Neodymium iron boron magnet sintering method and special device thereof

A sintering method and NdFeB technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of poor consistency of magnetic properties of magnets, and achieve uniform magnetic properties, good blank density consistency, and uniform dimensional shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

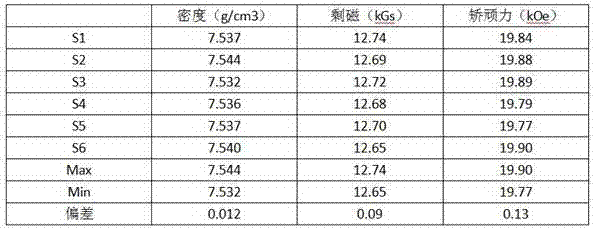

Embodiment 1

[0020] Example 1, taking a billet whose performance grade is N40SH sintered NdFeB material and whose specification is 60×43×36 (mm) as an example, its preparation includes the following process steps:

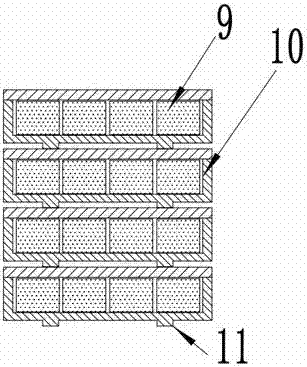

[0021] 1) Loading: Place the pressed N40SH compacts in the material box, the gap between the compacts is less than 1mm, after the material box is full of compacts, cover the material box cover, the material box and the material box cover form the material box tooling;

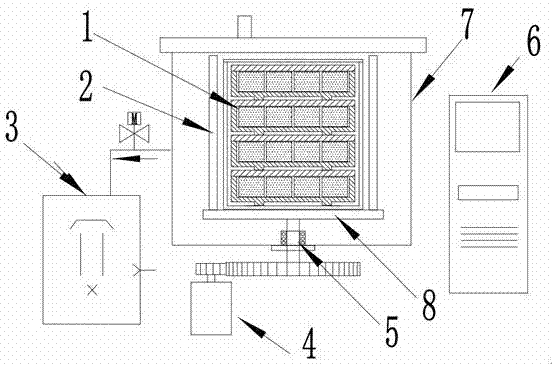

[0022] 2) Furnace entry: arrange the tooling boxes full of NdFeB compacts in sequence in the cavity of the rotary sintering furnace, and stack them; the stacking is composed of stacked tooling boxes loaded with NdFeB compacts;

[0023] 3) Sintering: According to the set rotation speed and sintering process of the rotary sintering furnace cavity, the compact is sintered into a NdFeB magnet; the rotation speed is 5rpm, and the sintering process is: a sintering temperature of 300°C for the first stage, a holding ti...

Embodiment 2

[0031] Example 2, taking a sintered NdFeB material with performance grade N42SH and a square billet with a specification of 100×80×30 (mm) as an example, its preparation includes the following process steps:

[0032] 1) Loading: Place the pressed N42SH compacts in the material box, the gap between the compacts is less than 1mm, after the material box is full of compacts, cover the material box cover, the material box and the material box cover form the material box Tooling;

[0033] 2) Furnace entry: arrange the tooling boxes full of NdFeB compacts in sequence in the cavity of the rotary sintering furnace, and stack them; the stacking is composed of stacked tooling boxes loaded with NdFeB compacts;

[0034] 3) Compact sintering: According to the set rotation speed and sintering process of the chamber of the rotary sintering furnace, the compact is sintered into an NdFeB magnet; the rotation speed is 16rpm, and the sintering process is: a sintering temperature of 450°C for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com