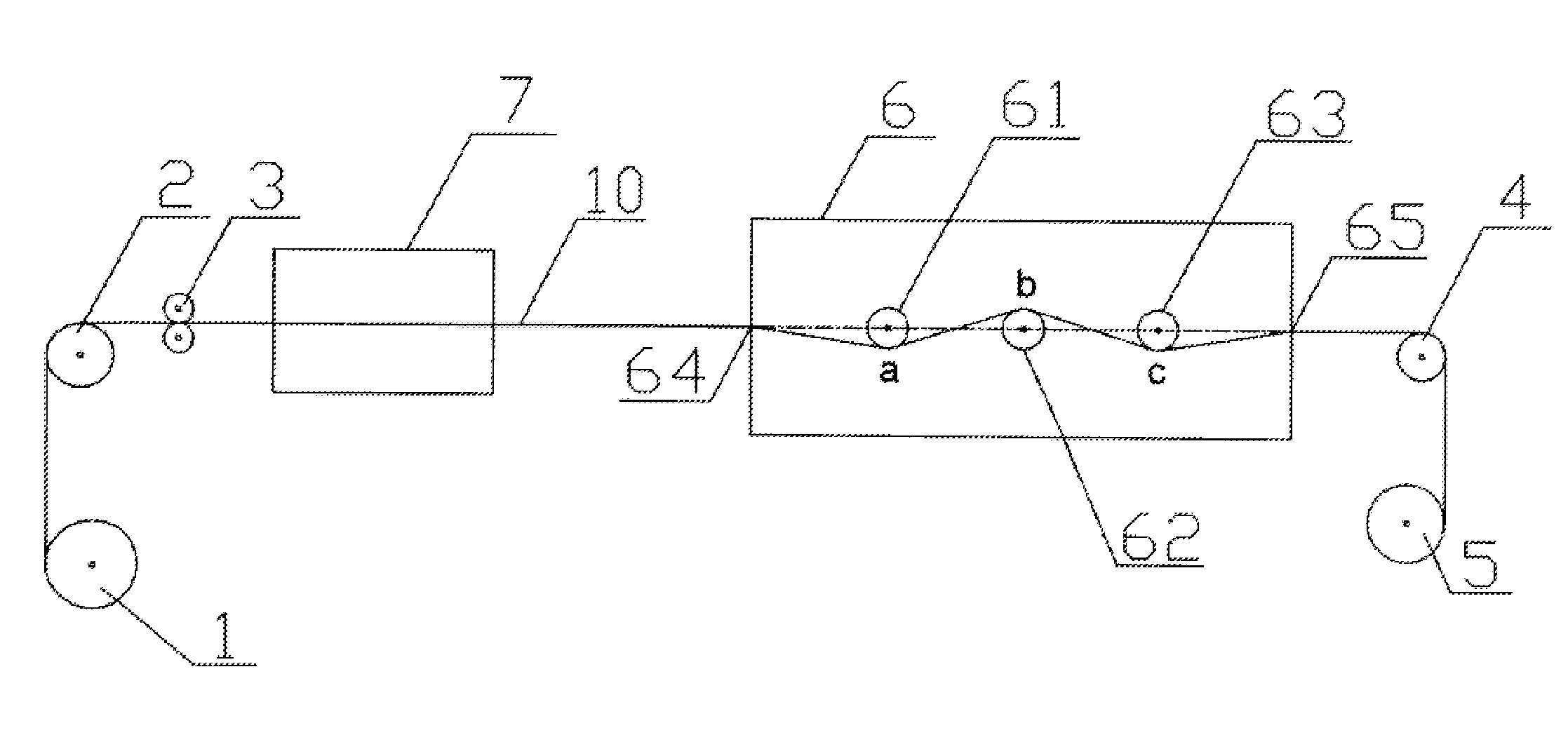

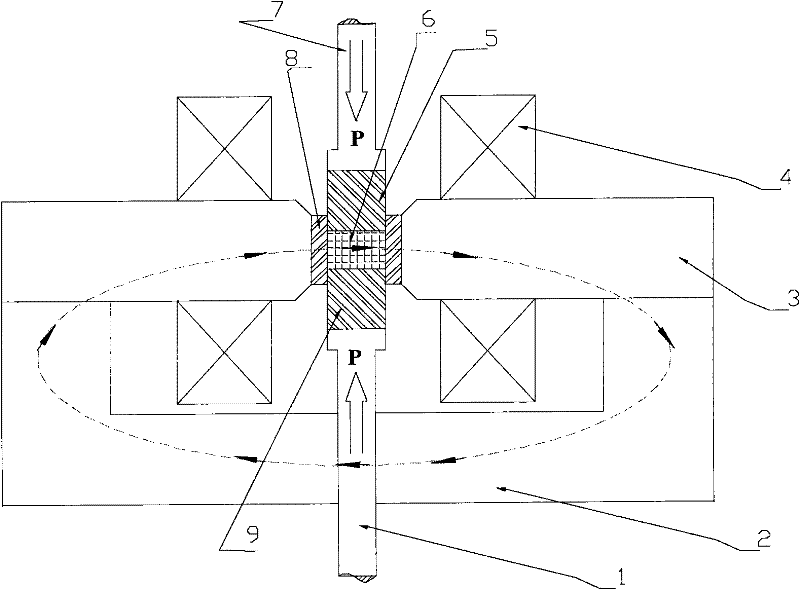

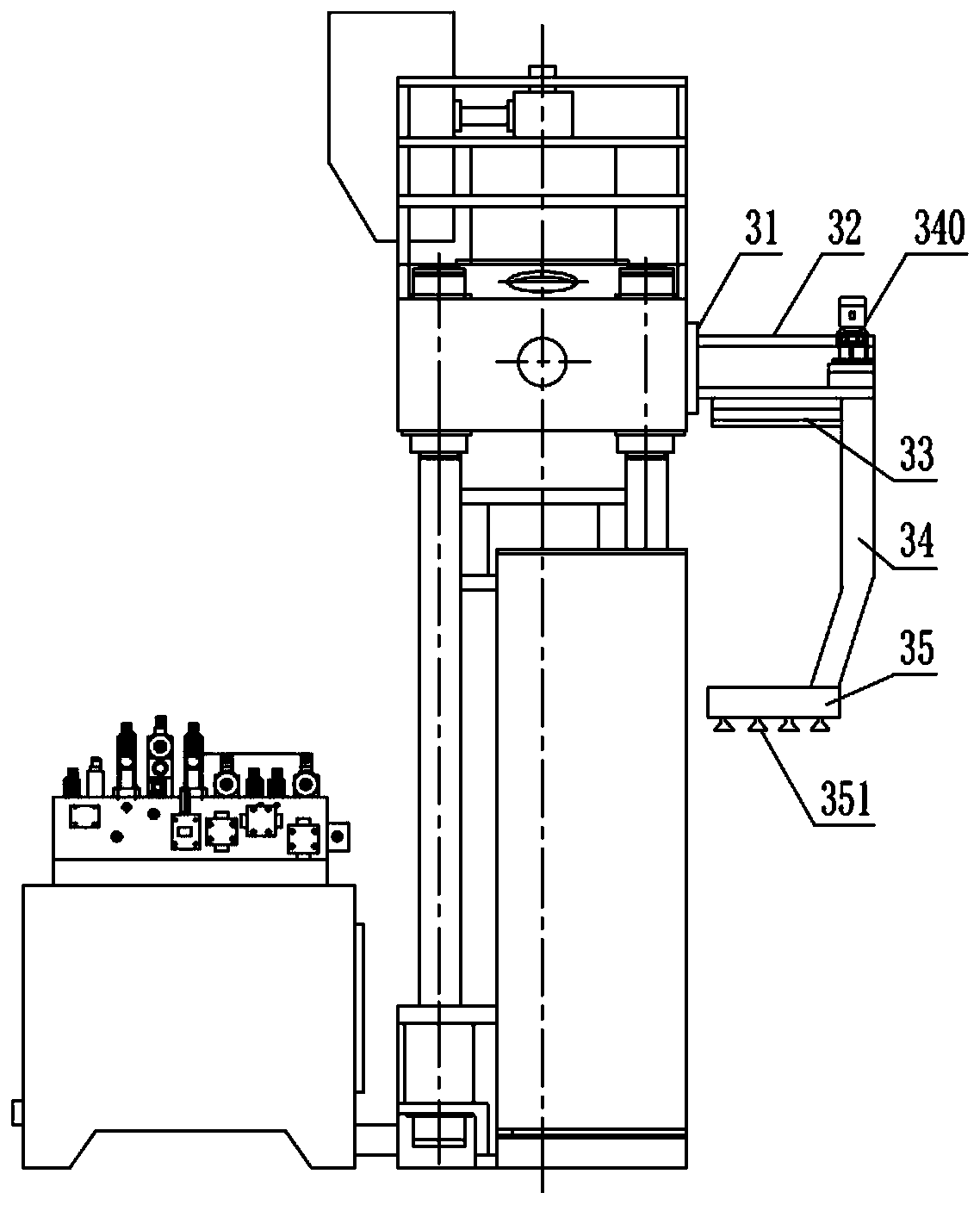

Device and method for molding bistable magnetic alloy wire

ActiveUS8099991B2Easy to controlEfficient productionContact member manufacturingWire articlesWire rodMaterials science

Taught herein is a method for molding a bistable magnetic alloy wire, comprising: processing an alloy wire by heat treatment; and processing the alloy wire by cold treatment of mechanical twisting, the mechanical twisting being a repeated twisting in a continuous state. Also taught herein is a device for molding a bistable magnetic alloy wire.

Owner:ZHANG NIANRONG +5

Organic-encapsulated magnetic nanoparticle composite bone bracket and preparation method thereof

InactiveCN110801536AImprove mechanical propertiesMagnetic homogeneityAdditive manufacturing apparatusPharmaceutical delivery mechanismSelective laser sinteringMagnetite Nanoparticles

The invention belongs to the field of a bone bracket material, and particularly discloses an organic-encapsulated magnetic nanoparticle composite bone bracket. The organic-encapsulated magnetic nanoparticle composite bone bracket is prepared by selective laser sintering on mixed raw materials containing organic-modified magnetic nanoparticles and polymers arranged in the mixed raw materials, wherein the organic-modified magnetic nanoparticles comprise magnetic nanoparticles and an organic compound coating the surfaces of the magnetic nanoparticles. The inventor creatively finds that the organic compound encapsulated magnetic nanoparticles and the polymers have obvious cooperativity, and by a selective laser sintering method, the properties of the bone bracket can be obviously improved, forexample, the hydrophobicity of the bone bracket can be improved, and the stretching and compressing strength can be improved. In addition, the biocompatibility can also be improved, and properties ofskeleton growth and the like can be improved.

Owner:CENT SOUTH UNIV

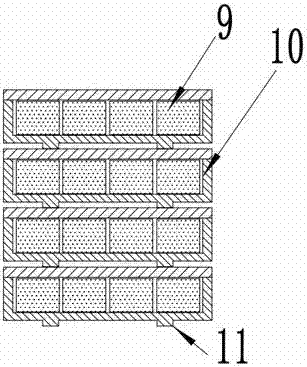

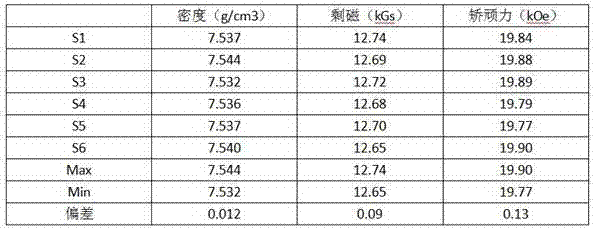

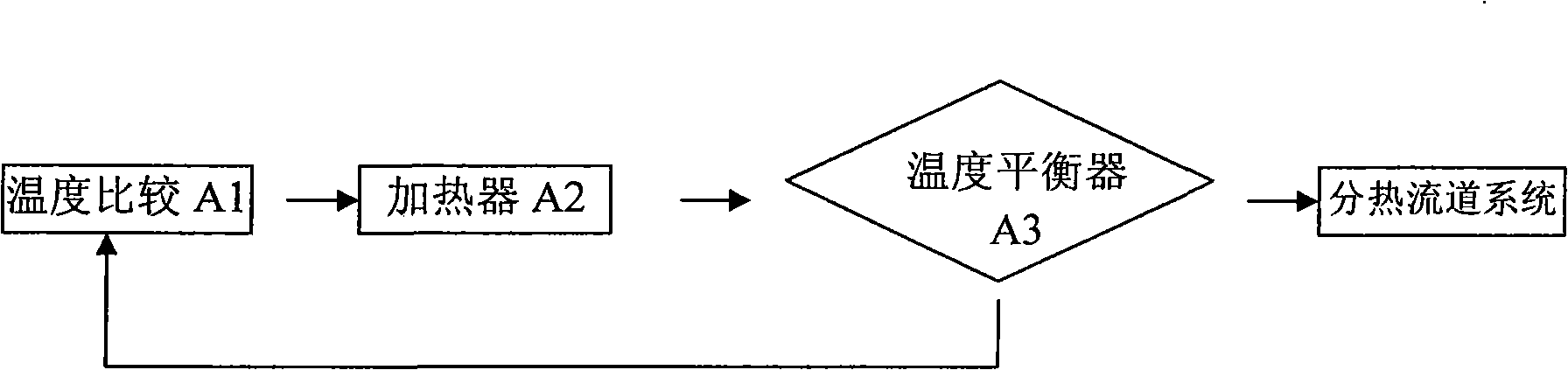

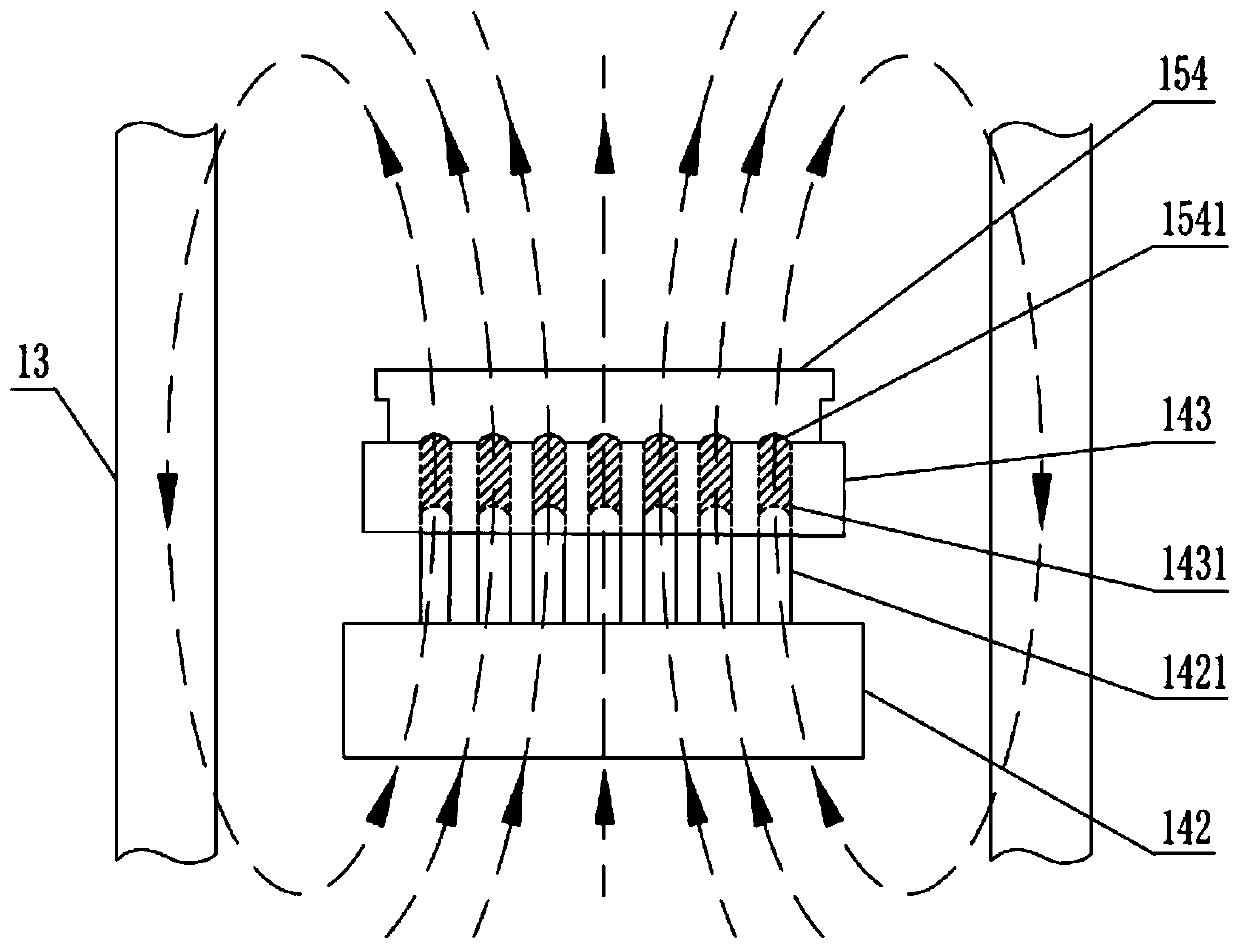

Neodymium iron boron magnet sintering method and special device thereof

PendingCN108010652AEvenly heatedGood density consistencyMuffle furnacesInorganic material magnetismRare-earth magnetNeodymium iron boron

The invention discloses a neodymium iron boron magnet sintering method and a special device thereof, and belongs to the technical field of rare earth magnet materials. The sintering method is characterized in that magnets are sintered by the aid of a rotary sintering furnace, the sintering method includes the steps: feeding; placing magnet into the furnace; magnet sintering. The sintering method solves the problems that different positions of a traditional sintering furnace have temperature deviations, density of the sintered blanks at different positions is nonuniform, and the uniformity of the magnetic performance of the sintered blanks is poor. The method is high in applicability and can meet sintering and forming of neodymium iron boron pressed blanks with different specifications.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

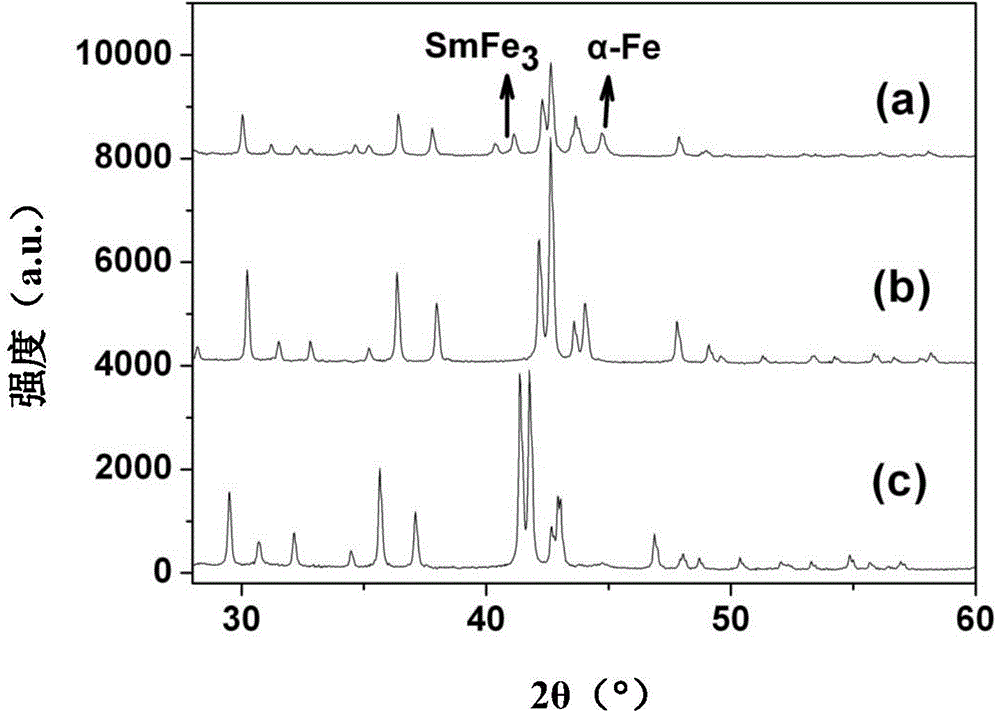

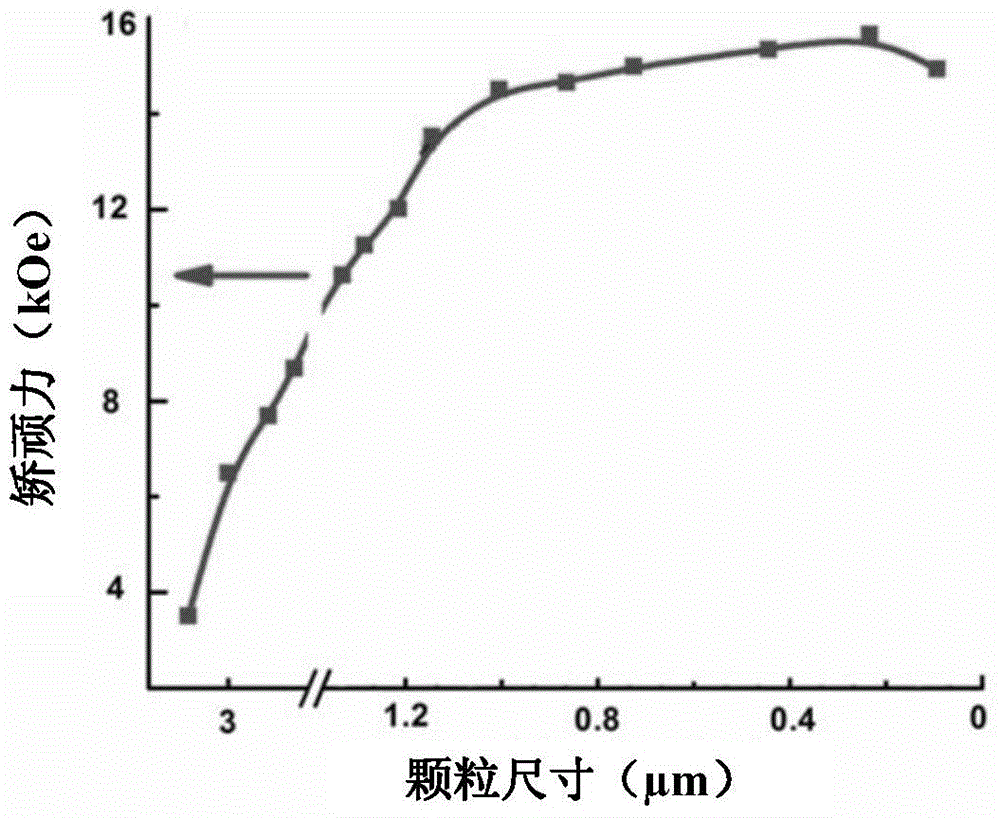

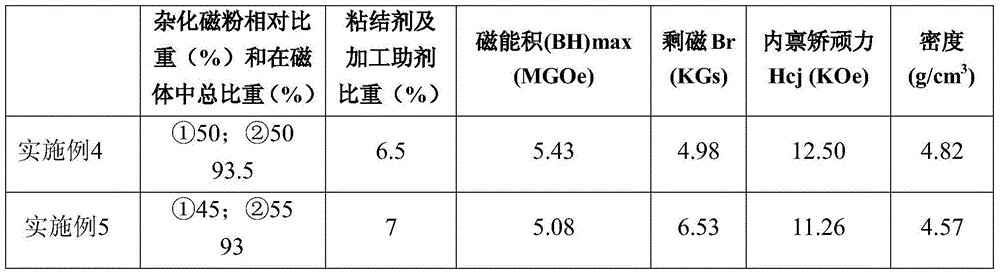

Preparation method of submicron anisotropic samarium iron nitrogen magnetic powder and hybrid bonded magnet thereof

ActiveCN106312077BHigh energy productImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsSingle crystalAlloy

The invention discloses a preparation method of submicron anisotropic samarium-iron-nitrogen magnetic powder and a hybrid bonded magnet thereof. Prepare samarium-iron alloys by quick-setting flake technology, and make them undergo gas-solid phase reaction in nitrogen or a mixed gas of nitrogen and hydrogen to form samarium-iron-nitrogen alloys, followed by jet milling and / or ball milling to obtain particle sizes between 0.01 and 3 μm Anisotropic SmFeN single crystal particle magnetic powder. Further, SmFeN single crystal particle magnetic powder is used as the first component and the second component composed of permanent magnet ferrite, rapidly quenched isotropic NdFeB, anisotropic NdFeB, SmCo and / or NdFeN The two components are mixed into hybrid magnetic powder, and the hybrid bonded magnet is prepared by calendering, molding, extrusion or injection after adding processing aids. The samarium-iron-nitrogen magnetic powder prepared by the present invention has high magnetic energy product, residual magnetism and intrinsic coercive force, low cost, small particle size, and the corresponding hybrid bonded magnet can play the advantages of different component magnetic powders, and has high forming degree and mechanical strength. , and good temperature performance.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

Rare earth permanent magnet material and preparation method and application thereof

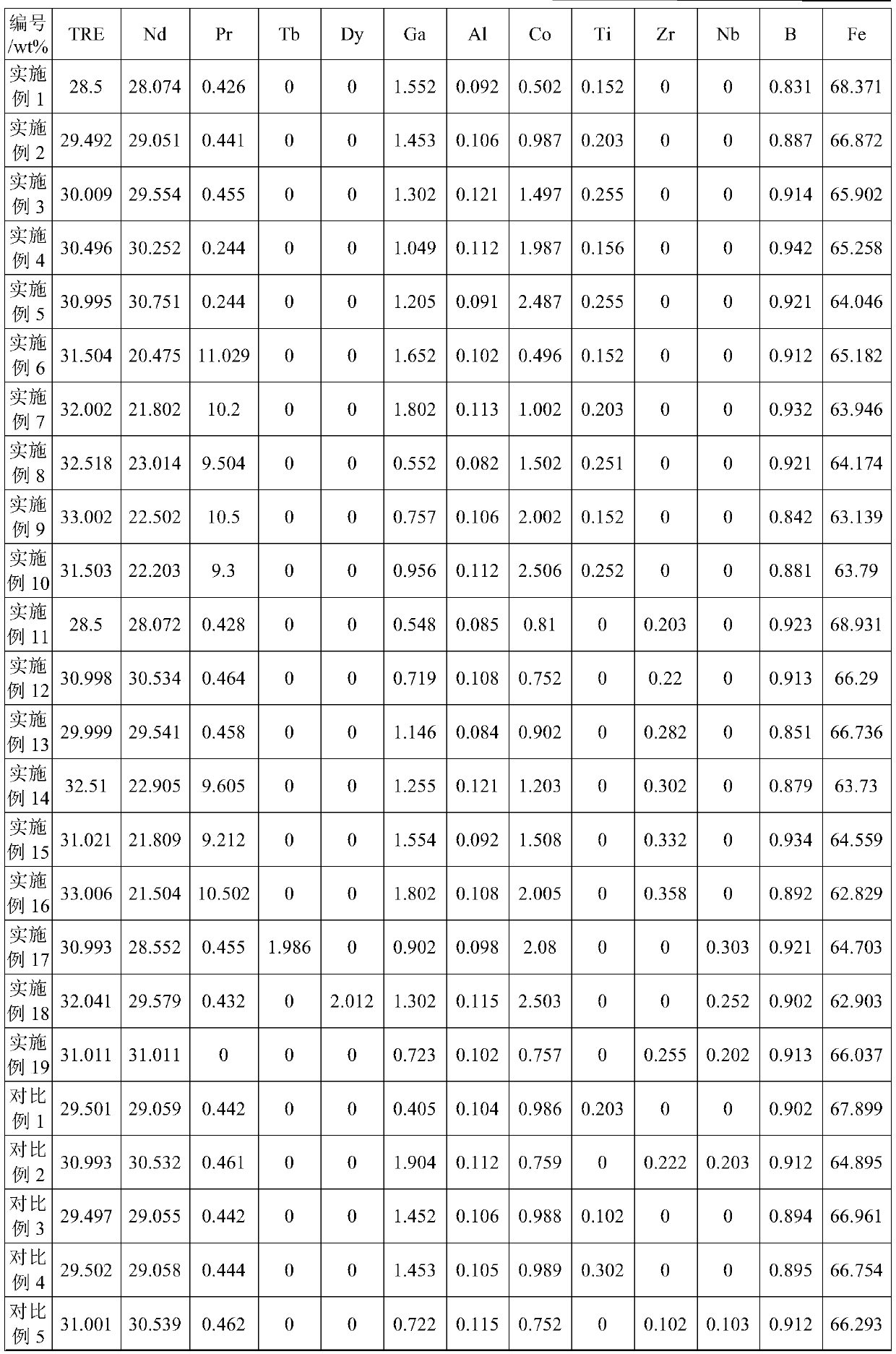

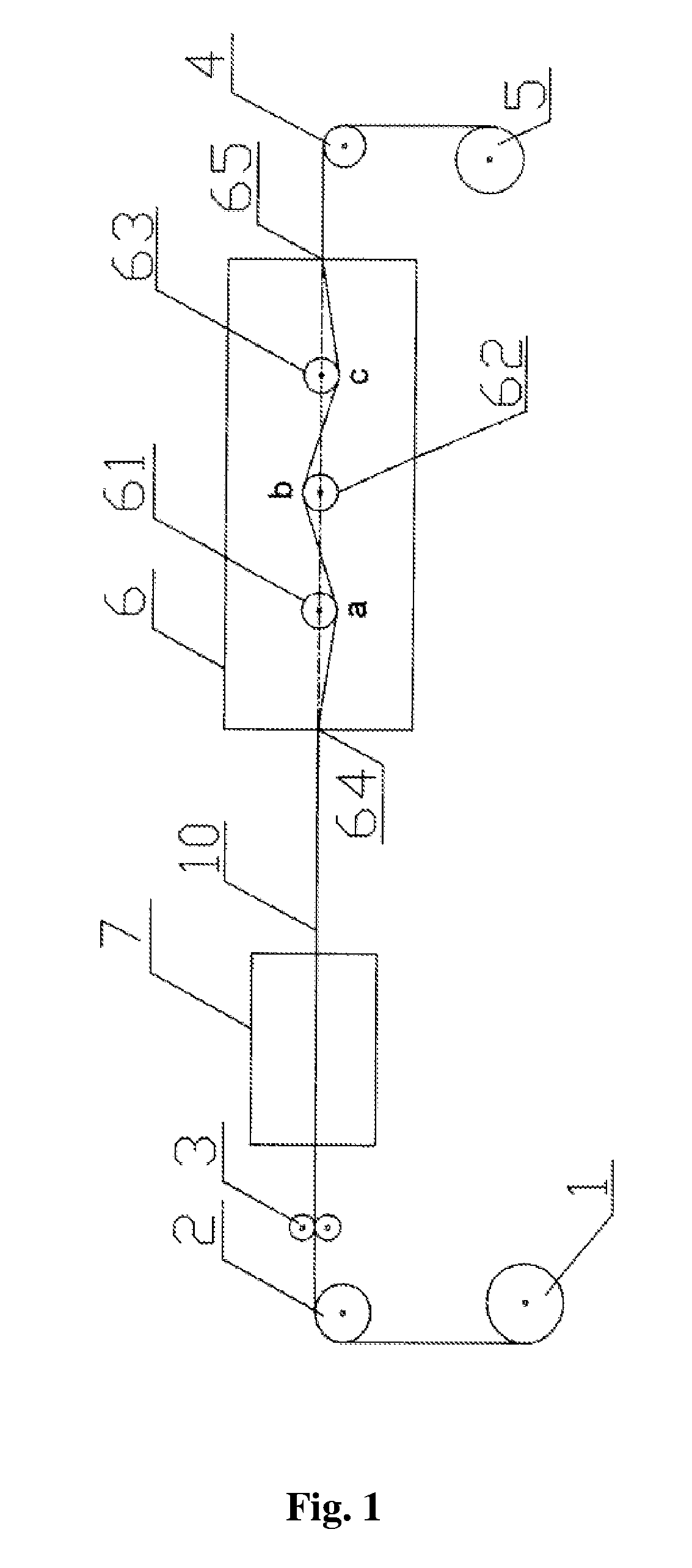

ActiveCN111326304AGood remanenceGood coercivityInductances/transformers/magnets manufactureMagnetic materialsMagnetMetallurgy

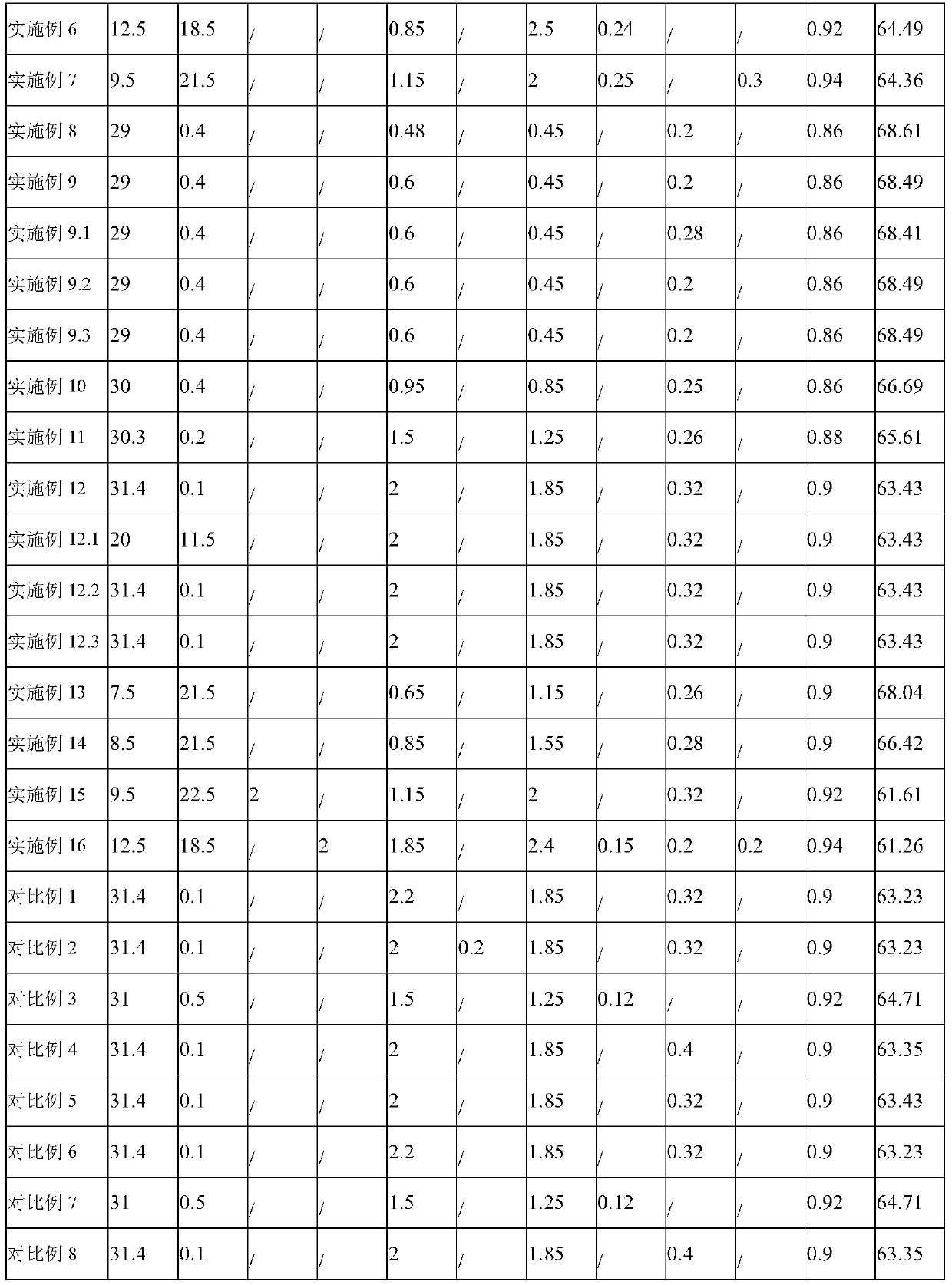

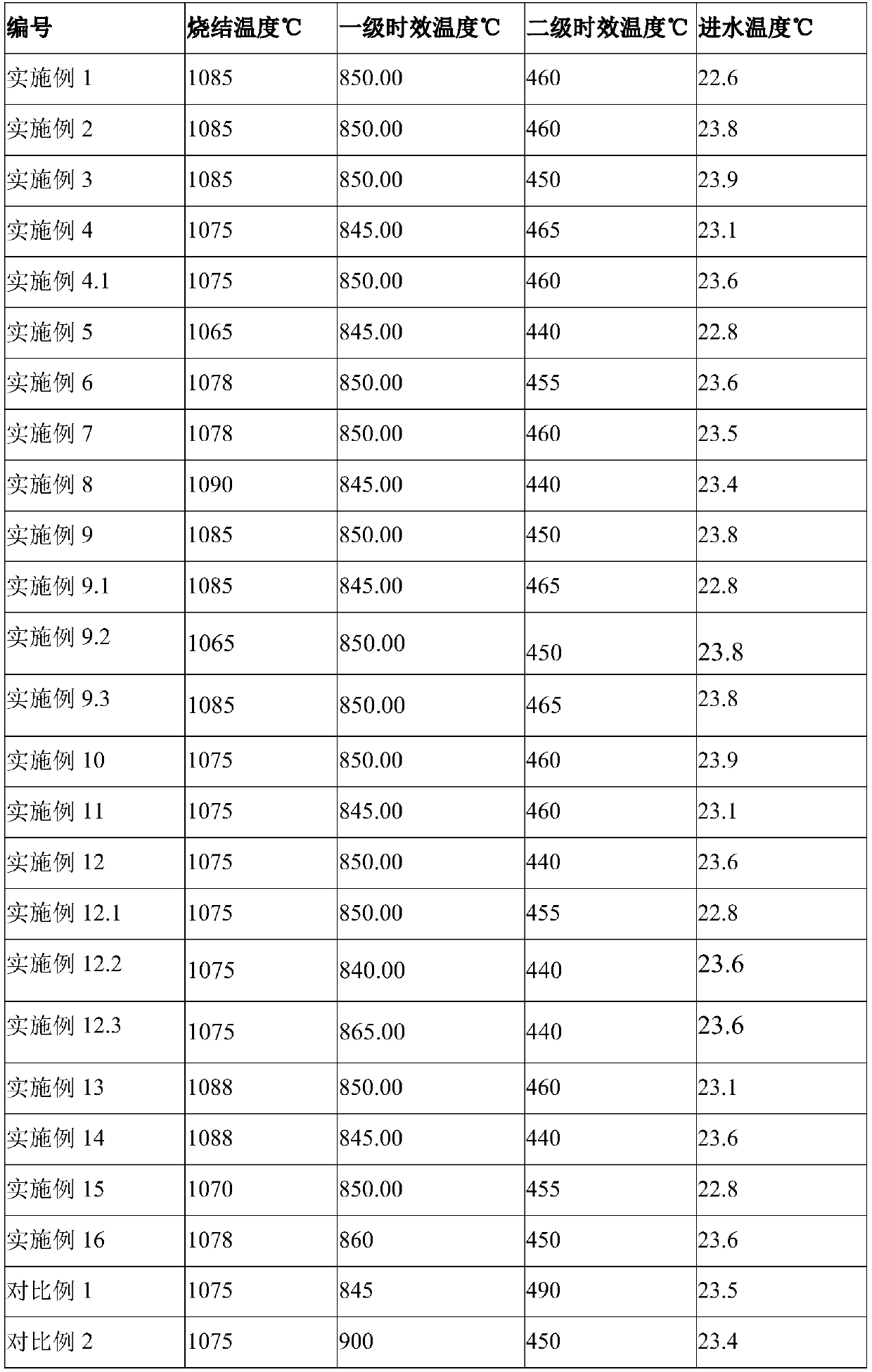

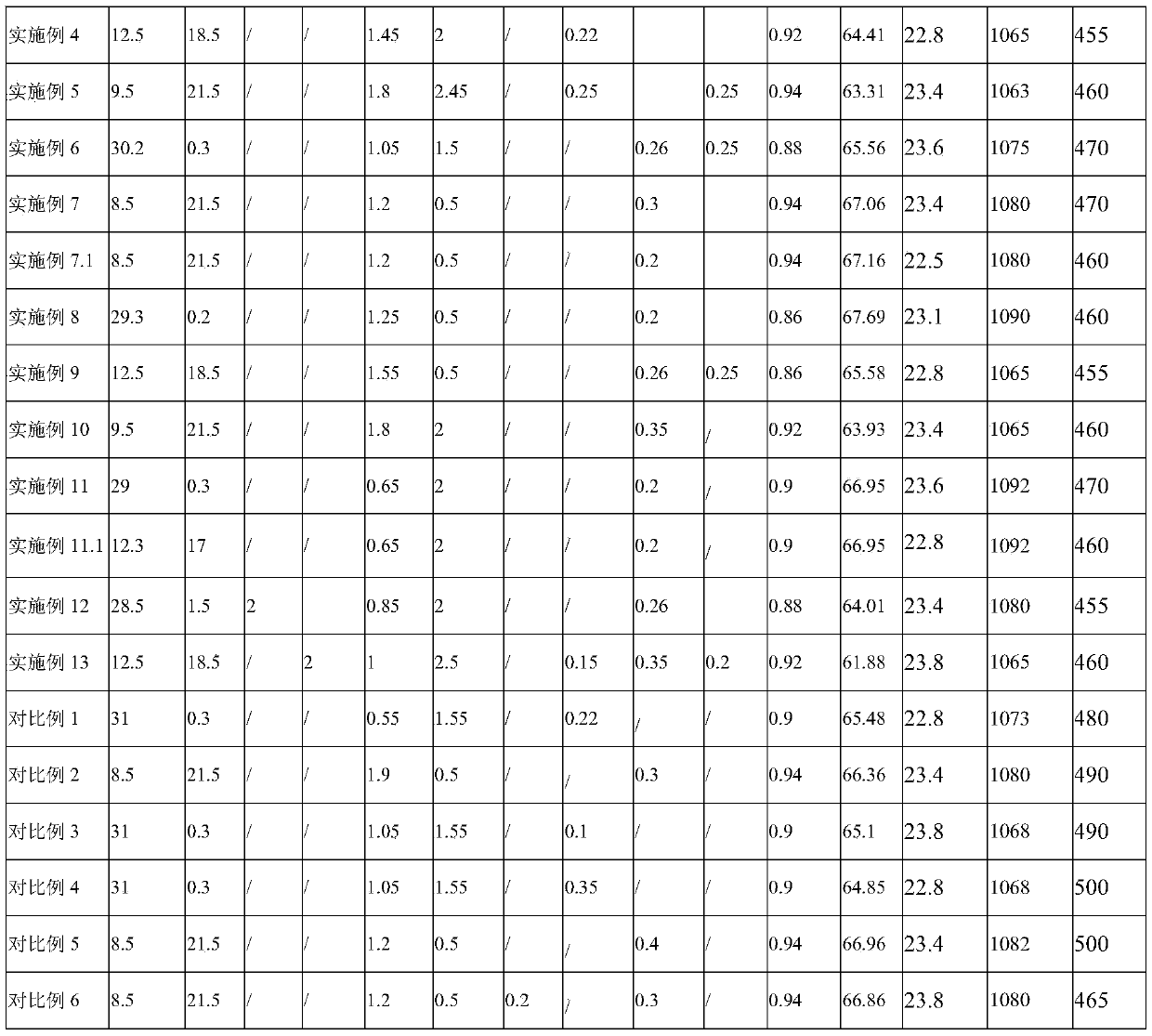

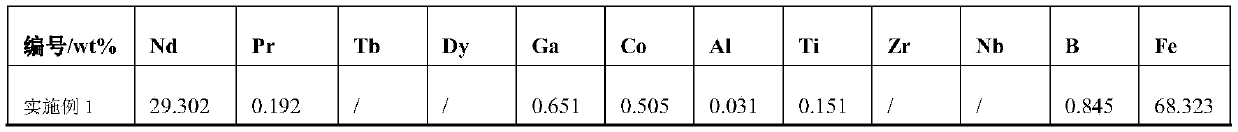

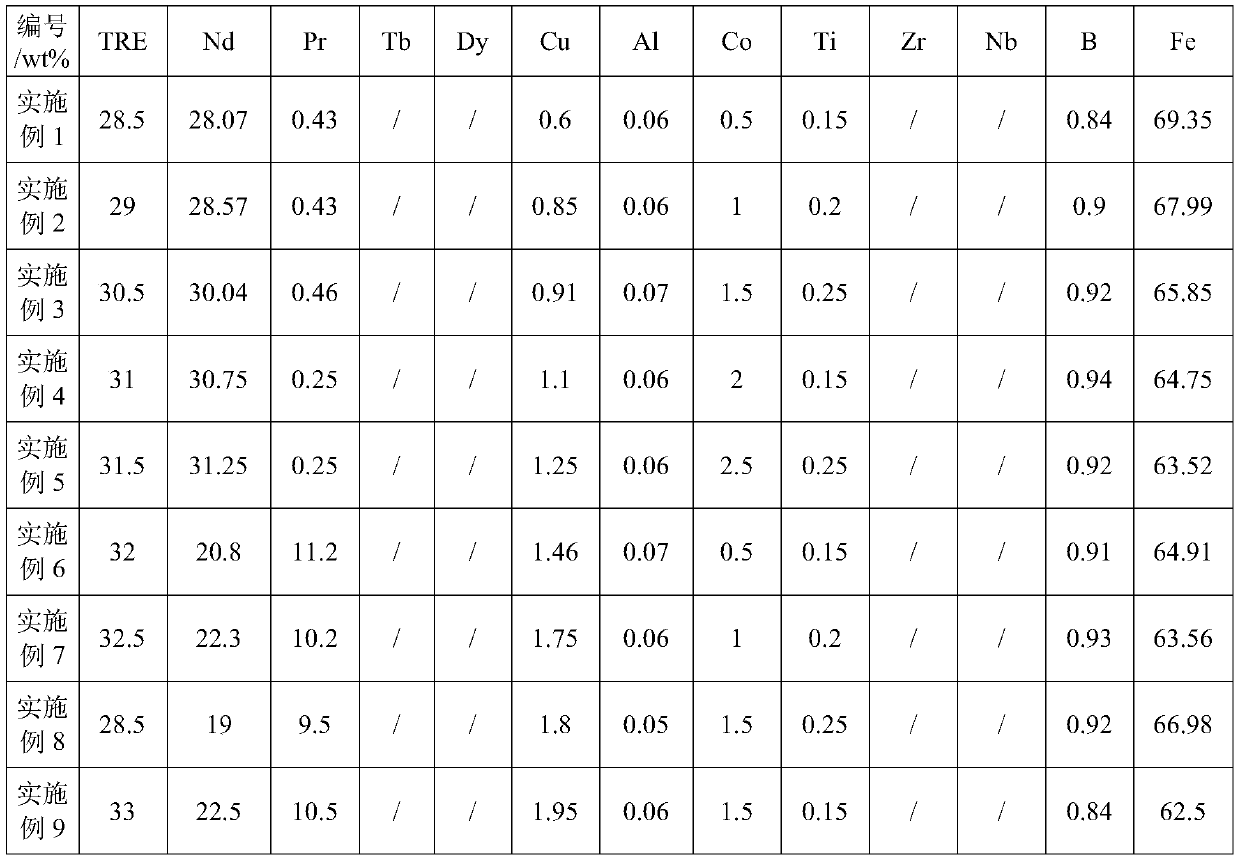

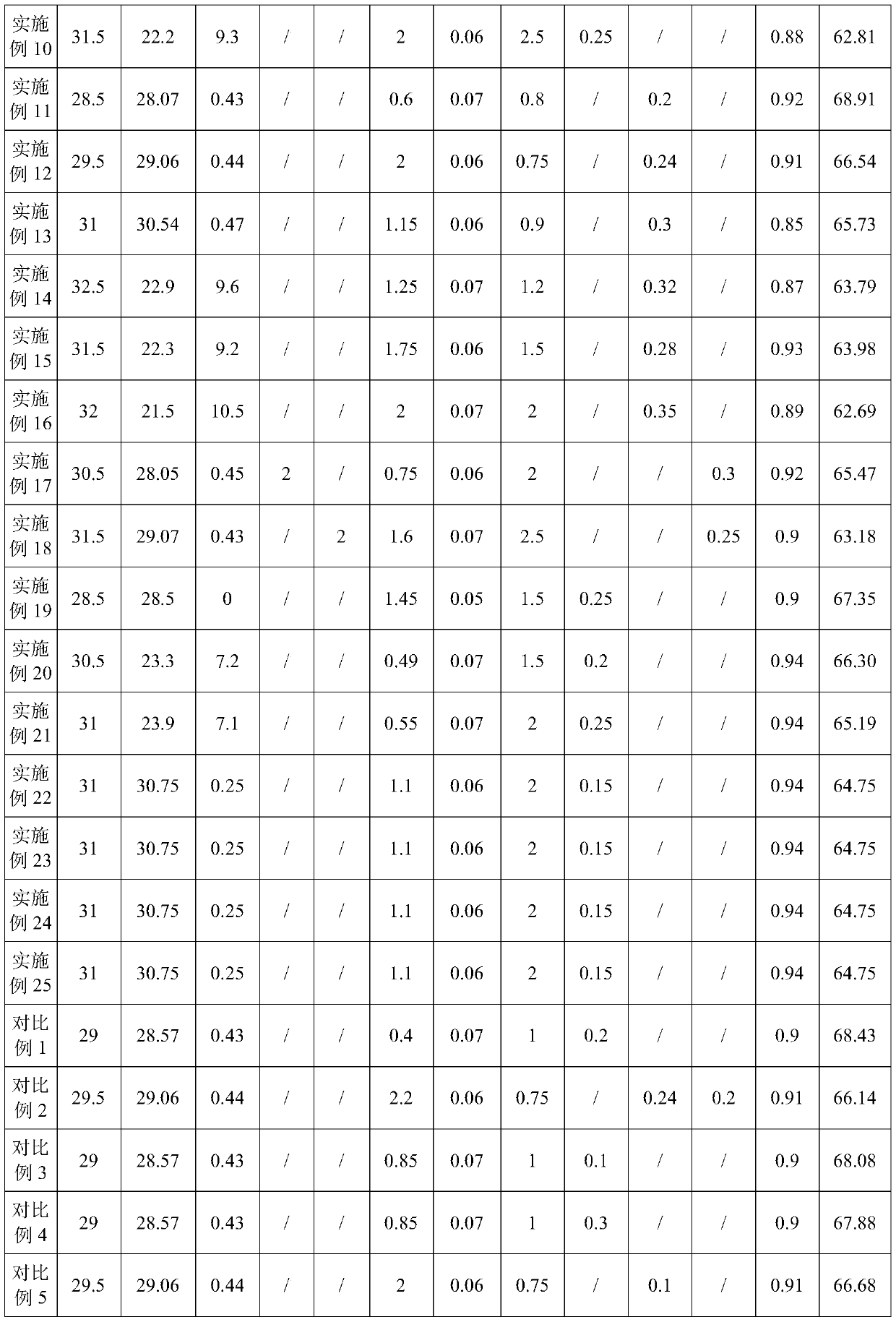

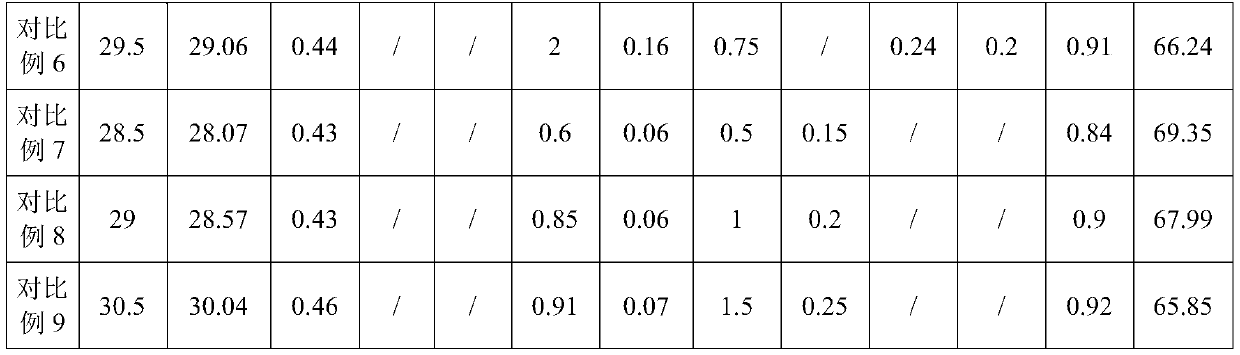

The invention discloses a rare earth permanent magnet material and a preparation method and application thereof. The raw material composition of the rare earth permanent magnet material comprises thefollowing components in percentage by mass: 28.5-33.0% of R, 0.5%-1.8% of Ga, but not 0.5 wt% of Ga, 0.84%-0.94% of B, 0.05 to 0.07% of Al, and <=2.5% but not 0 of Co, 62-69% of Fe; N is one or moreof Ti, Zr and Nb; when N contains Ti, the content of Ti is 0.15%-0.25%; when N contains Zr, the content of Zr is 0.2%-0.35%; when N contains Nb, the content of Nb is 0.2%-0.5%; and the percentage is the mass percentage of each component in the total mass of the raw material composition. The rare earth permanent magnet material has better magnetic properties (residual magnetism, coercive force, squareness and temperature stability), and the magnetic properties of the same batch of products are uniform.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Device and method for molding bistable magnetic alloy wire

ActiveUS20080052887A1Easy to controlEfficient productionContact member manufacturingWire articlesCold treatmentHeat treated

Taught herein is a method for molding a bistable magnetic alloy wire, comprising: processing an alloy wire by heat treatment; and processing the alloy wire by cold treatment of mechanical twisting, the mechanical twisting being a repeated twisting in a continuous state. Also taught herein is a device for molding a bistable magnetic alloy wire.

Owner:ZHANG NIANRONG +5

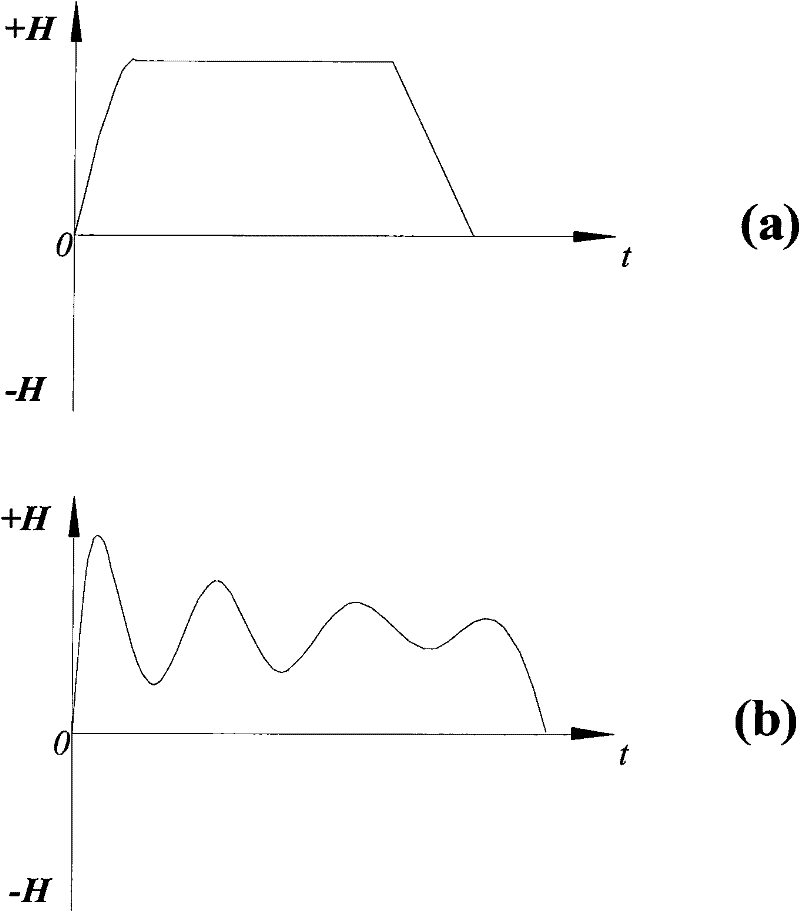

Manufacture method of permanent magnet

InactiveCN102479599AGood orientationIncrease productivityPermanent magnetsInductances/transformers/magnets manufactureAlloyAlternating current

The invention provides a manufacture method of a permanent magnet. The manufacture method comprises the following step of: arranging permanent magnet alloy powder in a forming mold in an alternating magnetic field which is provided with a positive magnetic field and a negative magnetic field, for orientation and compression, wherein the alternating magnetic field is generated by an alternating current which is input into coils; the alternating current has constant amplitude and frequency; and the frequency of the alternating current is in a range of 0.1-100 Hz in different orientation and compression processes. The invention has the advantages of uniform orientation degree, low equipment cost, low energy consumption, long service life, high production efficiency and the like.

Owner:湖南吉瑞斯材料科技有限公司

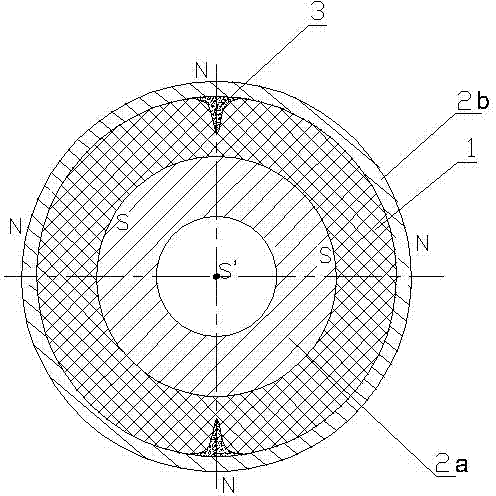

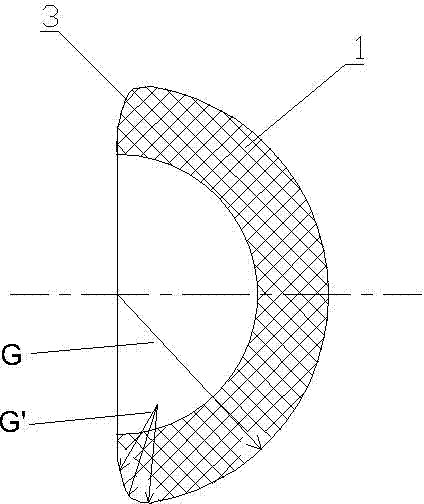

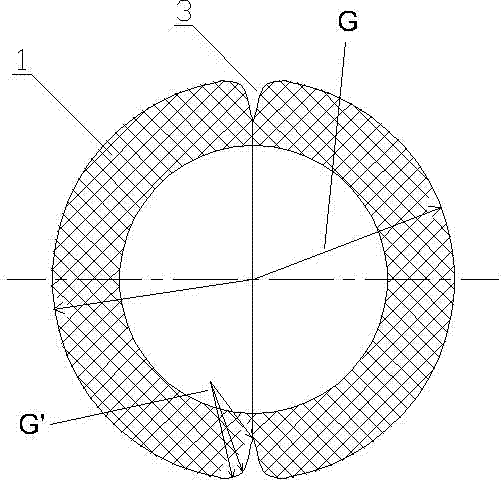

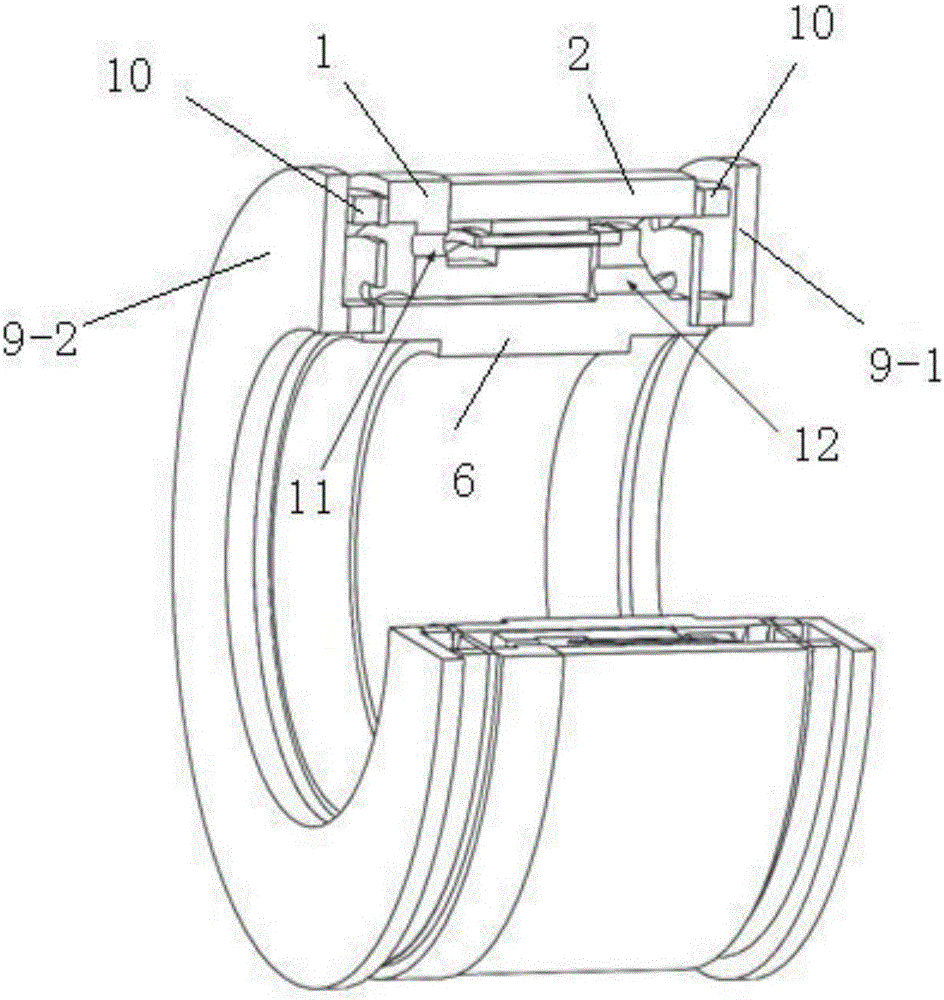

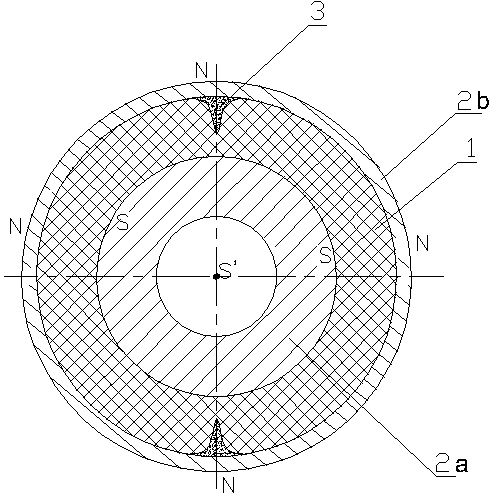

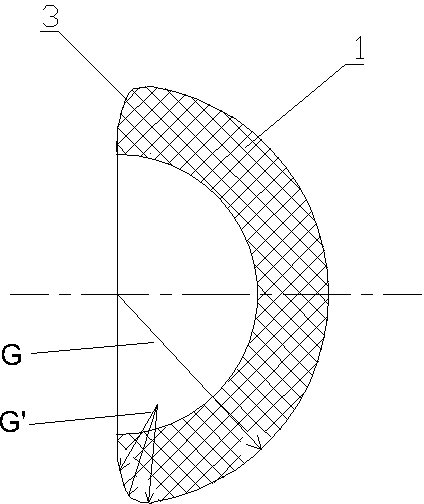

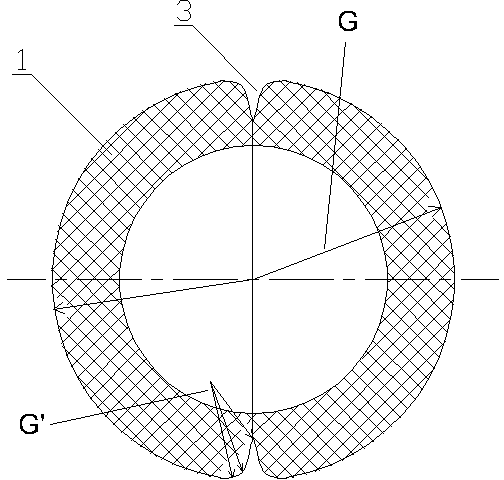

Quasi magnetic monopole model

InactiveCN102867447AMagnetic homogeneityReduce combination gapPermanent magnetsEducational modelsMagnetic monopoleMagnet

The invention relates to a quasi magnetic monopole model and belongs to the technical field of physics application. A hollow hemispherical permanent magnet is manufactured by variable magnetic shaft orientation pressing, forming, sintering and magnetizing; a hollow spherical permanent magnet is formed by butting and combining two hollow hemispherical permanent magnets; high magnetic permeability materials are arranged on the inner and outer surfaces of the hollow spherical permanent magnet; the outer edge of the hemispherical bottom of the hollow hemispherical permanent magnet has inverted chamfering; and variable magnetic shaft orientation magnetizing is performed at the inverted chamfering. According to the quasi magnetic monopole model, a stray heteropolar magnetic field at the periphery of the magnetic monopole is eliminated, so that the monopole on the outer surface is uniform in magnetic field, and a magnetic monopole model which is strict and practical is manufactured.

Owner:崔实

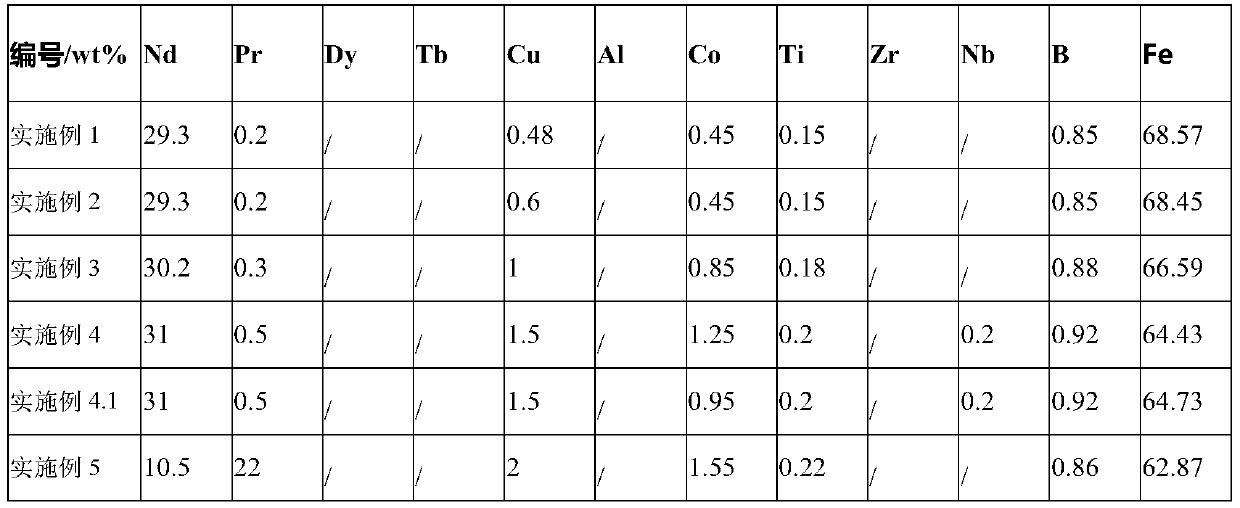

Neodymium iron boron material and preparation method and application thereof

ActiveCN111312462AGood remanenceGood coercivityInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementBoron

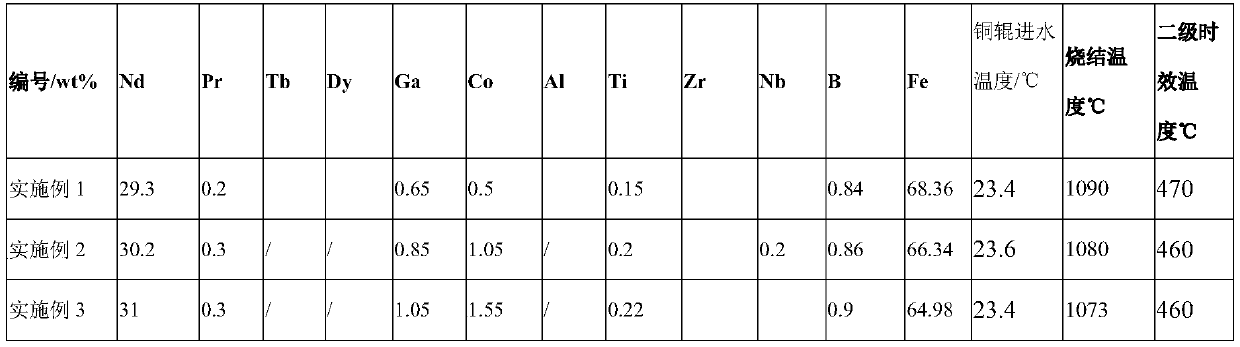

The invention discloses a neodymium iron boron material and a preparation method and application thereof. The raw material composition of the neodymium iron boron material comprises the following components by mass: 28.5-34% of R; R is a rare earth element and comprises Nd; 0.84%-0.94% of B; Cu: 0.45 < Cu < = 2%; Co: < = 2.5%, but not 0; Fe: 61 to 69 %; N, containing one or more of Ti, Zr and Nb.When N contains Ti, the content of Ti is 0.15%-0.25%. When N contains Zr, the content of Zr is 0.2%-0.35%. When N contains Nb, Nb is 0.2%-0.5%; wherein the percentage is the mass percentage of each component in the total mass of the raw material composition. According to the neodymium iron boron material, on the premise of not adding heavy rare earth elements, the neodymium iron boron material which is good in magnetic performance and uniform in magnetic performance in the same batch can still be prepared by adopting a low-boron aluminum-free system.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Rare earth permanent magnet material and preparation method and application thereof

ActiveCN111312463ARandom combinationGood remanenceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementAluminium

The invention discloses a rare earth permanent magnet material and a preparation method and application thereof. The raw material composition of the rare earth permanent magnet material comprises thefollowing components: R: 28.5-33%, R beig a rare earth element and comprising Nd; B: 0.84%-0.94% of the total weight of the raw materials; Ga: 0.6 < Ga < = 1.8%; Co: < = 2.5%; Fe: 61.6-69 %; wherein Ncomprises one or more of Ti, Zr and Nb. When N contains Ti, the content of Ti is 0.15%-0.25%. When N contains Zr, the content of Zr is 0.2%-0.35%. When N contains Nb, Nb is 0.2%-0.5%, wherein the percentage is the percentage of each component in the total mass of the rare earth permanent magnet material. According to the rare earth permanent magnet material, under the condition that no heavy rareearth element is added, a low-boron aluminum-free system is adopted, the magnetic properties such as residual magnetism, coercive force, temperature stability and squareness are still good, and meanwhile the magnetic properties of permanent magnet materials of the same batch are uniform.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Neodymium iron boron material and preparation method and application thereof

ActiveCN111243811AGood remanenceGood coercivityInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a neodymium iron boron material and a preparation method and application thereof. The raw material composition of the neodymium-iron-boron material comprises the following components in percentage by mass: 28.5-33.0% of R and the balance of Fe and inevitable impurities, r is a rare earth element at least containing Nd; 0.45%-2% of Cu, but not 0.45% of Cu; b: 0.84%-0.94% ofthe total weight of the raw materials; 0.05 to 0.07% of Al; co: < = 2.5% but not 0; 62 to 70 percent of Fe; n is one or more of Ti, Zr and Nb; when N contains Ti, the content of Ti is 0.15%-0.25%; when N contains Zr, the content of Zr is 0.2%-0.35%; when N contains Nb, the content of Nb is 0.2%-0.5%; wherein the percentage is the mass percentage of each component in the total mass of the raw material composition. The neodymium iron boron material is good in magnetic performance, and the magnetic performance of products of the same batch is uniform.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

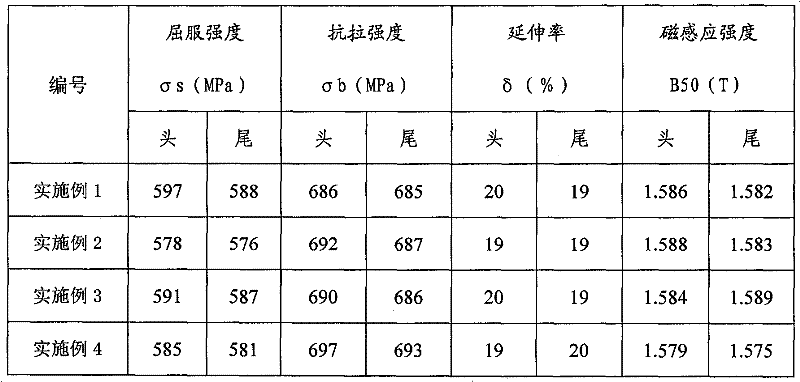

Manufacturing method of 500Mpa-grade cold-rolled magnetic steel

ActiveCN101871076BHigh yield strengthImprove mechanical propertiesTemperature control deviceFurnace typesSheet steelAcid washing

The invention discloses a manufacturing method of 500MPa-grade cold-rolled magnetic steel, which comprises the following steps that: (1) heating a slat to 1200 to 1260 DEG C, then rolling the slab into a steel sheet, the final rolling temperature is 830 to 890 DEG C, and adopting a laminar flow cooling way to cool the steel sheet to 550 to 600 DEG C to be rolled; (2) cooling the steel sheet in anair cooling way, and acid-washing the steel sheet; (3) cold rolling; (4) continuous annealing: the temperature of a uniformly-heated section of an annealing furnace is controlled within the range of 740 to 760 DEG C, the speed of the annealing process section is controlled at the range of 120 to 125 meter per minutes, and the time of the uniformly-heated section is controlled within the range of 230 to 239 s; (5) flattening. The cold-rolled magnetic steel produced with the method has high yield strength which can reach more than 570 MPa, uniform performance, small performance difference, favorable match between the magnetic sensing strength and the strength of the steel plate, favorable shape, high size precision, good surface quality and high yield.

Owner:BAOSHAN IRON & STEEL CO LTD

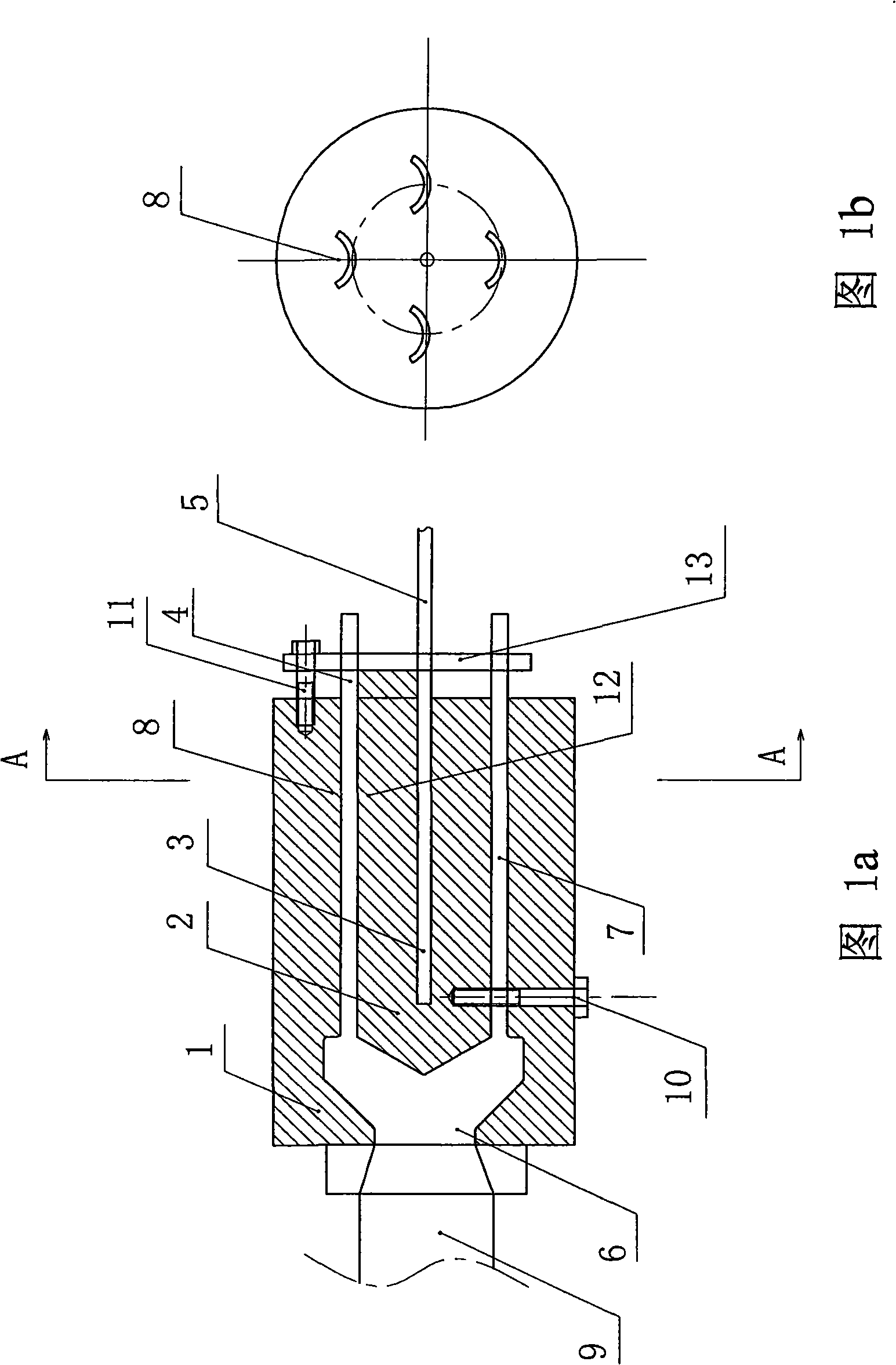

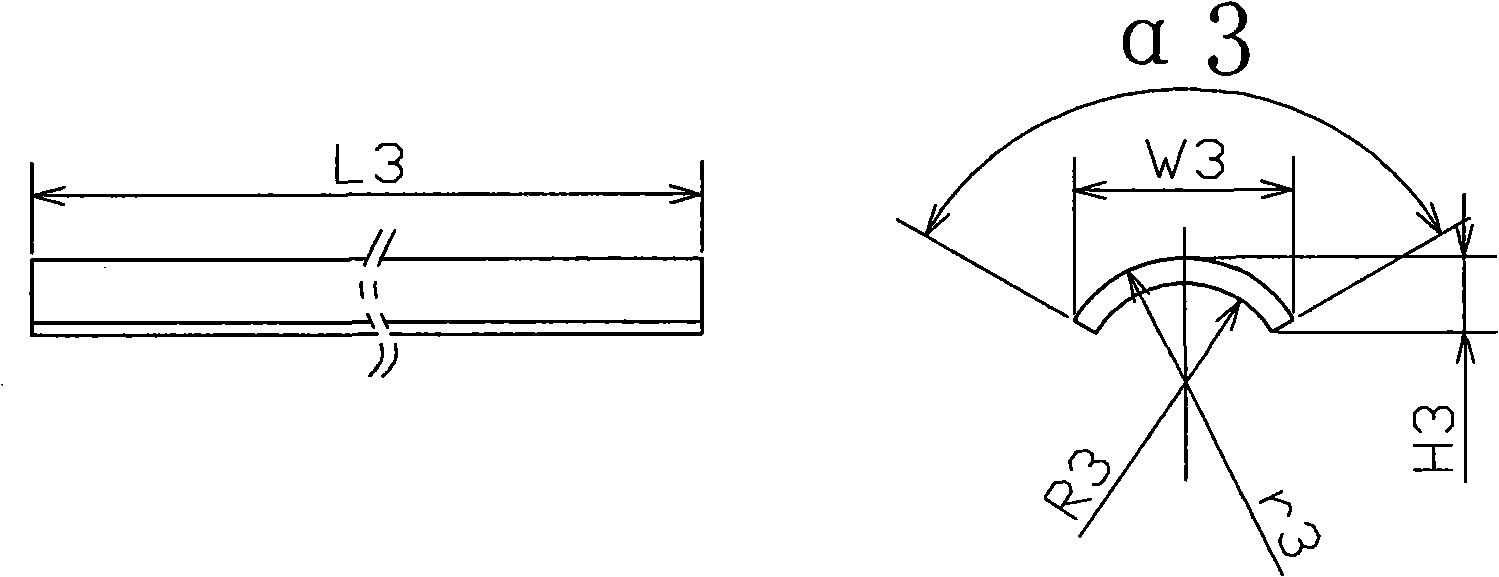

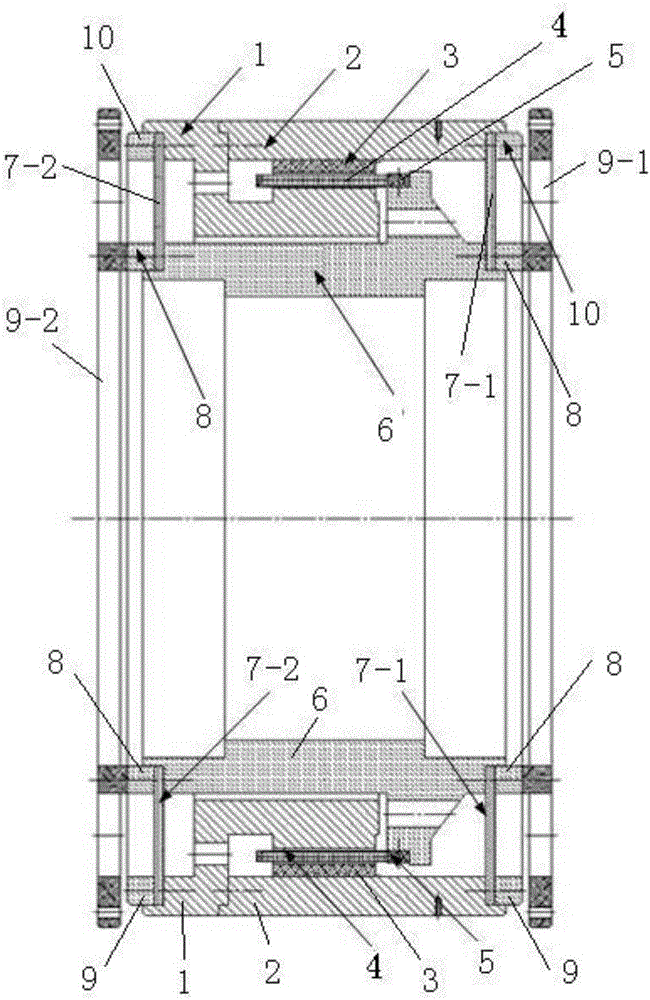

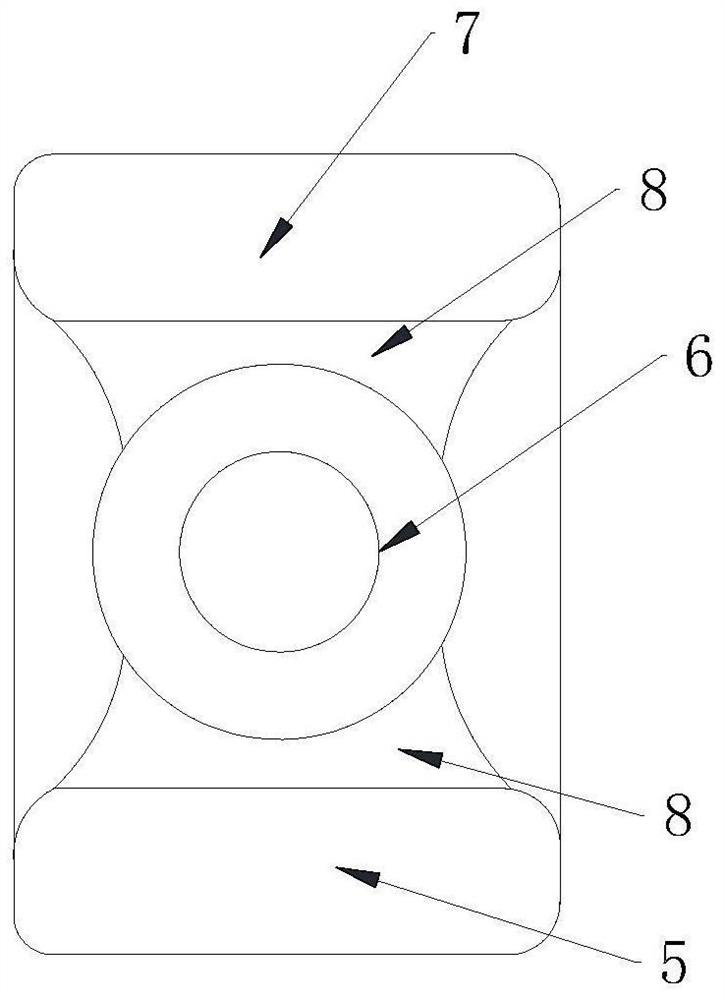

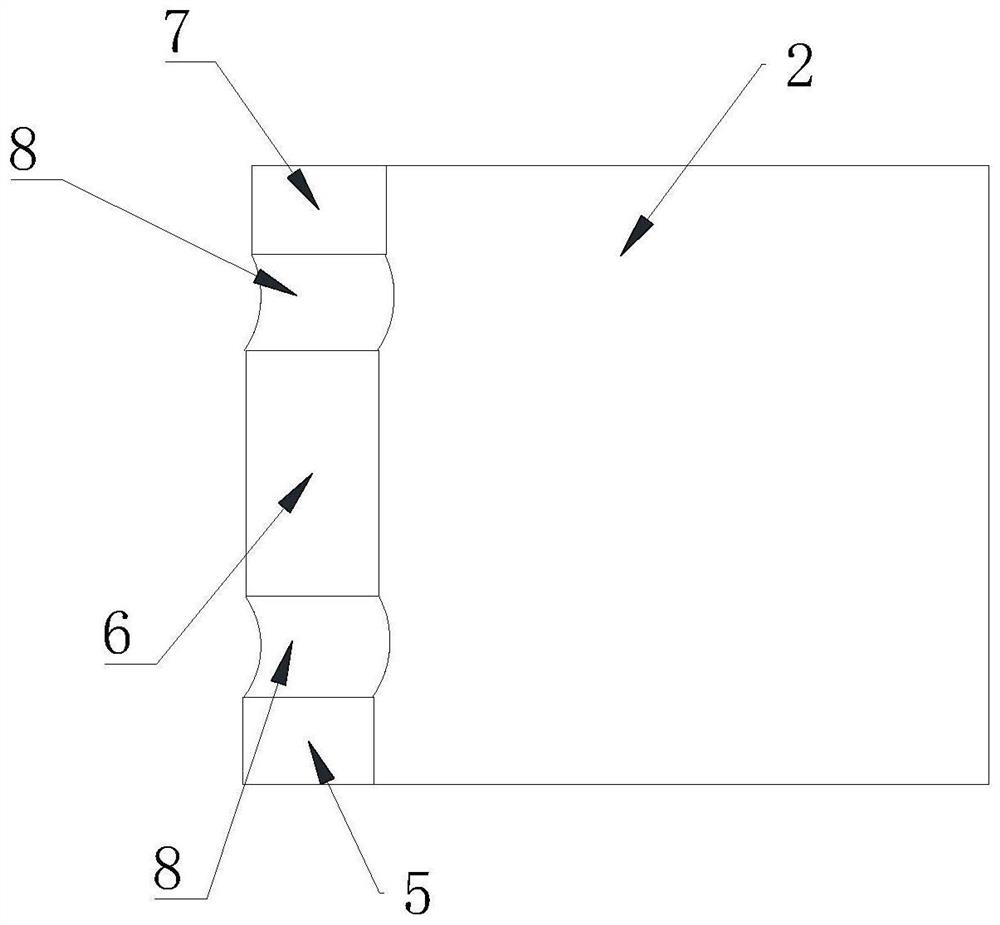

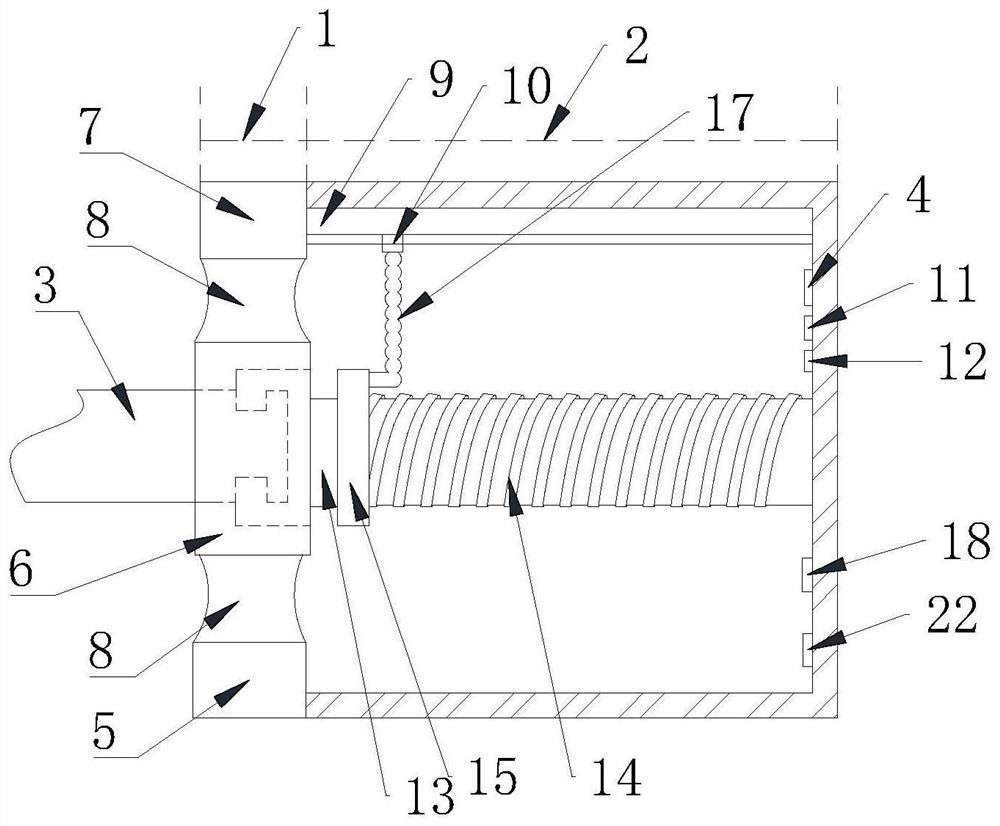

Flow channel device capable of extruding out a plurality of magnets once for extruding machine and preparation method using same

ActiveCN101513673AGood central symmetryImprove straightnessInorganic material magnetismHeat flowEngineering

The invention provides a flow channel device capable of extruding out a plurality of rare earth magnets once for an extruding machine, and a method for preparing the plurality of the rare earth magnets extruded out once by the extruding flow channel device. The flow channel device comprises a device main body (1), a core rod (2), a cooling pipe (3), a cooler (5), a main heat flow channel (6), a plurality of branched heat flow channels (7), temperature sensors (8) and (12), and a mixing material inlet (9). The flow channel device can efficiently obtain novel rare earth magnets which have even texture, uniform magnetic property, high dimension precision in the length direction and good corrosion resistance without conicity and needle eyes.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Electromagnetic actuator for ship

ActiveCN105840707AIncrease the electromagnetic force coefficientIncrease active powerVibration dampersMagnetic springsElectromagnetic actuatorElectrical and Electronics engineering

The invention discloses an electromagnetic actuator for a ship. The electromagnetic actuator comprises a ring-shaped magnetic steel supporting body and a ring-shaped magnetizer, wherein the section of the magnetizer is U-shaped; one end of the magnetizer is connected with the magnetic steel supporting body; a coil framework and magnetic steel are sequentially arranged between the other end of the magnetizer and the magnetic steel supporting body; a coil is winded around the coil framework; a clearance is formed between the coil and the magnetic steel; the coil framework is connected with a force transfer frame; first spring sheets and second spring sheets are respectively arranged on the two sides of the force transfer frame; the first spring sheets are connected with the magnetizer; the second spring sheets are connected with the magnetic steel supporting body; a first baffle is arranged outside the magnetic steel supporting body; a second baffle is arranged outside the magnetizer; a first air vent is arranged on the magnetizer; and a second air vent is arranged on the magnetic steel supporting body. The electromagnetic actuator provided by the invention is good in heat dissipating effect, high in electromagnetic force coefficient and large in activation force.

Owner:CHINA SHIP DEV & DESIGN CENT

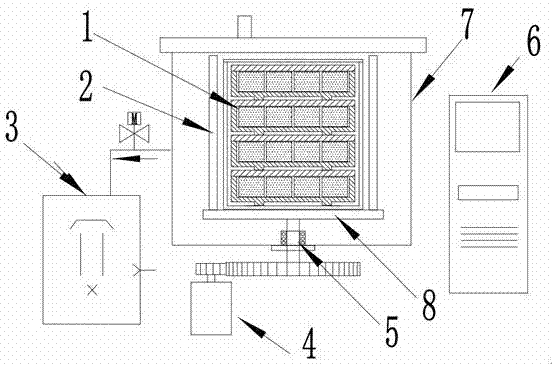

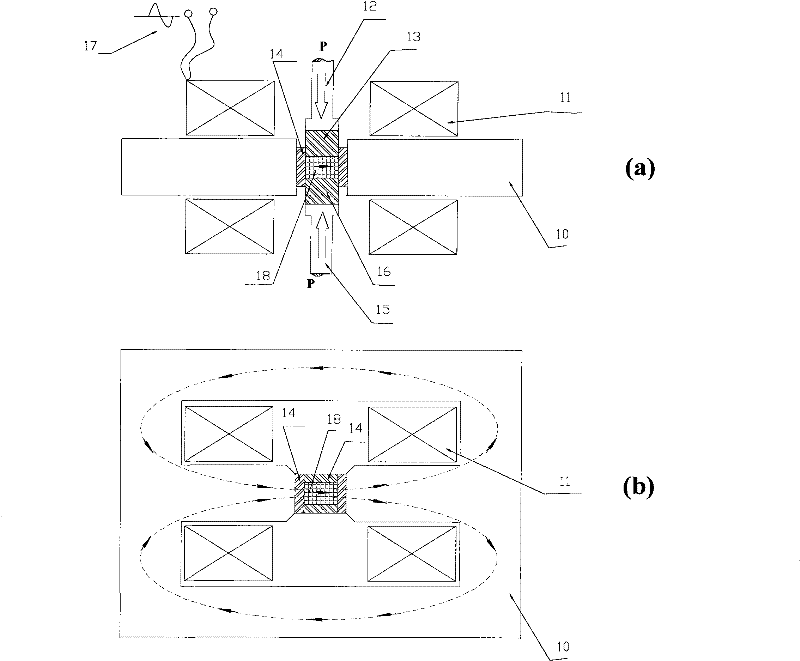

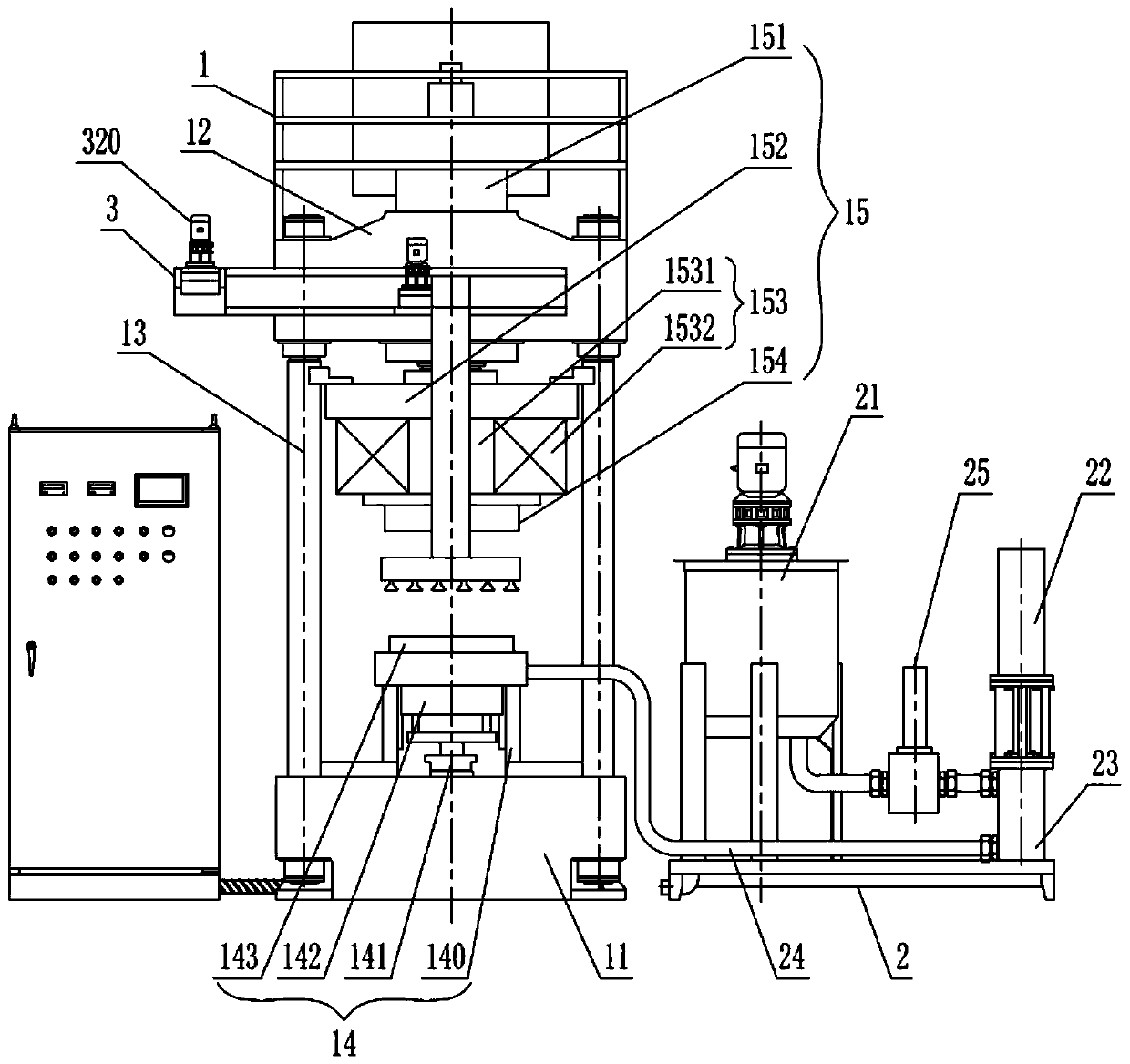

1,500 KN magnetic material wet type forming hydraulic machine and hydraulic forming process

PendingCN110181661AHigh Magnetic ConsistencyMagnetic homogeneityMagnetic film to substrate applicationShaping press ramDemagnetizing deviceHydroforming

The invention discloses a 1,500 KN magnetic material wet type forming hydraulic machine and a hydraulic forming process, and relates to the technical field of magnetic product production. The 1,500 KNmagnetic material wet type forming hydraulic machine comprises a hydraulic machine body. The hydraulic machine body comprises an upper workbench, a lower workbench, magnetism conducting vertical columns, a lower die part and an upper die part. The upper die part comprises an upper sliding block driven to slide up and down, a magnetizing and demagnetizing device fixed to the lower end of the uppersliding block, and an upper die fixed to the lower end of the magnetizing and demagnetizing device. The upper sliding block is slidingly connected with the magnetism conducting vertical columns on the periphery. The lower die part comprises a lower die support fixed to the lower workbench, a lower die fixed to the lower die support, and a lower sliding block arranged below the lower die and driven to slide up and down. The lower sliding block is slidingly connected with the lower die support, and the lower die support is connected with the magnetism conducting vertical columns on the periphery. A magnetism conducting circuit can be formed during magnetizing, and produced workpieces have good magnetism uniformity and stability; and in combination with the special hydraulic forming process,the produced products have uniform and stable magnetism and high mechanical performance and consistency.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

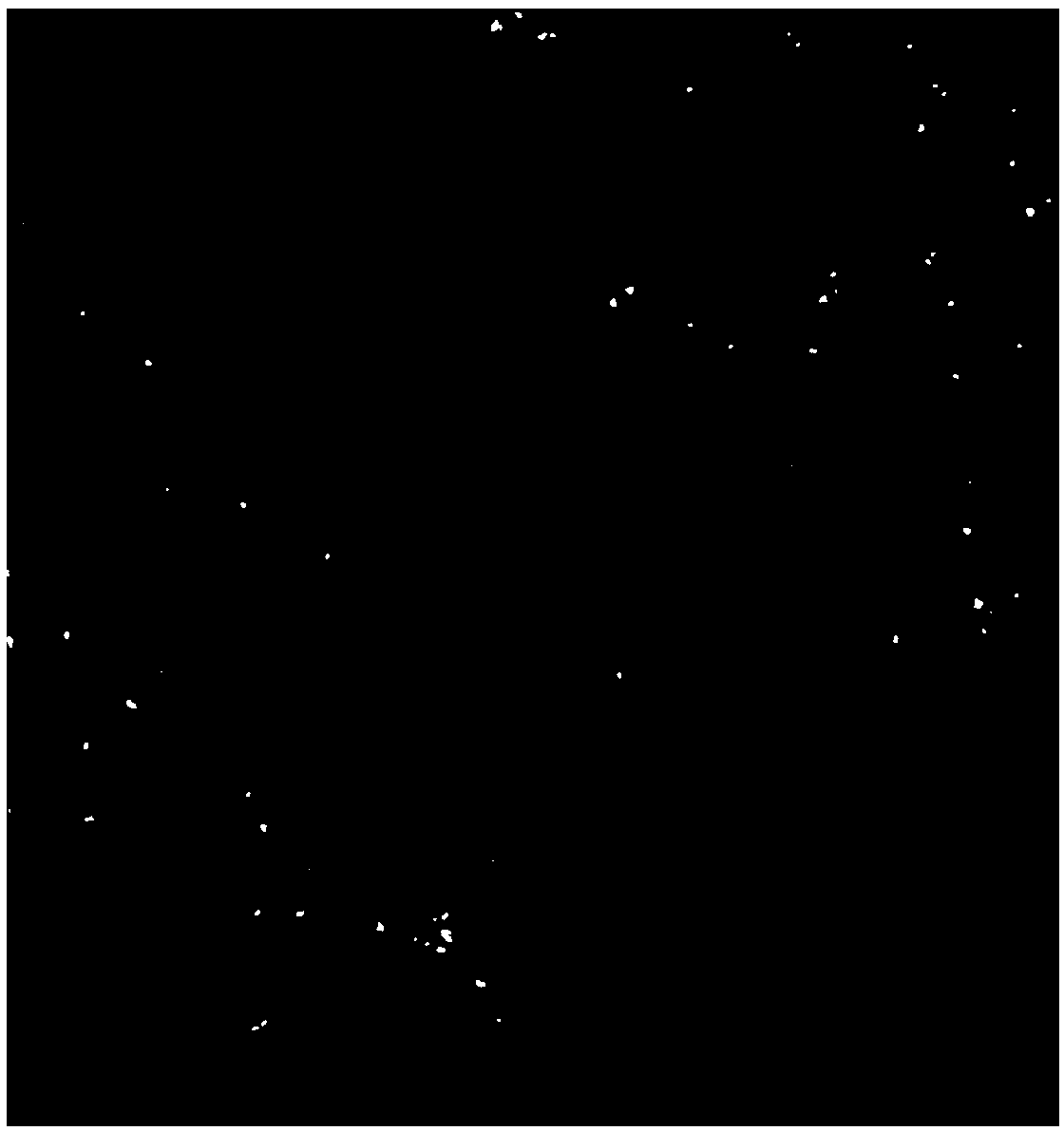

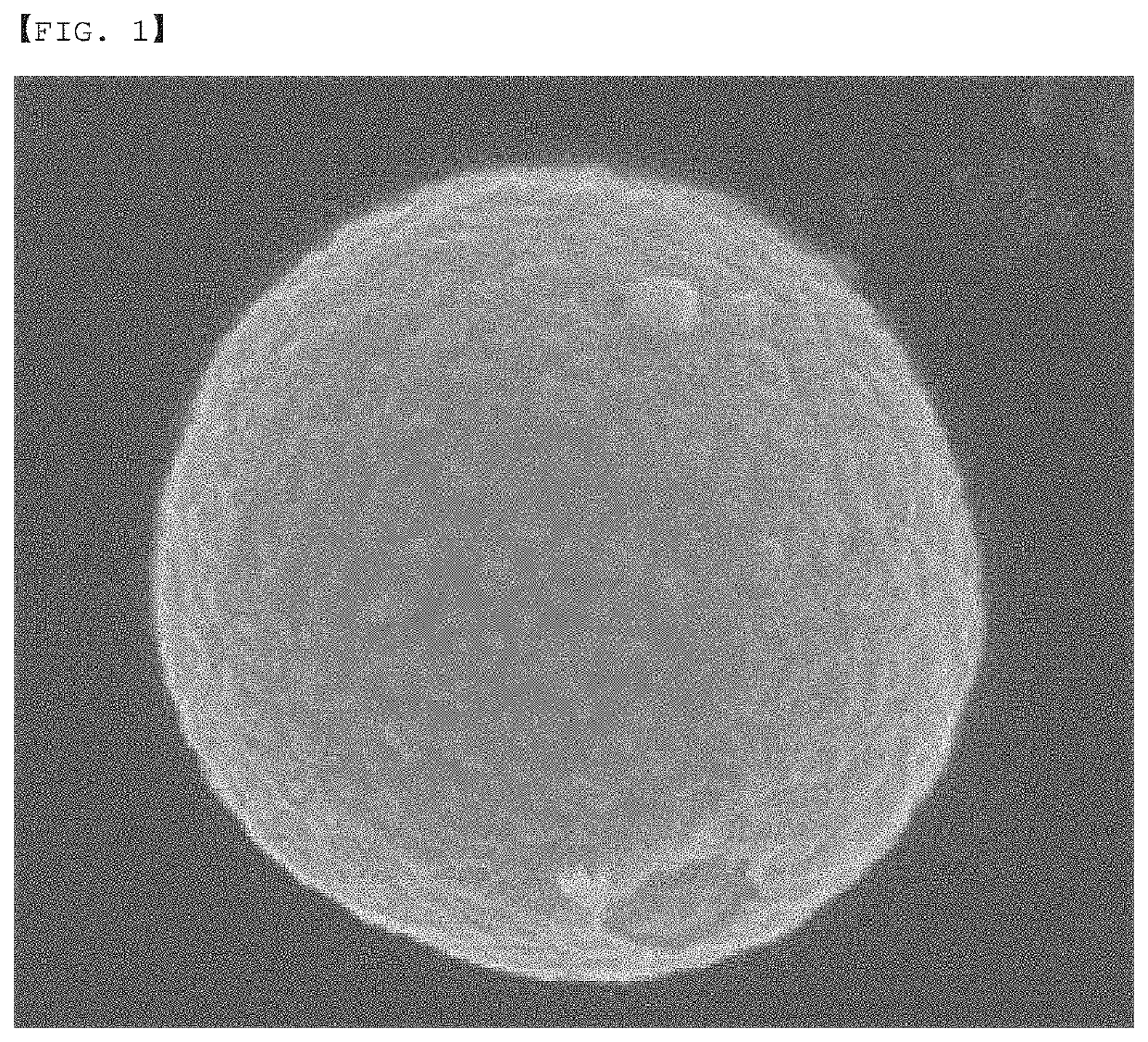

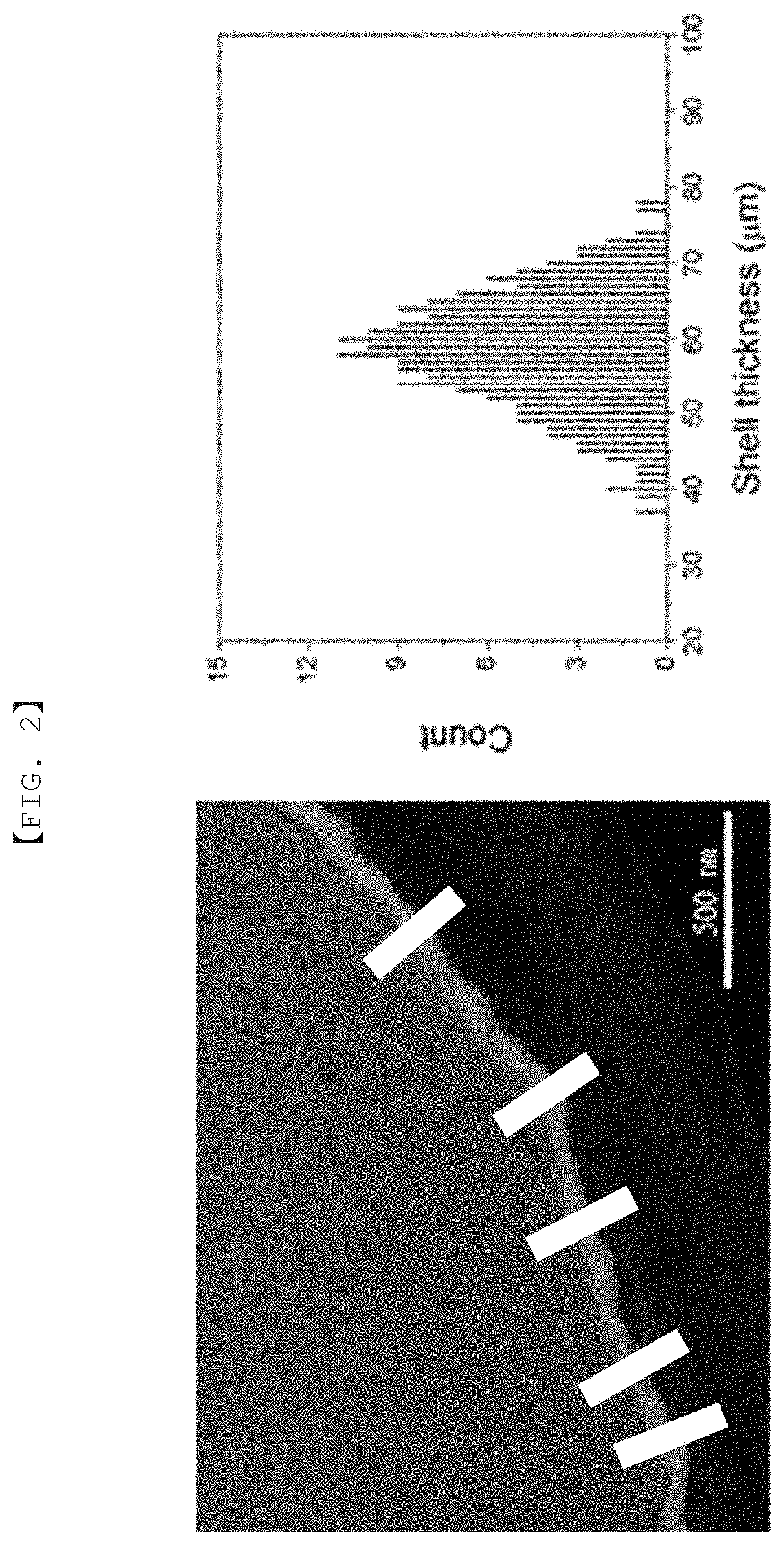

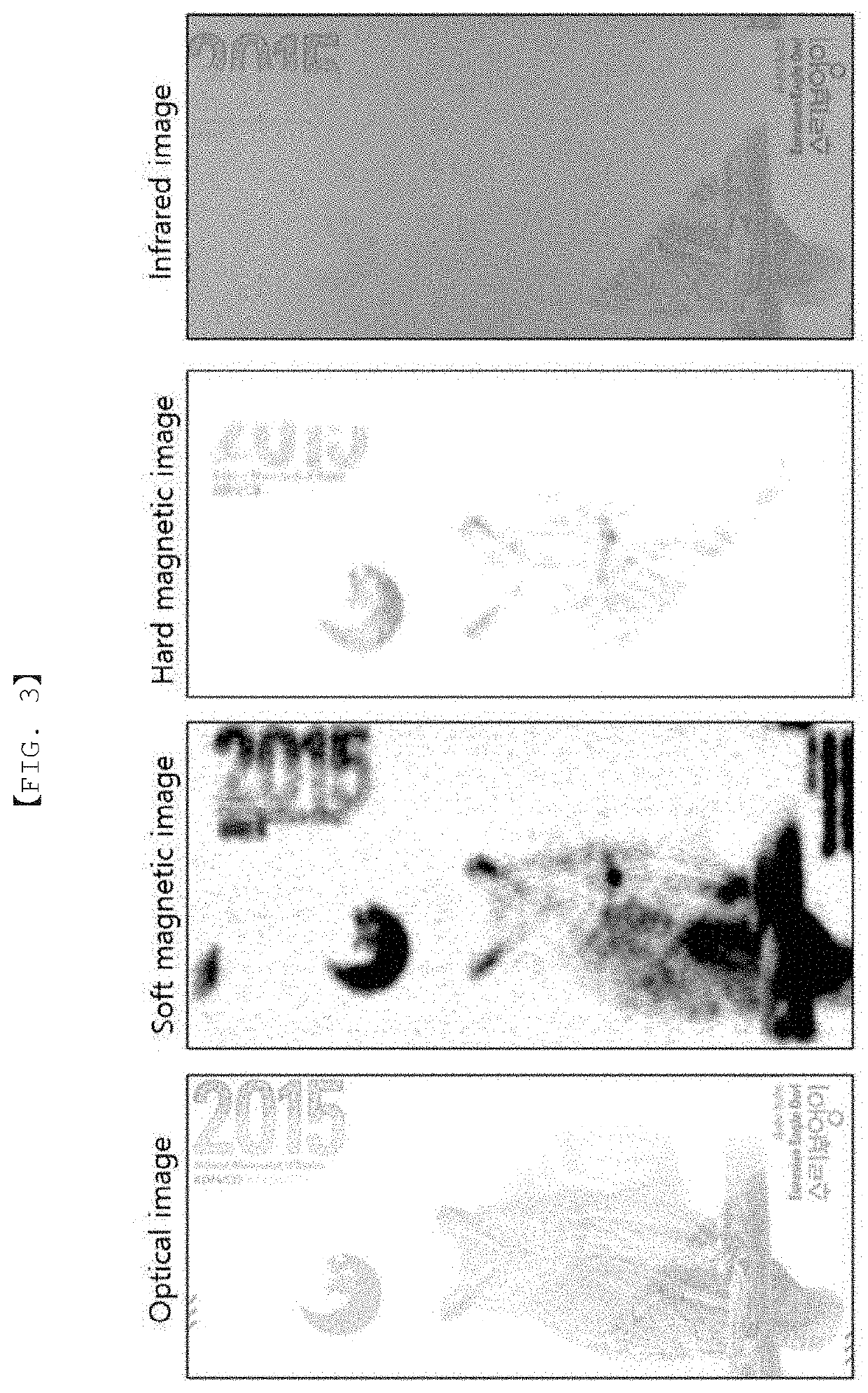

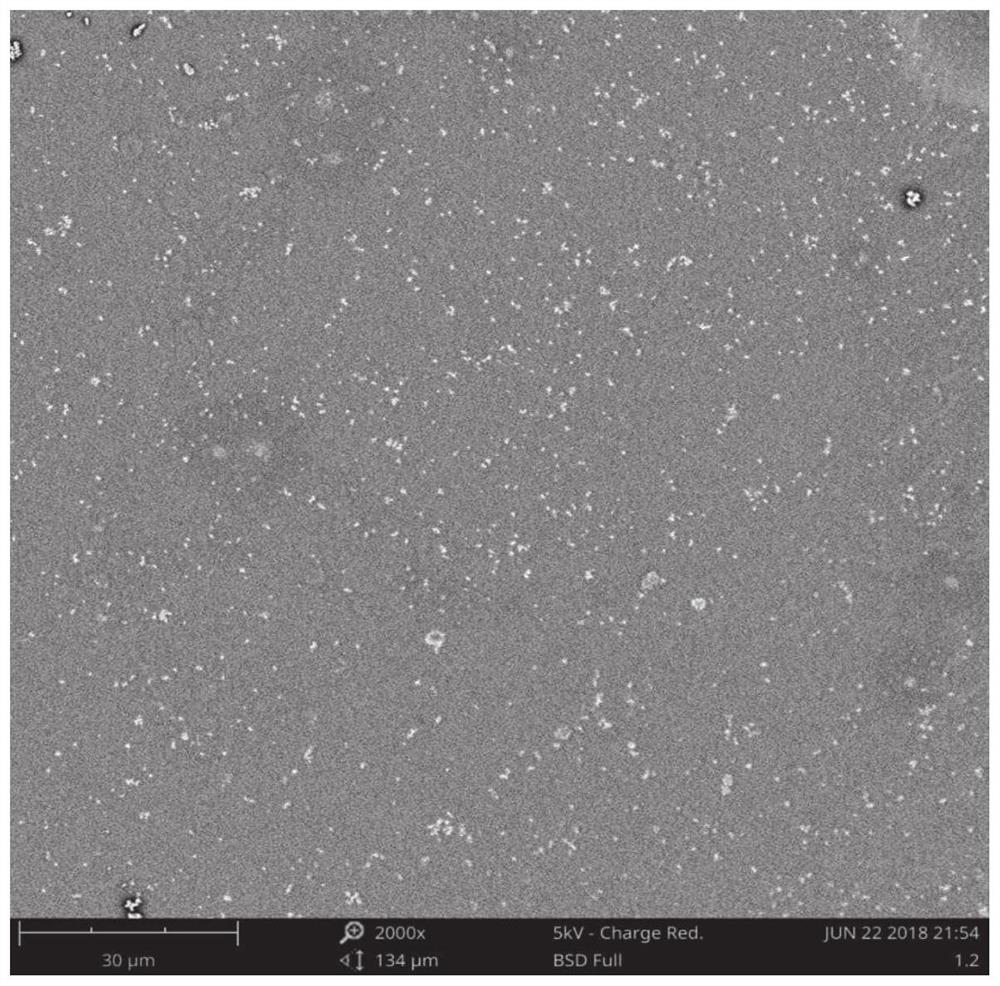

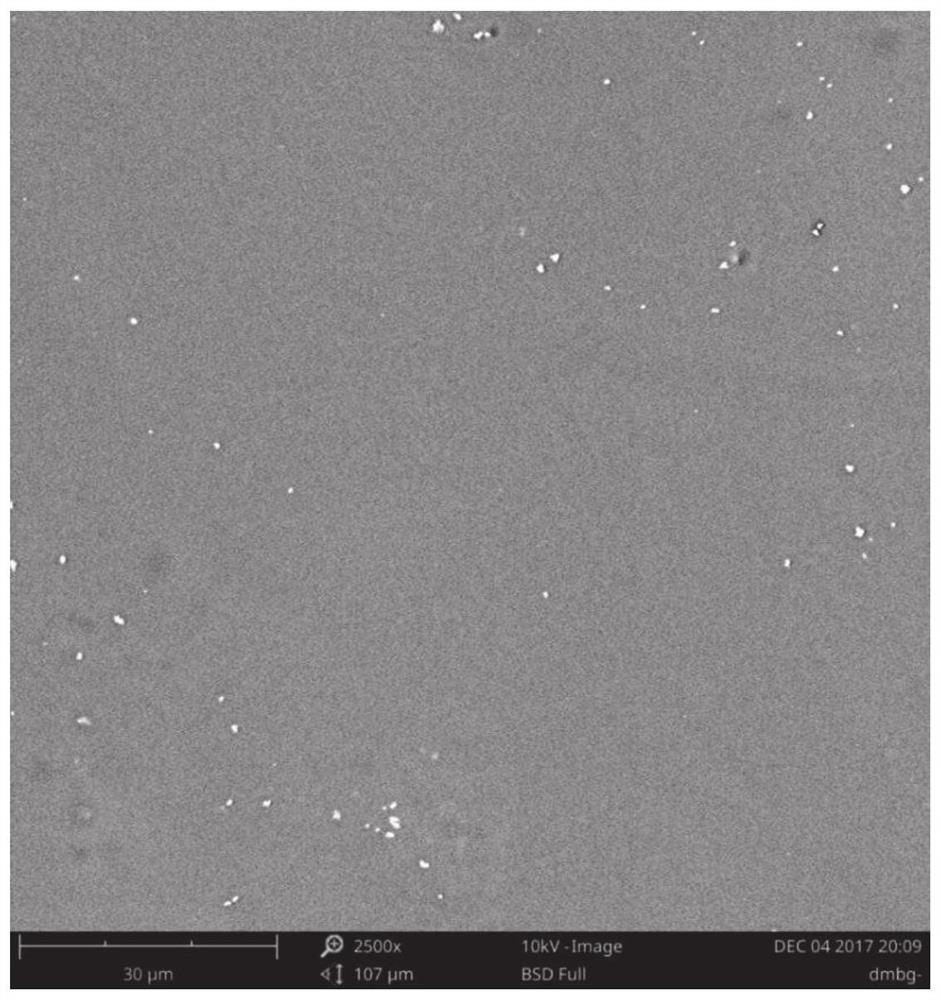

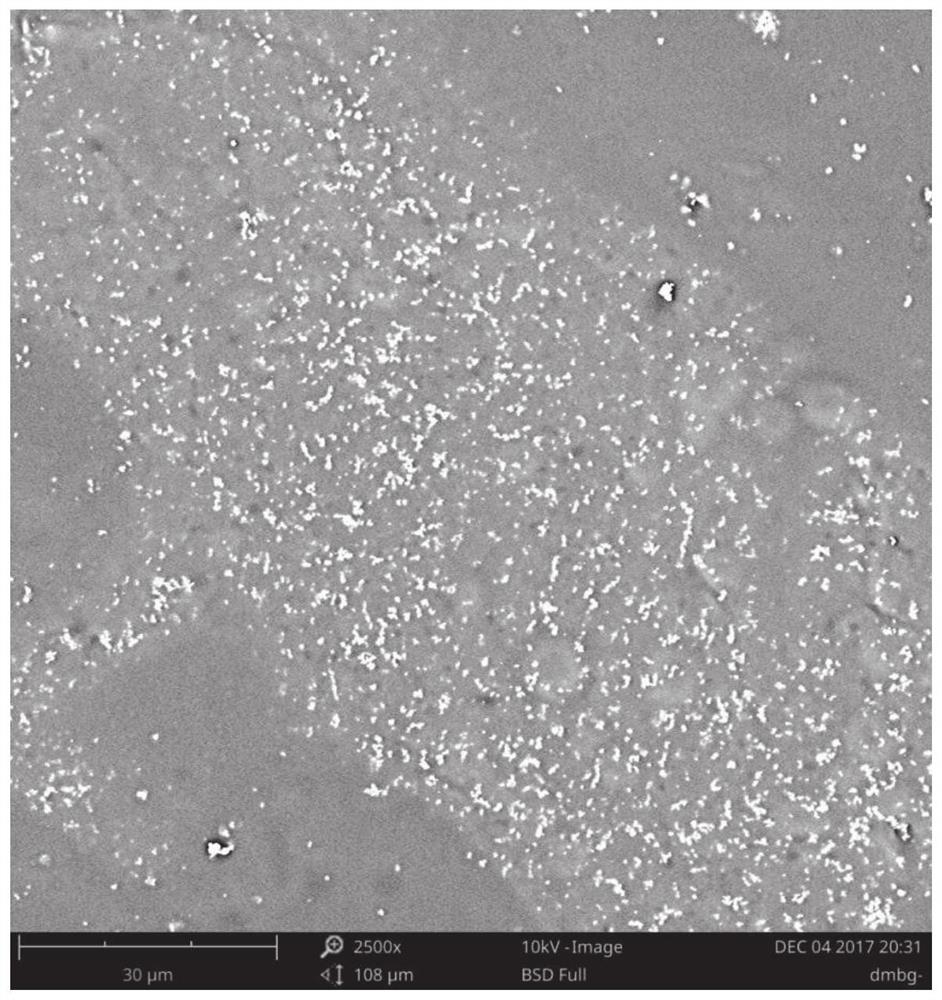

Alnico-Based Magnetic Particles for Security Ink

InactiveUS20200391285A1Improve securityMagnetic homogeneityTransportation and packagingMetal-working apparatusCondensed matter physicsCore Particle

AlNiCo-based magnetic particles according to the present invention are hard magnetic particles each including: a core particle containing Al, Ni, and Co; and an inorganic shell enclosing the core particle. The core particle is an ultra-fine particle having D50 of smaller than 12 μm, D50 being particle size corresponding to 50% in the core particle diameter cumulative distribution.

Owner:KOREA MINTING SECURITY PRINTING & ID CARD OPERATING CORP

Quasi magnetic monopole model

InactiveCN102867447BMagnetic homogeneityReduce combination gapPermanent magnetsEducational modelsMagnetic monopoleHollow core

The invention relates to a quasi magnetic monopole model and belongs to the technical field of physics application. A hollow hemispherical permanent magnet is manufactured by variable magnetic shaft orientation pressing, forming, sintering and magnetizing; a hollow spherical permanent magnet is formed by butting and combining two hollow hemispherical permanent magnets; high magnetic permeability materials are arranged on the inner and outer surfaces of the hollow spherical permanent magnet; the outer edge of the hemispherical bottom of the hollow hemispherical permanent magnet has inverted chamfering; and variable magnetic shaft orientation magnetizing is performed at the inverted chamfering. According to the quasi magnetic monopole model, a stray heteropolar magnetic field at the periphery of the magnetic monopole is eliminated, so that the monopole on the outer surface is uniform in magnetic field, and a magnetic monopole model which is strict and practical is manufactured.

Owner:崔实

Rotary position sensor

PendingCN114166104AMagnetic homogeneitySmall magnetic field distortionElectric/magnetic position measurementsUsing electrical meansRotary switchEngineering

The invention discloses a rotary position sensor, which belongs to the technical field of position sensing, and is characterized by comprising a front shell, a rear shell and a controller, the front shell comprises a base block, a cylinder part, a supporting block and two arc-shaped plates; the end face of the side, close to the rear shell, of the supporting block is fixedly connected with a convex fixed ruler. The bottom surface of the convex fixed ruler is connected with a concave sliding ruler in a sliding manner; a rotating body and a linkage body are embedded in the inner wall of the cylinder part; one end of the linkage body is joggled with the rotating body, the other end of the linkage body is fixedly connected with a screw rod, the outer wall of the screw rod is sleeved with a nut, and the outer wall of the screw rod is meshed with the inner wall of the nut; a round groove is formed in the end face of the side, away from the linkage body, of the nut, an L-shaped rod is movably connected into the round groove, and the top end of the L-shaped rod is fixedly connected with the concave sliding ruler. The device is mainly used for multi-gear rotary input or a multi-gear rotary switch, can freely and continuously rotate, is simple in structure, reliable in operation and accurate in measurement, and can effectively eliminate temperature influence so as to realize long-term use.

Owner:LESHAN NORMAL UNIV

An organically encapsulated magnetic nanoparticle composite bone scaffold and its preparation method

InactiveCN110801536BImprove mechanical propertiesMagnetic homogeneityAdditive manufacturing apparatusPharmaceutical delivery mechanismSelective laser sinteringMagnetite Nanoparticles

The invention belongs to the field of a bone bracket material, and particularly discloses an organic-encapsulated magnetic nanoparticle composite bone bracket. The organic-encapsulated magnetic nanoparticle composite bone bracket is prepared by selective laser sintering on mixed raw materials containing organic-modified magnetic nanoparticles and polymers arranged in the mixed raw materials, wherein the organic-modified magnetic nanoparticles comprise magnetic nanoparticles and an organic compound coating the surfaces of the magnetic nanoparticles. The inventor creatively finds that the organic compound encapsulated magnetic nanoparticles and the polymers have obvious cooperativity, and by a selective laser sintering method, the properties of the bone bracket can be obviously improved, forexample, the hydrophobicity of the bone bracket can be improved, and the stretching and compressing strength can be improved. In addition, the biocompatibility can also be improved, and properties ofskeleton growth and the like can be improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com