Patents

Literature

42results about How to "Formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparation of organofluoro compounds in alcohol solvents

InactiveUS20100113763A1Inhibition formationReduced responseIsotope introduction to heterocyclic compoundsIn-vivo radioactive preparationsAlcoholIsotope

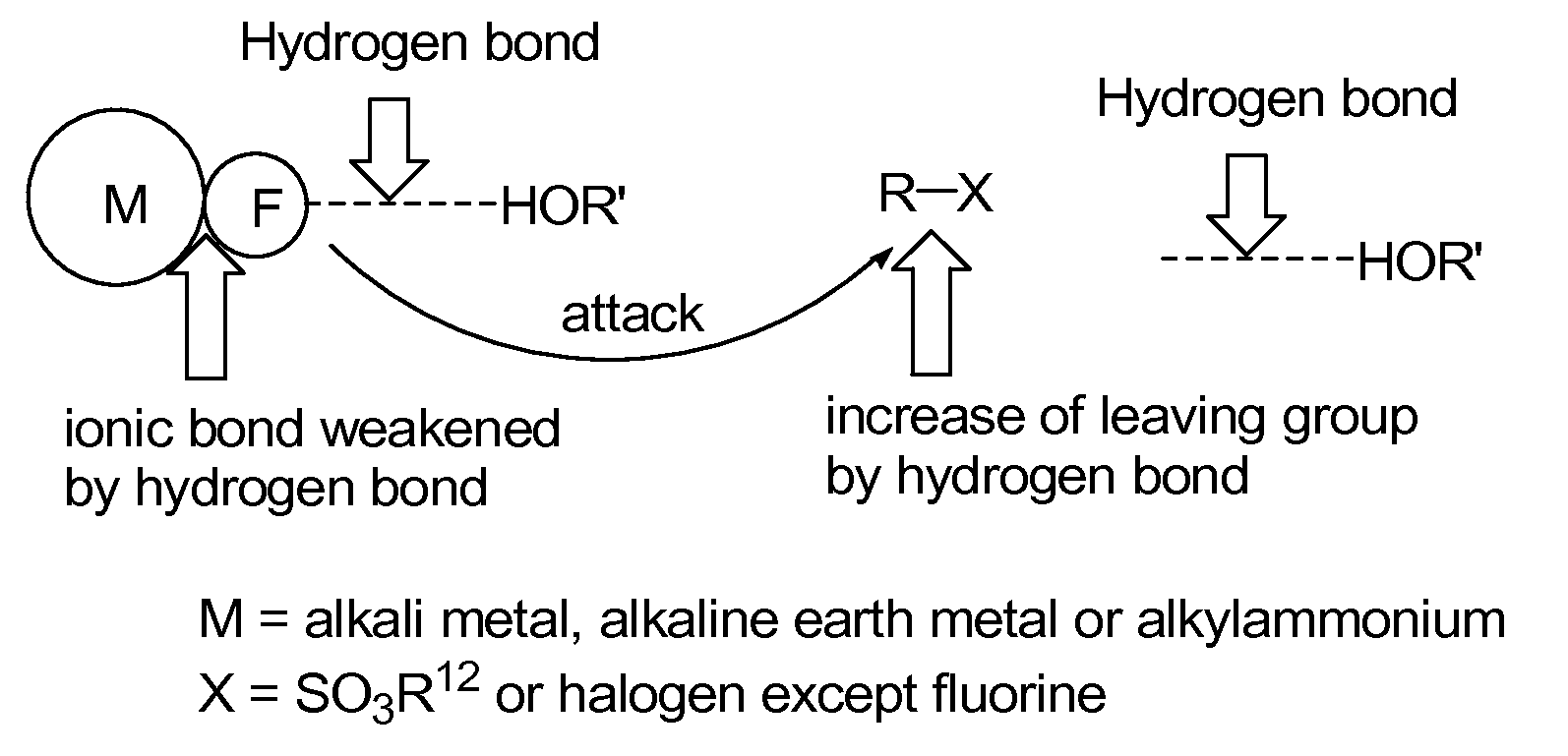

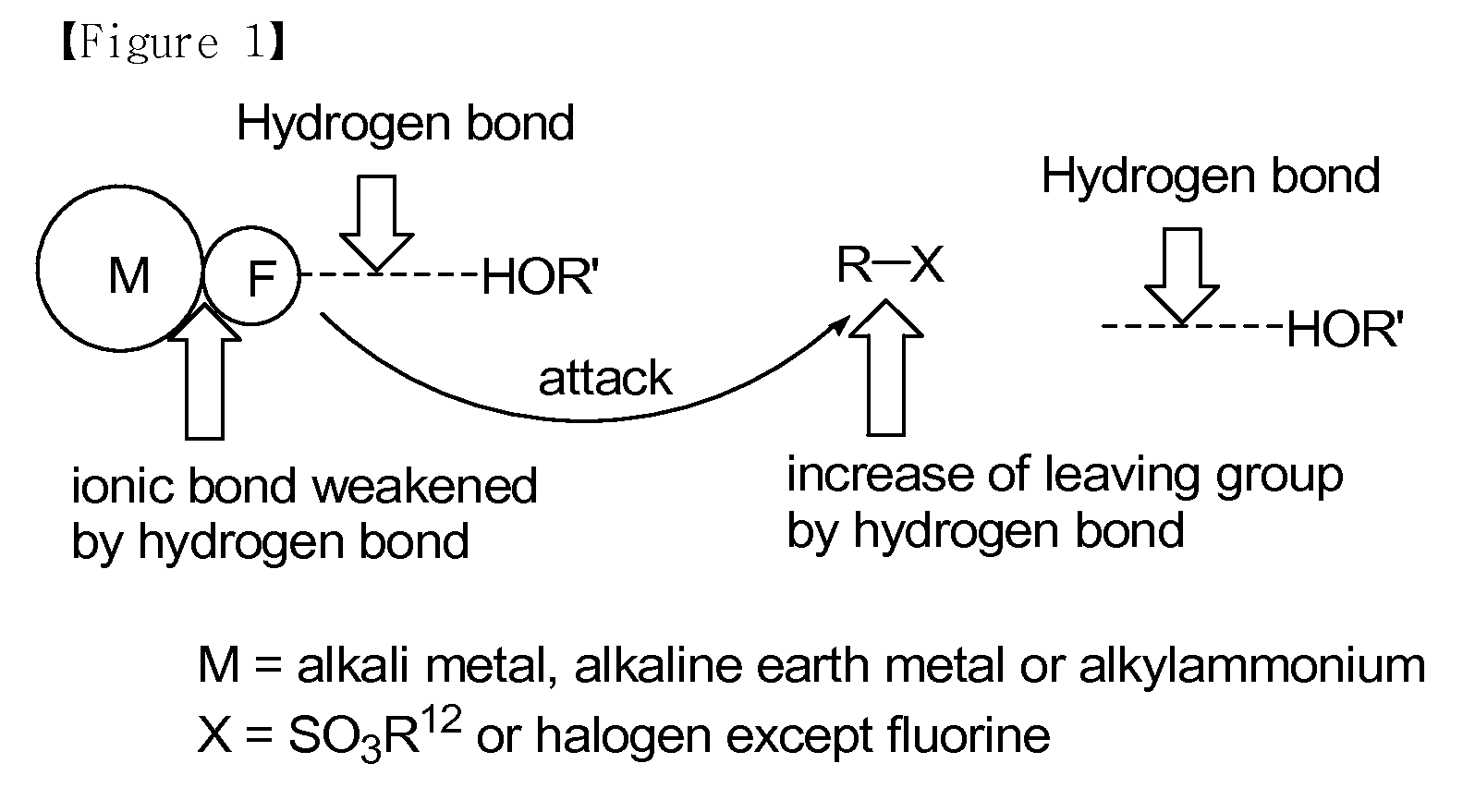

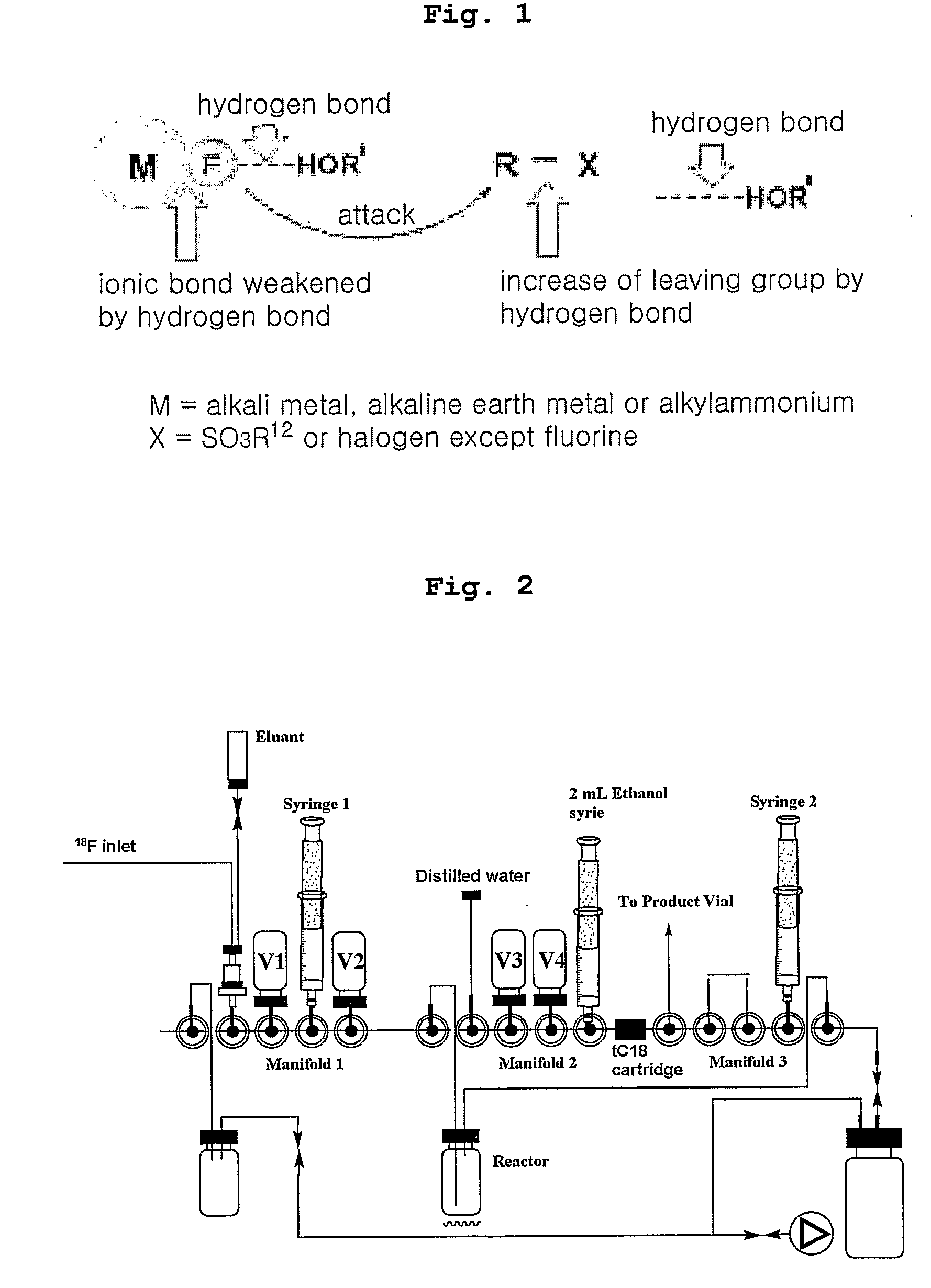

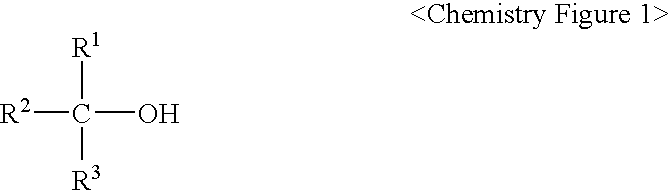

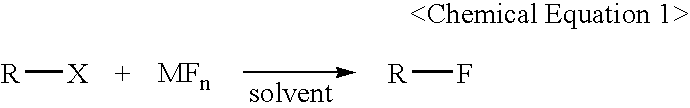

The present invention relates to a method for preparation of organofluoro compounds containing radioactive isotope fluorine-18. More particularly, the present invention relates to a method for preparation of organofluoro compound [18F]florbetaben or [18F]AV-45 having <Chemistry Formula 11> and <Chemistry Formula 12>, respectively, by reacting fluorine salt containing radioactive isotope fluorine-18 with alkyl halide or alkyl sulfonate in the presence of alcohol of Chemistry Formula 1 as a solvent to obtain high yield of organofluoro compound. Synthesis reaction according to the present invention may be carried out under mild condition to give high yield of the organofluoro compounds and the reaction time is decreased, and thereby is suitable for the mass production of the organofluoro compounds.

Owner:FUTURECHEM +1

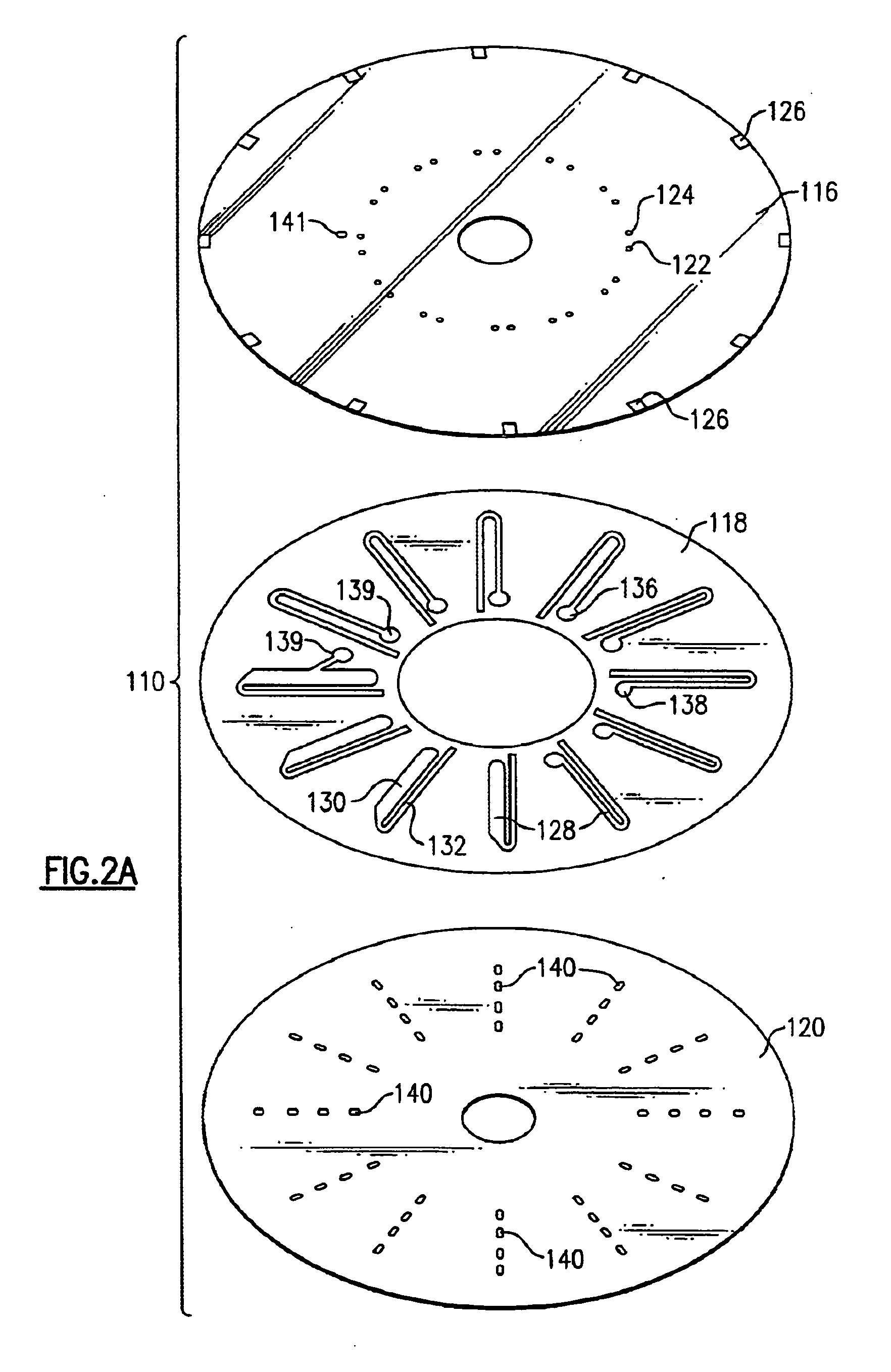

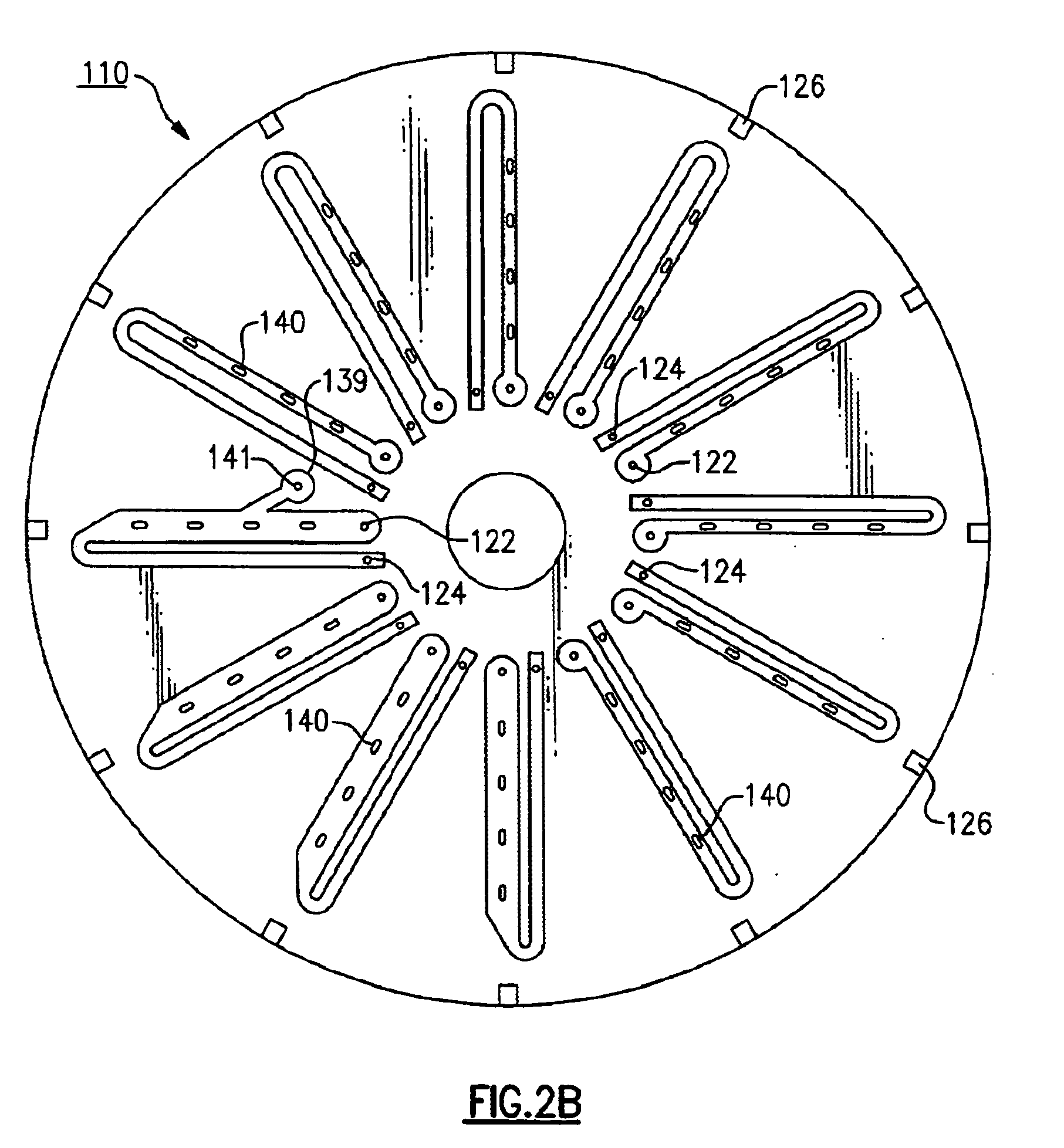

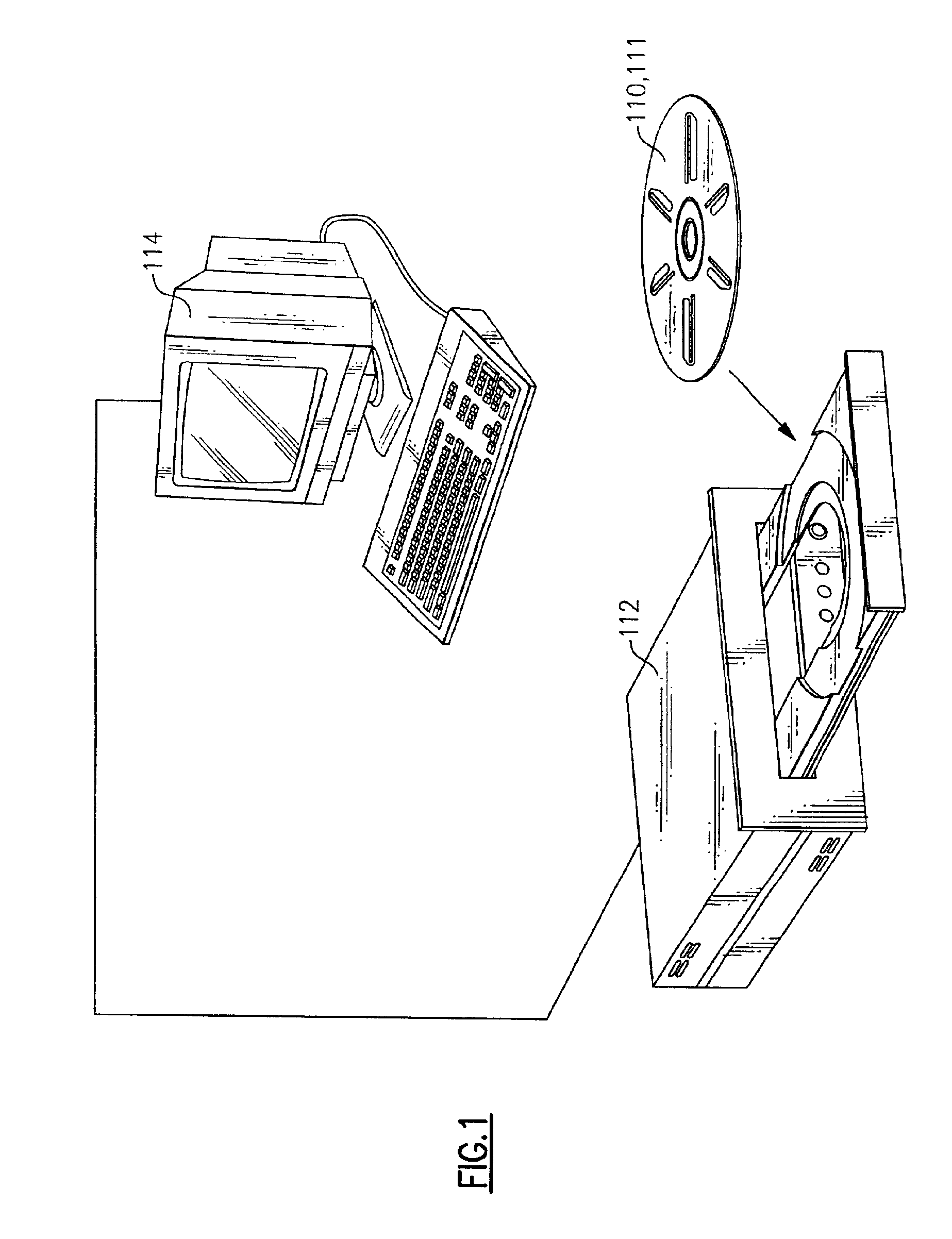

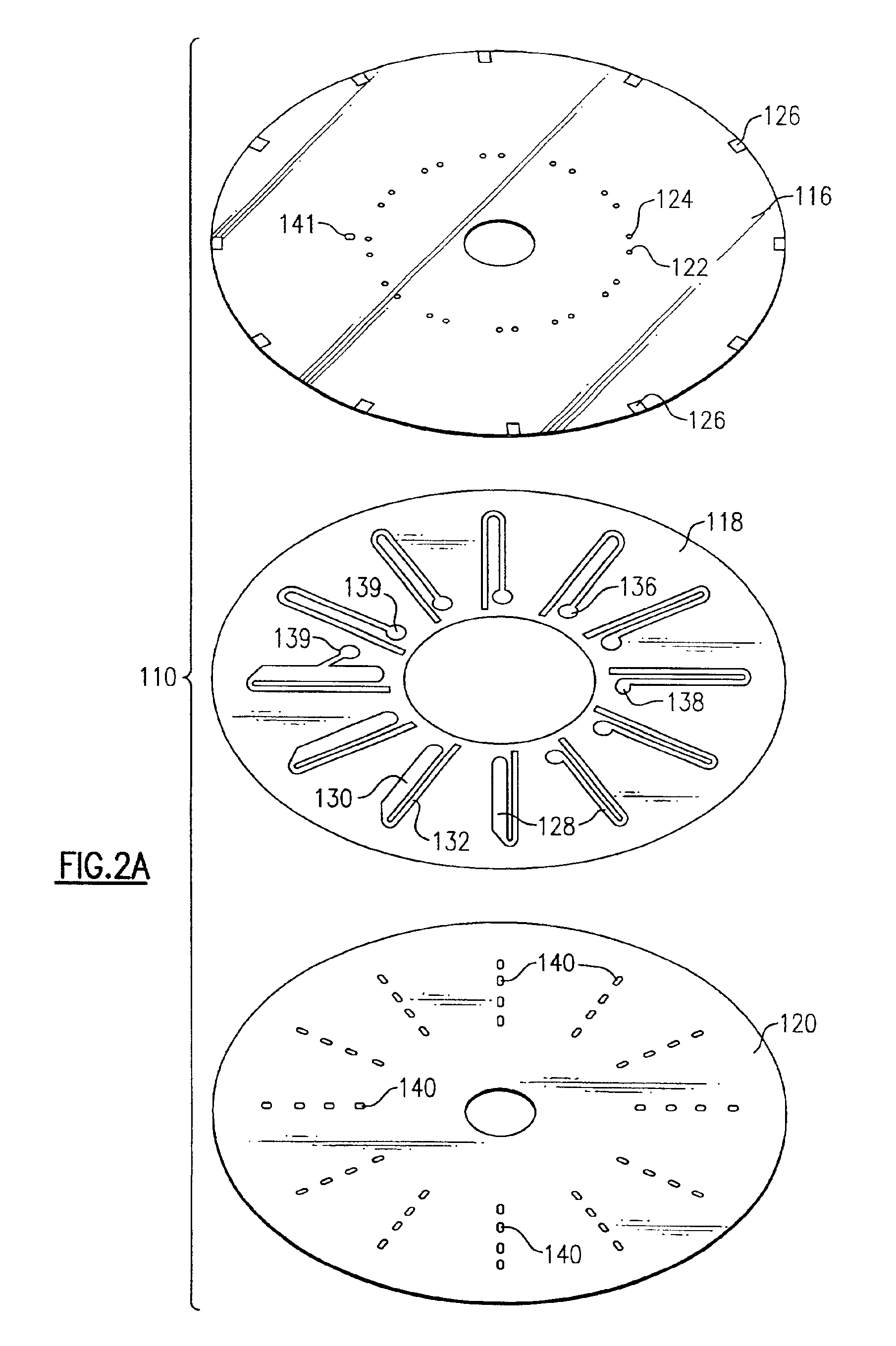

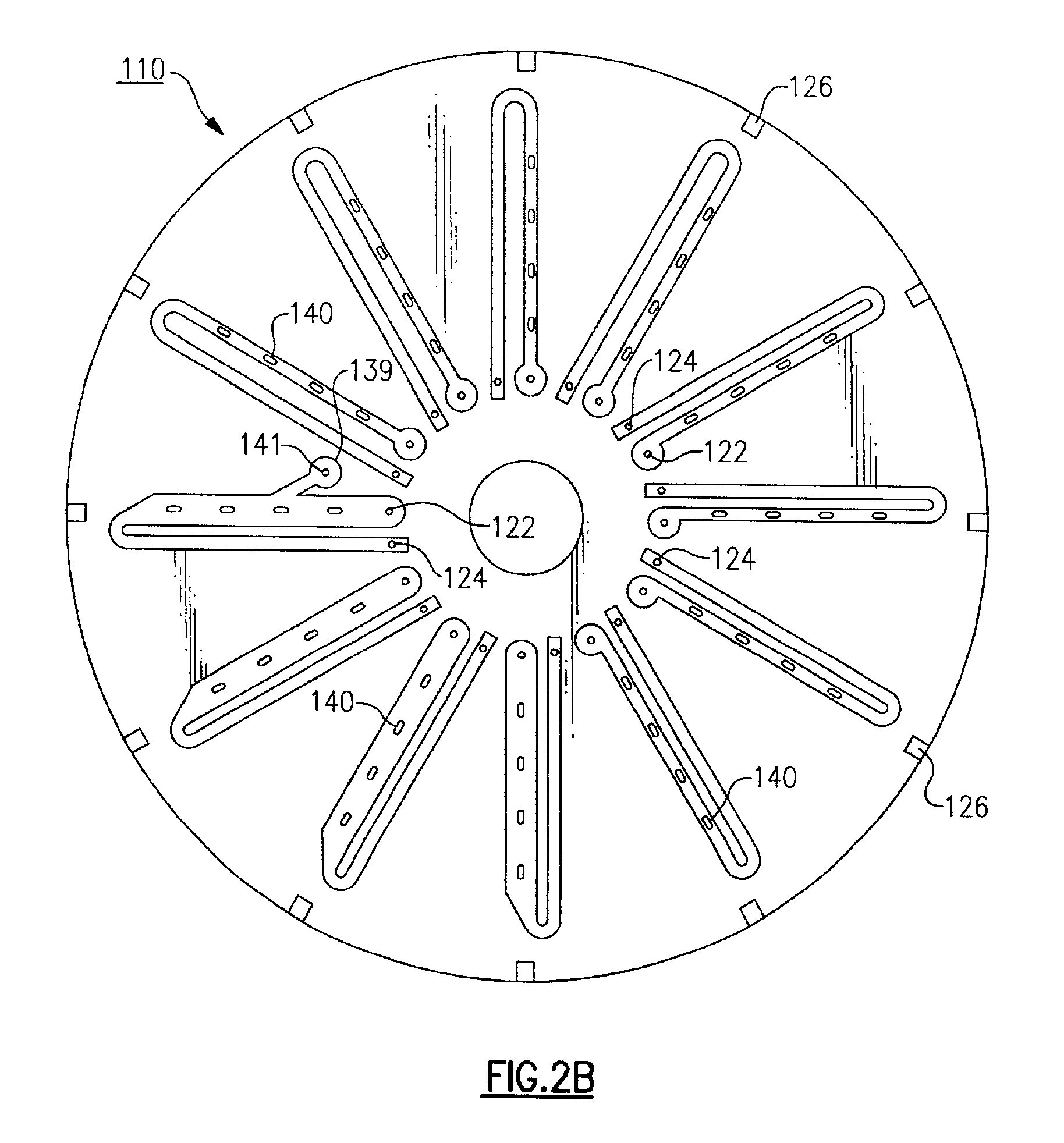

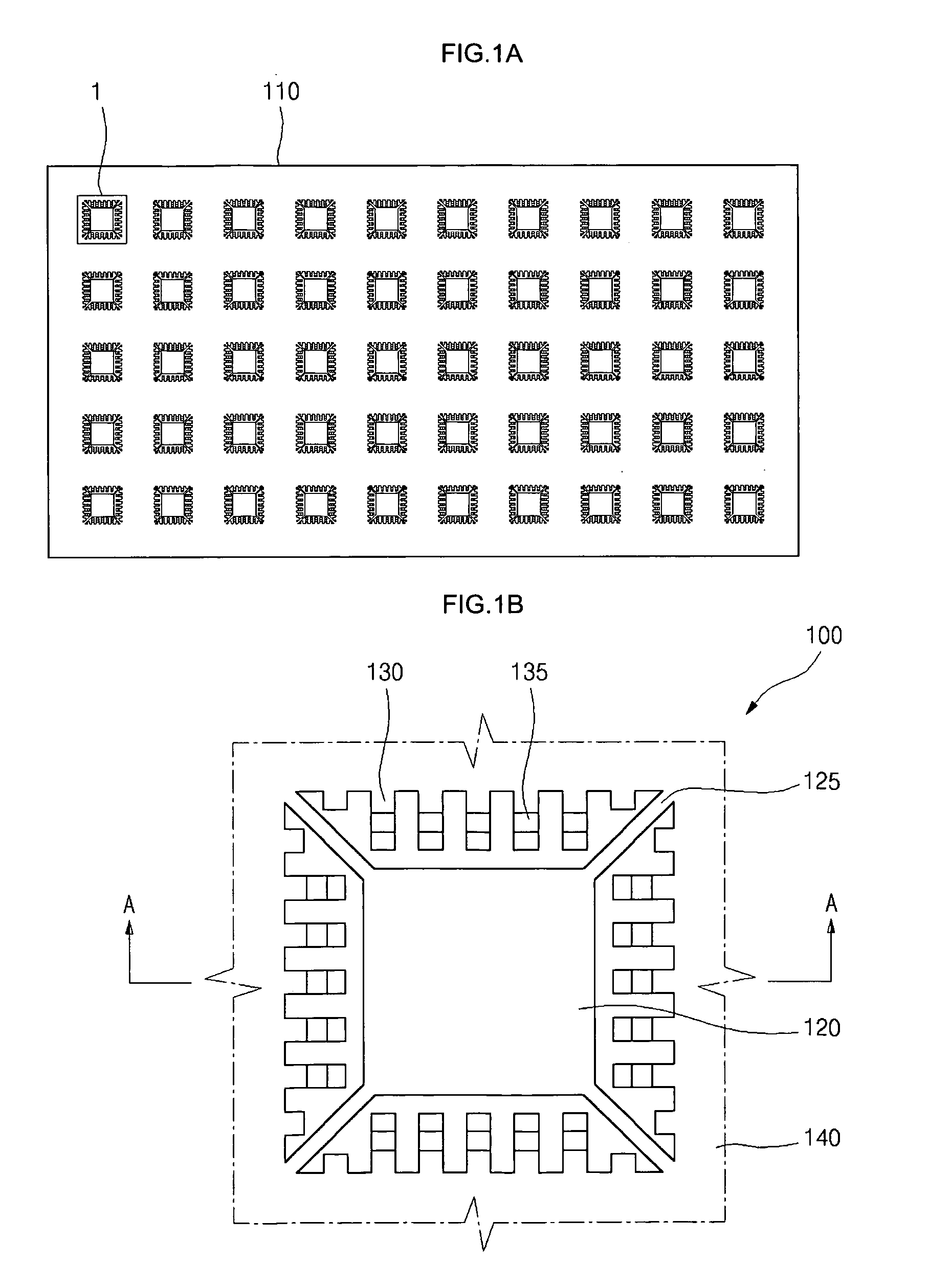

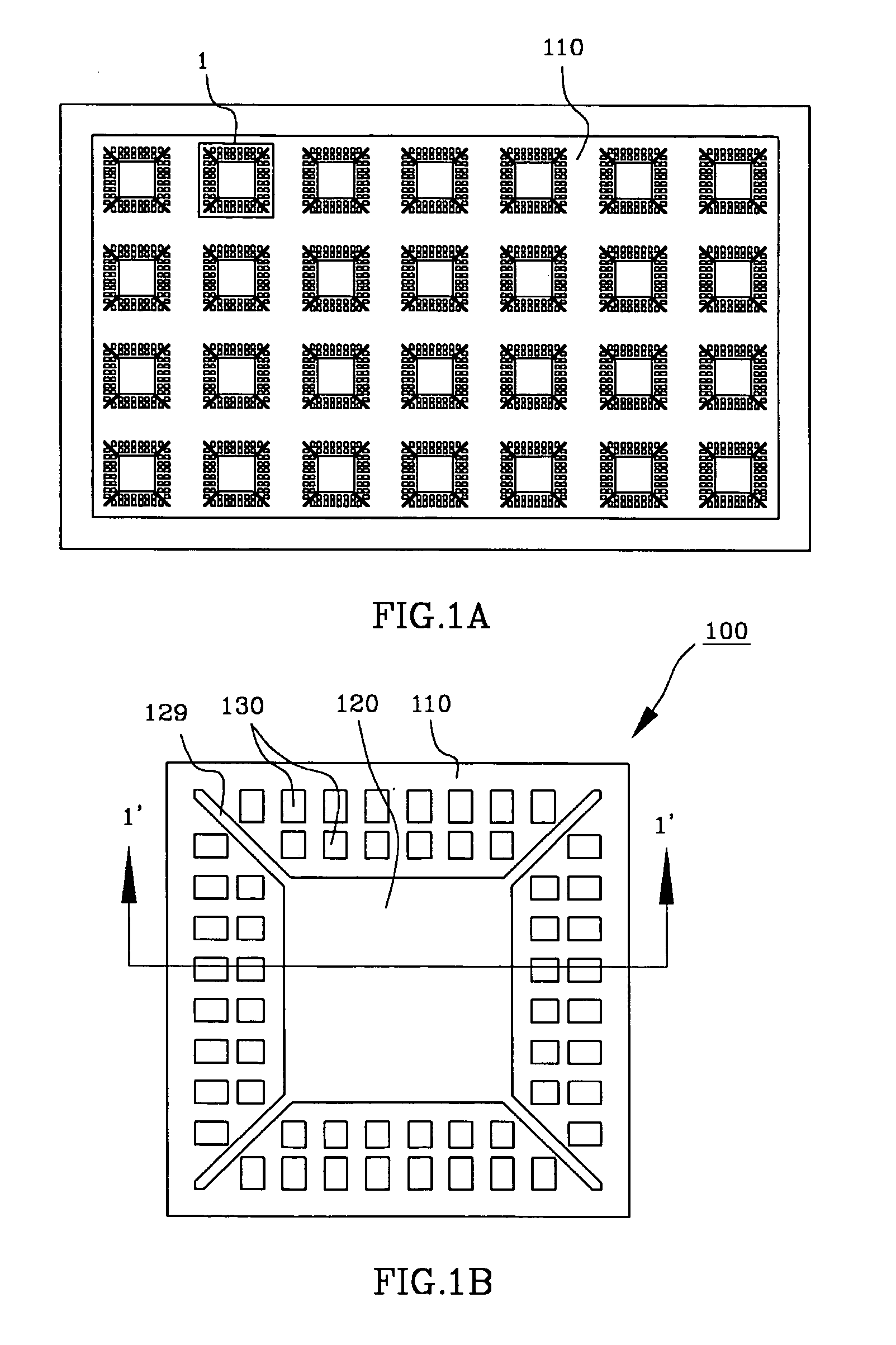

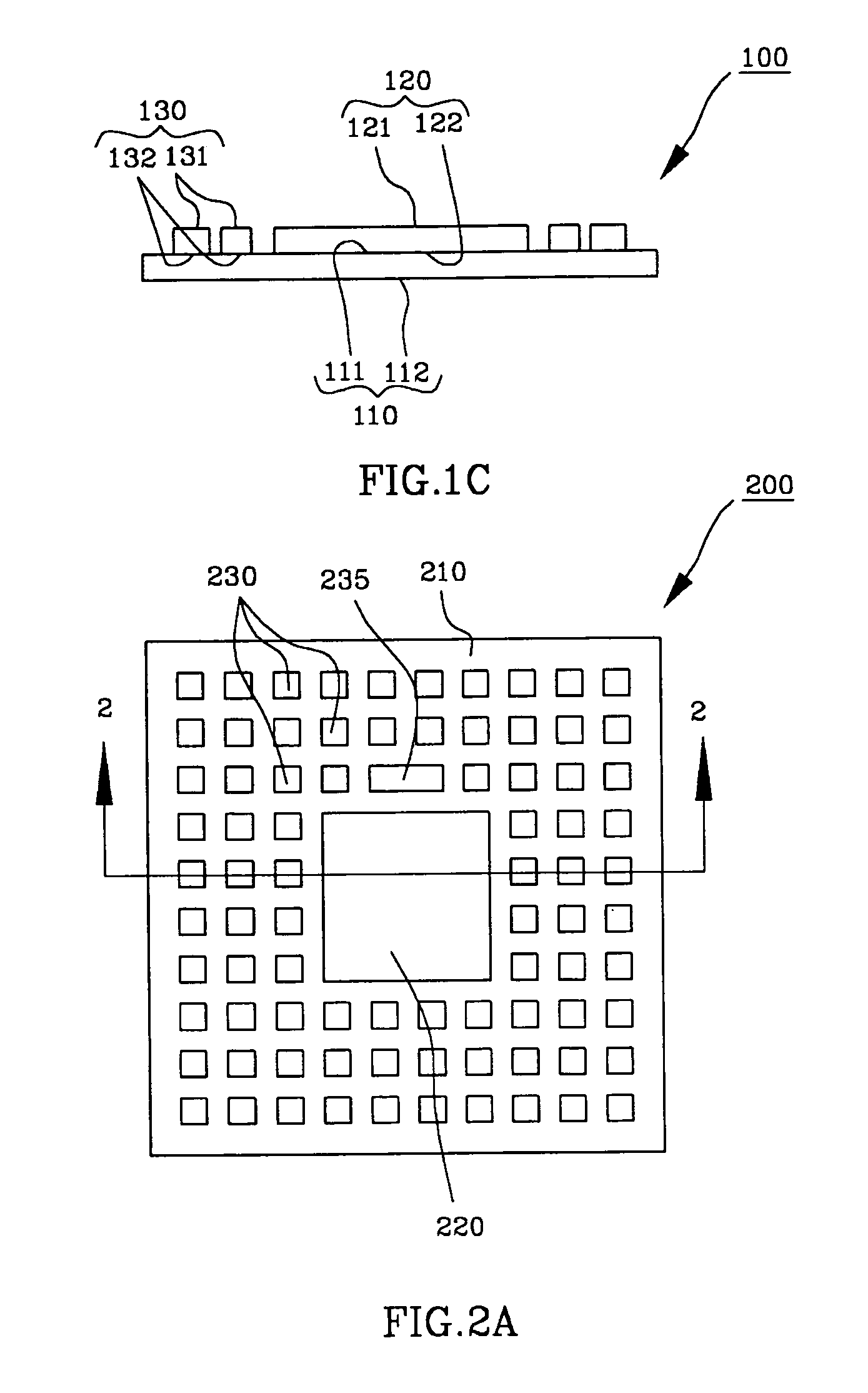

Surface assembly for immobilizing DNA capture probes in genetic assays using enzymatic reactions to generate signal in optical bio-discs and methods relating thereto

InactiveUS20060078935A1FormationEfficiently projectedMaterial nanotechnologyBioreactor/fermenter combinationsLight spectrumAssay

The invention relates to methods and systems for use of bio-discs in quantifying an amount or concentration of one or more substances that are present in a biological sample. The system includes an optical disc having one or more samples deposited thereon, an optical element configured to emit and divert radiation onto the samples and components for measuring spectral change of the compound and determining an amount or concentration of one or more target substances. The bio-disc is prepared using a method including providing a membrane that is or can be dimensional to fit within a channel of the bio-disc, applying a reagent on the membrane which is configured to allow the reagent to be released from the membrane into a solution in contact with the membrane, and depositing the membrane in a channel of the bio-disc.

Owner:VINDUR TECH

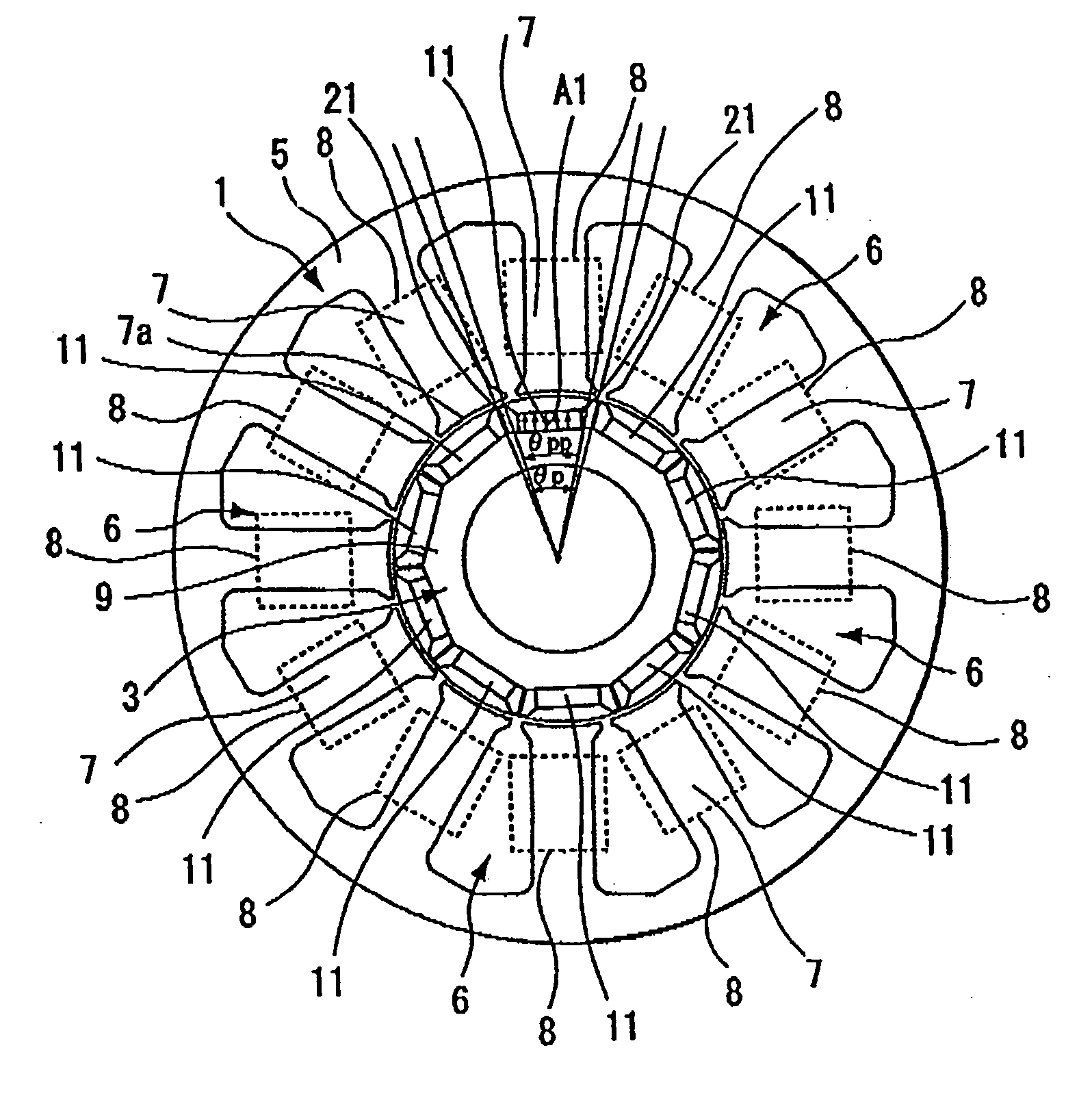

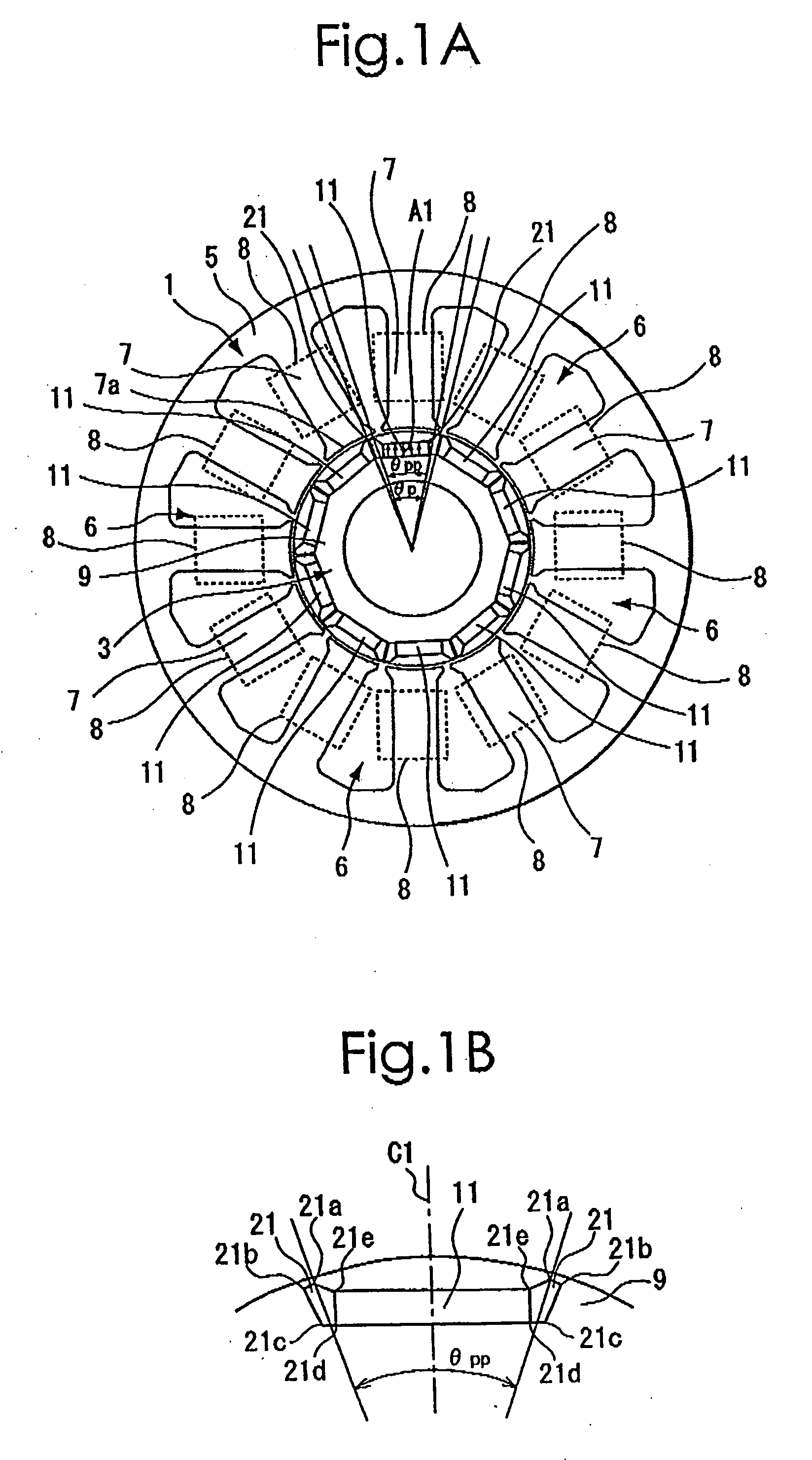

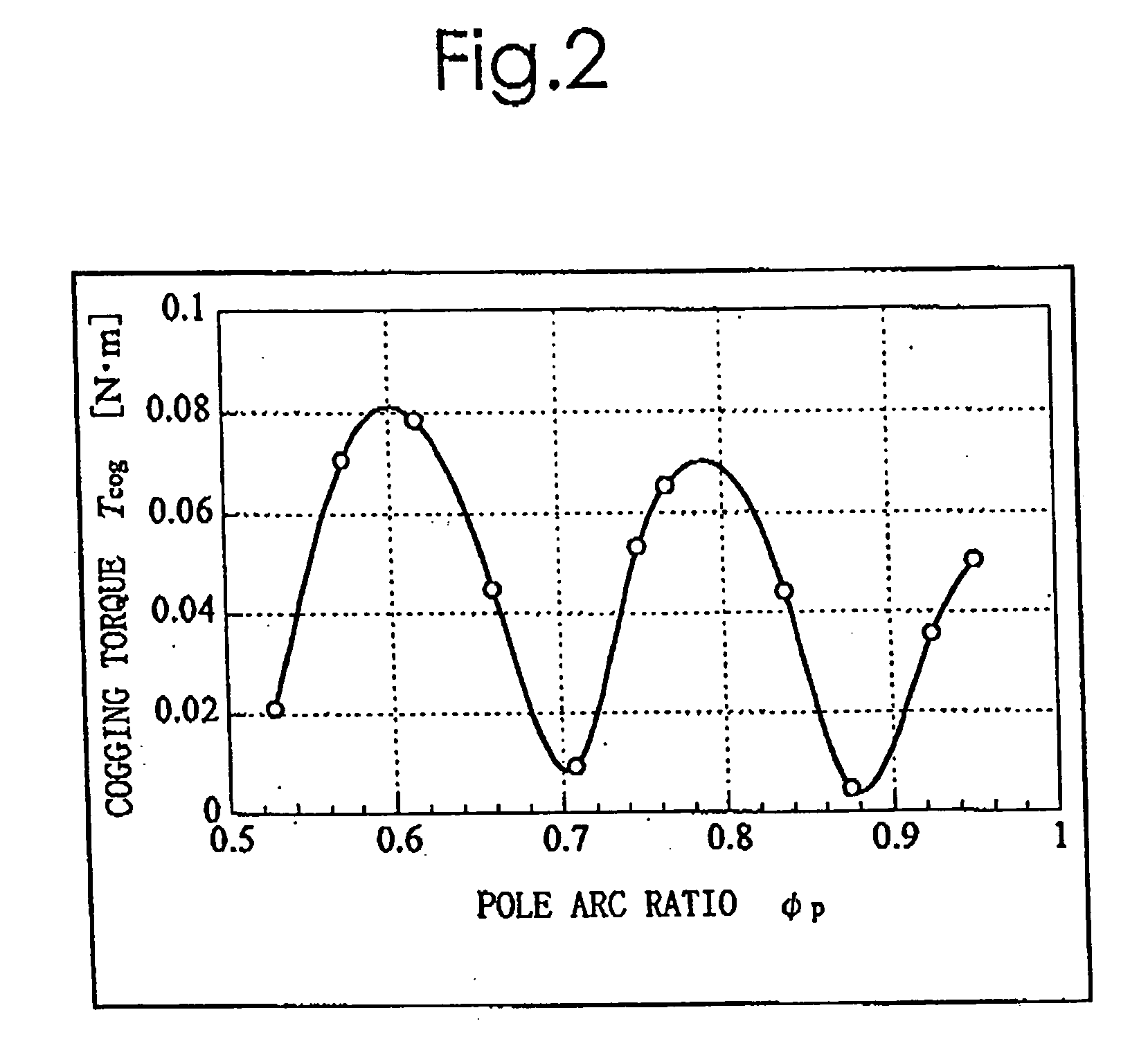

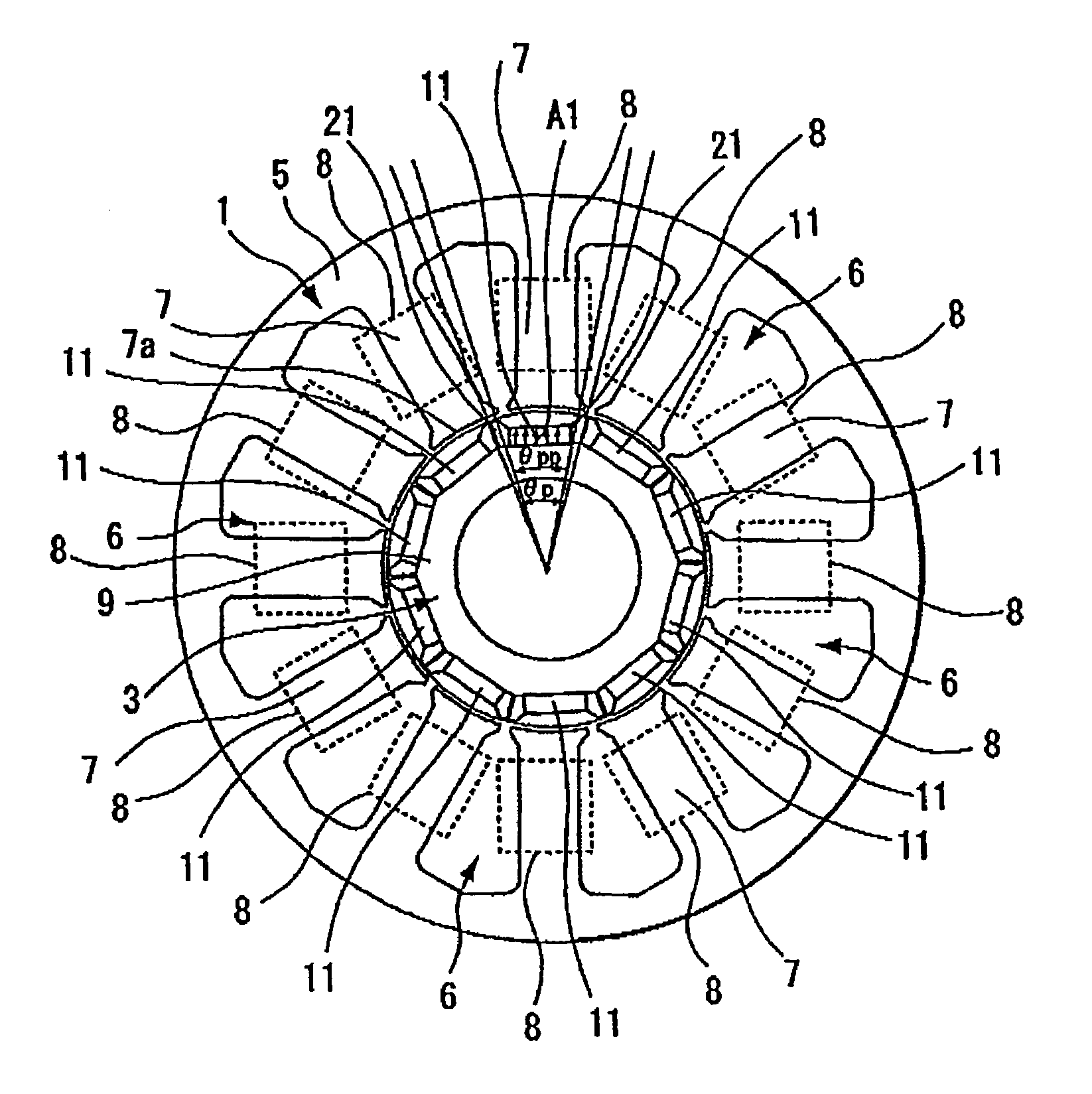

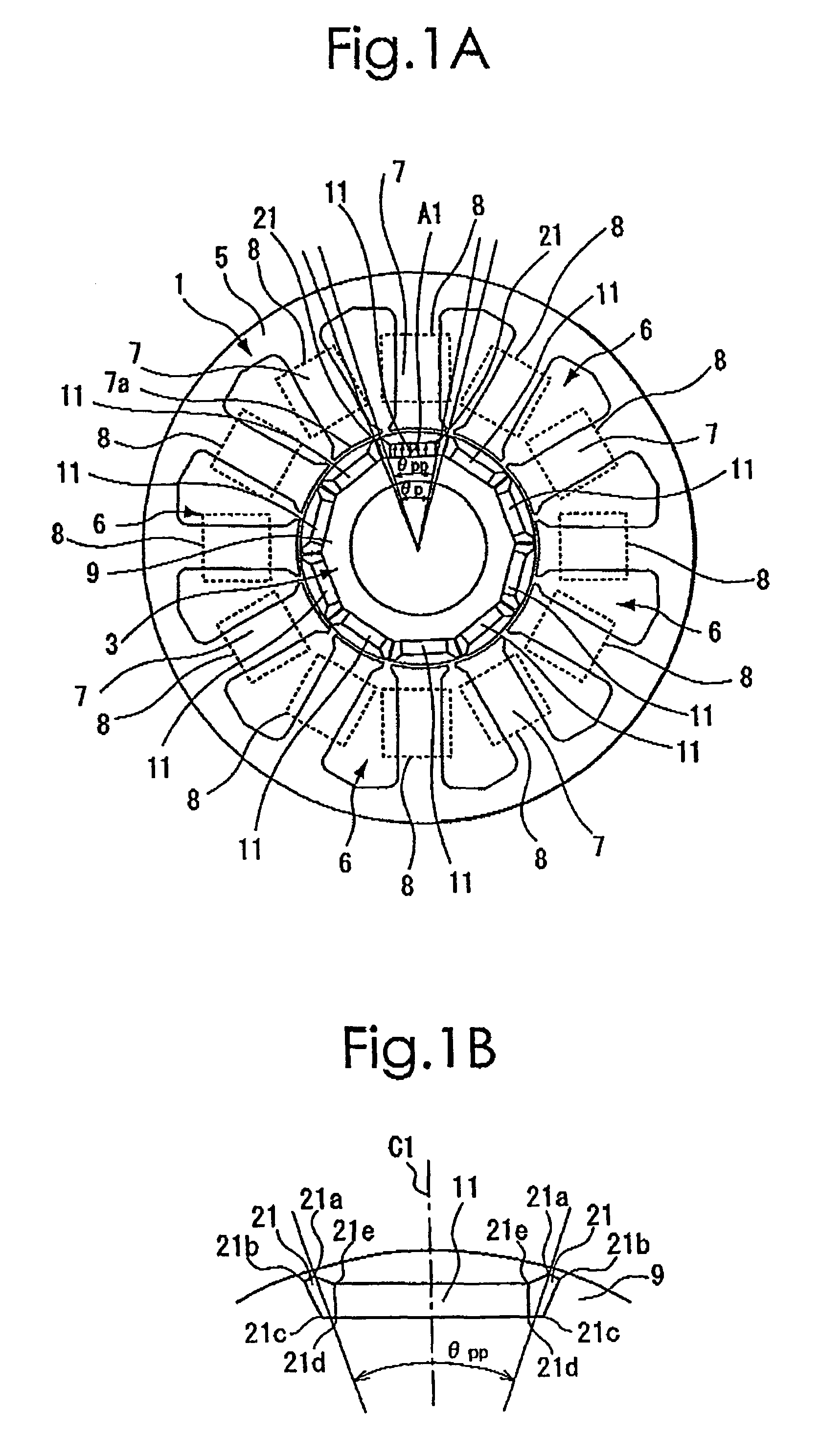

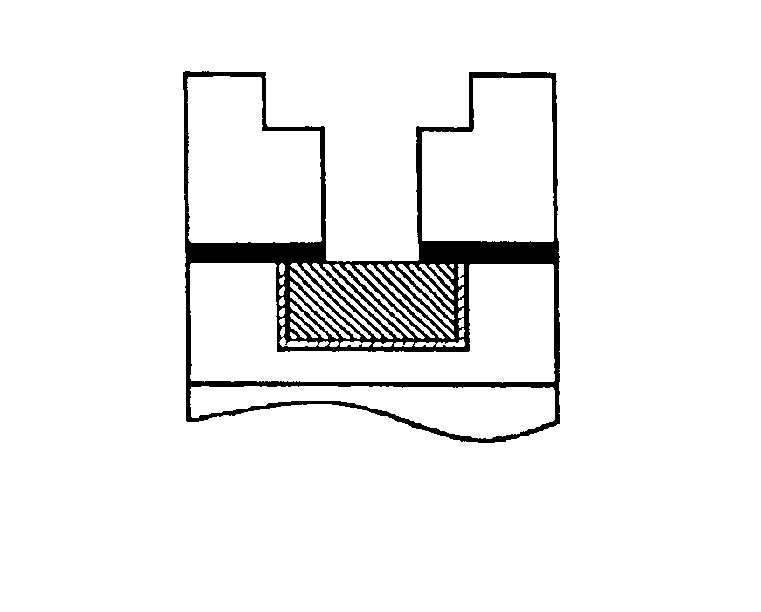

Method of determining pole arc ratio of interior permanent magnet rotary motor and interior permanent magnet rotary motor

InactiveUS20050168089A1Reduce the amount requiredReduce torqueMagnetic circuit rotating partsManufacturing dynamo-electric machinesMagnetic polesControl theory

There is provided an interior permanent magnet rotary motor that can reduce cogging torque and can also reduce the amount of permanent magnet used, without reducing torque. In an interior permanent magnet rotary motor of the present invention having N slots 6 and P permanent magnet magnetic pole sections 11, in which P / N is set in the range of ⅔ to 43 / 45 and Po in a irreducible fraction Po / No of the P / N is set to be an odd number, an pole arc ratio ψp is defined to be the ratio of θpp / θp where an angle between two line segments assumed for a pair of flux barriers 21, each of which connects the center of a rotor core and one of a plurality of corners of the section of each flux barrier that is closest to the surface of the rotor core 9 is indicated by the θpp and an angle obtained by dividing the full circumference angle (360°) of the rotor core by the number of the permanent magnet pole sections is indicated by the θp. Then, the pole arc ratio indicated by Ψp is determined is so as to satisfy the relation of Ψp=2mP / N+P / 4LCM (P, N)−2n, in which LCM (P, N) is the least common multiple between P and N, m and n are arbitrary natural numbers, and the Ψp is larger than zero but smaller than one.

Owner:SANYO DENKI CO LTD

Flux for lead-free solder and soldering Method

ActiveUS20090308496A1Inhibition formationIncrease costPrinted circuit assemblingCooking-vessel materialsPhosphateNitrogen atmosphere

A soldering flux which is suitable as a no-clean post flux in flow soldering and which can prevent the formation of whiskers which tends to occur when soldering electronic parts to a printed circuit board using a lead-free solder (such as Sn-3.0Ag-0.5Cu) having a higher Sn content and a higher melting point than the eutectic solder contains, in addition to a rosin as a base resin and an activator, 0.2-4 mass % of at least one compound selected from acid phosphate esters and derivatives thereof. The formation of whiskers can be more effectively prevented by carrying out soldering in a nitrogen atmosphere.

Owner:SENJU METAL IND CO LTD +1

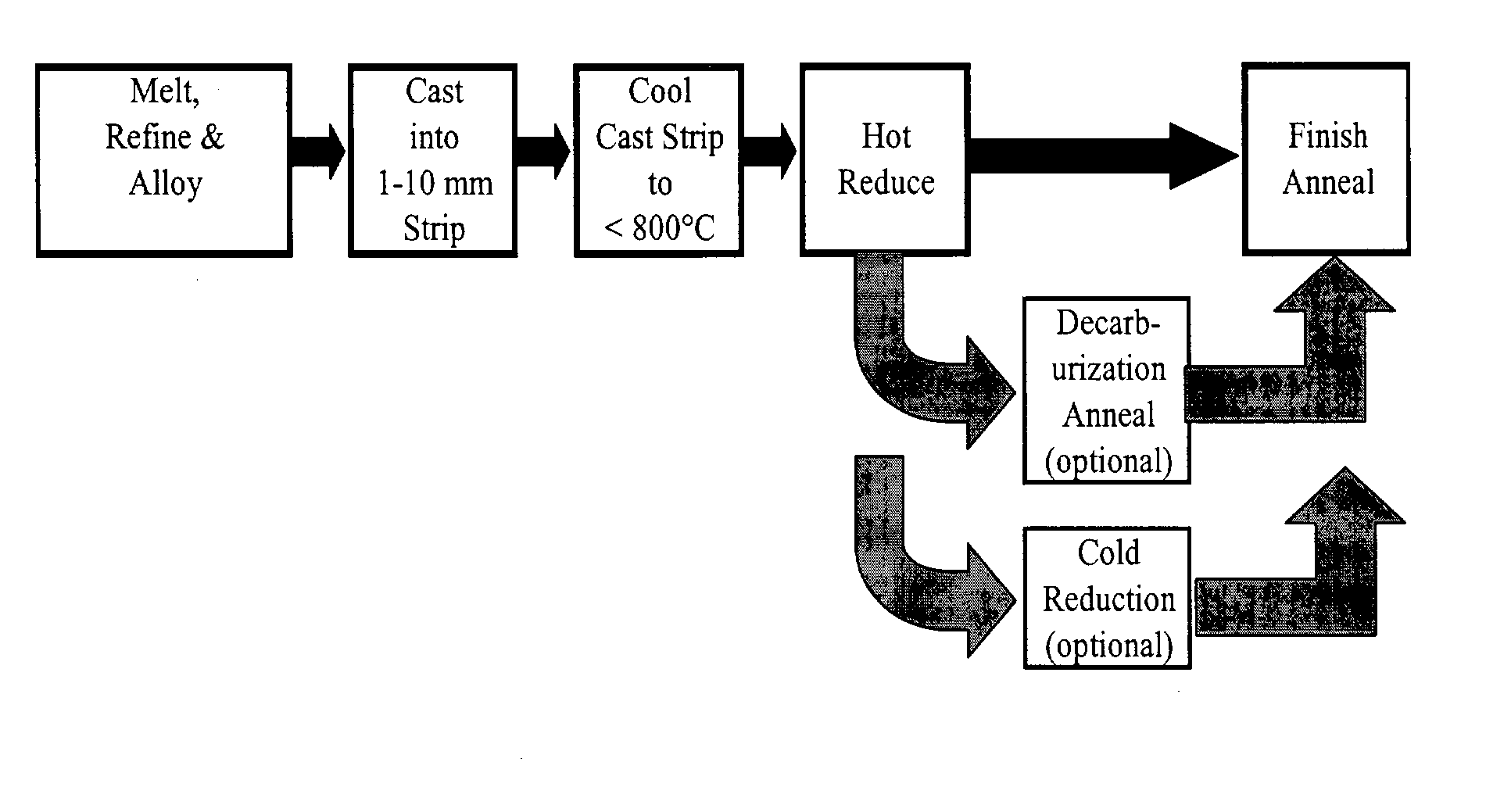

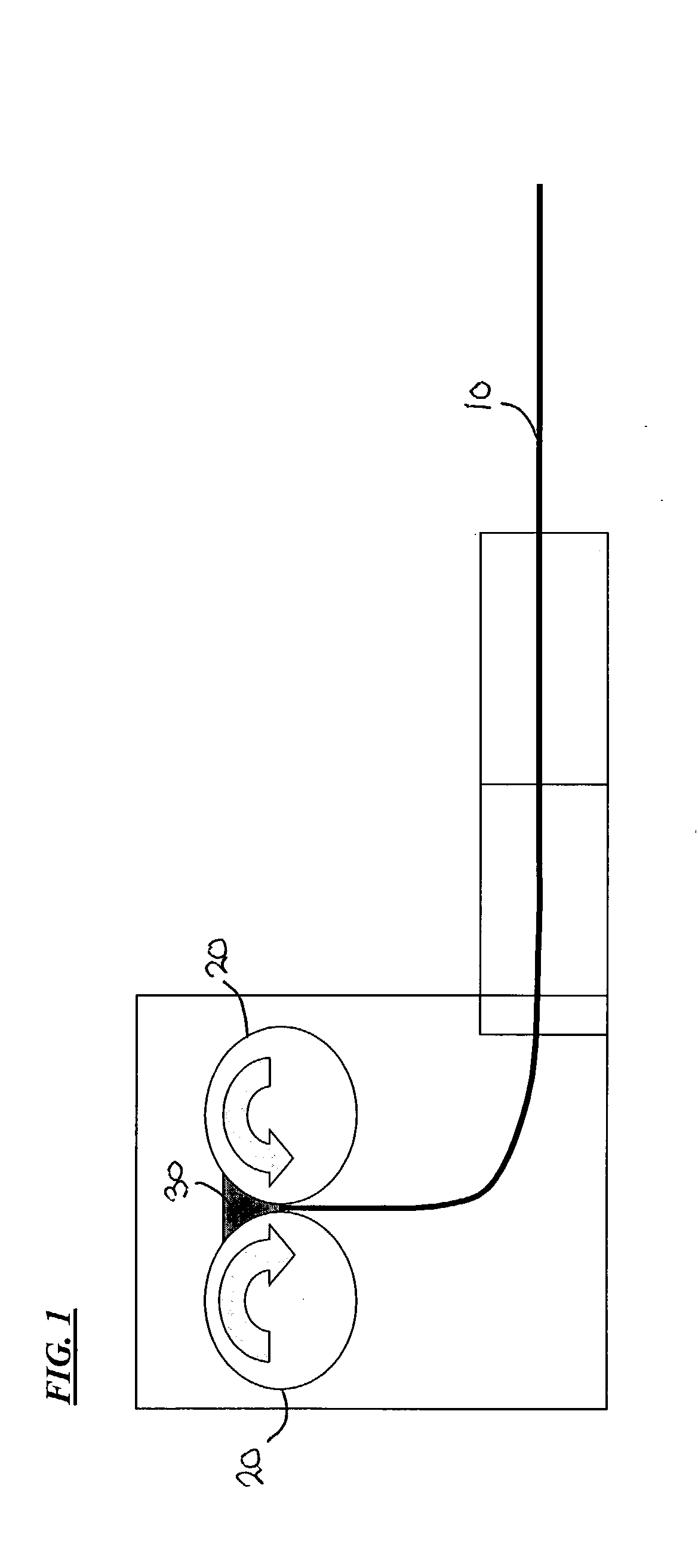

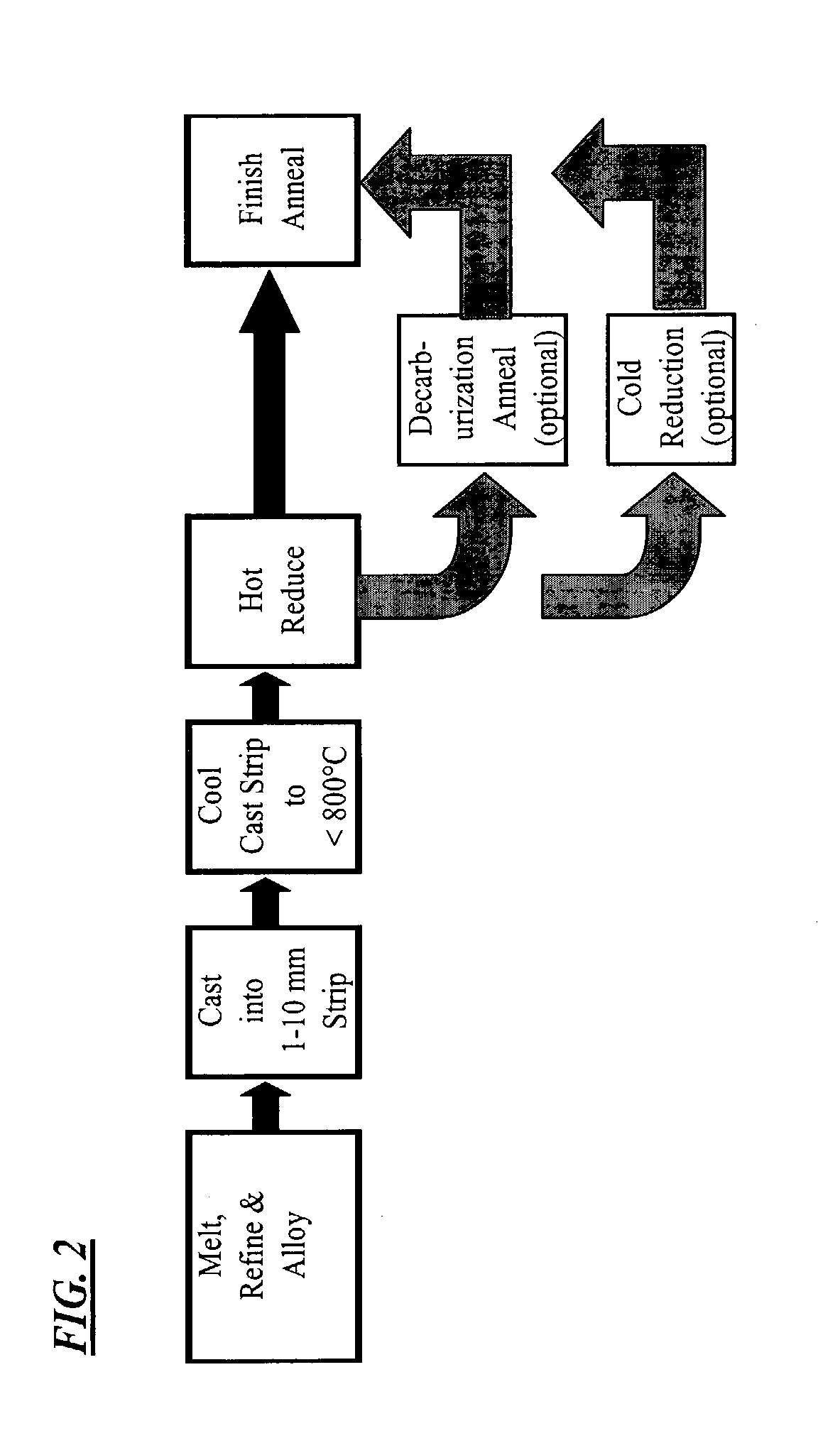

Method of continuous casting non-oriented electrical steel strip

InactiveUS20040016530A1Great resistanceImproved mechanical propertyMagnetic materialsElectric machineryMagnetic core

Non-oriented electrical steels are widely used as the magnetic core material in a variety of electrical machinery and devices, particularly in motors where low core loss and high magnetic permeability in all directions of the strip are desired. The present invention relates to a method for producing a non-oriented electrical steel with low core loss and high magnetic permeability whereby the steel is produced from a steel melt which is cast as a thin strip or sheet, cooled, hot rolled and / or cold rolled into a finished strip. The finished strip is further subjected to at least one annealing treatment wherein the magnetic properties are developed, making the steel strip of the present invention suitable for use in electrical machinery such as motors or transformers.

Owner:CLEVELAND CLIFFS STEEL PROPERTIES INC

Surface assembly for immobilizing DNA capture probes in genetic assays using enzymatic reactions to generate signal in optical bio-discs and methods relating thereto

InactiveUS7083920B2FormationEfficiently projectedMaterial nanotechnologyBioreactor/fermenter combinationsAssayAnalyte

The present invention relates to methods and systems for the detection of specific sequences of nucleic acids or oligonucleotides. It relates more particularly to a conjugated enzyme based assay system utilizing reflective and / or transmissive optical bio-discs for detection of specific sequences of nucleic acids. In the assay according to the present invention, an enzyme reaction is used to detect the presence of an analyte (DNA or RNA) in a microchannel in an optical bio-disc. The analyte is immobilized by hybridization with a specific capture probe on a capture layer on the surface and the signal that is generated is localized and specific. The signal can be in the form of a pellet, a fluorescent product, and / or a colored product, and can be detected and quantified by an optical bio-disc reader utilized in conjunction with the inventions hereof. This assay is thus quantitative in nature.

Owner:VINDUR TECH

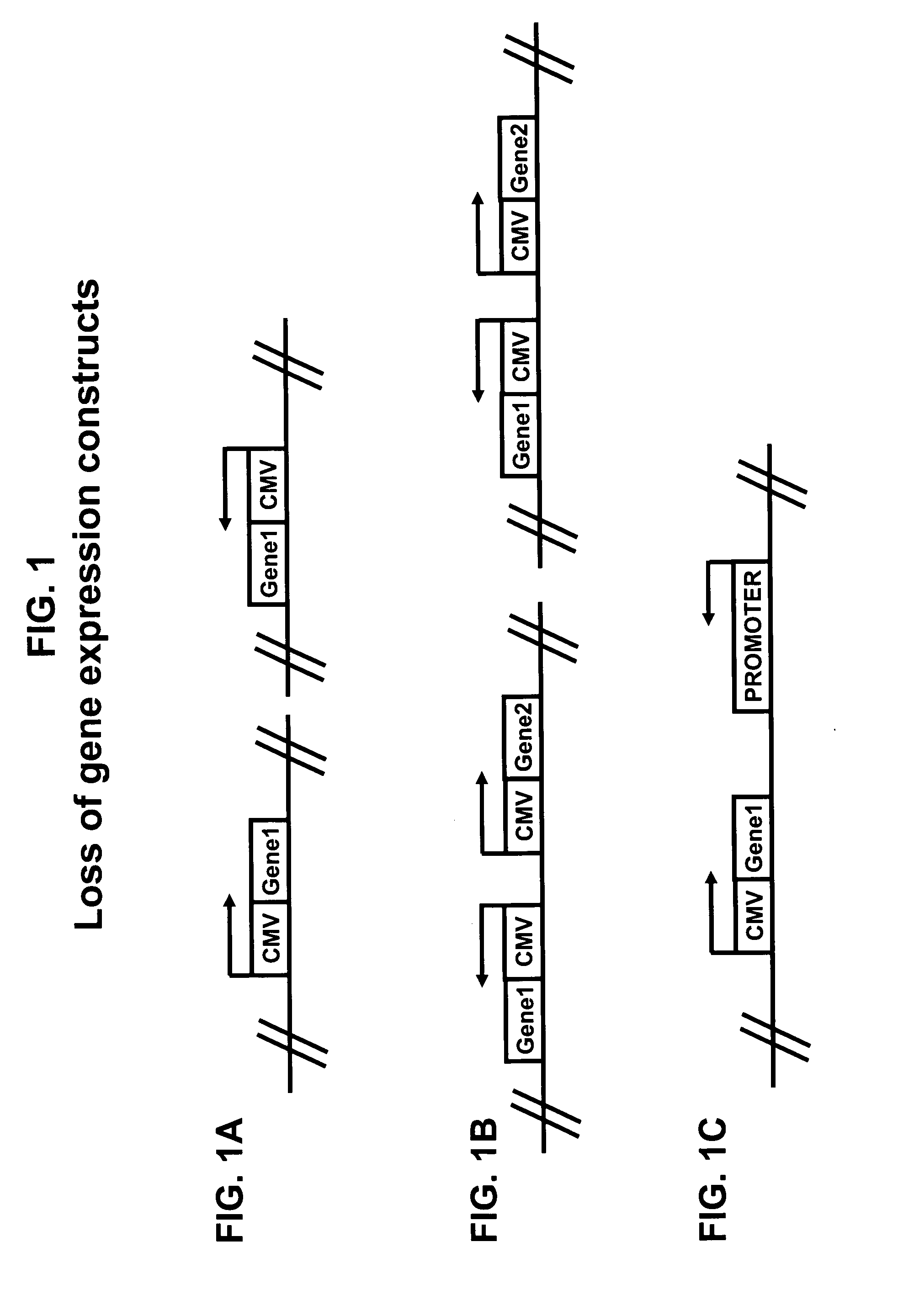

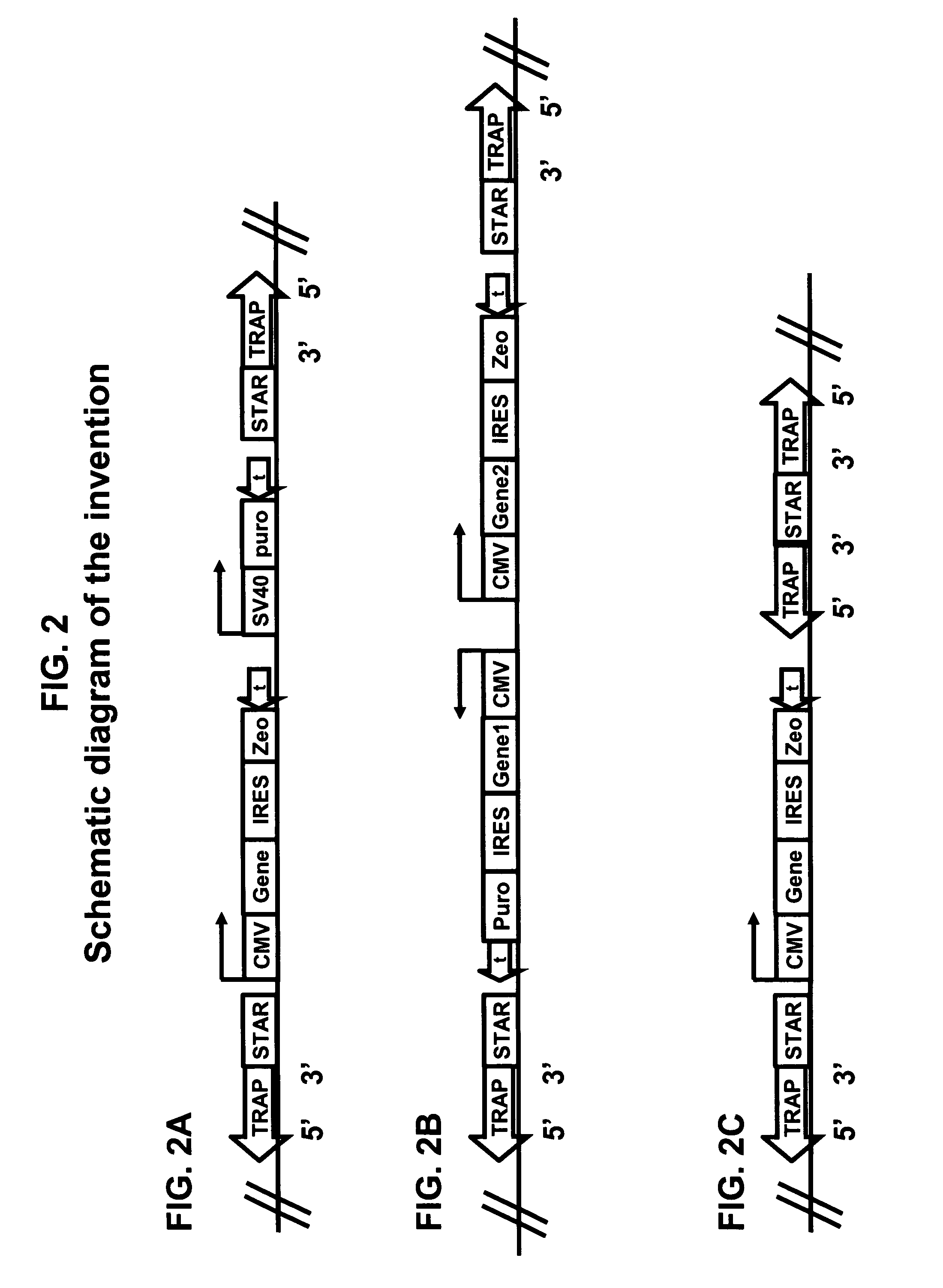

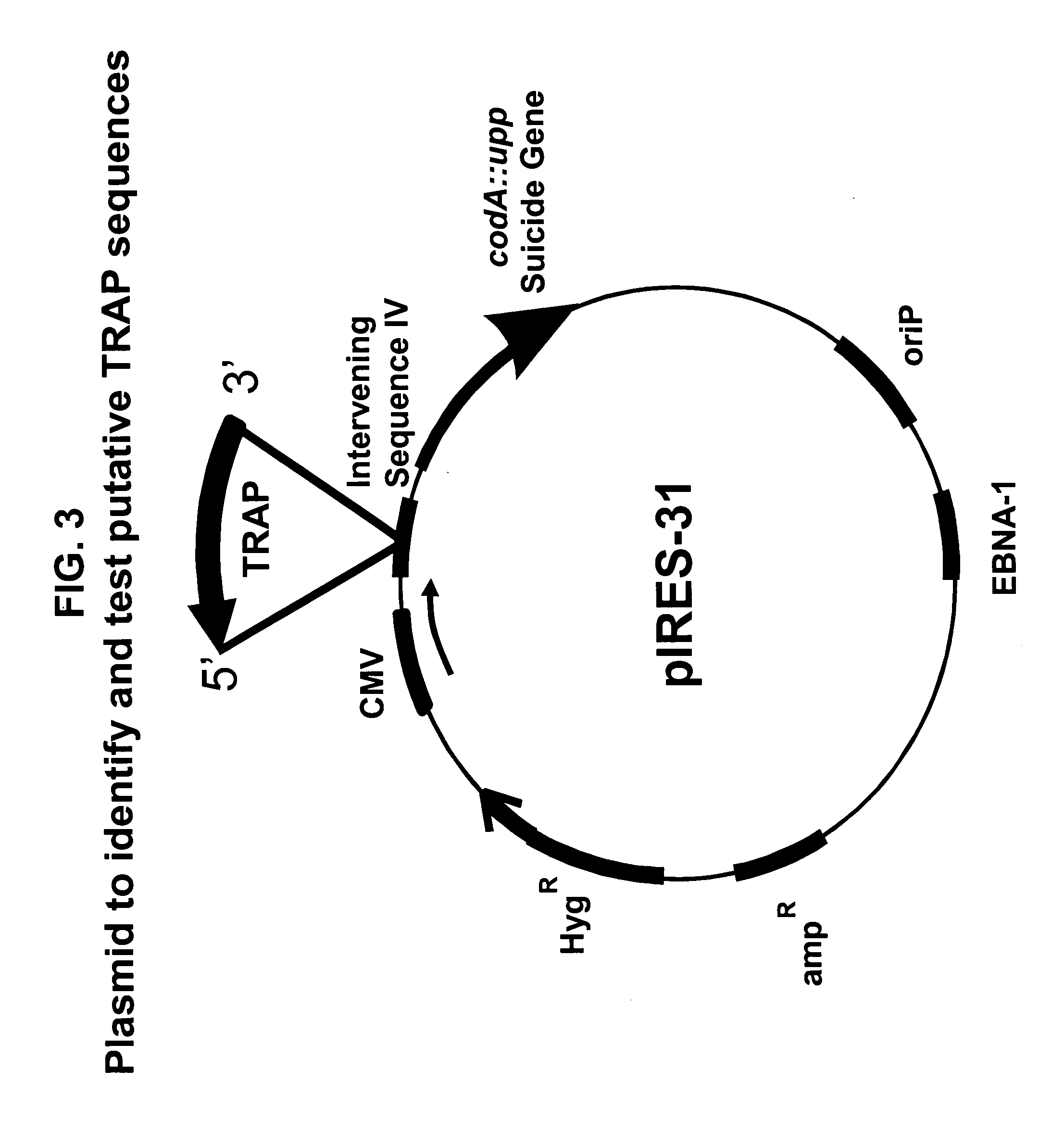

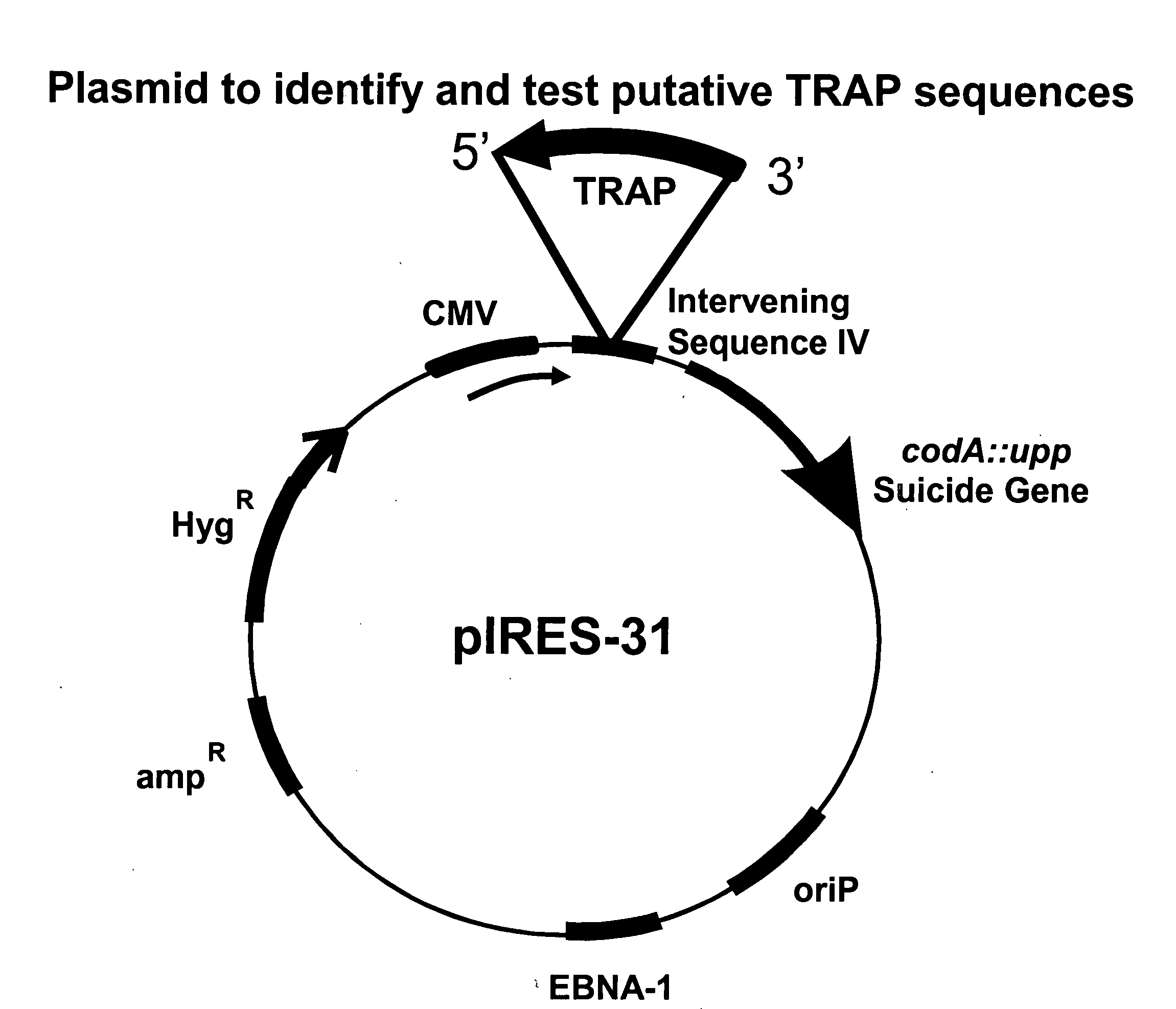

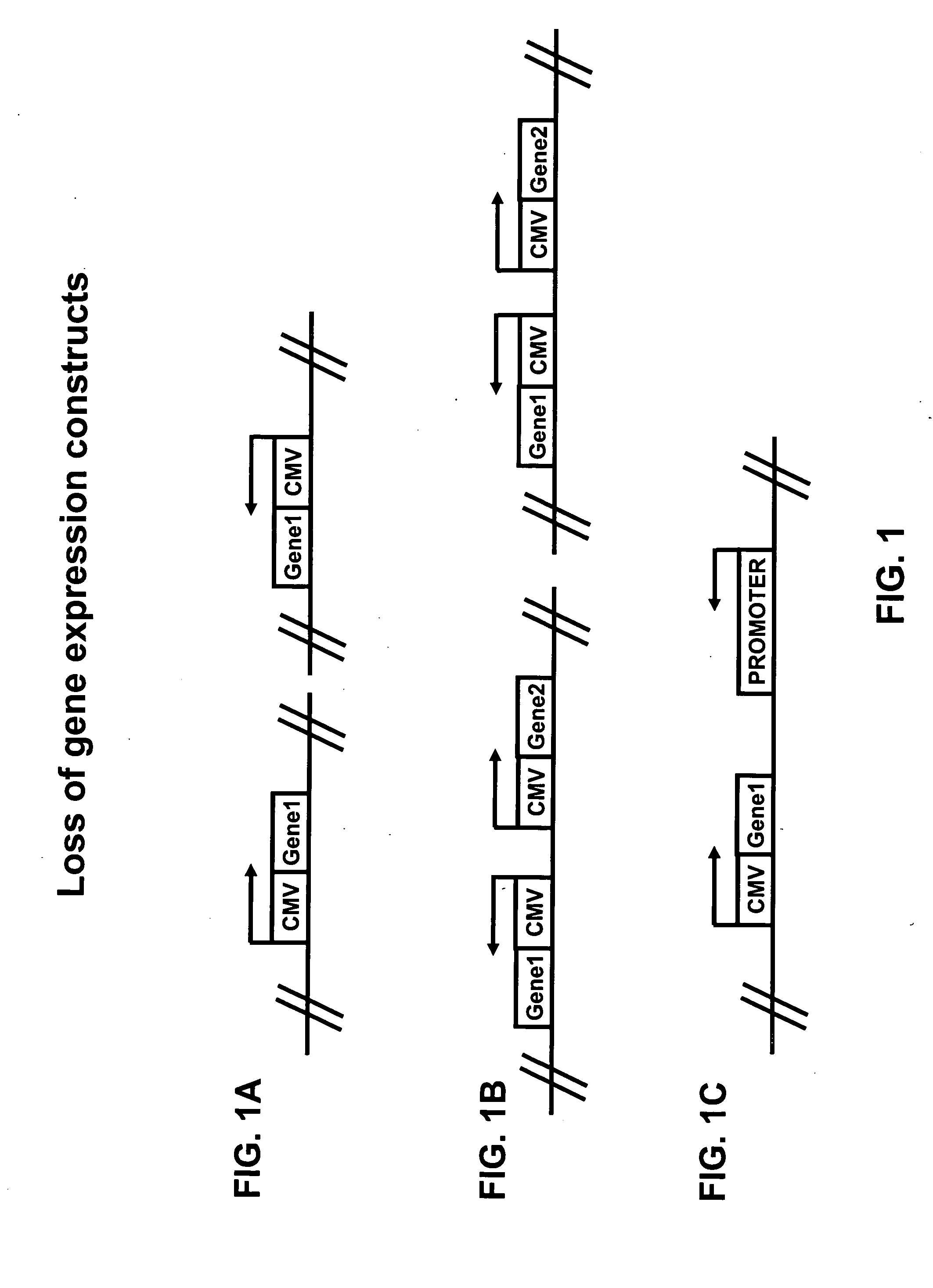

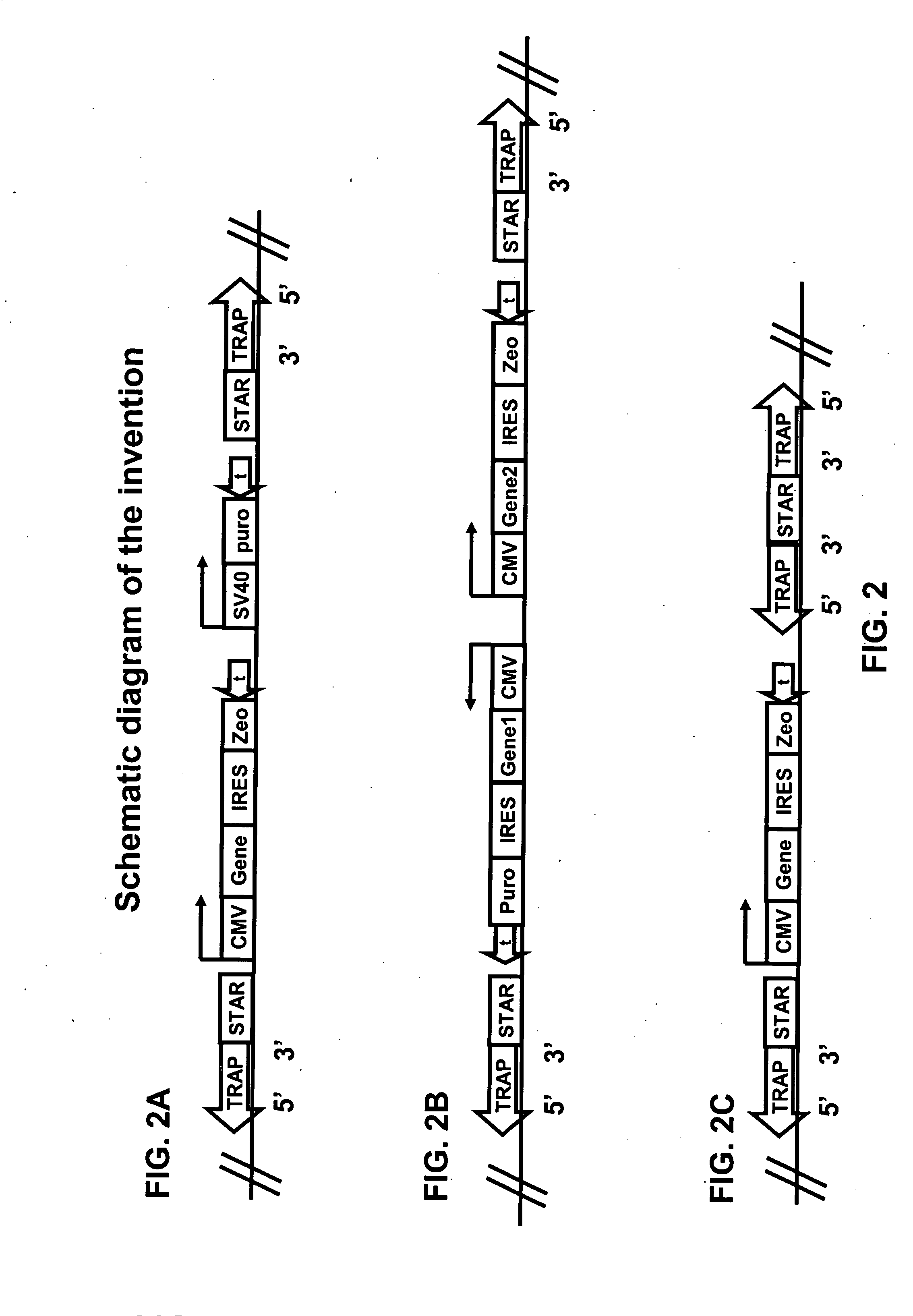

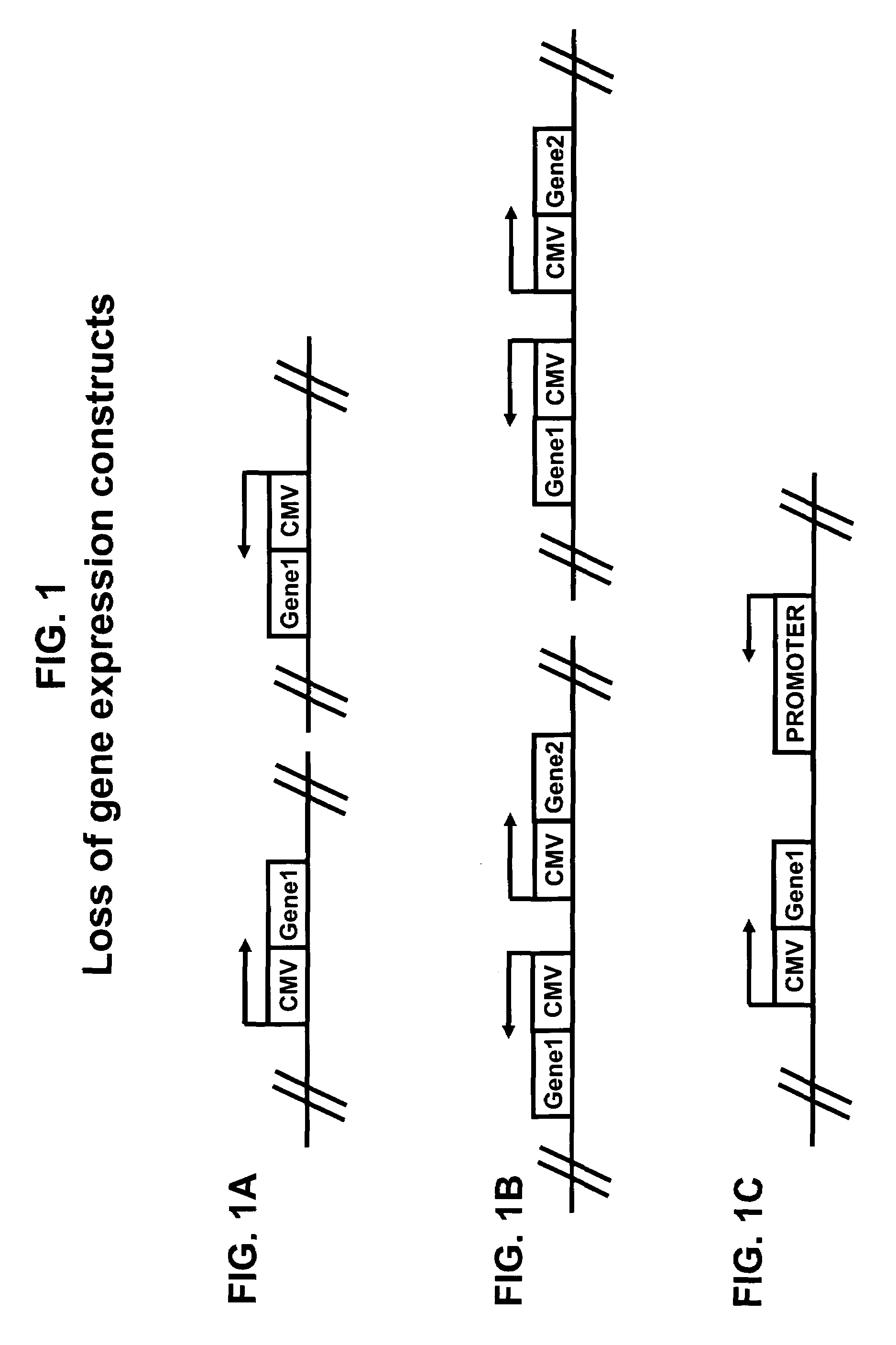

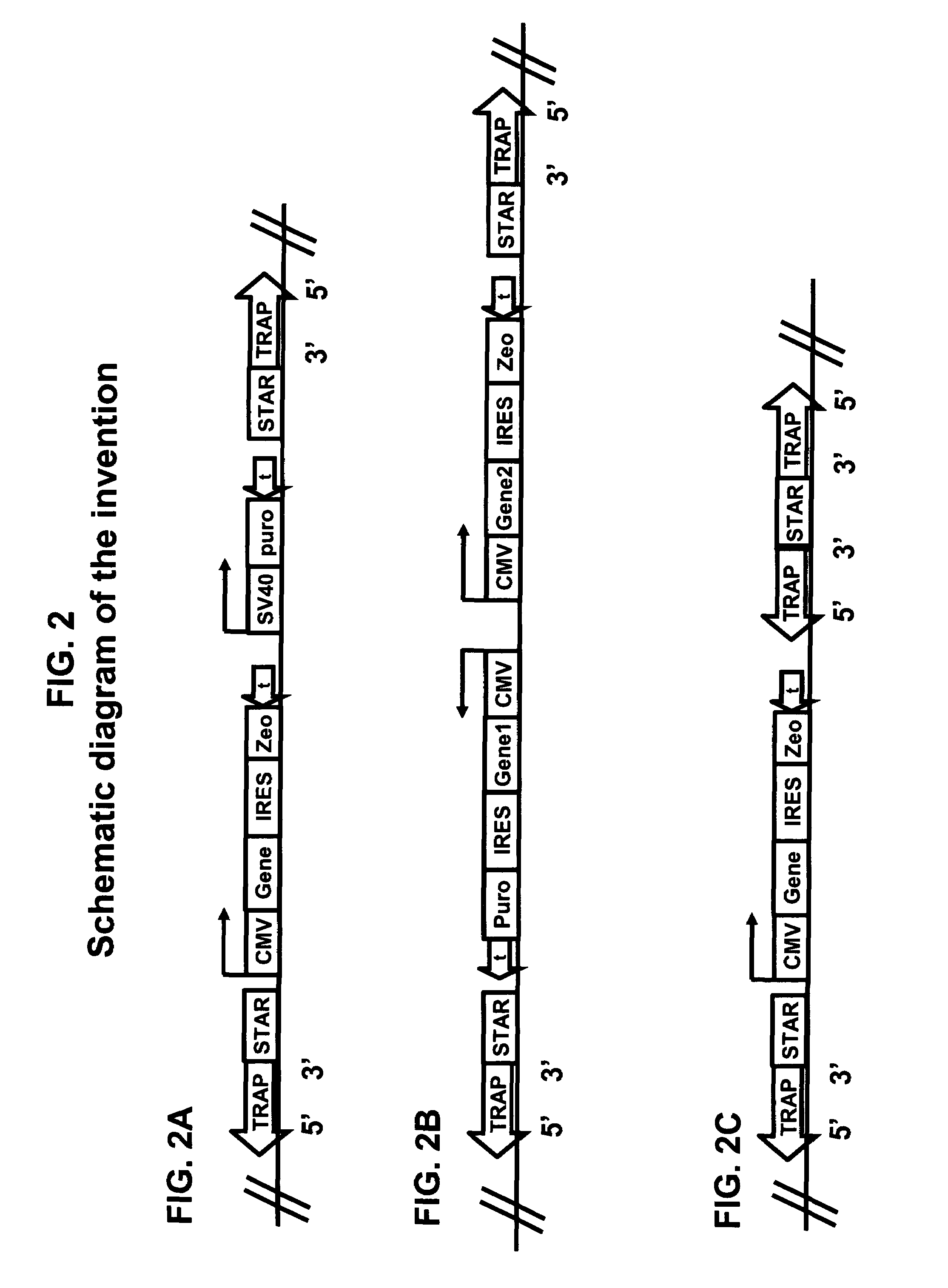

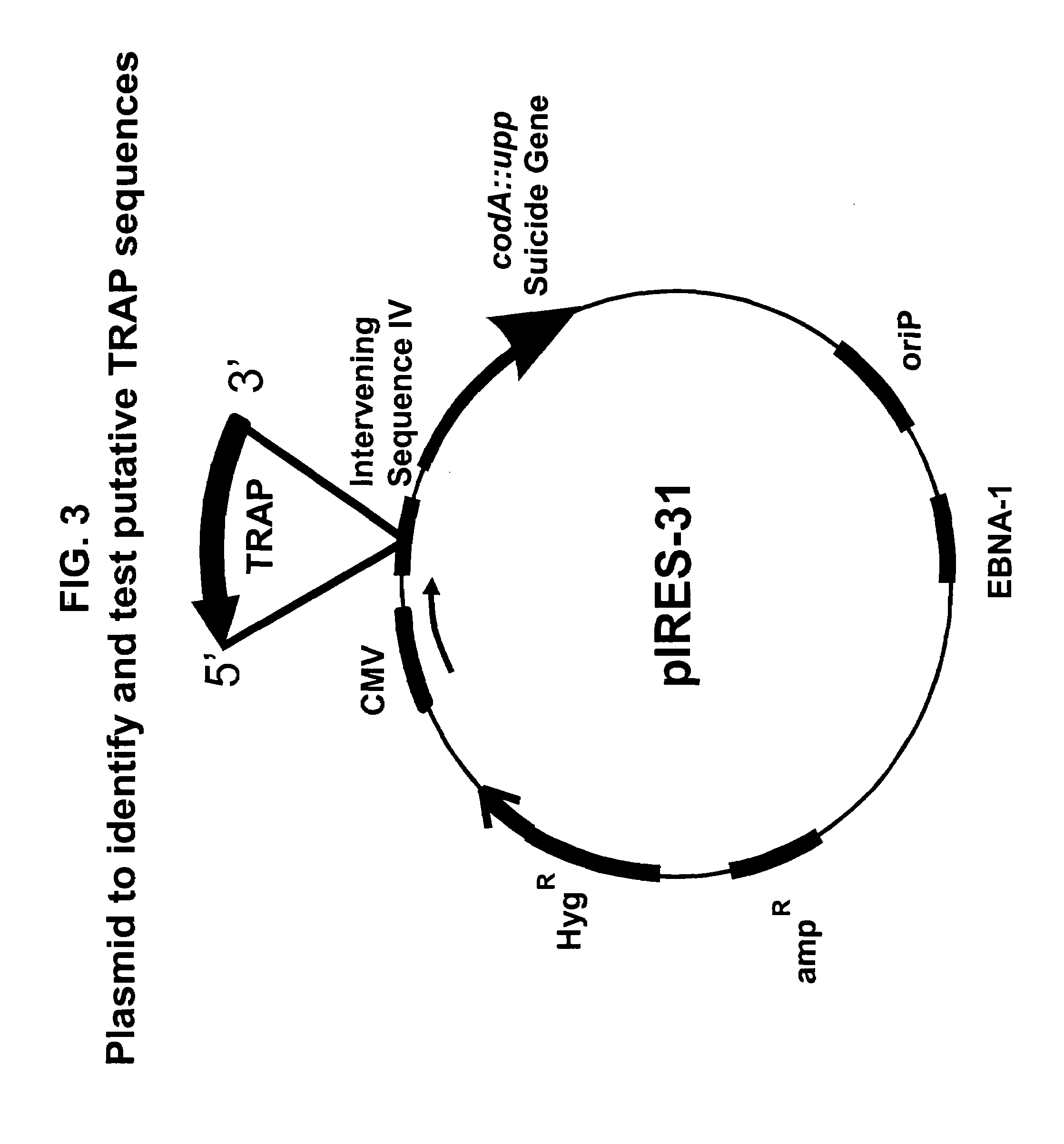

Method for improving protein production

ActiveUS20060010506A1Improve featuresStable transcriptionSugar derivativesMicrobiological testing/measurementAntisense RNAOpen reading frame

The present invention relates to the production of proteins in a cell or host cell. The invention uses a TRAnscription Pause (TRAP) sequence to enhance a protein expression characteristic of a protein expression unit. The TRAP sequence is thought to prevent, at least in part, formation of antisense RNA or to, at least in part, prevent transcription to enter the protein expression unit. In one embodiment, the invention provides a method for expression of at least one protein of interest in a cell comprising providing the cell with at least one protein expression unit that comprises a promoter functionally linked to an open reading frame encoding at least one protein of interest, characterized in that the protein expression unit further comprises at least one TRAP sequence and wherein the TRAP sequence is functionally located downstream of the open reading frame and at least in part prevents formation of antisense RNA. In another embodiment, the TRAP sequence is functionally located upstream of the promoter and at least in part prevents transcription to enter the expression unit. Preferably, the expression protein unit further comprises at least one STabilizing Anti-Repressor sequence.

Owner:CHROMAGENICS BV

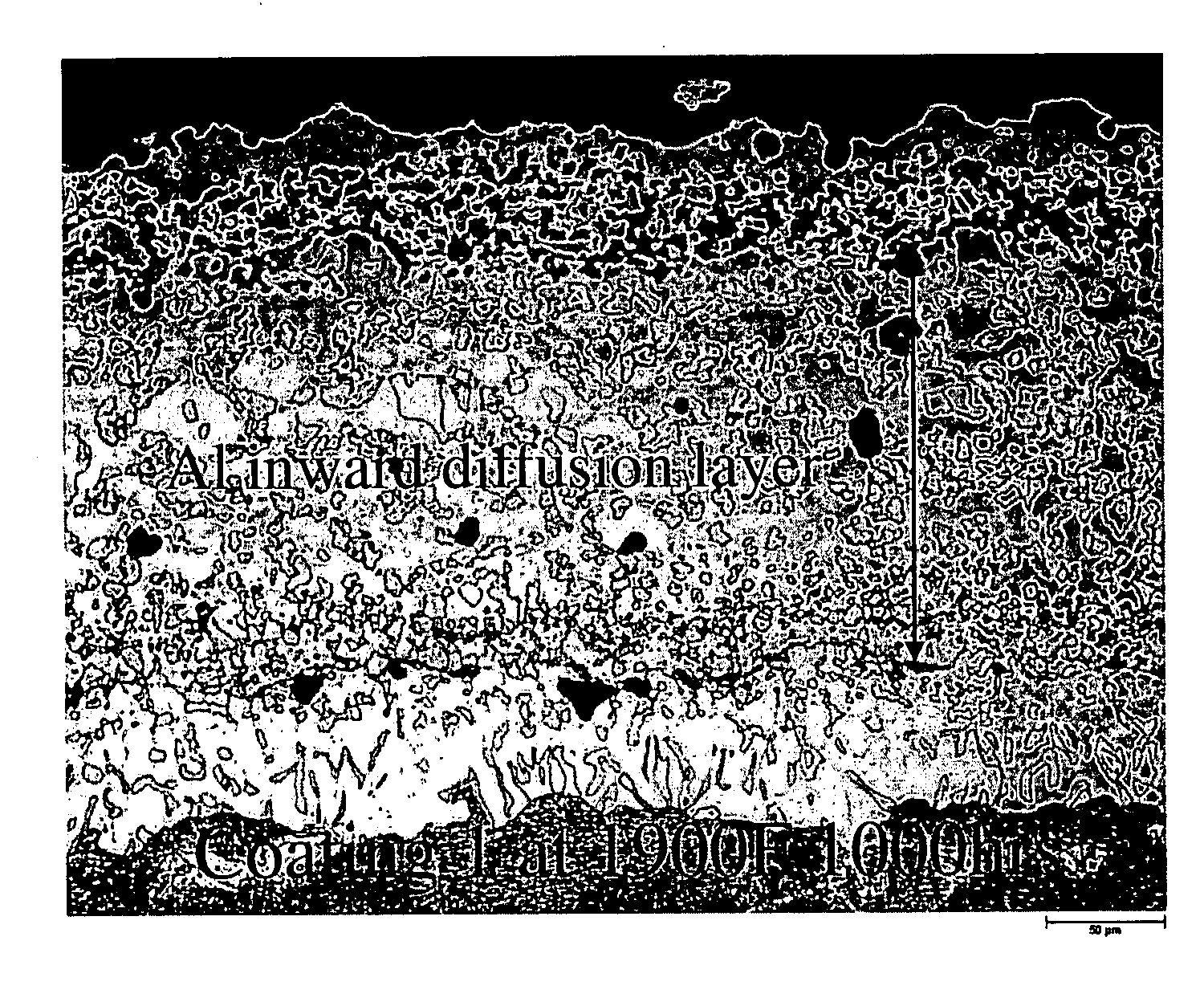

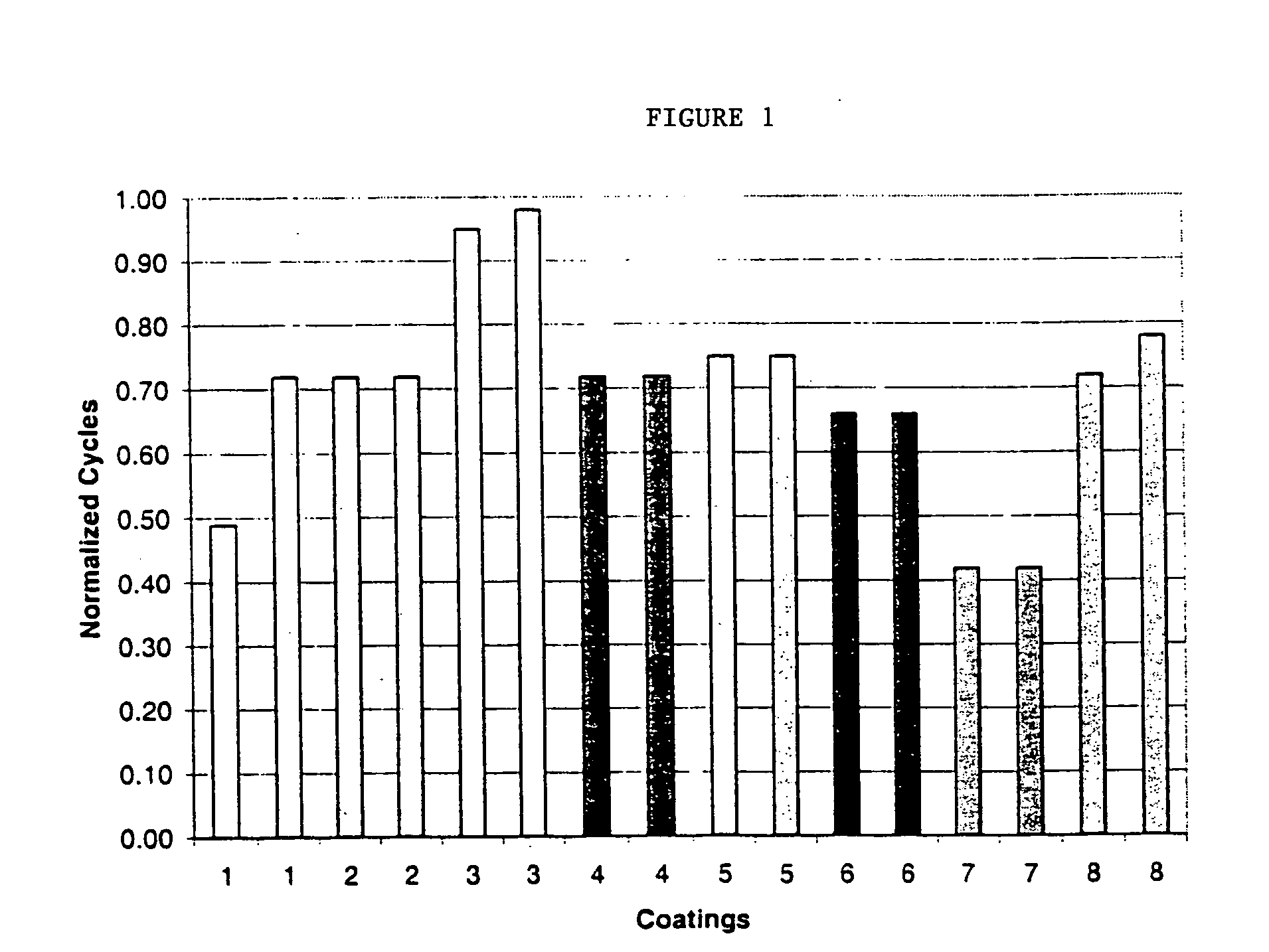

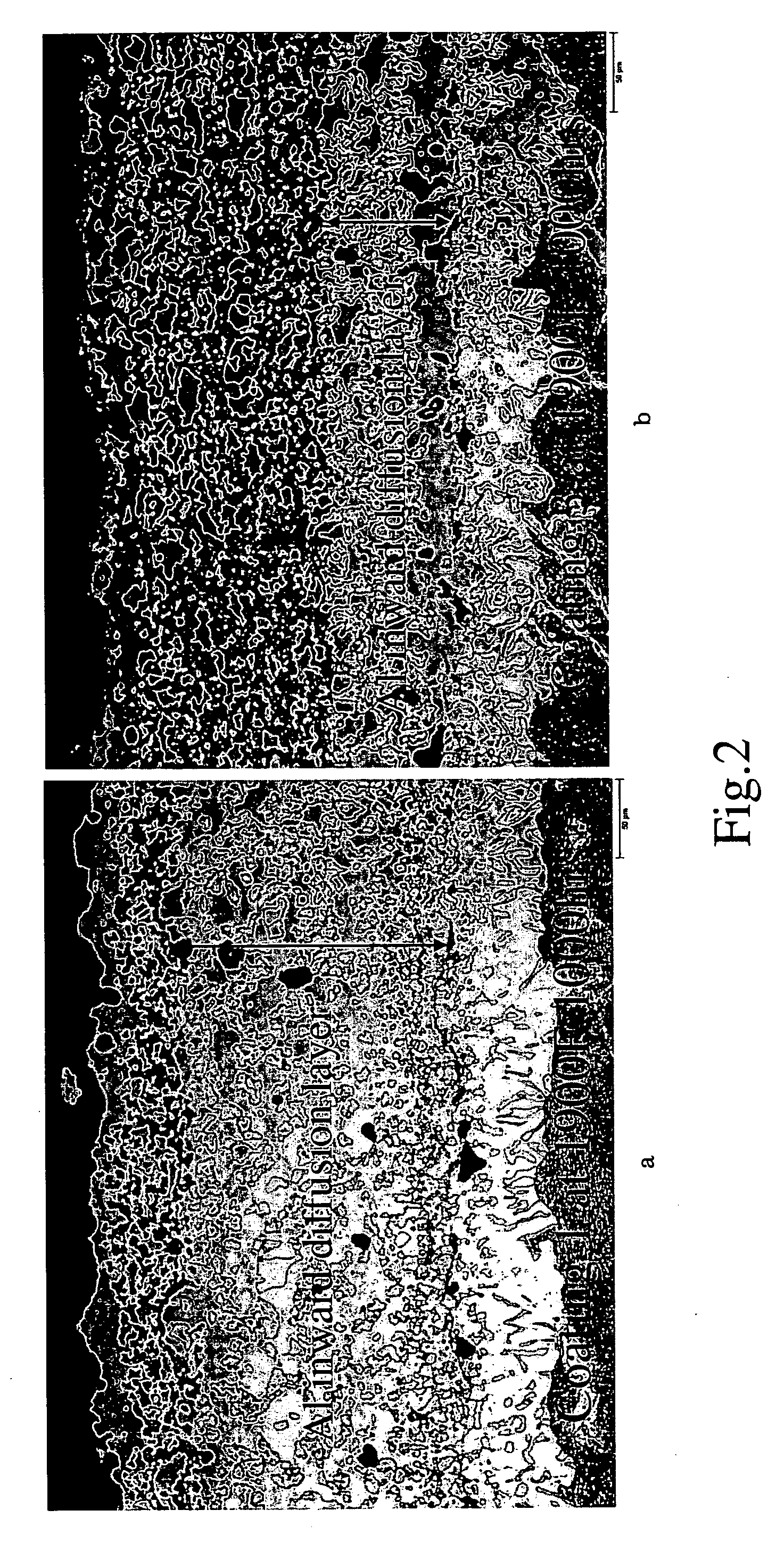

Modified bond coat for increasing the cyclic spallation life of thermal barrier coating

Owner:GENERAL ELECTRIC CO

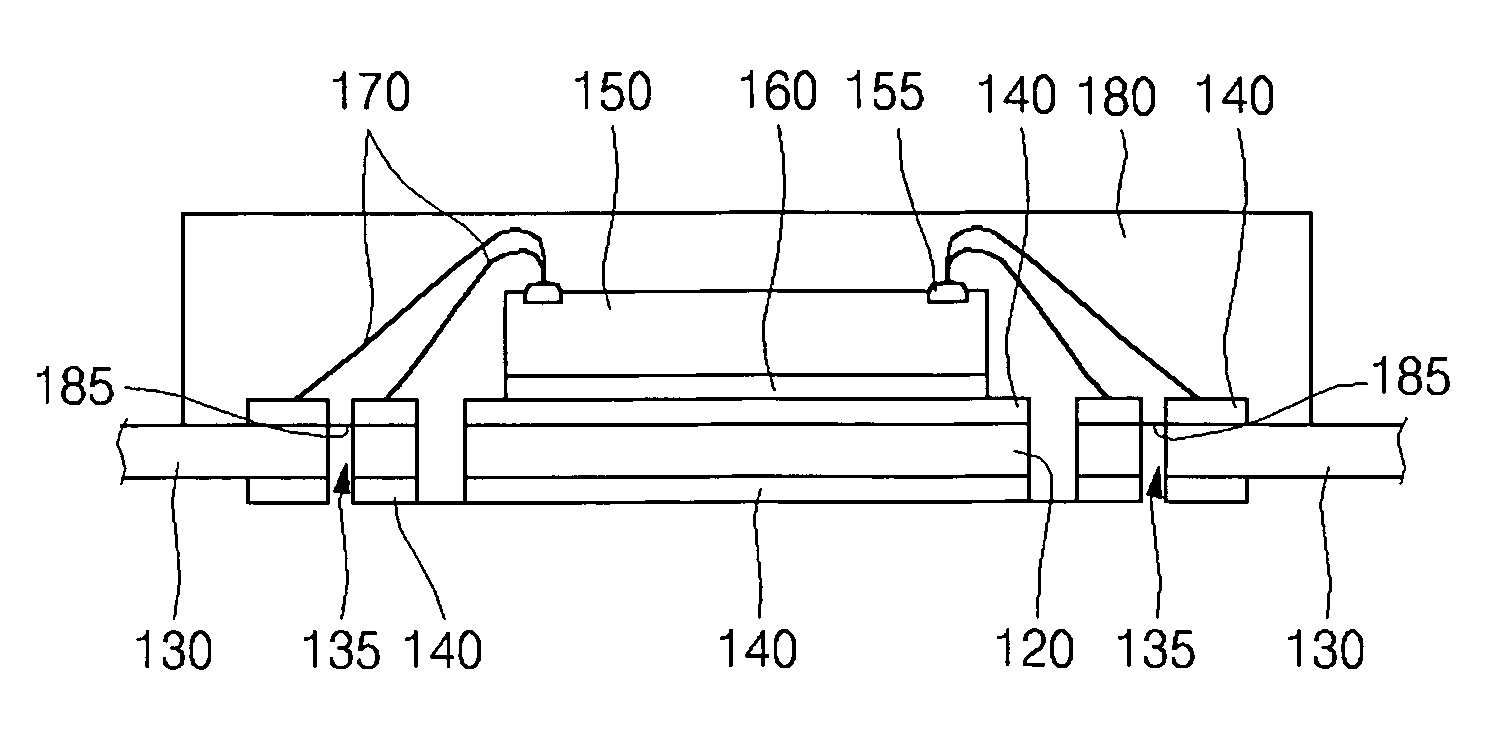

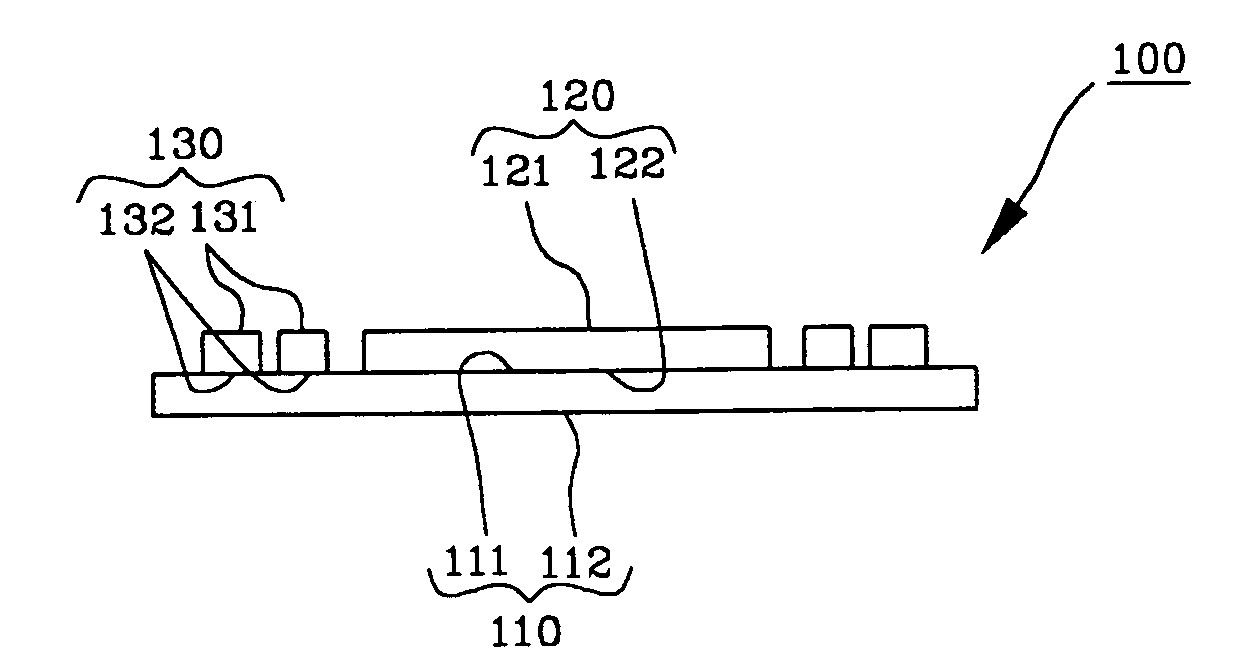

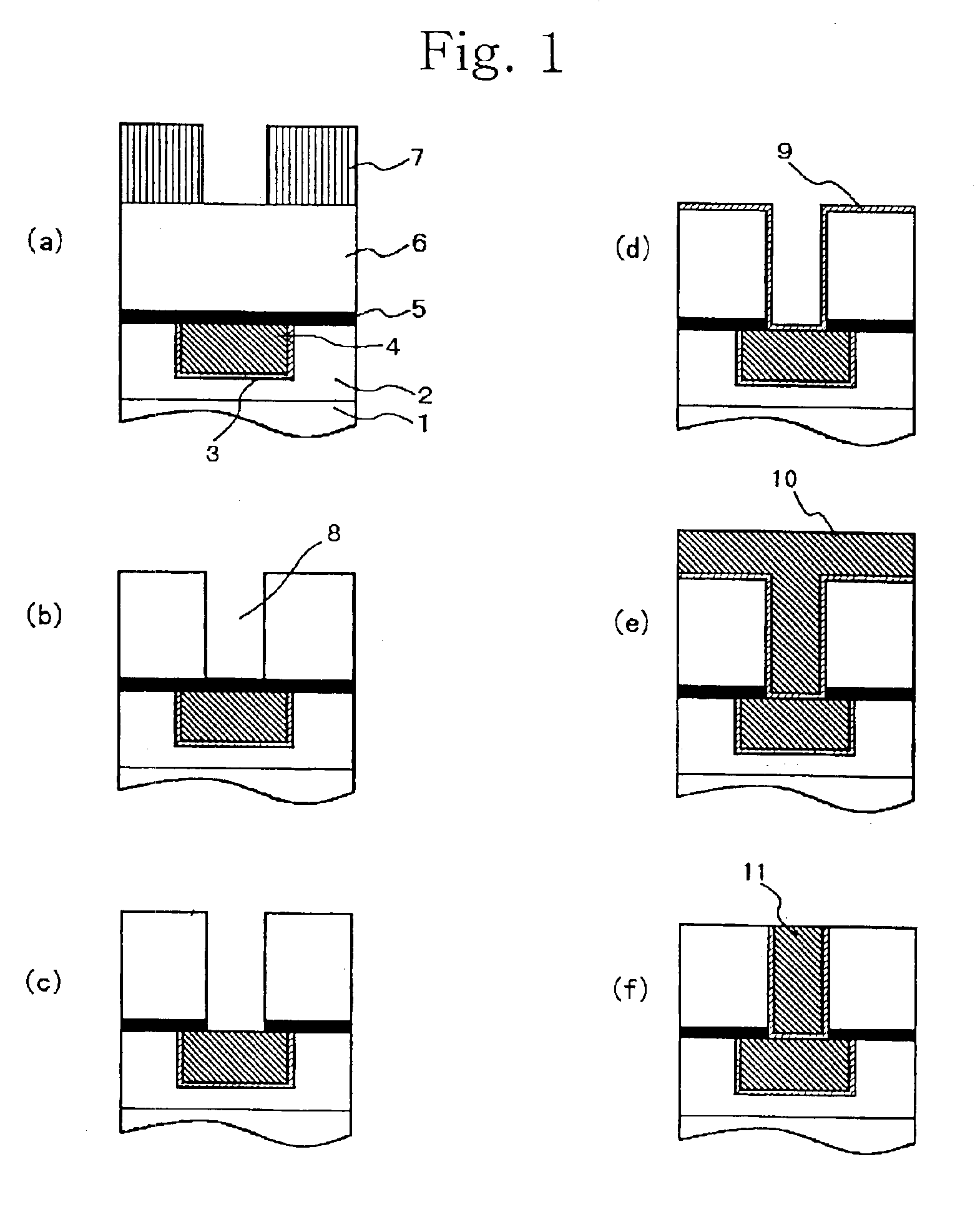

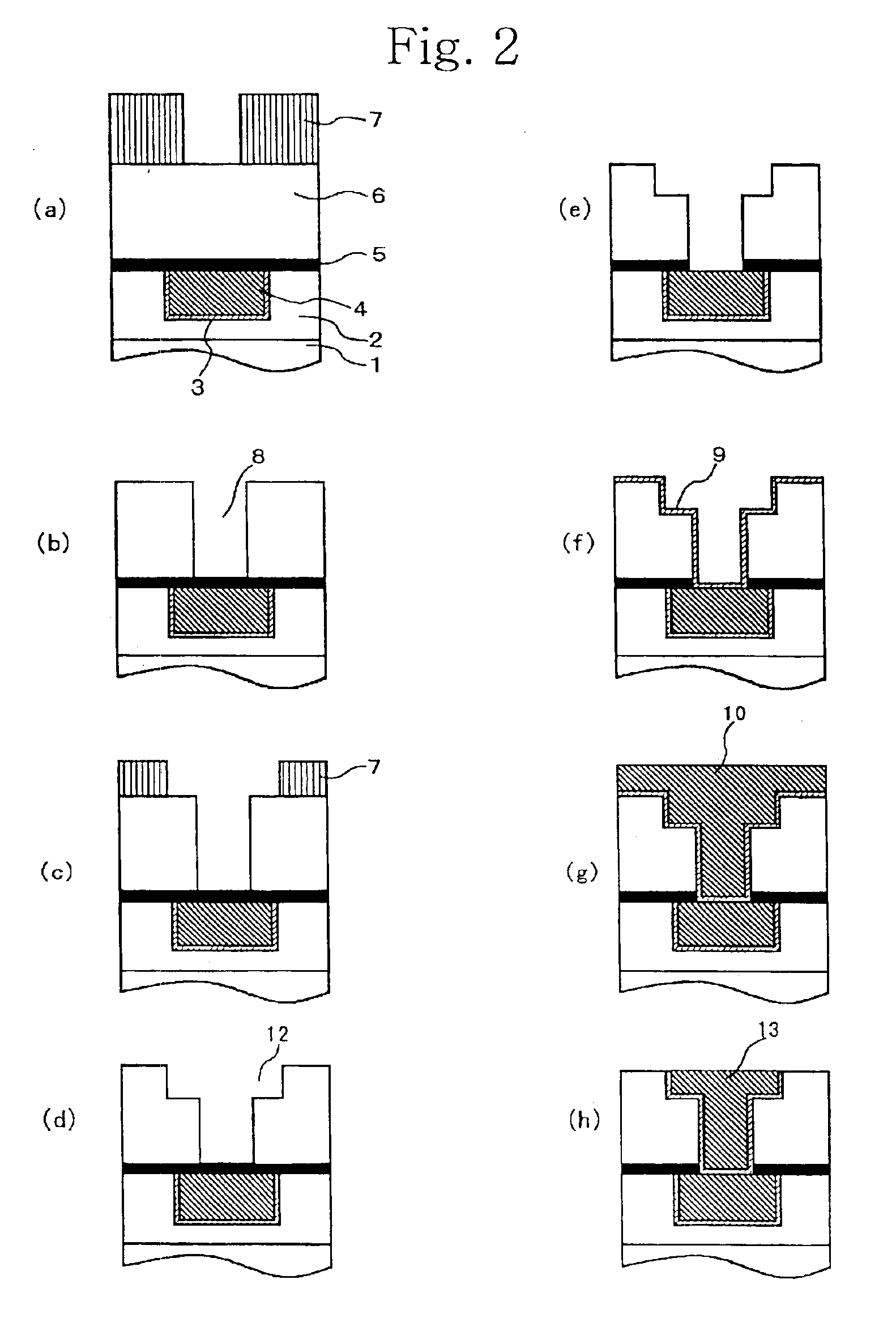

Increased capacity leadframe and semiconductor package using the same

ActiveUS7214326B1FormationFormation of both the leads and the die paddle of the leadframeDecorative surface effectsSolid-state devicesSemiconductor packageEngineering

In accordance with the present invention, there is provided a method for manufacturing a semiconductor package. The method comprises the initial step of applying first and second photoresist layers to respective ones of opposed first and second surfaces of a metal plate which includes a die paddle and a plurality of leads extending at least partially about the die paddle in spaced relation thereto. The first and second photoresist layers are then patterned to expose the die paddle and prescribed portions of each of the leads. Thereafter, first and second conductive layers are applied to portions of respective ones of the first and second surfaces which are not covered by the first and second photoresist layers. The first and second photoresist layers are then removed to facilitate the creation of an exposed area in each of leads which is not covered by the first and second conductive layers. Next, a semiconductor die is attached to a portion of the first conductive layer covering the die paddle and electrically connected to portions of the first conductive layer covering the leads. The semiconductor die, the die paddle, the leads and the first and second conductive layers are then encapsulated with a package body such that portions of the second conductive layer covering the die paddle and the leads, and the exposed area of each of the leads are exposed in a common surface of the package body. Finally, the exposed area of each of the leads is etched to facilitate the division of the leads into an inner set extending at least partially about the die paddle and an outer set extending at least partially about the inner set.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

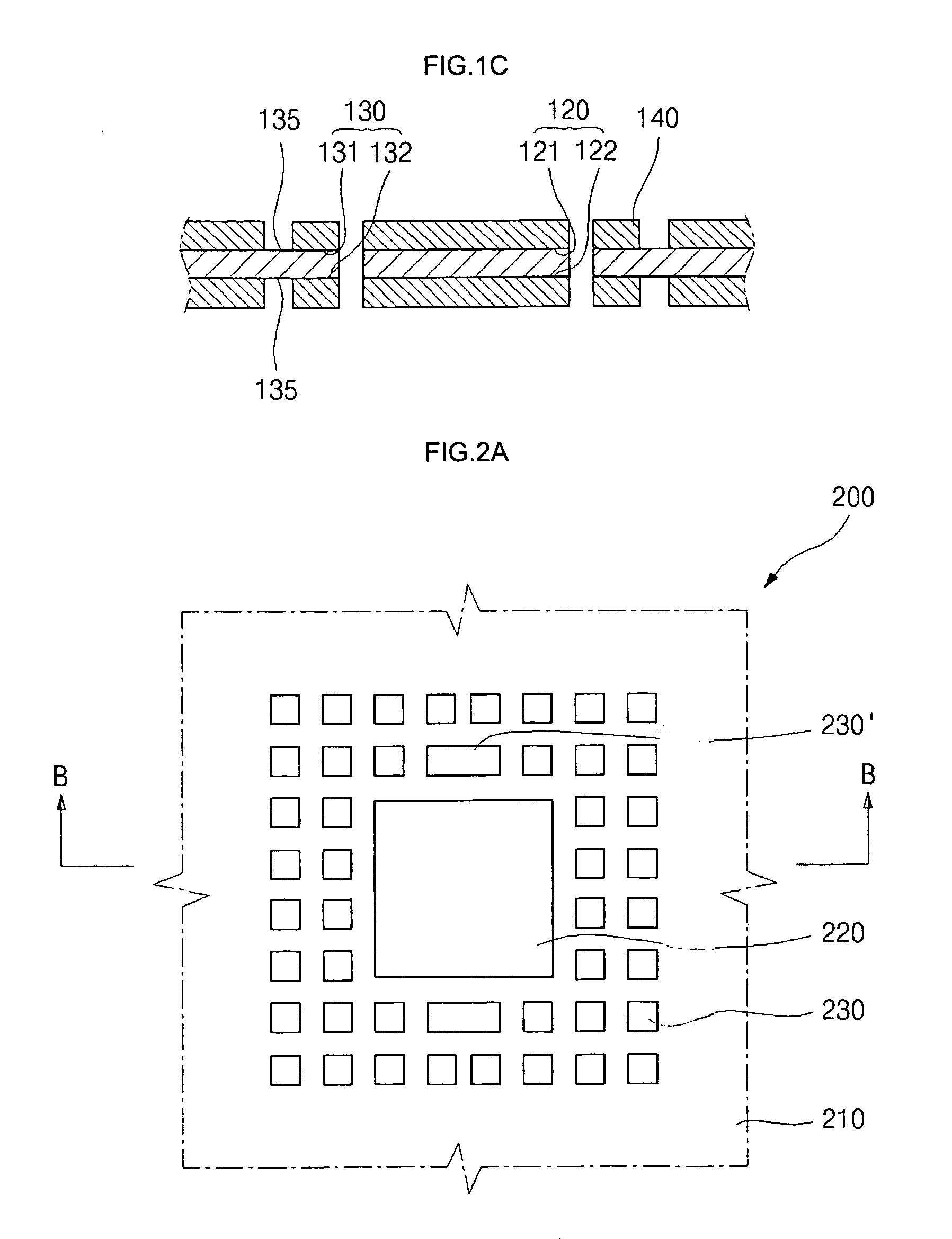

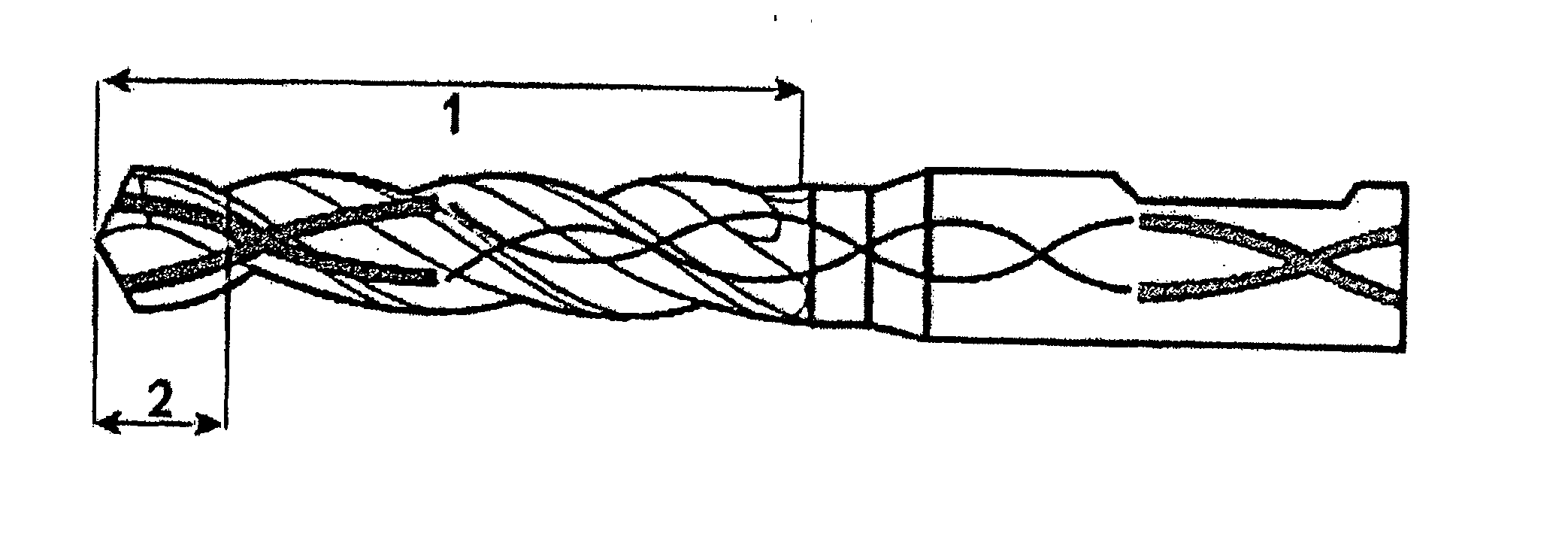

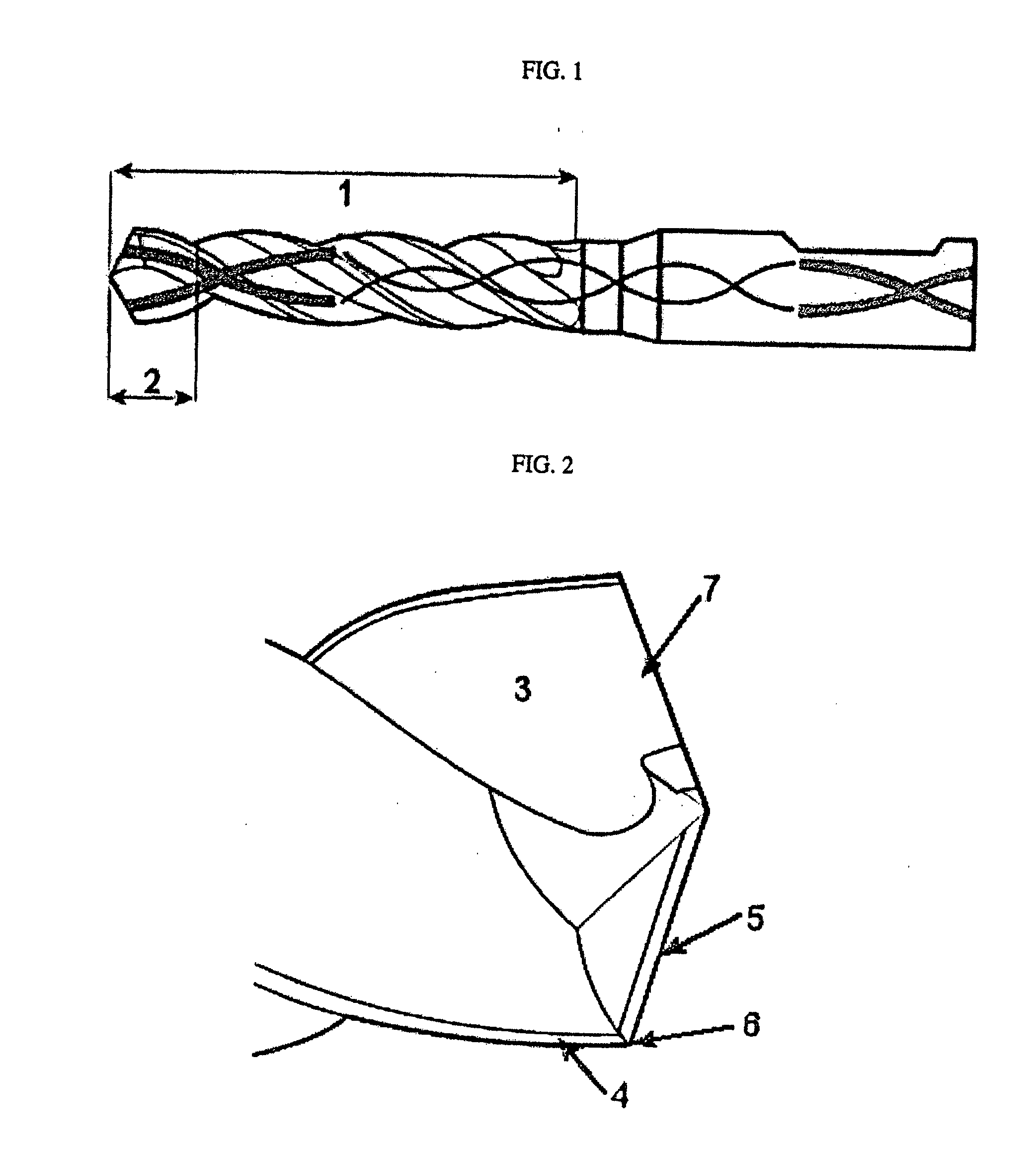

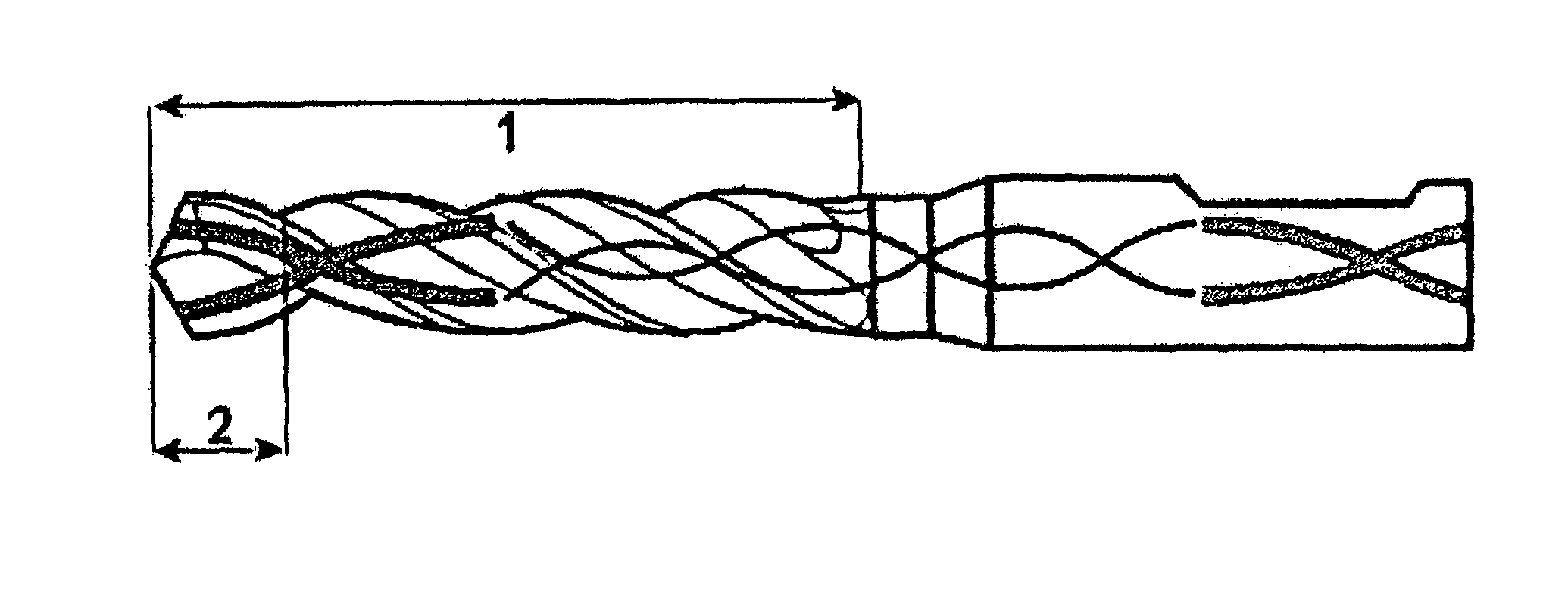

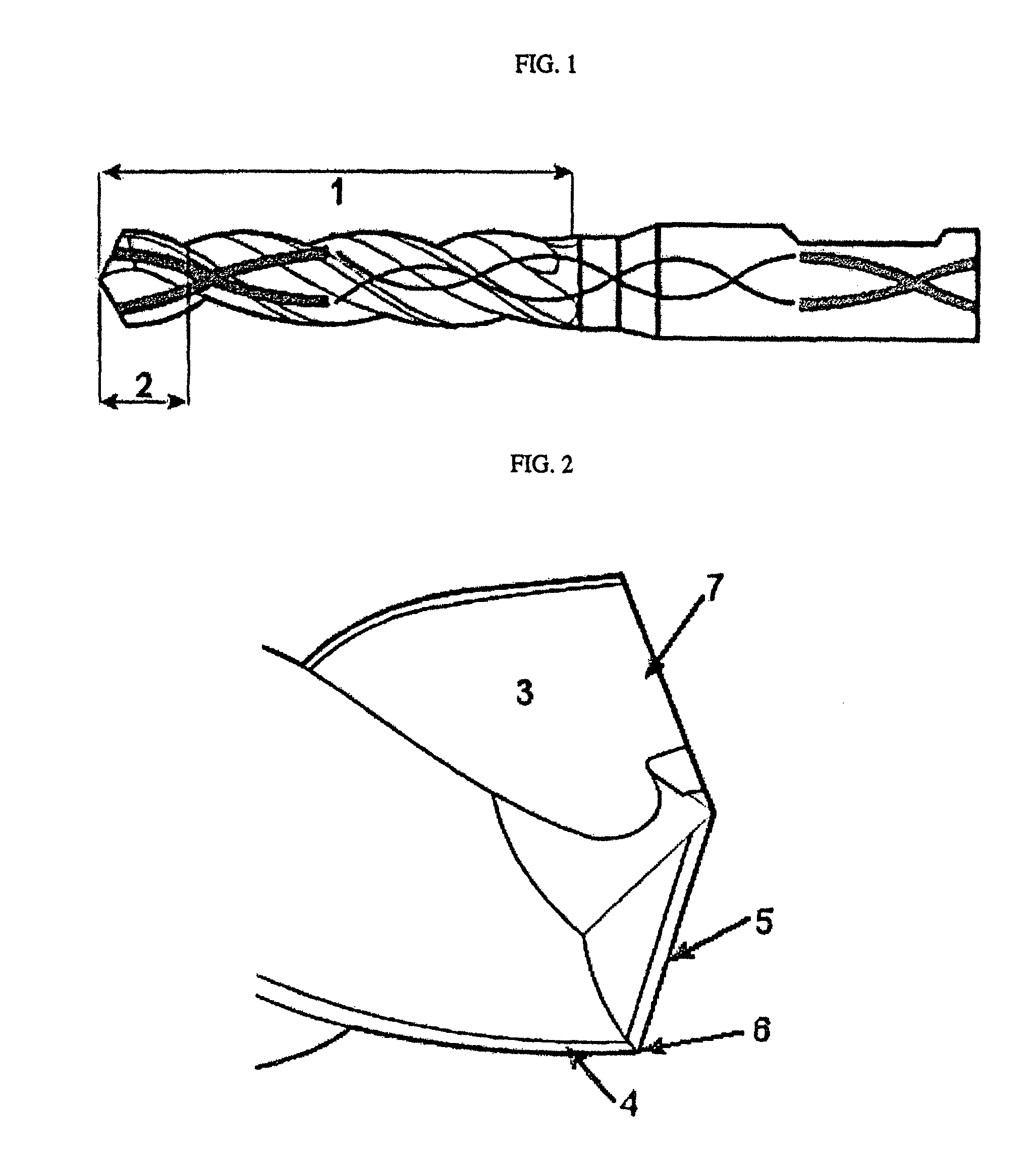

Coated drill and method of making the same

ActiveUS20080056835A1Improve wear resistanceMaintain good propertiesMetal-working drilling toolsTransportation and packagingCemented carbideWear resistance

The present invention relates to a drill comprising a cemented carbide or high speed steel substrate and a coating wherein the coating comprises: a first layer system having a multilayered structure covering substantially the whole active part of the drill, a second layer system having a multilayered structure covering only the tip area of the drill. Drills according to the present invention have good wear resistance and improved properties when reconditioning the drill. The present invention also relates to a method of making a drill according to the present invention.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method of determining pole arc ratio of interior permanent magnet rotary motor and interior permanent magnet rotary motor

InactiveUS7358638B2Reduced dimensionReduce the amount requiredMagnetic circuit rotating partsManufacturing dynamo-electric machinesMagnetic polesLine segment

An interior permanent magnet rotary motor of the present invention has N slots and P permanent magnet magnetic pole sections, (2 / 3<=P / N<= 43 / 45). Po is an irreducible fraction Po / No of the P / N is an odd number, and a pole arc ratio psip equals thetapp / thetap. thetapp is an angle between two line segments assumed for a pair of flux barriers, each of which connects the center of a rotor core and one of corners of the section of each flux barrier that is closest to the surface of the rotor core. thetap is an angle obtained by dividing 360° by the number of the permanent magnet pole sections. The pole arc ratio indicated by Psip (0<4n<1) is determined by the expression of Psip=2mP / N+P / 4LCM (P, N)-2n, where LCM (P, N) is the least common multiple between P and N, m and n are arbitrary natural numbers.

Owner:SANYO DENKI CO LTD

Method for improving protein production

ActiveUS20090011468A1Improve featuresStable transcriptionSugar derivativesMicrobiological testing/measurementAntisense RNATRAP Sequence

The present invention relates to the production of proteins in a cell or host cell. The invention uses a TRAnscription Pause (TRAP) sequence to enhance a protein expression characteristic of a protein expression unit. The TRAP sequence is thought to prevent, at least in part, formation of antisense RNA or to, at least in part, prevent transcription to enter the protein expression unit. In one embodiment, the invention provides a method for expression of at least one protein of interest in a cell comprising providing the cell with at least one protein expression unit that comprises a promoter functionally linked to an open reading frame encoding at least one protein of interest, characterized in that the protein expression unit further comprises at least one TRAP sequence and wherein the TRAP sequence is functionally located downstream of the open reading frame and at least in part prevents formation of antisense RNA. In another embodiment, the TRAP sequence is functionally located upstream of the promoter and at least in part prevents transcription to enter the expression unit. Preferably, the expression protein unit further comprises at least one STabilizing Anti-Repressor sequence.

Owner:CHROMAGENICS BV

Manufacturing method for leadframe and for semiconductor package using the leadframe

ActiveUS7144517B1FormationPromote formationDecorative surface effectsSolid-state devicesResistSemiconductor package

In accordance with the present invention, there is provided a method for manufacturing a leadframe. The method comprises the initial step of bonding a primary leadframe to an adhesive tape layer, the primary leadframe including a die paddle and a plurality of leads which extend at least partially about the die paddle in spaced relation thereto. Thereafter, a photo resist is applied to the primary leadframe and to the adhesive tape layer. The photo resist is then patterned to define at least one exposed area in each of the leads of the primary leadframe. The exposed areas of the leads are then etched to divide the leads into an inner set which extends at least partially about the die paddle and an outer set which extends at least partially about the inner set. Thereafter, the photo resist is removed from the die paddle and from the inner and outer sets of the leads.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

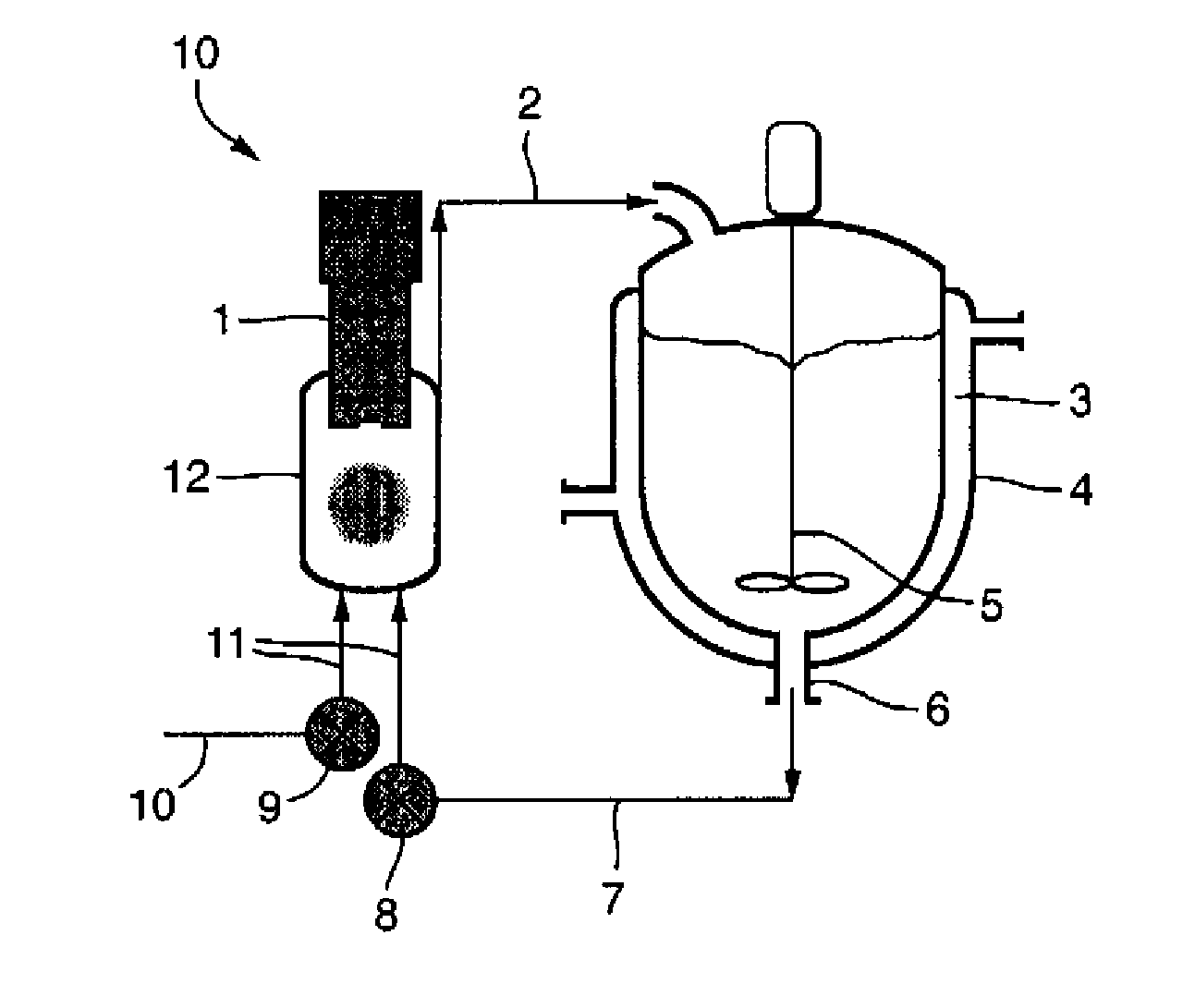

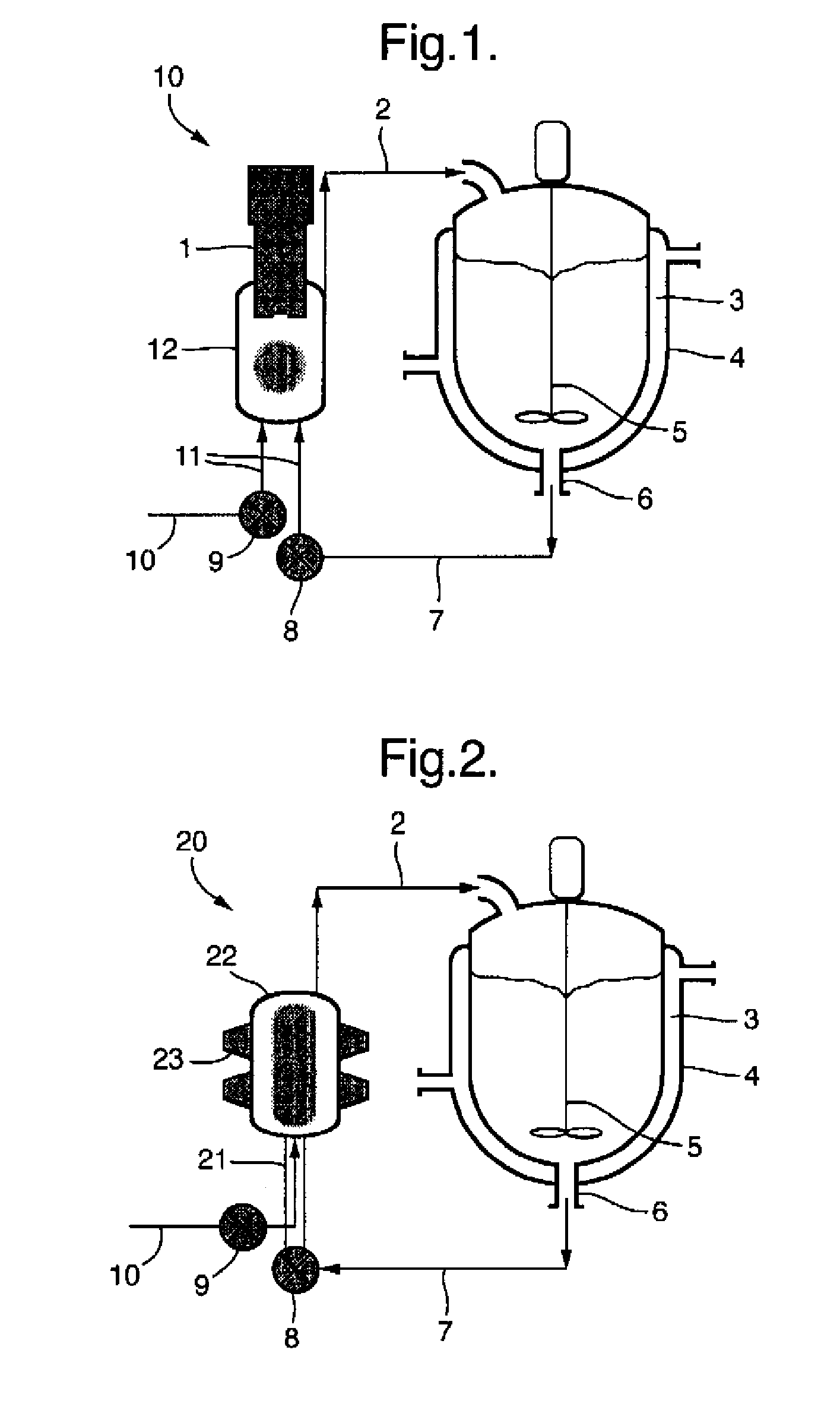

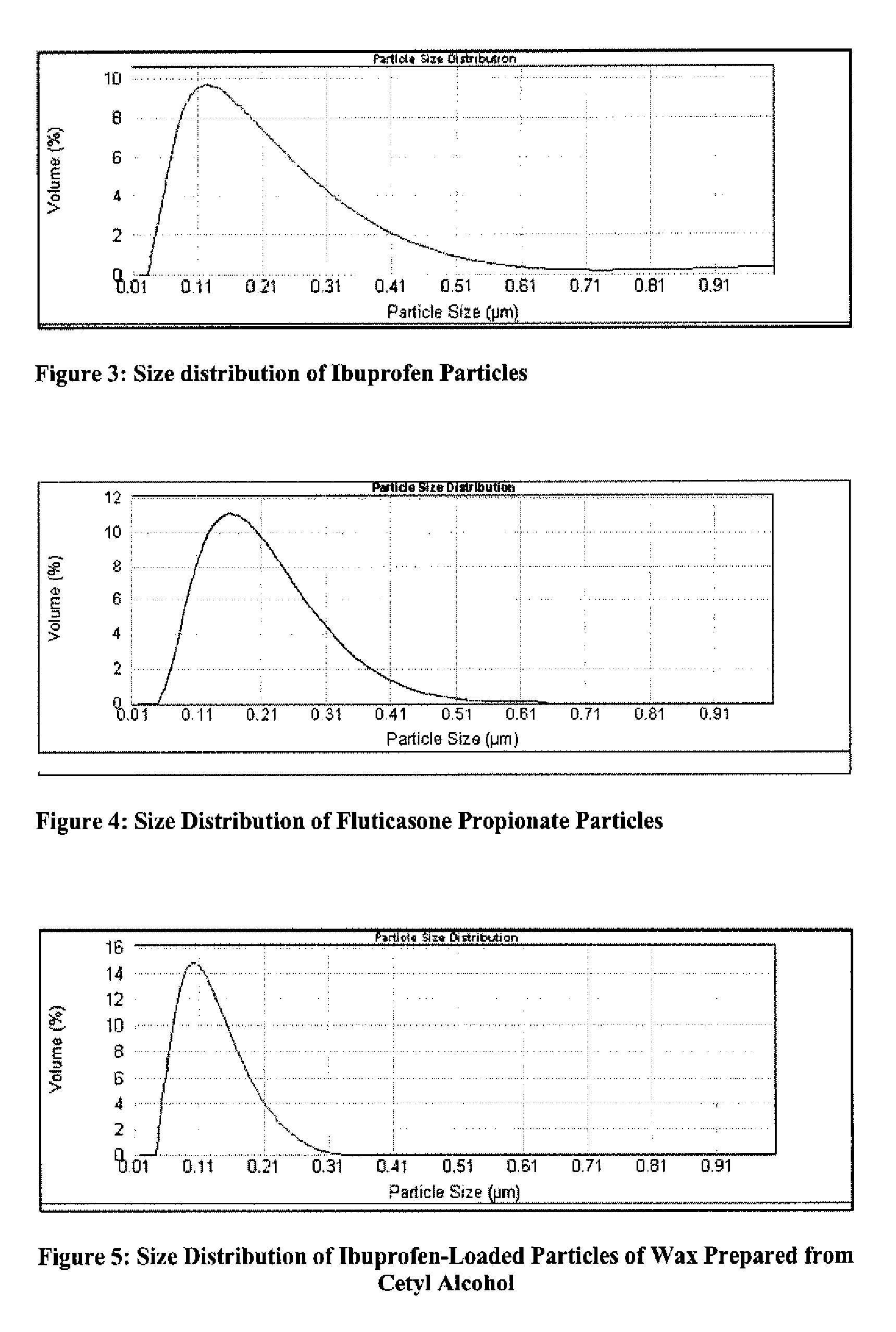

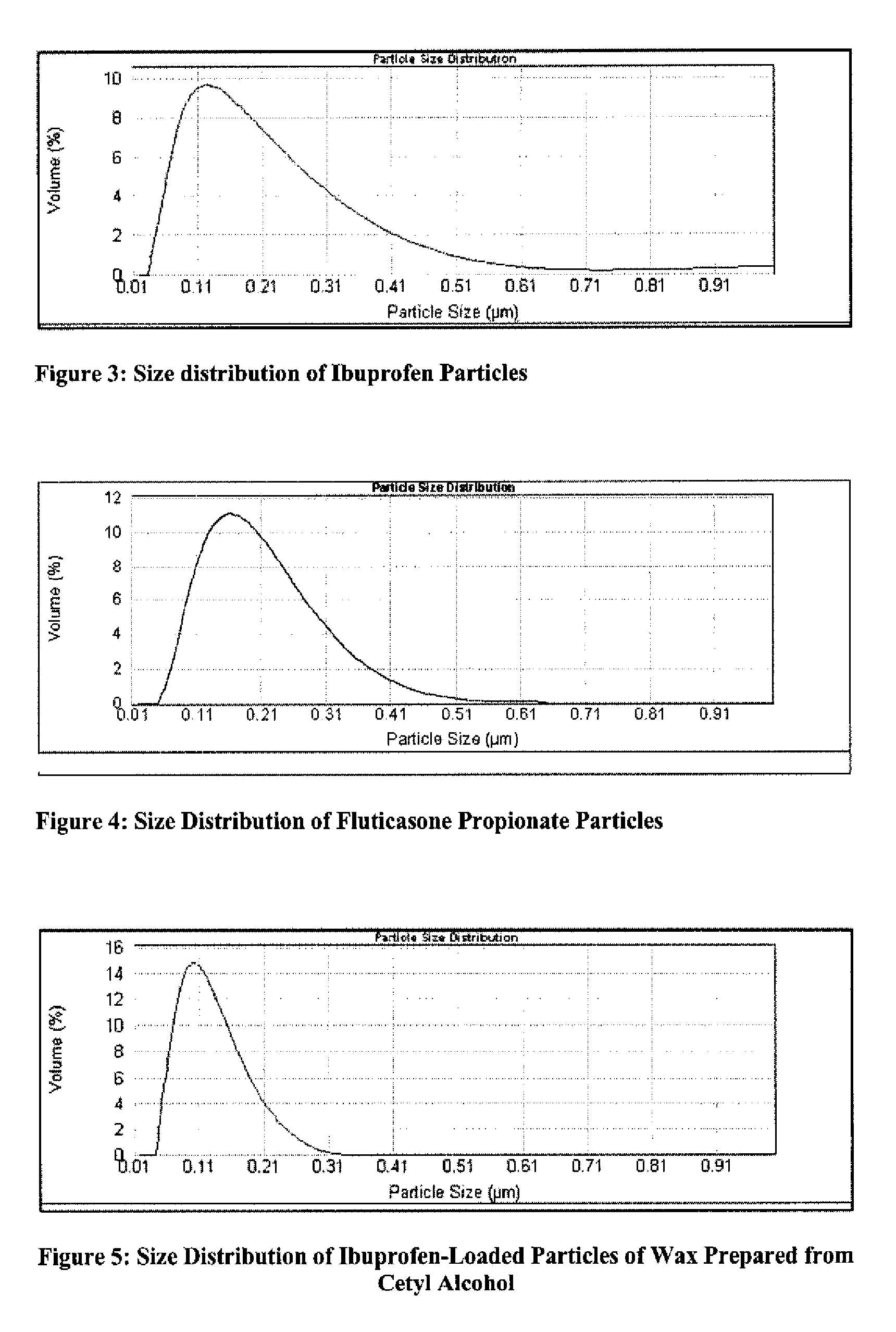

Process for Making Crystals

ActiveUS20100190760A1Optimise activity and stabilityGood dispersionBiocidePowder deliveryEmulsionChemistry

A process for preparing an emulsion or a dispersion comprising crystalline particles of at least one active principal that comprises contacting a solution of at least one solute in a solvent or mixture of solvents in a first flowing stream with a non-solvent in a second flowing stream wherein the non-solvent and solvent are not miscible with each other, so as to form an emulsion or a dispersion. Super saturation is brought about by suitable means, and the emulsion or dispersion is subjected to ultrasonic irradiation to mediate crystal nucleation.

Owner:CIRCASSIA

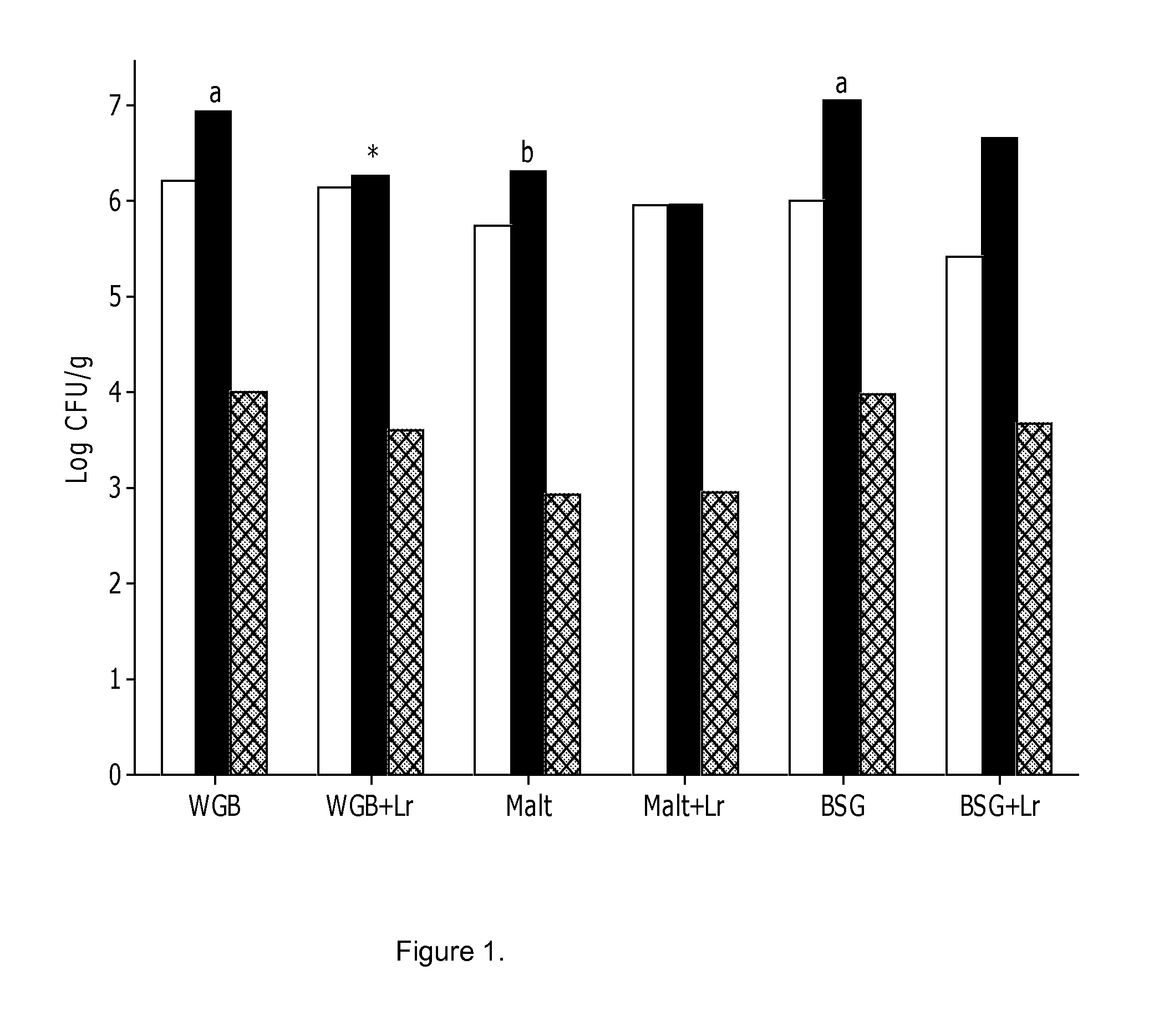

Non-fermented compositions comprising a cereal based fraction and a probiotic and uses thereof

The present invention relates to a non-fermented composition having the ability to increase the formation of butyric acid in the colon and comprising at least one cereal based fraction and at least one isolated probiotic strain of Lactobacillus as well as the use of said non-fermented composition as a synbiotic and for treatment of the metabolic syndrome, ulcerative colitis, Crohns disease, Irritable bowel syndrome (IBS), or Inflammatory bowel disease (IBD). The non-fermented composition of the invention is useful for the maintenance of a healthy gut-mucosa and / or for the provision of an increased barrier function of the gutmucosa.

Owner:PROBI AB LUND SE

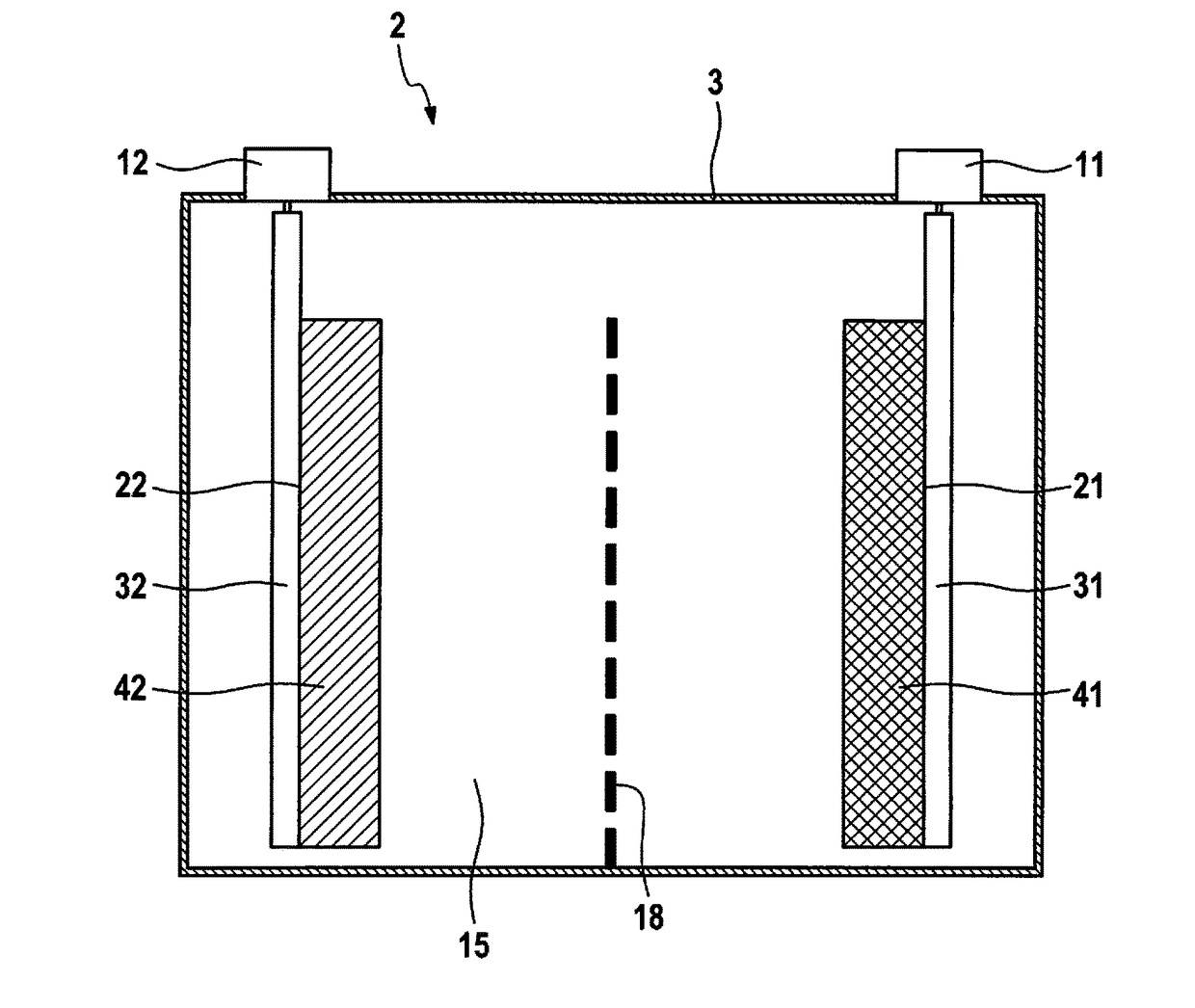

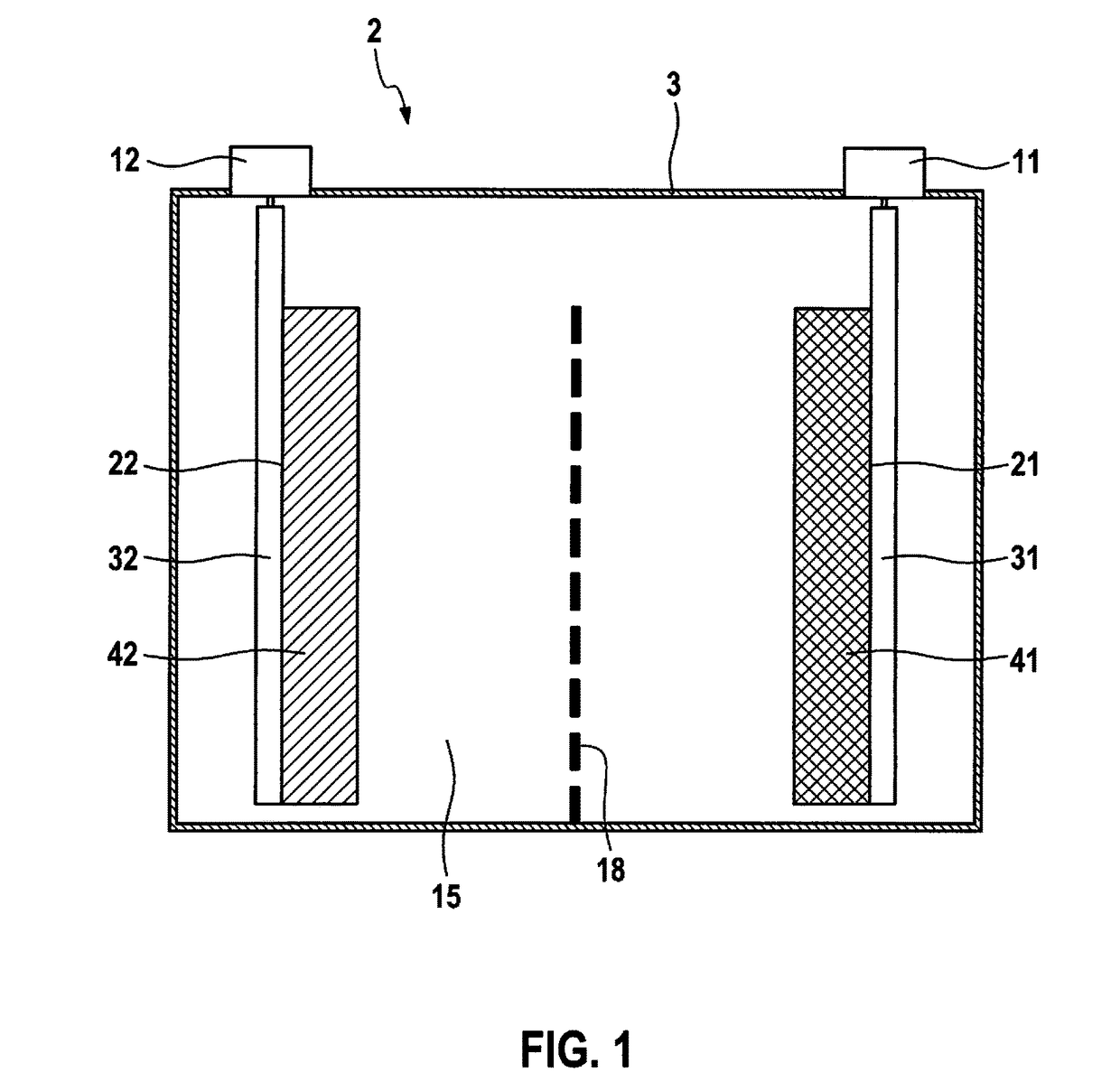

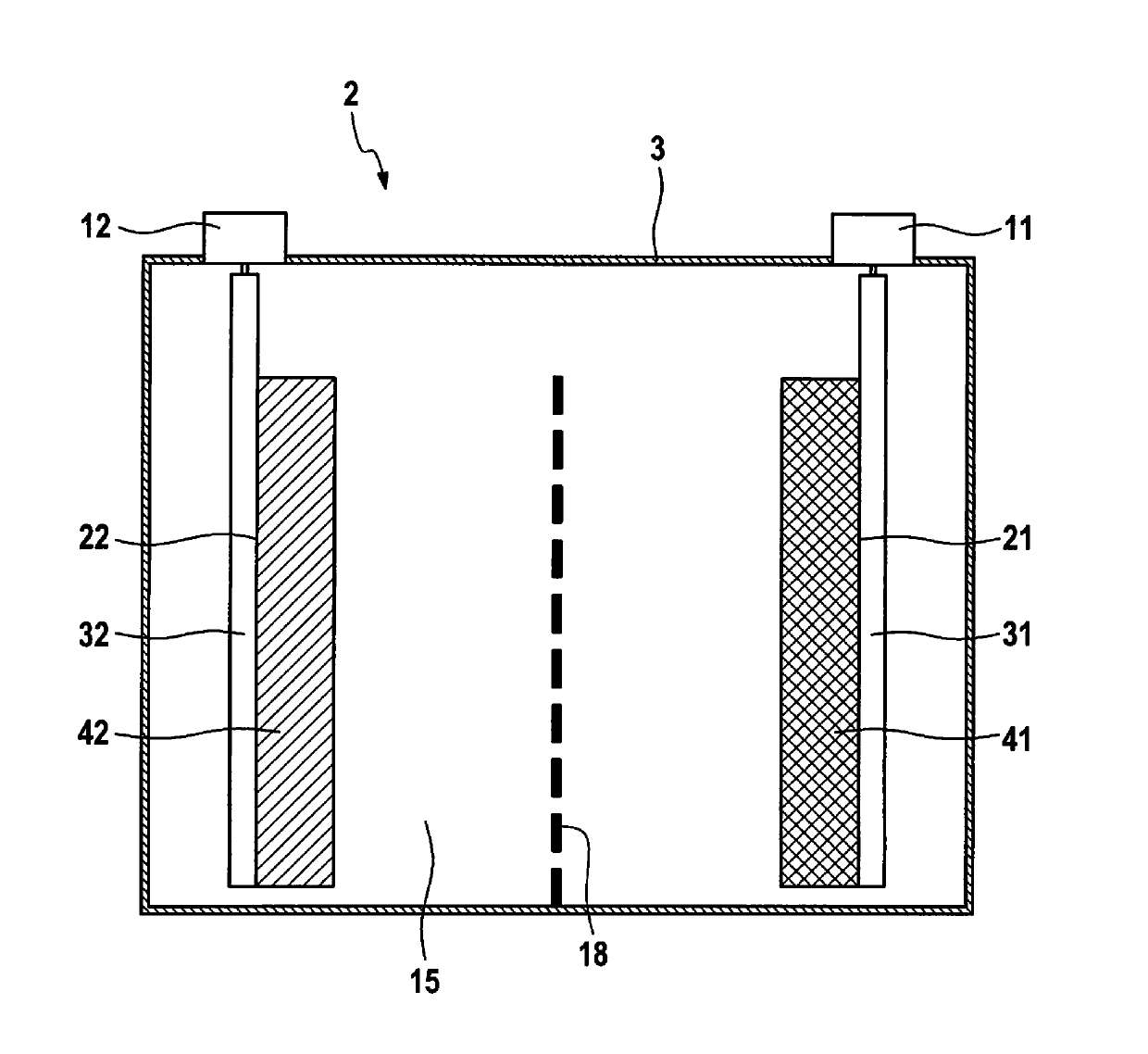

Hybrid supercapacitor, including an electrolyte composition, having improved conductivity

InactiveUS20170352498A1Improve stabilityImprove conductivityHybrid capacitor separatorsHybrid capacitor electrolytesOrganic solventSupercapacitor

A hybrid supercapacitor, including at least one negative electrode that includes a statically capacitive active material, an electrochemical redox active material, or a mixture thereof, at least one positive electrode that includes a statically capacitive active material, an electrochemical redox active material, or a mixture thereof, at least one separator that is situated between the at least one negative electrode and the at least one positive electrode, and an electrolyte composition, with the condition that at least one electrode includes a statically capacitive active material, and at least one electrode includes an electrochemical redox active material, the electrolyte composition being a liquid electrolyte composition and including at least one liquid, aprotic, organic solvent, at least one conducting salt, and at least one additive.

Owner:ROBERT BOSCH GMBH

Coated drill and method of making the same

ActiveUS8043035B2Improve wear resistanceMaintain good propertiesMetal-working drilling toolsTransportation and packagingCemented carbideWear resistance

The present invention relates to a drill comprising a cemented carbide or high speed steel substrate and a coating wherein the coating comprises: a first layer system having a multilayered structure covering substantially the whole active part of the drill, a second layer system having a multilayered structure covering only the tip area of the drill.Drills according to the present invention have good wear resistance and improved properties when reconditioning the drill.The present invention also relates to a method of making a drill according to the present invention.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

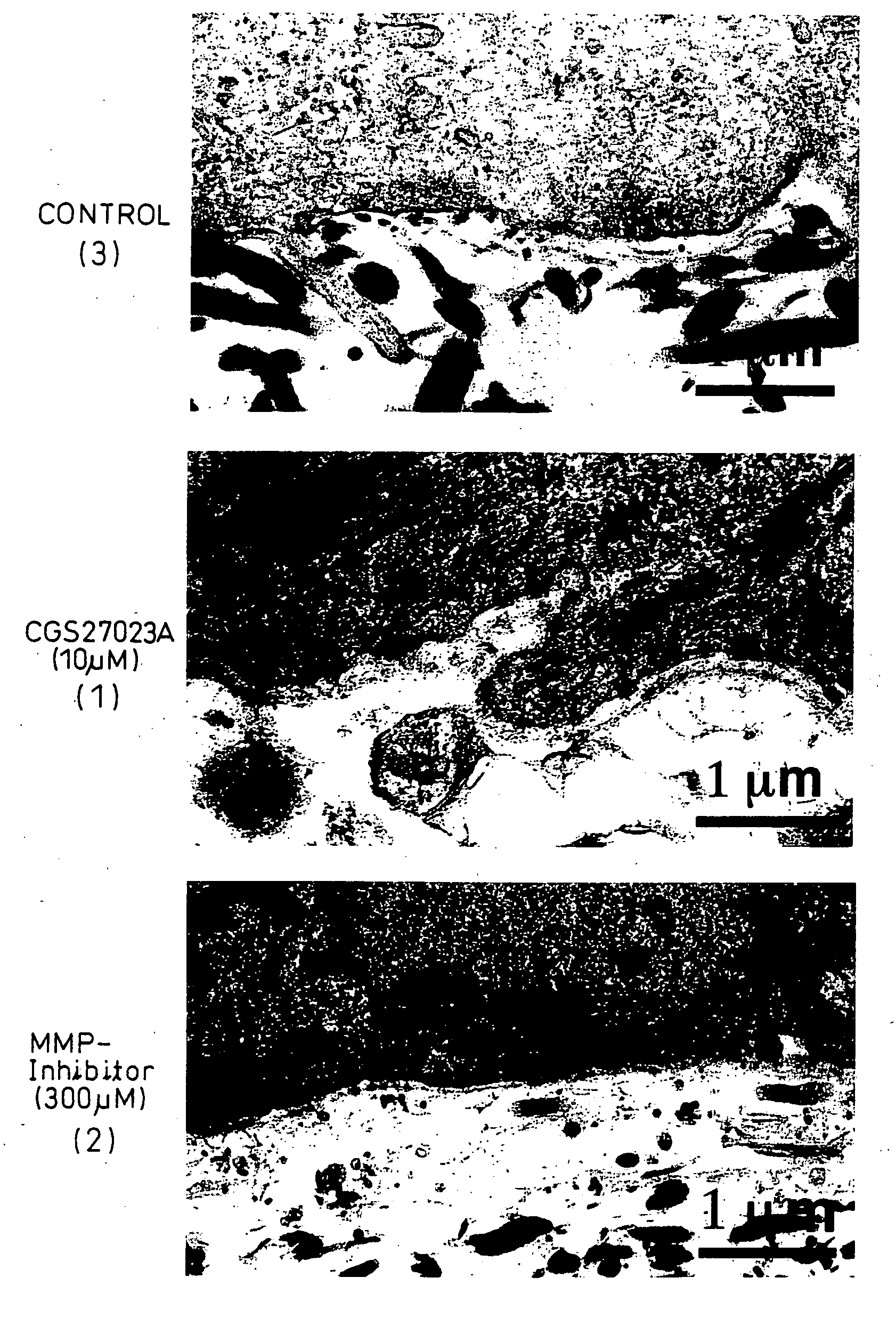

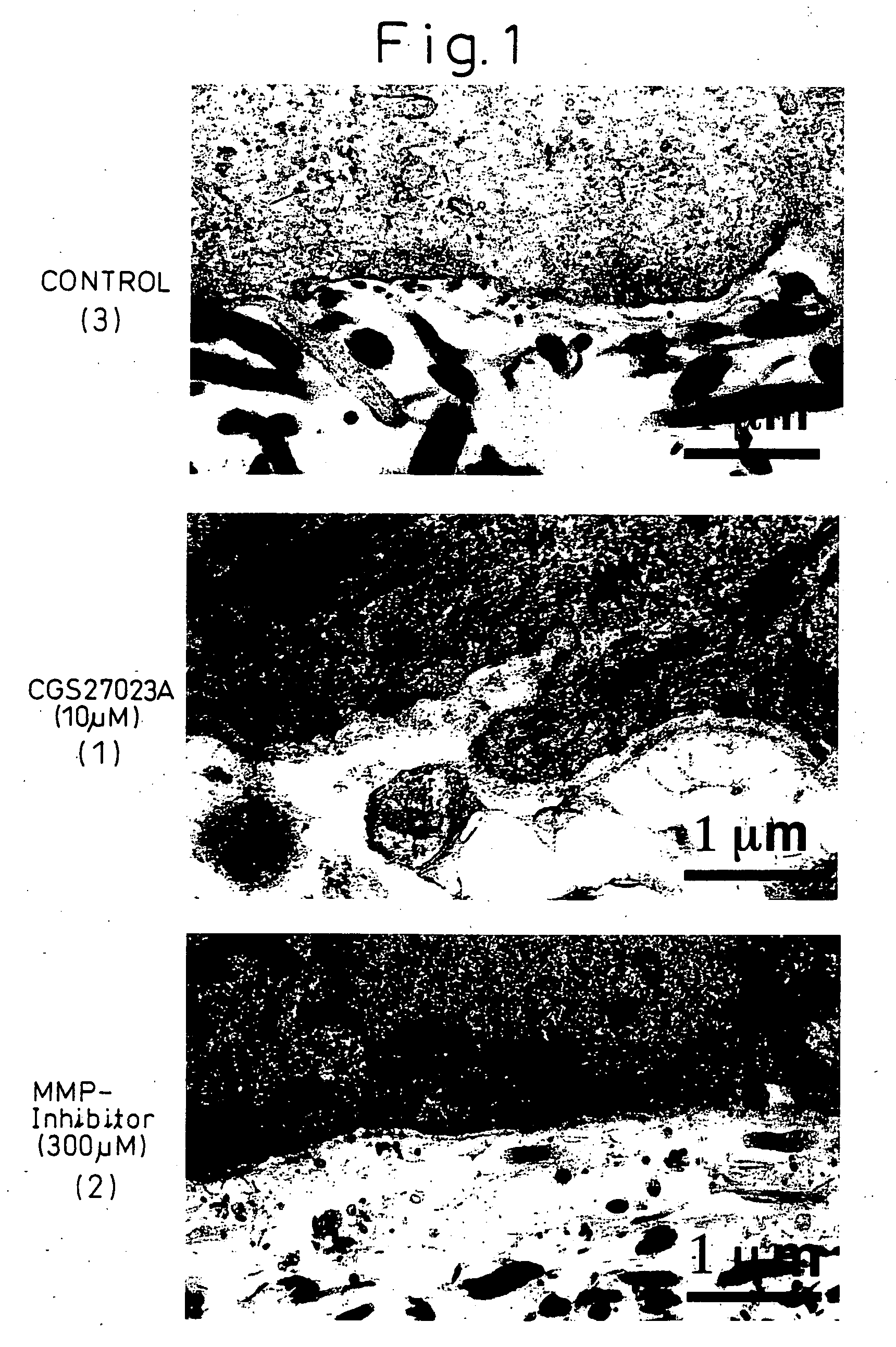

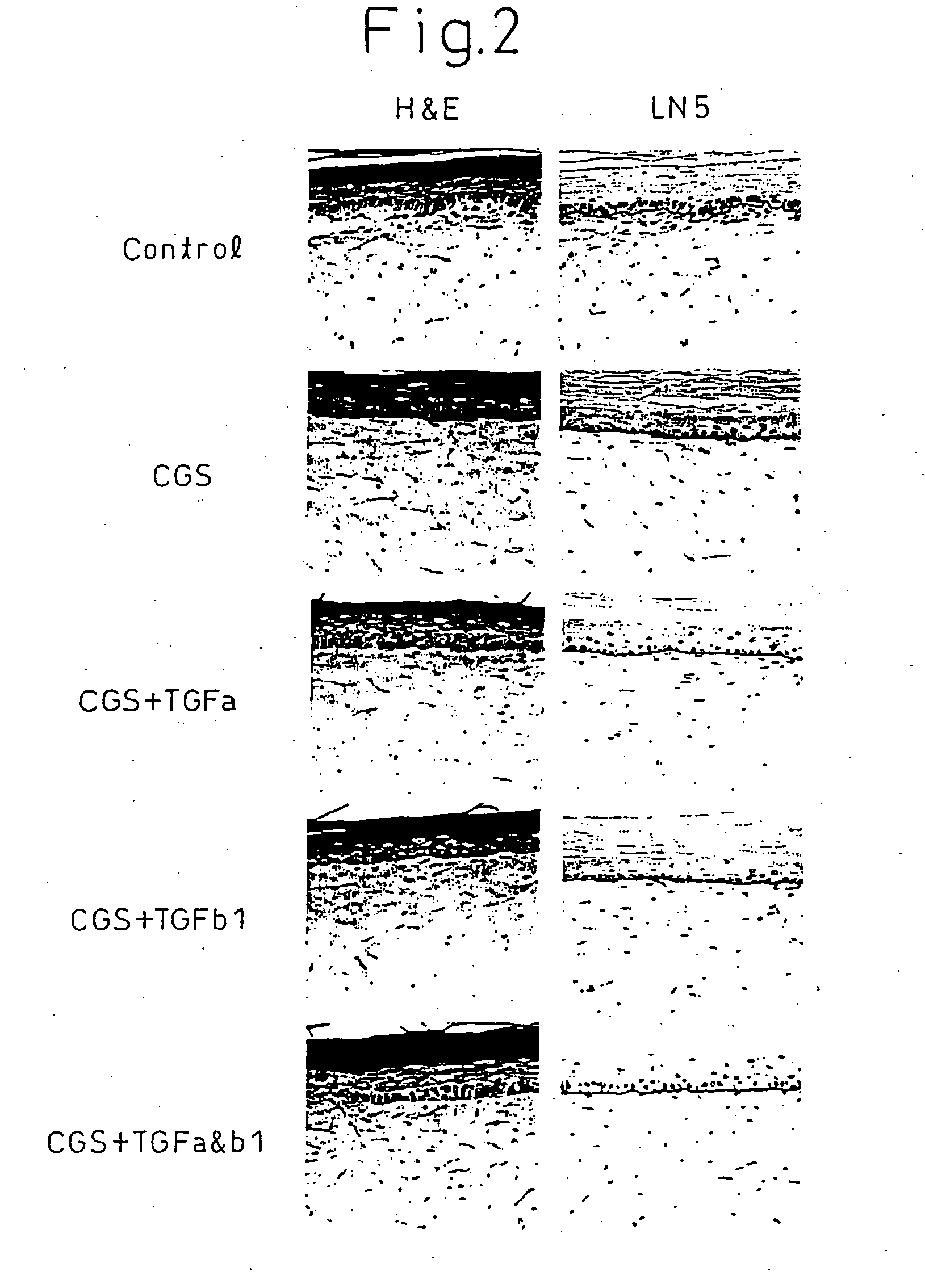

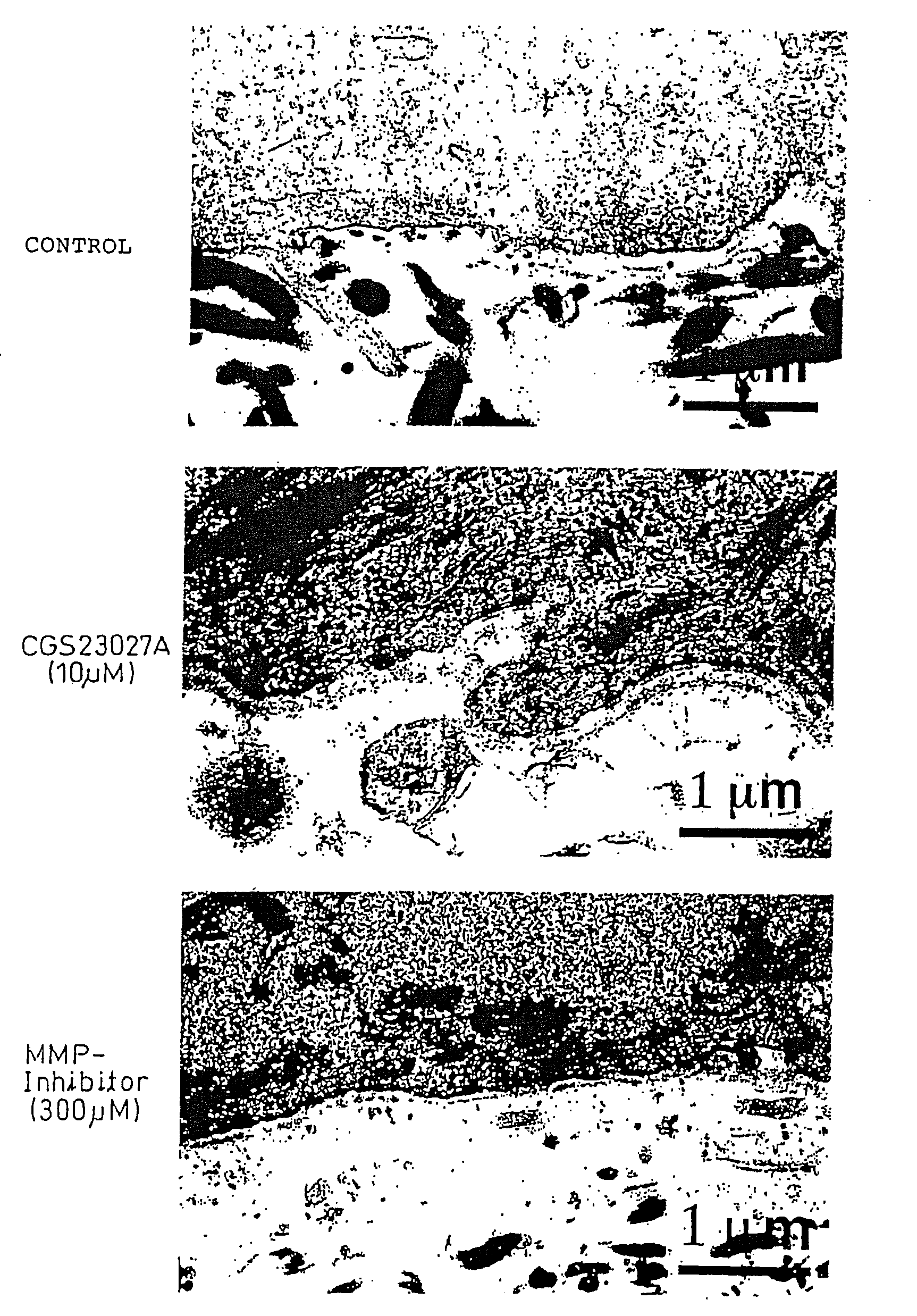

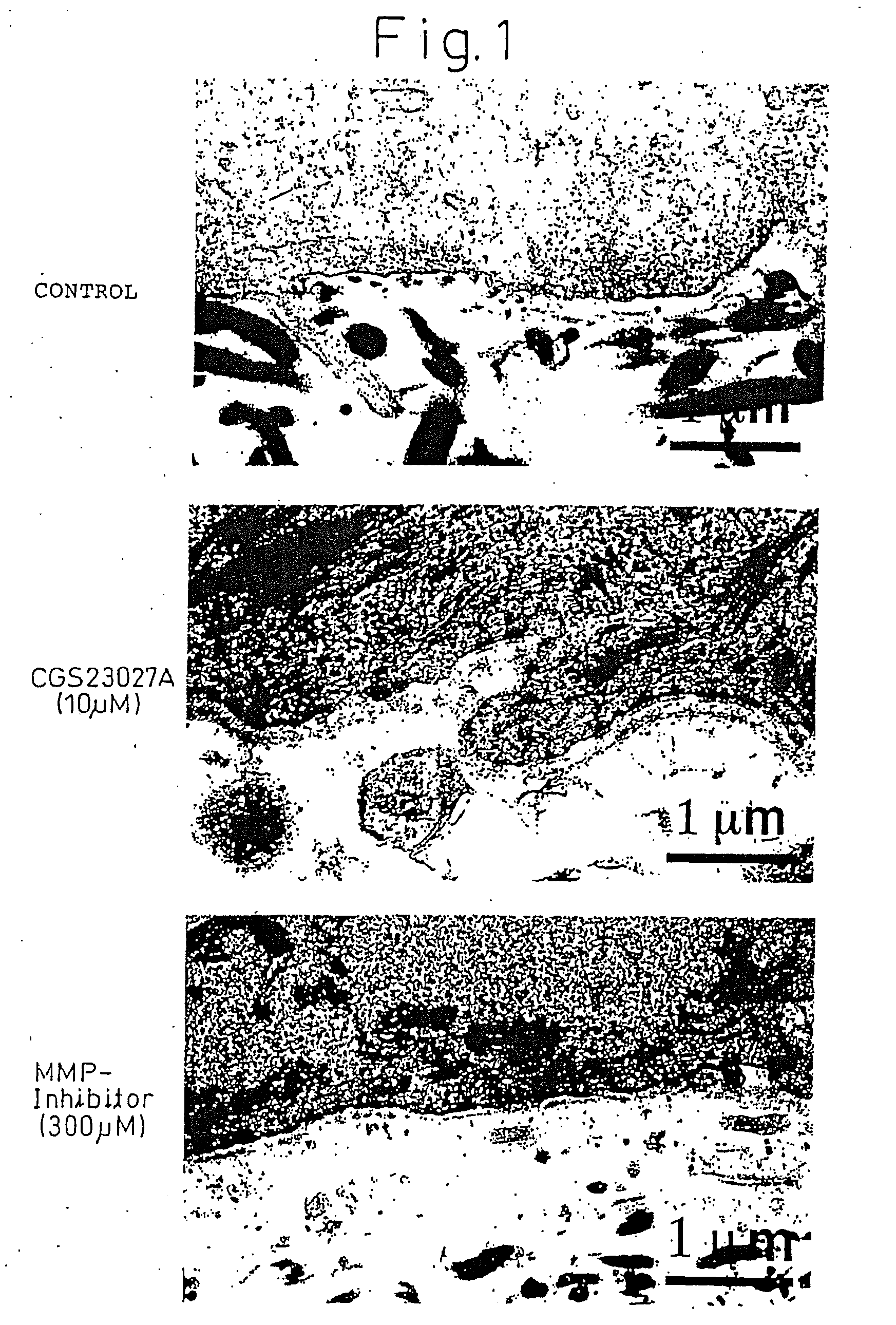

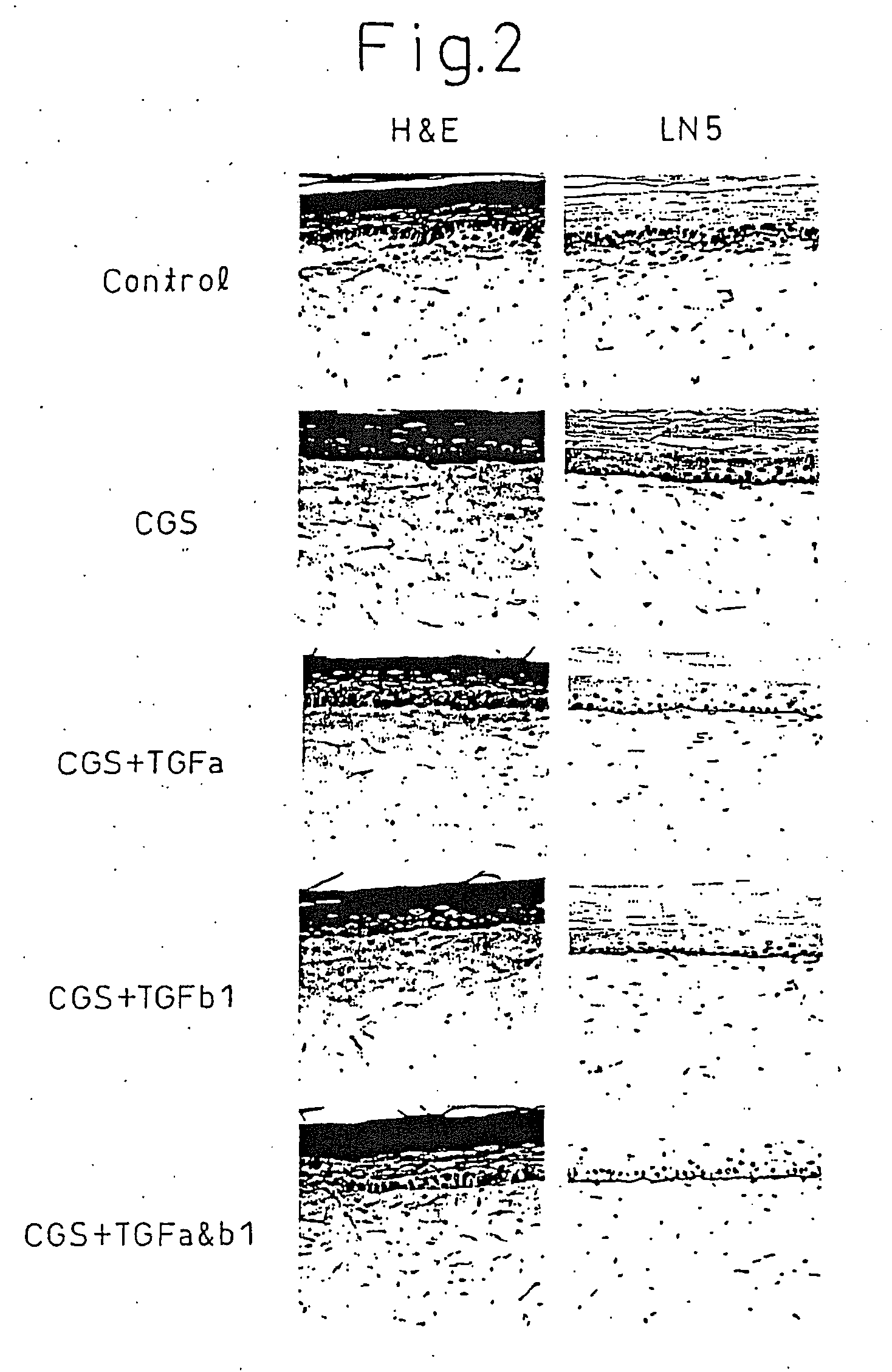

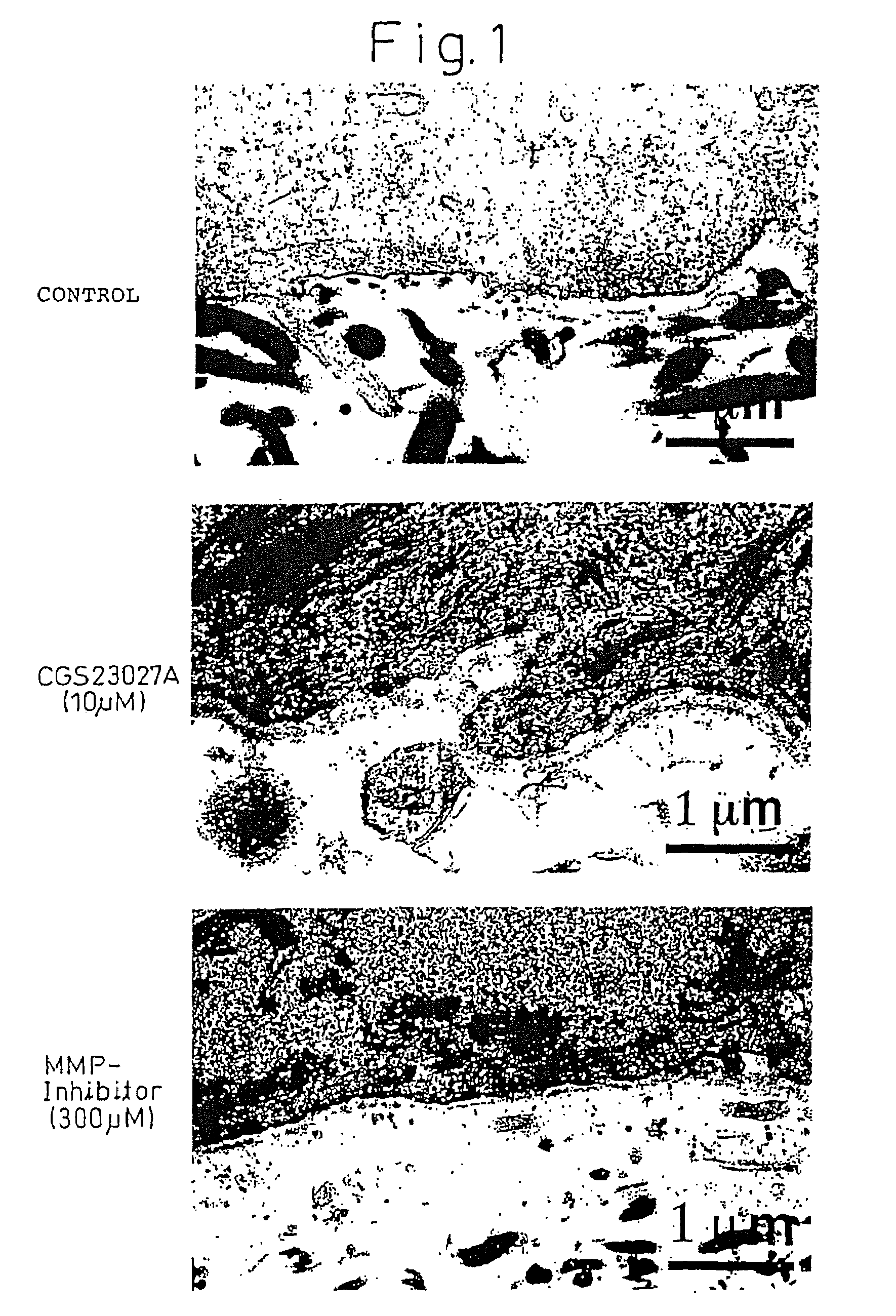

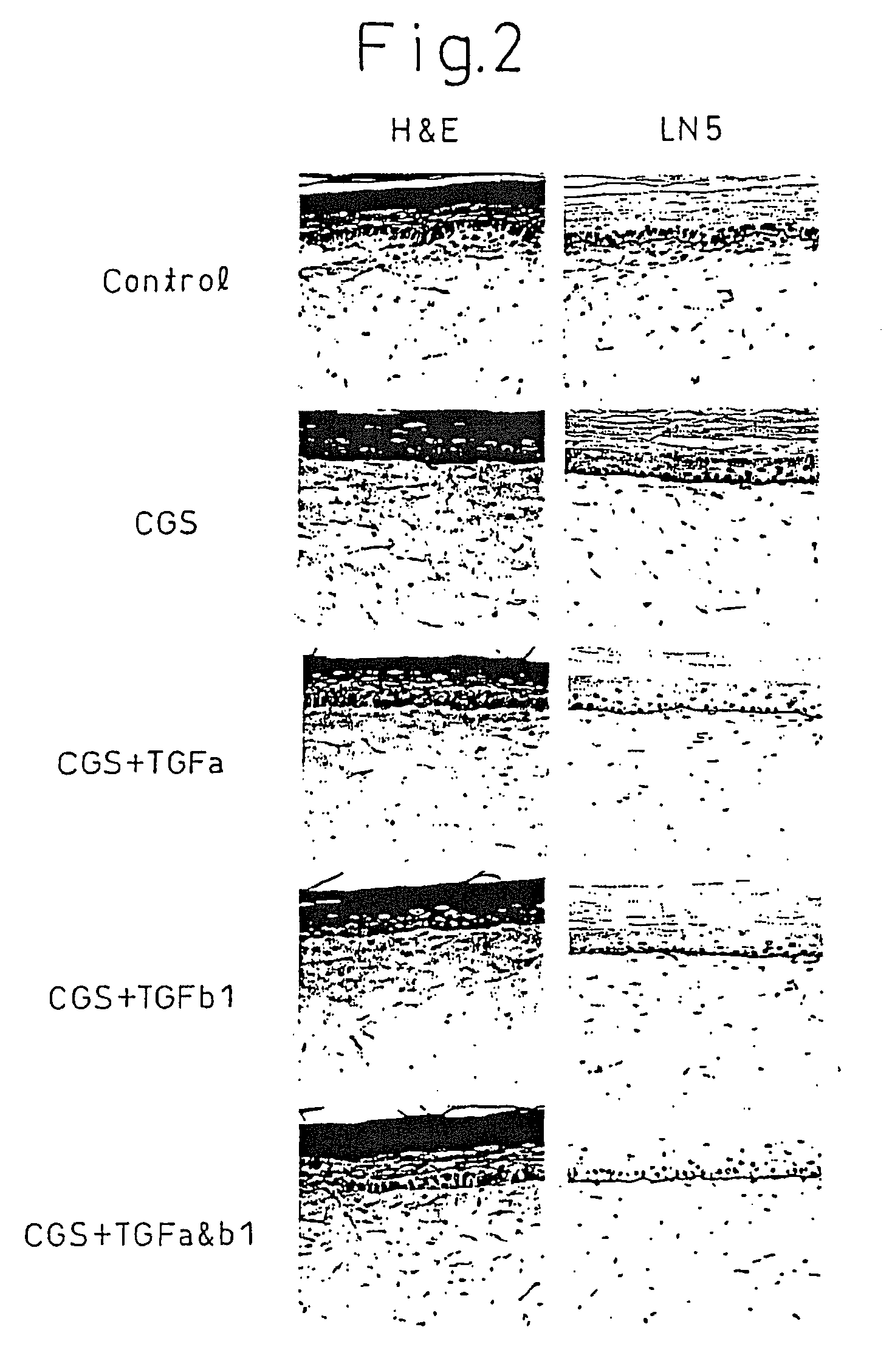

Material for promoting skin basement formation

InactiveUS20060159782A1FormationPromote formationBiocideCosmetic preparationsBasementMatrix metalloproteinase inhibitor

A method for promoting skin basement membrane formation comprises administering matrix metalloproteinase inhibitor or matrix metalloproteinase inhibitor and matrix protein production promoting agent. The matrix metalloproteinase inhibitor is N-hydroxy-2(R)-[[(4-methoxyphenyl)sulfonyl](3-picolyl)amino]-3-methylbutanamide hydrochloride.

Owner:SHISEIDO CO LTD

Method for Preparing of Organofluoro Compounds in Alcohol Solvents

ActiveUS20080171863A1Increase reactivityLow reactivityIsotope introduction to heterocyclic compoundsIn-vivo radioactive preparationsREACTION TIME DECREASEDSolvent

The present invention relates to a method for preparation of organofluoro compounds containing radioactive isotope fluorine-18. More particularly, the present invention relates to a method for preparation of organofluoro compound by reacting fluorine salt containing radioactive isotope fluorine-18 with alkyl halide or alkyl sulfonate in the presence of alcohol of Chemistry (FIG. 1) as a solvent to obtain high yield of organofluoro compound. Synthesis reaction according to the present invention may be carried out under mild condition to give high yield of the organofluoro compounds and the reaction time is decreased, and thereby is suitable for the mass production of the organofluoro compounds.

Owner:FUTURECHEM +1

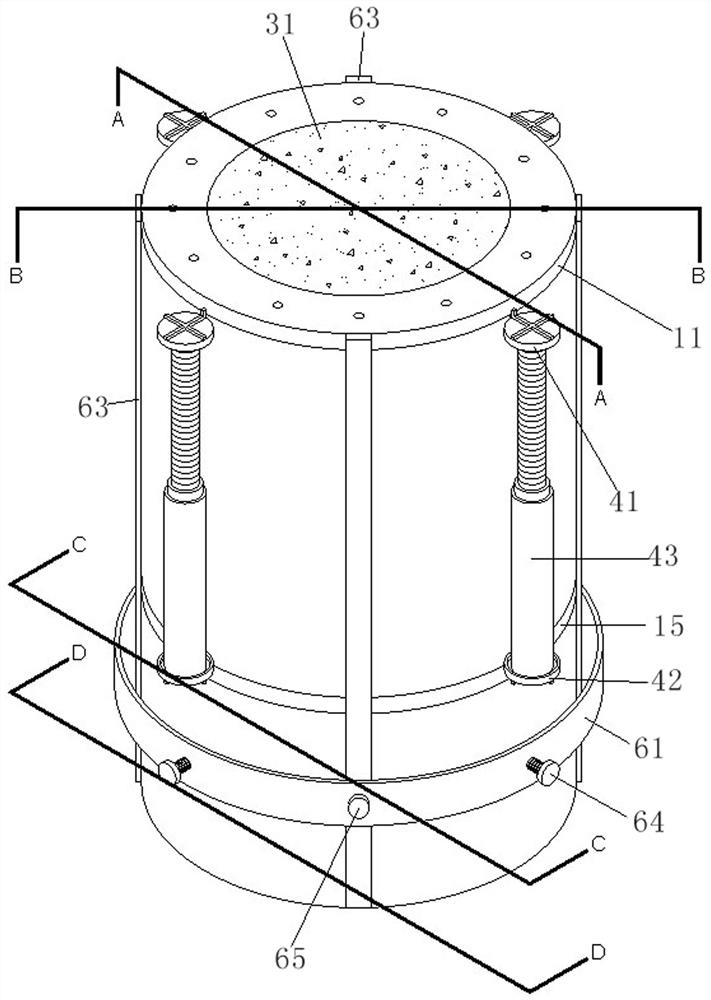

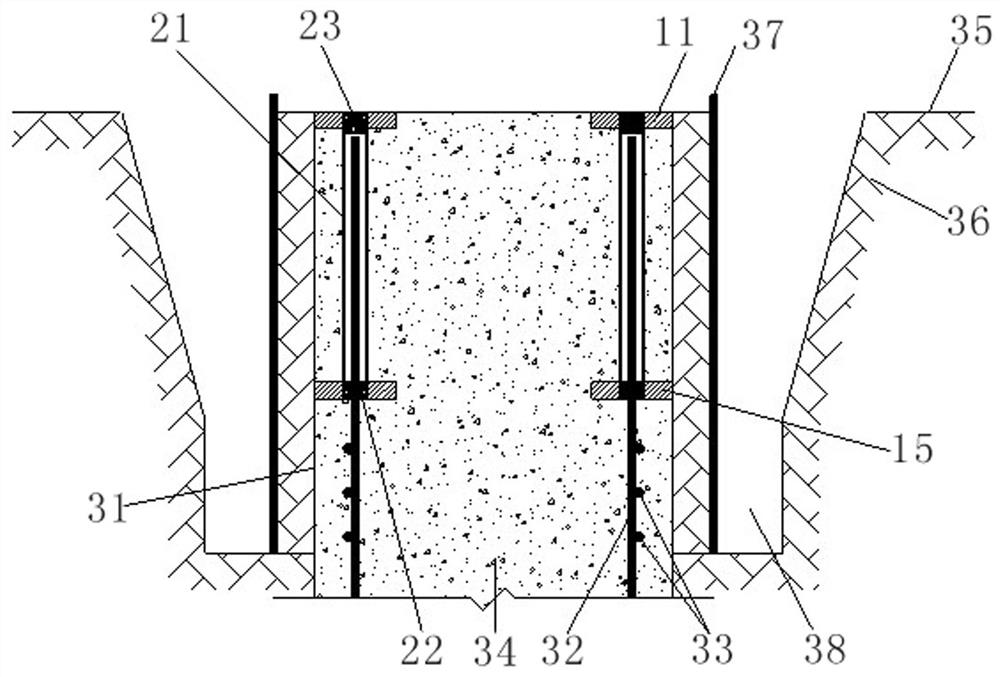

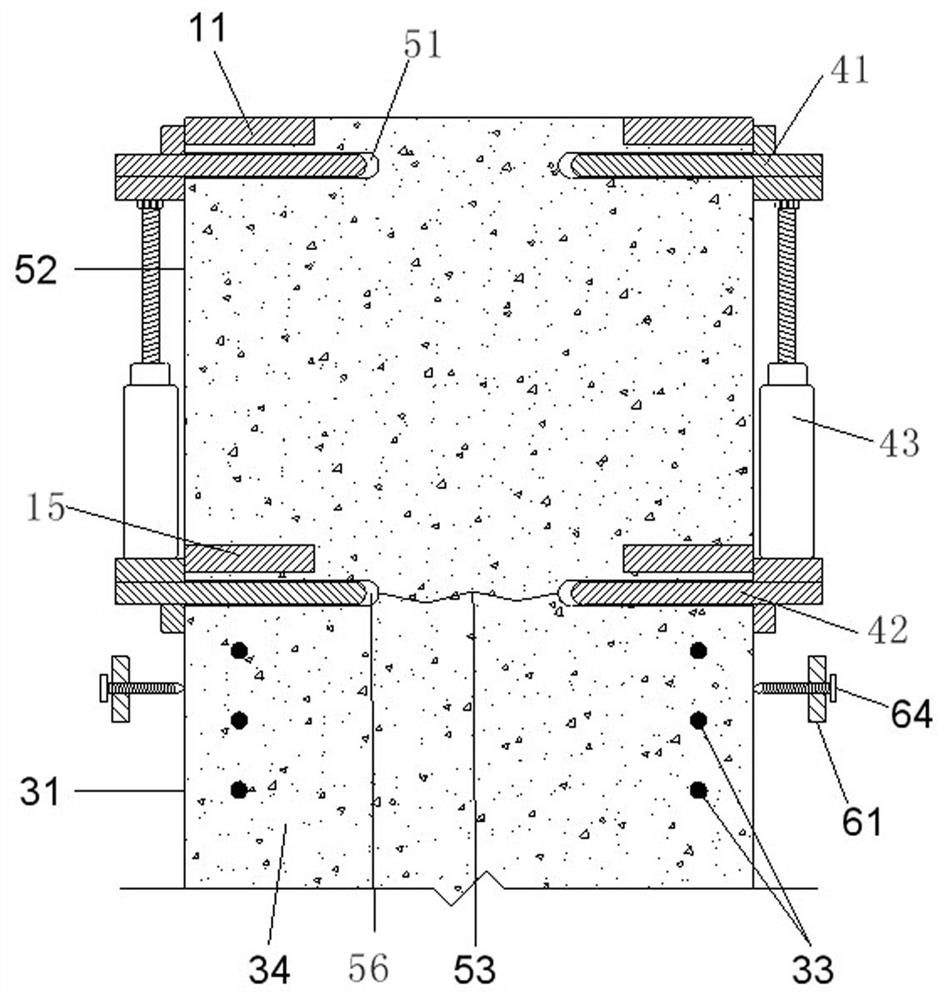

Large-diameter cast-in-situ bored pile head overall breaking system and construction method

The invention belongs to the technical field of cast-in-situ pile construction. A large-diameter cast-in-situ bored pile head overall breaking system comprises a pile head separation support, isolation sleeves, a first counter-force frame, a second counter-force frame and a driving part, wherein the first counter-force frame and the second counter-force frame are correspondingly arranged up and down; the multiple isolation sleeves are arranged on the pile head separation support, longitudinal main ribs on the upper portion of a steel reinforcement cage of a cast-in-situ pile are arranged in the isolation sleeves in a matched and penetrating manner, and the pile head separation support and the isolation sleeves are poured on the top of the cast-in-situ pile; and a plurality of first counter-force holes are circumferentially distributed in a pile head of the cast-in-situ pile, a plurality of second counter-force holes are circumferentially distributed in the position, on the lower portion of the pile head separation support, of the cast-in-situ pile, and the first counter-force frame and the second counter-force frame are correspondingly arranged in the first counter-force holes and the second counter-force holes correspondingly. The invention further discloses a large-diameter cast-in-situ bored pile construction method. The large-diameter cast-in-situ bored pile head overall breaking system is reasonable in overall design, the problem existing in breaking of the pile head of the large-diameter cast-in-situ bored pile in the prior art can be solved, the breaking efficiency is improved, and the structural damage to a pile body is reduced.

Owner:HENAN HIGHWAY ENG GROUP +1

Method of Production of Artificial Skin

InactiveUS20080248571A1FormationPromote formationBiocideCosmetic preparationsMedicineMethods of production

A method for production of artificial skin by administering matrix metalloproteinase inhibitor or matrix metalloproteinase inhibitor and matrix protein production promoting agent. The matrix metalloproteinase inhibitor is N-hydroxy-2(R)-[[(4-methoxyphenyl)sulfonyl](3-picolyl)amino]-3-methylbutanamide hydrochloride.

Owner:SHISEIDO CO LTD

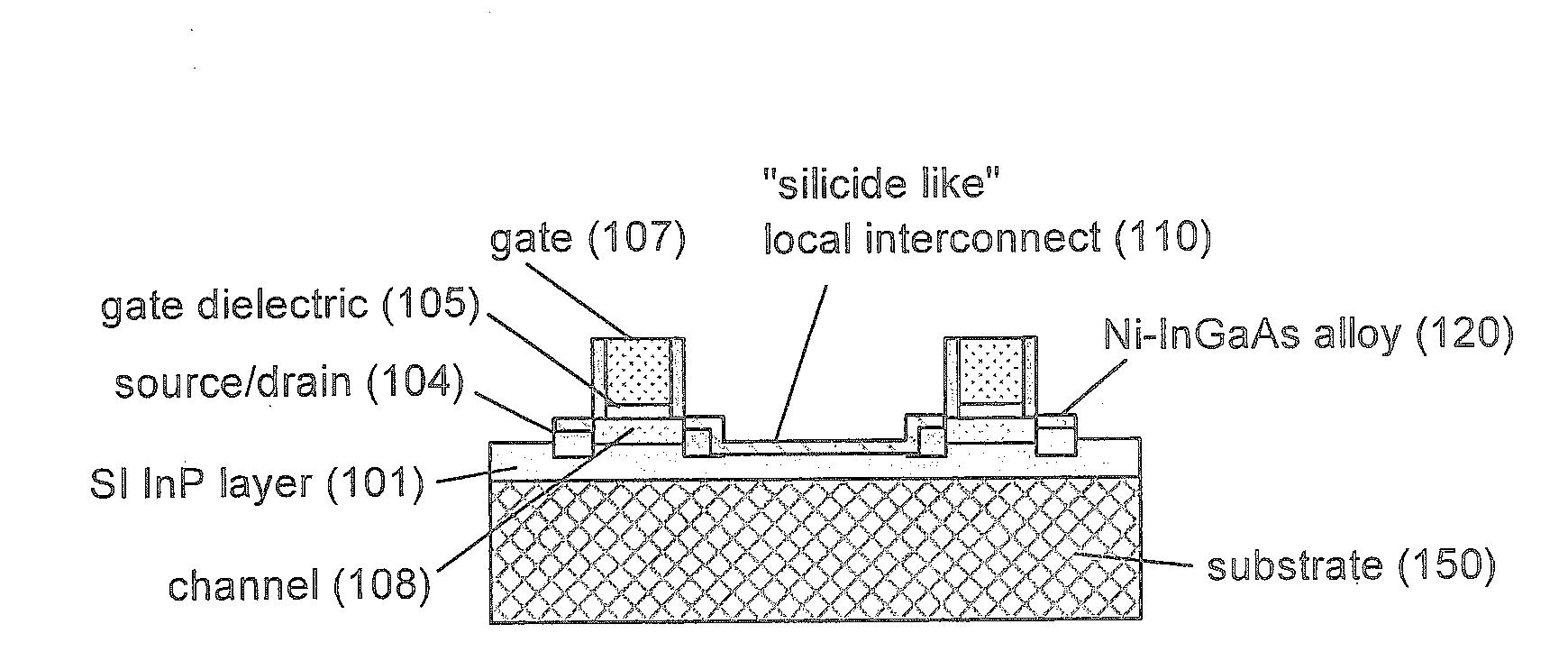

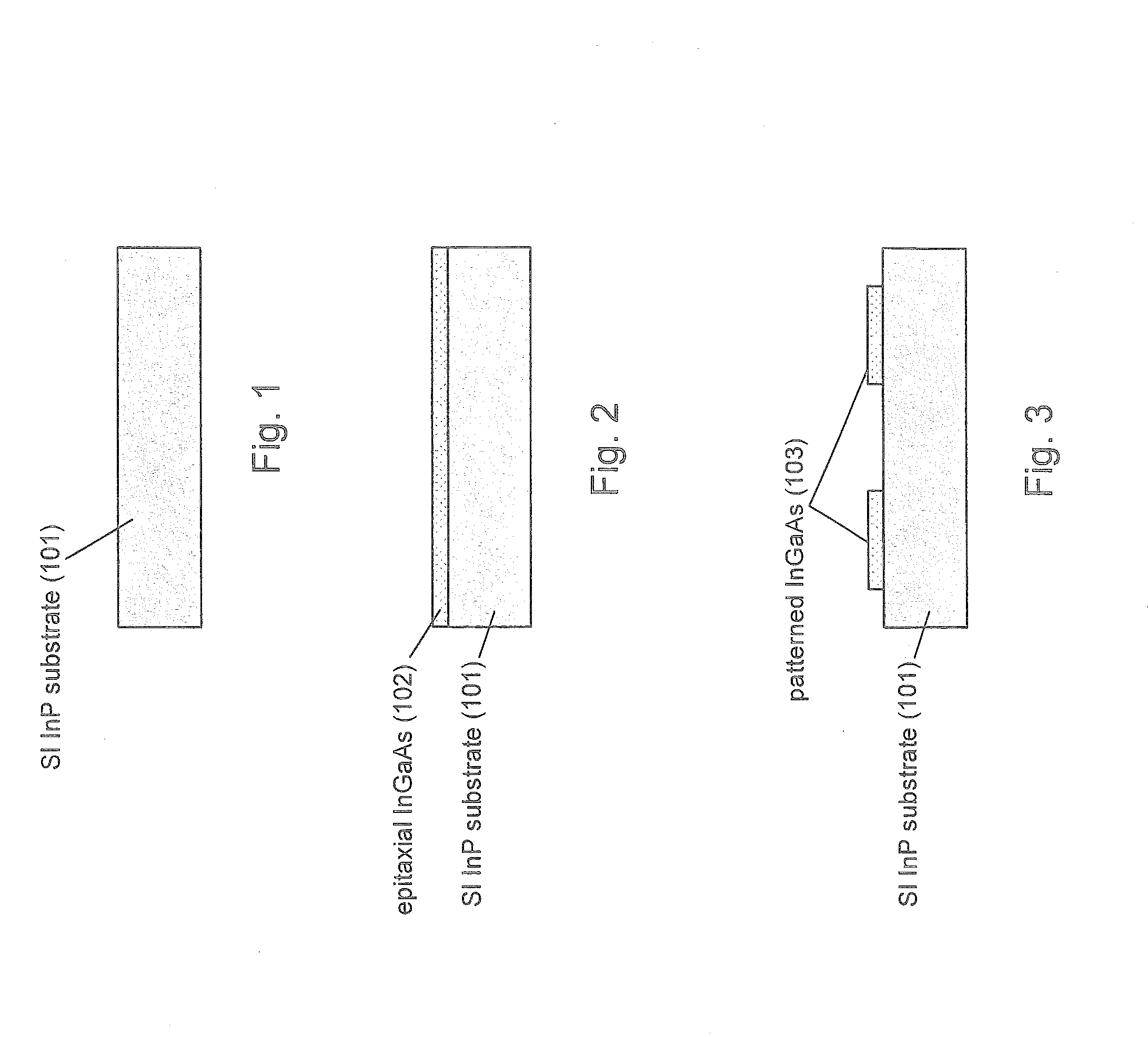

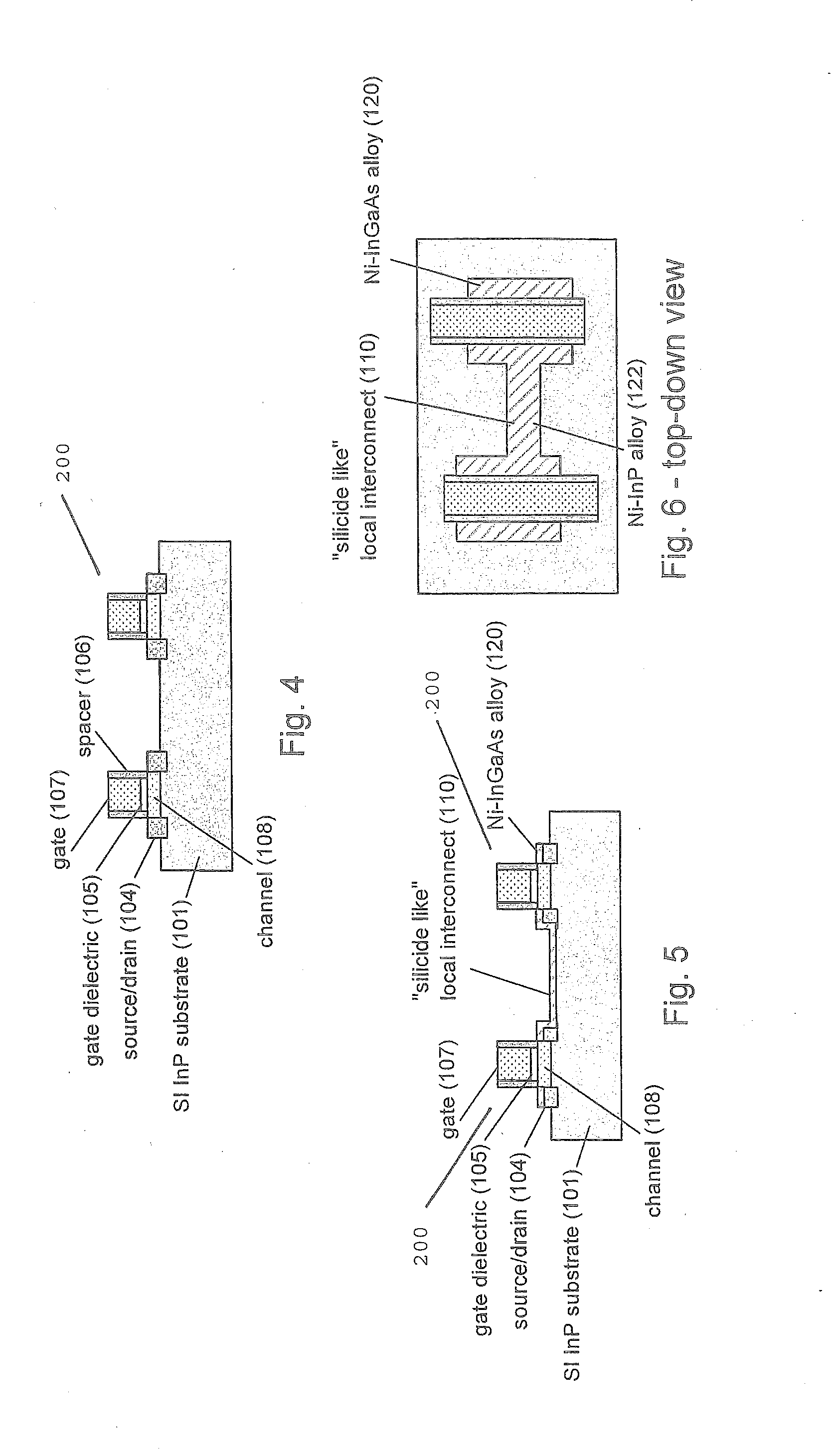

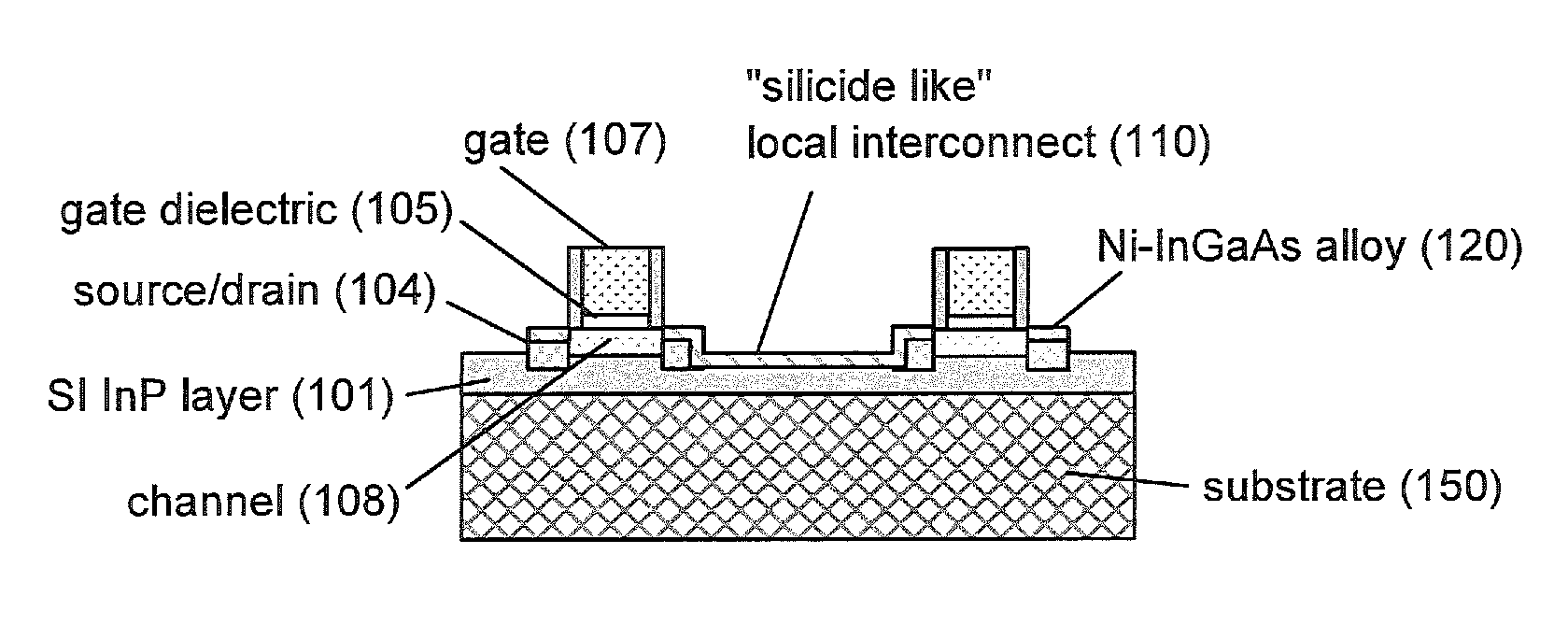

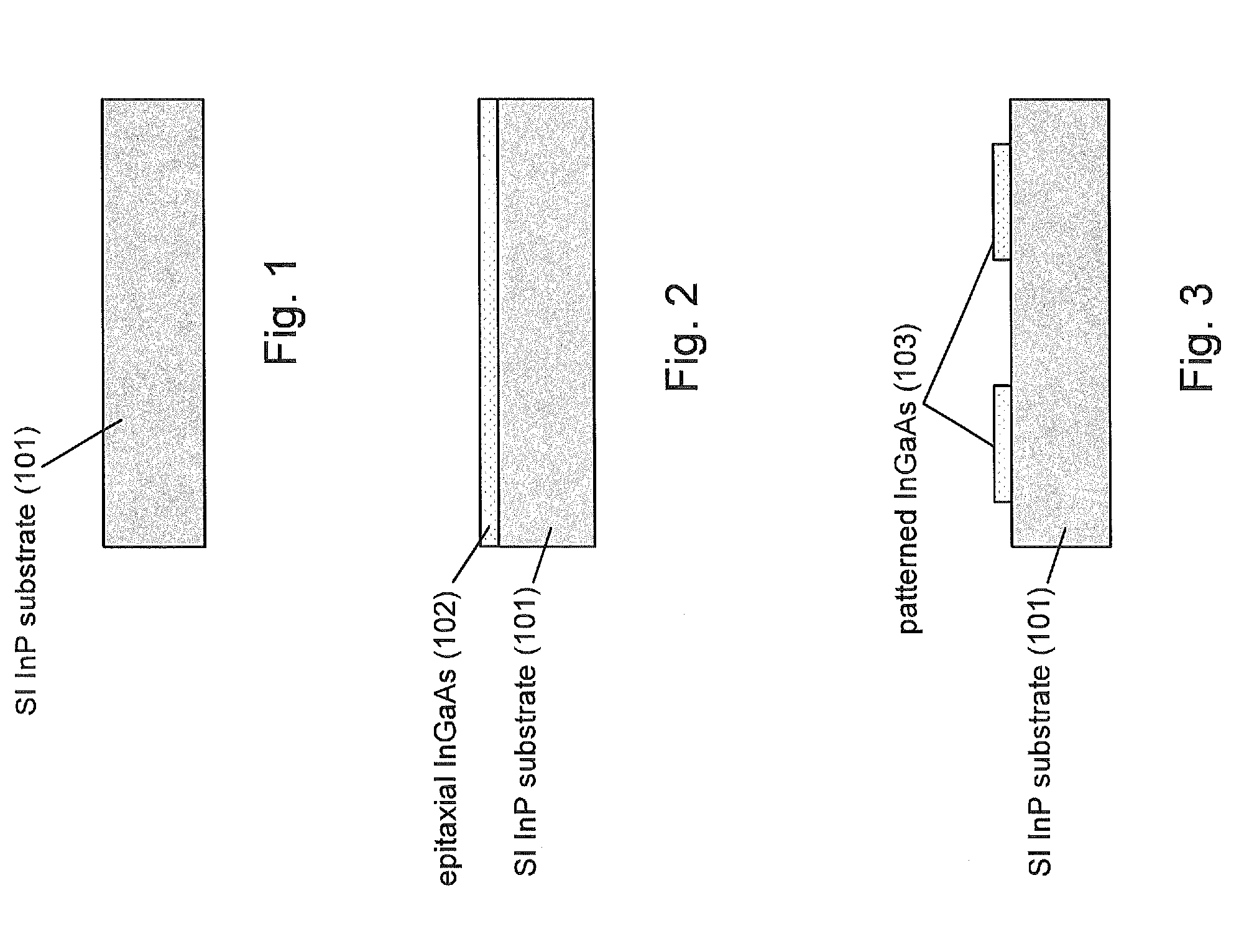

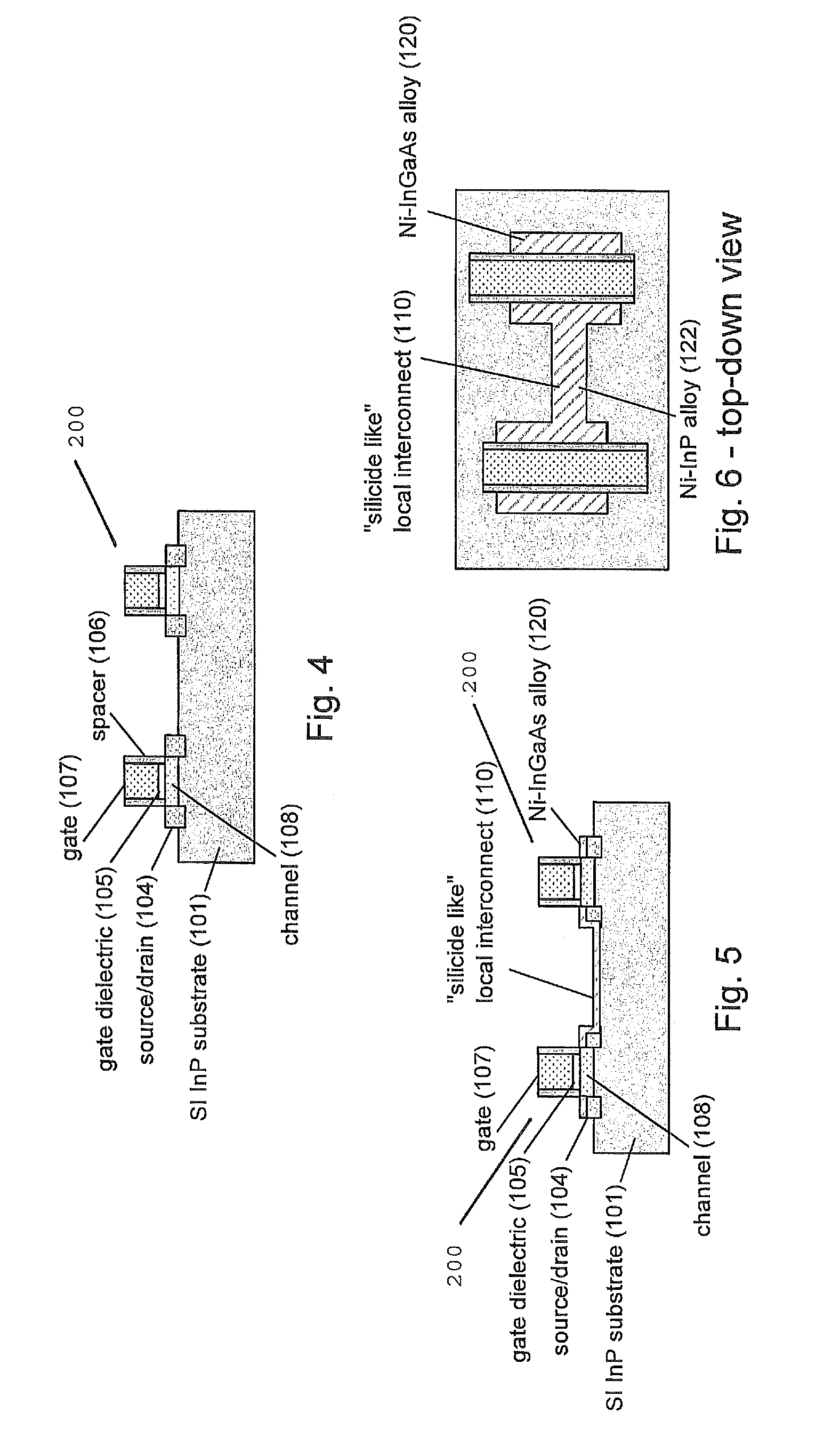

Local interconnects by metal-iii-v alloy wiring in semi-insulating iii-v substrates

InactiveUS20150054092A1FormationEfficient formationTransistorSemiconductor/solid-state device detailsSemiconductor structureSemiconductor alloys

A structure and method of producing a semiconductor structure including a semi-insulating semiconductor layer, a plurality of isolated devices formed over the semi-insulating semiconductor layer, and a metal-semiconductor alloy region formed in the semi-insulating semiconductor layer, where the metal-semiconductor alloy region electrically connects two or more of the isolated devices. The metal-semiconductor alloy region has a metal concentration in a range from 1×1021 atoms / cm3 to 1×1023 atoms / cm3

Owner:GLOBALFOUNDRIES INC

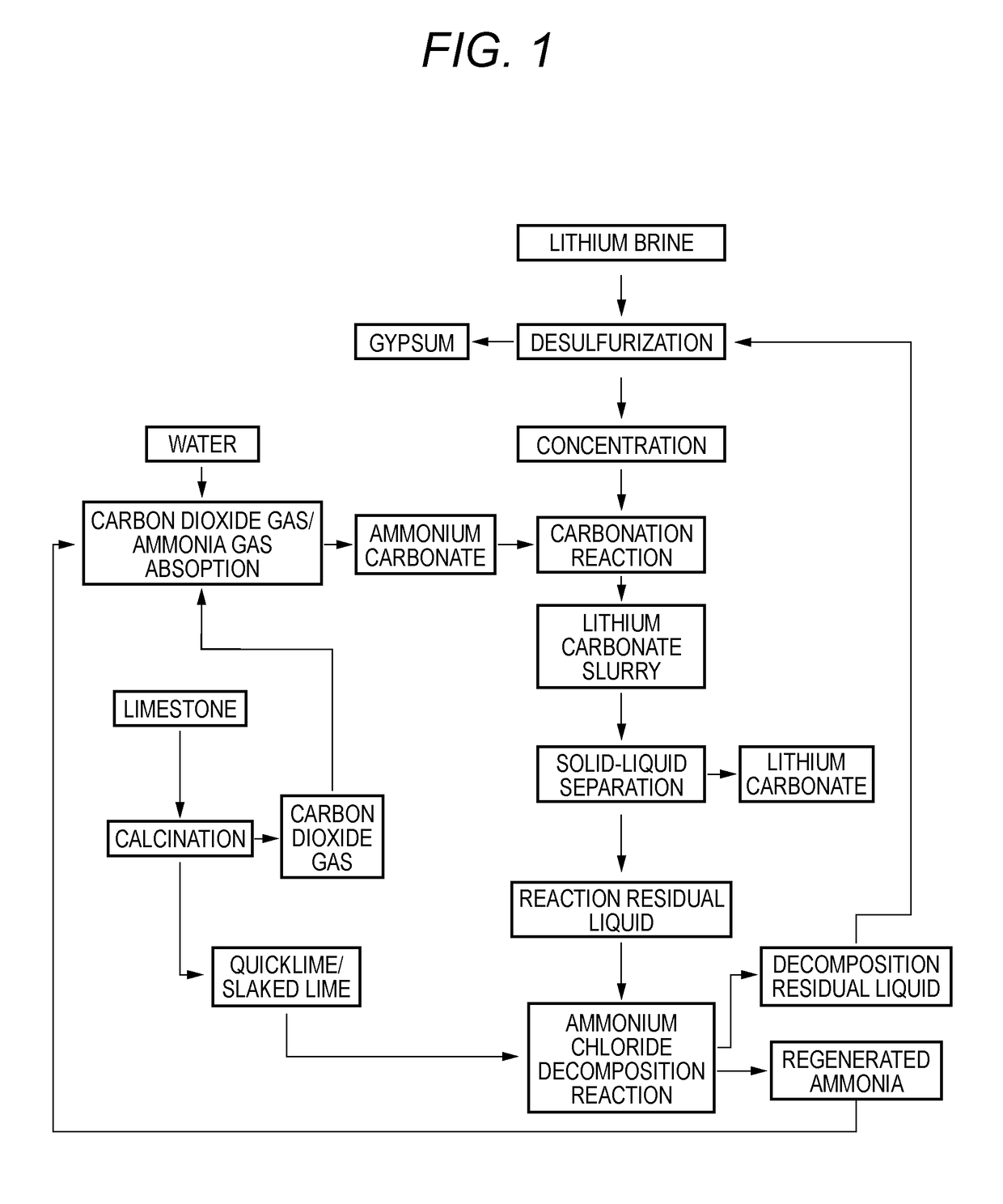

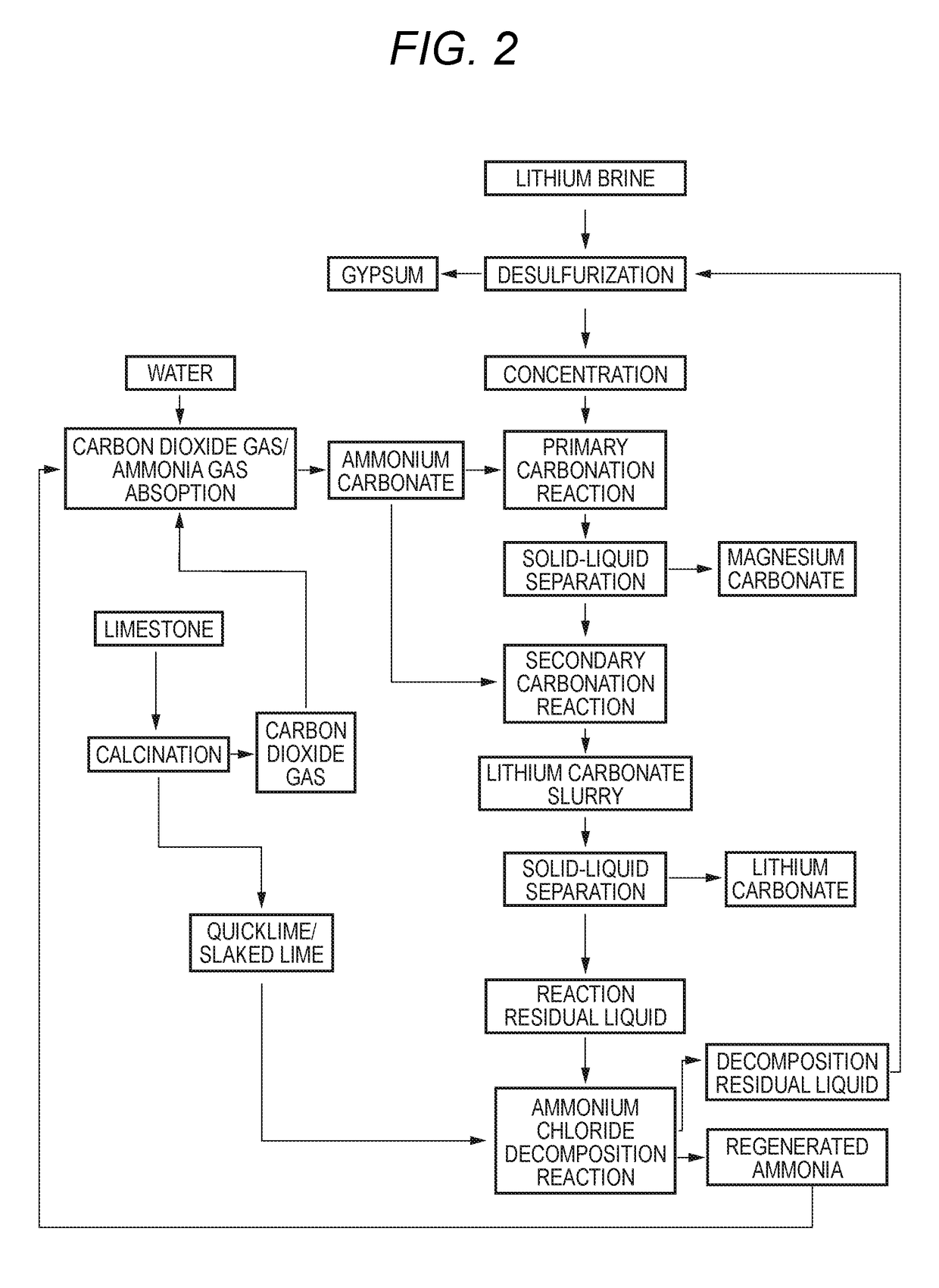

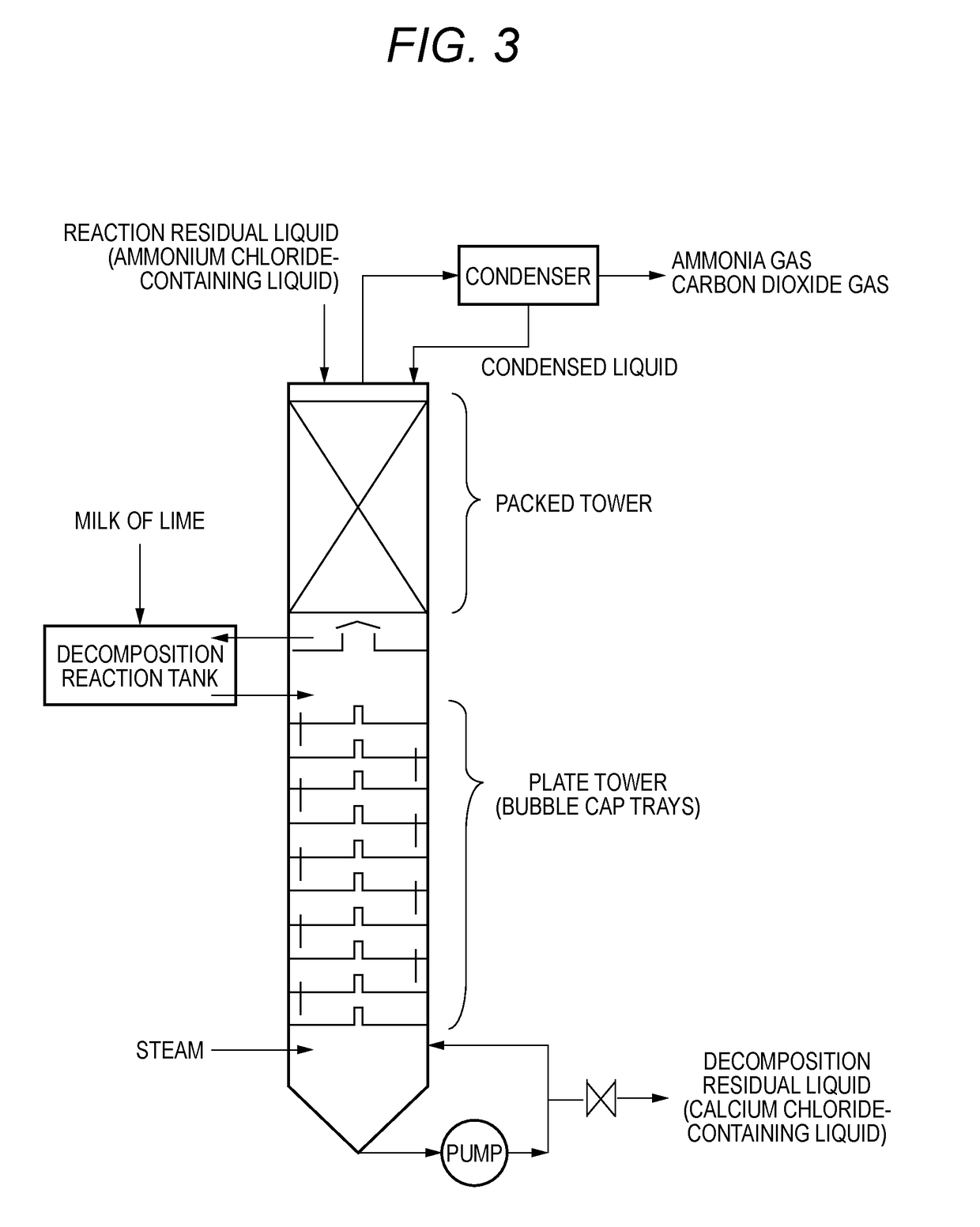

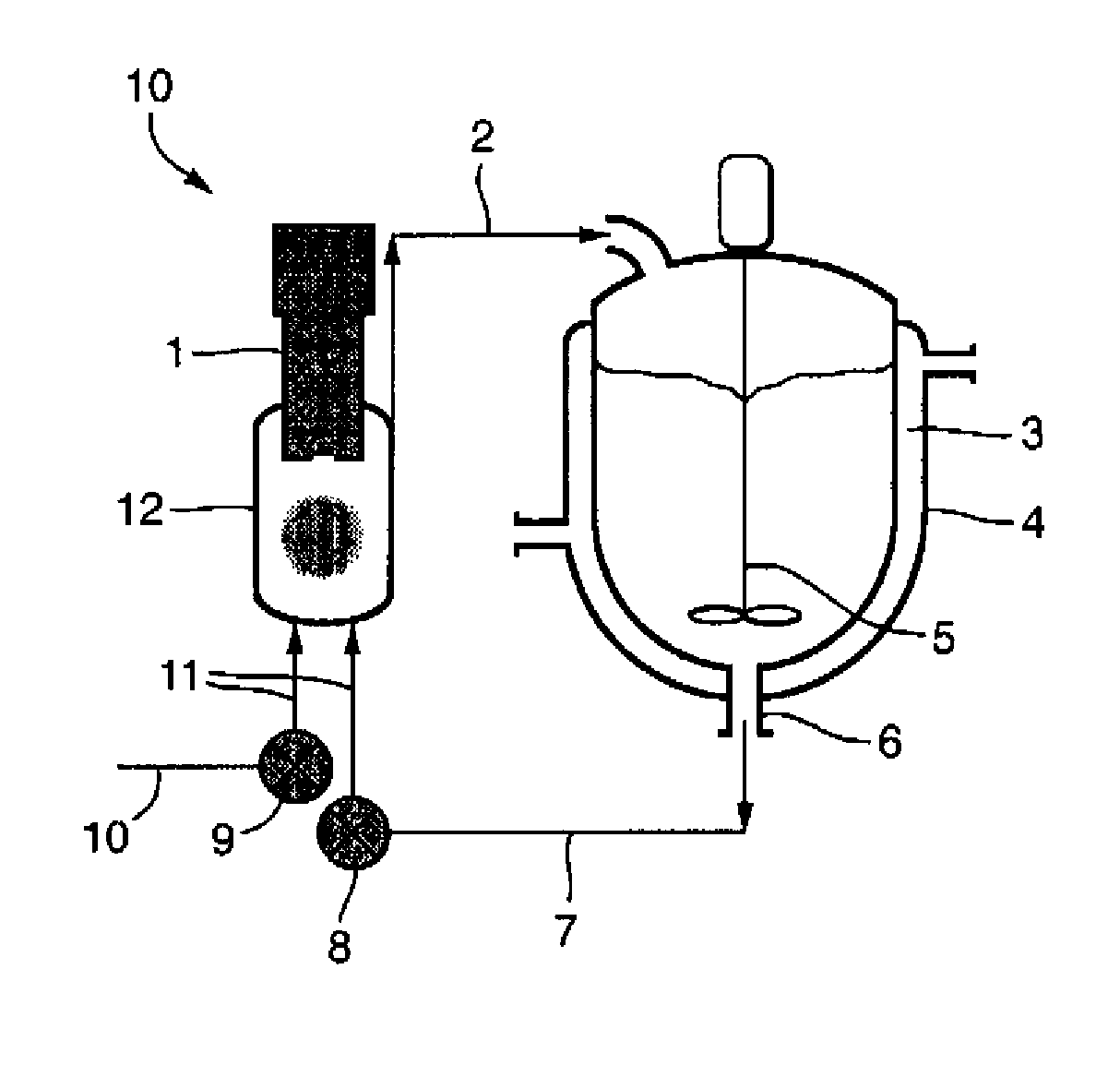

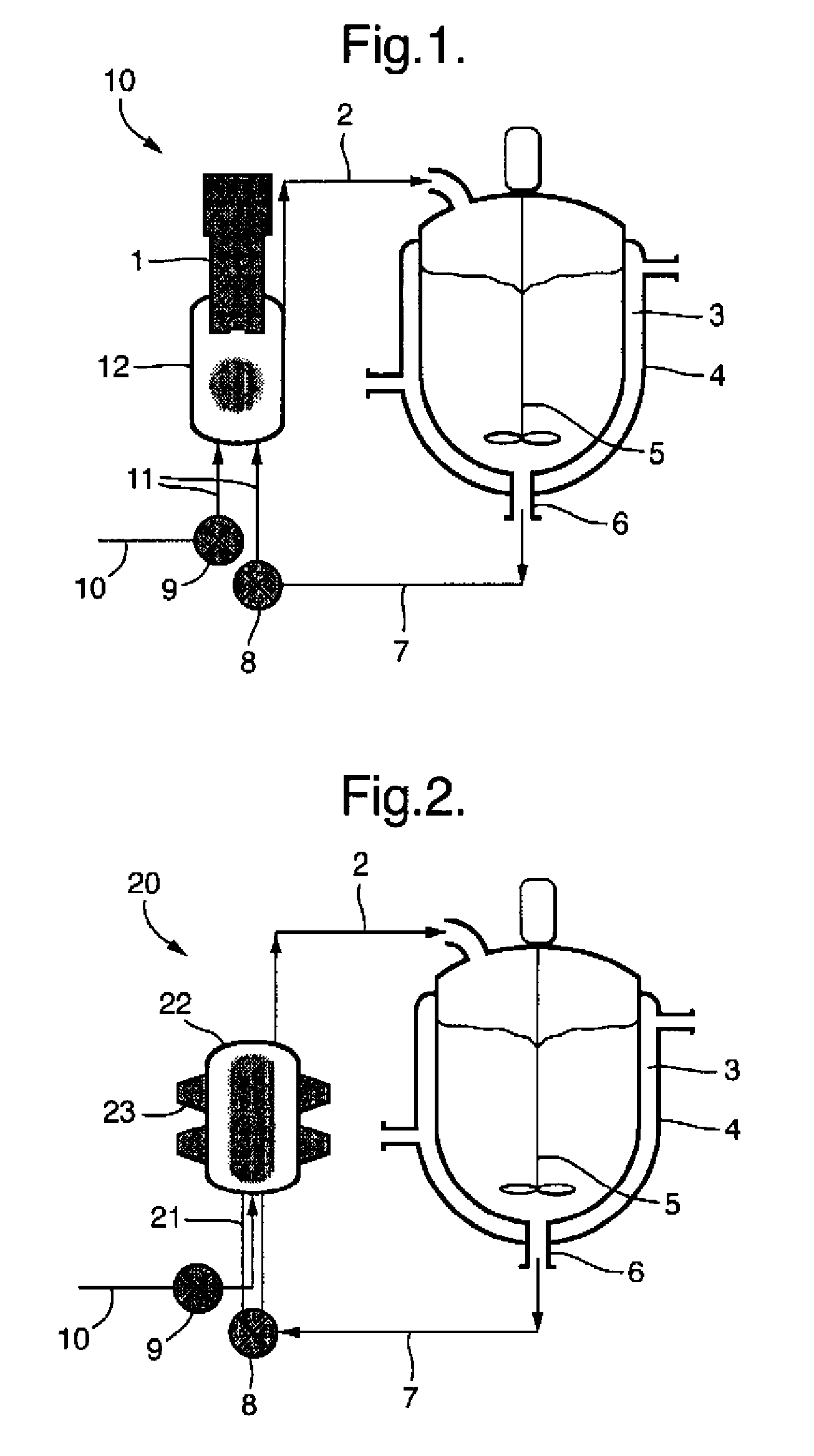

Method for producing lithium carbonate

ActiveUS20170113942A1Excellent maintenance propertyImprove production efficiencyLithium carbonates/bicarbonatesLithium carbonateChemistry

The present invention provides a method for producing lithium carbonate, that can shorten the time required in the production of lithium carbonate and has excellent maintenance property and production efficiency without forming fixed matters that require complicated procedures to remove in a reaction apparatus.

Owner:NITTETABU MINING CORP +1

Method for improving protein production

InactiveUS7413896B2Improve featuresStable transcriptionSugar derivativesMicrobiological testing/measurementAntisense RNAOpen reading frame

The present invention relates to the production of proteins in a cell or host cell. The invention uses a TRAnscription Pause (TRAP) sequence to enhance a protein expression characteristic of a protein expression unit. The TRAP sequence is thought to prevent, at least in part, formation of antisense RNA or to, at least in part, prevent transcription to enter the protein expression unit. In one embodiment, the invention provides a method for expression of at least one protein of interest in a cell comprising providing the cell with at least one protein expression unit that comprises a promoter functionally linked to an open reading frame encoding at least one protein of interest, characterized in that the protein expression unit further comprises at least one TRAP sequence and wherein the TRAP sequence is functionally located downstream of the open reading frame and at least in part prevents formation of antisense RNA. In another embodiment, the TRAP sequence is functionally located upstream of the promoter and at least in part prevents transcription to enter the expression unit. Preferably, the expression protein unit further comprises at least one STabilizing Anti-Repressor sequence.

Owner:CHROMAGENICS BV

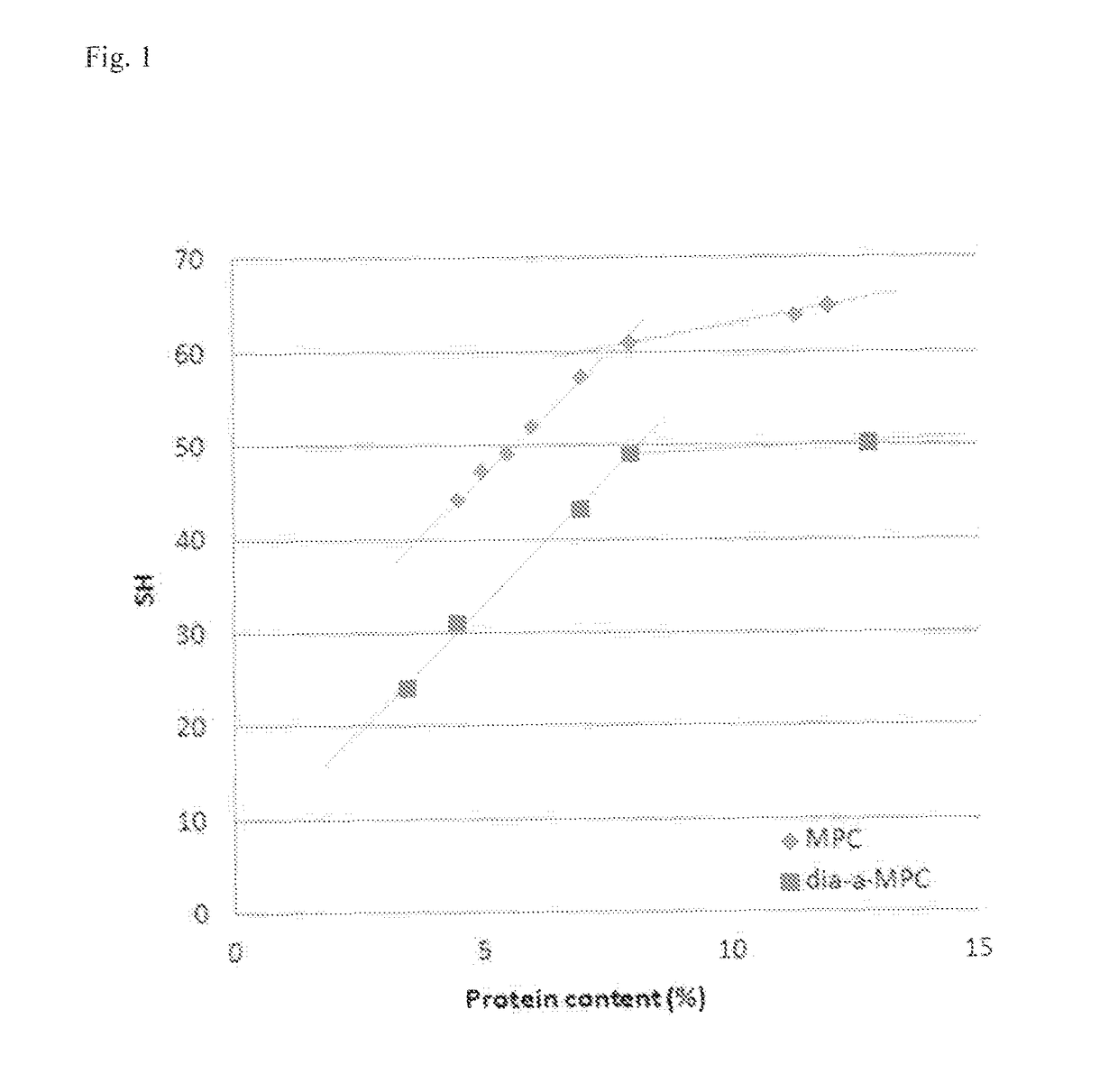

Modification of mineral composition of milk for the production of an acidified milk product

ActiveUS20180368430A1Easy to useEnhanced cost-effectiveMilk preparationFood thermal treatmentFiltrationAqueous solution

The invention relates to a method for producing an acidified milk product comprising the steps of: providing a milk raw material; concentrating the milk raw material by membrane filtration to provide a filtration retentate; acidifying the filtration retentate with an acidic aqueous solution to provide an acidified filtration retentate having a pH in the range of about 5.2 to about 6.5, a calcium / protein ratio of at most about 0.03, and a phosphorous / protei ratio of at most about 0.025; processing the acidified filtration retentate to the acidified milk product having moisture on a fat-free basis of at least 70%. The invention also relates to an acidified milk product having moisture on a fat-free basis of at least 70% and a calcium / casein ratio of at most about 0.04 and a calcium / protein ratio of at most about 0.03 and a phosphorous / casein ratio of at most about 0.03. The invention also relates to an acidified milk product having moisture on a fat-free basis of at least 70%, a calcium / casein ratio of at most about 0.04, a calcium / protein ratio of at most about 0.03 and a phosphorous / protein ratio of at most about 0.025.

Owner:VALIO LTD

Method of etching silicon nitride film and method of producing semiconductor device

InactiveUS6893973B2Suppress formationFormationElectronic circuit testingError detection/correctionCopper fluorideFluorocarbon

Provided is a method of etching a silicon nitride film, which comprises subjecting the silicon nitride film located on copper to dry etching using a mixture of fluorocarbon gas and an inert gas as the reaction gas, the fluorocarbon gas containing CF4 and CHF3 supplied at flow rates in a ratio of 3:7 to 0:1 or contains CF4 and CH2F2 supplied at flow rates in a ratio of 2.5:1 to 0:1, thereby suppressing the formation of copper fluoride.

Owner:RENESAS ELECTRONICS CORP

Process for making crystals

A process for preparing an emulsion or a dispersion comprising crystalline particles of at least one active principal that comprises contacting a solution of at least one solute in a solvent or mixture of solvents in a first flowing stream with a non-solvent in a second flowing stream wherein the non-solvent and solvent are not miscible with each other, so as to form an emulsion or a dispersion. Super saturation is brought about by suitable means, and the emulsion or dispersion is subjected to ultrasonic irradiation to mediate crystal nucleation.

Owner:CIRCASSIA

Hybrid supercapacitor, including an electrolyte composition, having improved conductivity

InactiveUS10269507B2Improve stabilityImprove conductivityHybrid capacitor separatorsHybrid capacitor electrolytesOrganic solventSupercapacitor

Owner:ROBERT BOSCH GMBH

Method of production of artificial skin

InactiveUS7645595B2FormationPromote formationCosmetic preparationsBiocideMedicineMethods of production

A method for production of artificial skin by administering matrix metalloproteinase inhibitor or matrix metalloproteinase inhibitor and matrix protein production promoting agent. The matrix metalloproteinase inhibitor is N-hydroxy-2(R)-[[(4-methoxyphenyl)sulfonyl](3-picolyl)amino]-3-methylbutanamide hydrochloride.

Owner:SHISEIDO CO LTD

Local interconnects by metal-III-V alloy wiring in semi-insulating III-V substrates

ActiveUS8941123B2FormationEfficient formationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDevice form

A structure and method of producing a semiconductor structure including a semi-insulating semiconductor layer, a plurality of isolated devices formed over the semi-insulating semiconductor layer, and a metal-semiconductor alloy region formed in the semi-insulating semiconductor layer, where the metal-semiconductor alloy region electrically connects two or more of the isolated devices.

Owner:GLOBALFOUNDRIES U S INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com