Electromagnetic actuator for ship

An electromagnetic actuator, marine technology, applied in the direction of shock absorber, magnetic spring, spring/shock absorber, etc., can solve the problems of long time delay, poor heat dissipation performance, engineering application limitations, etc., and achieve the effect of improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

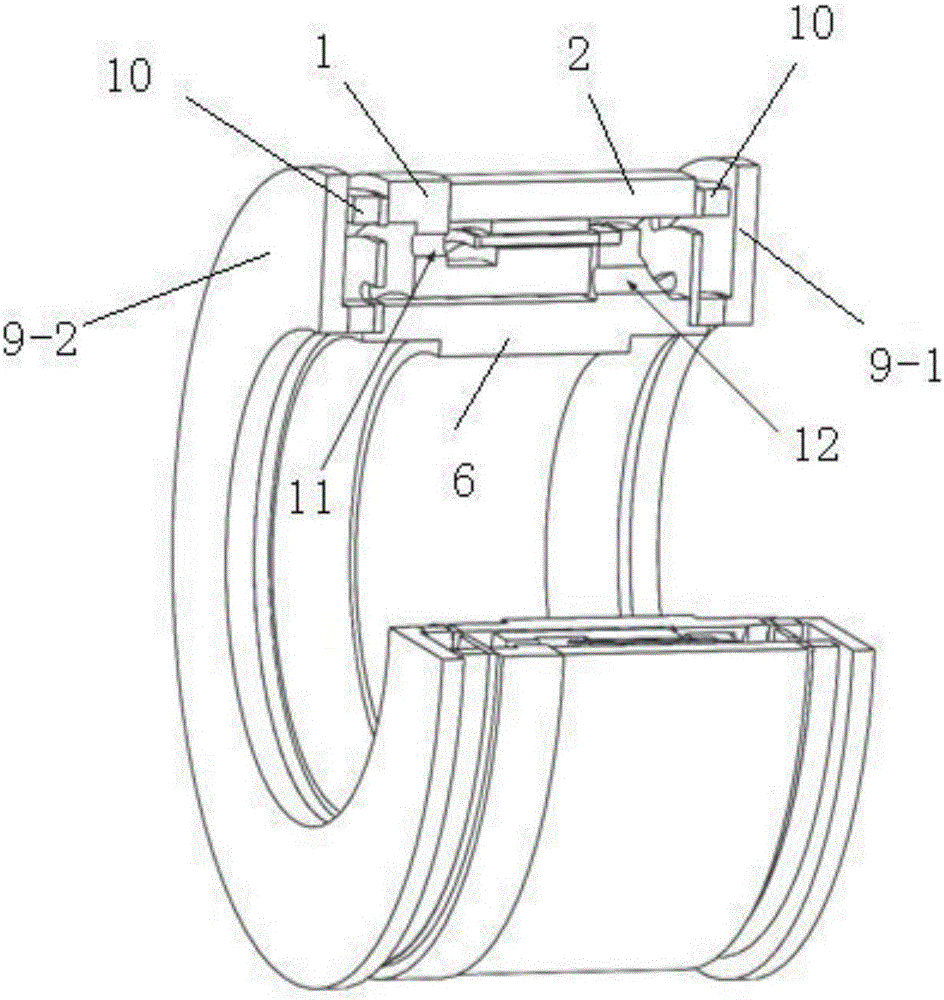

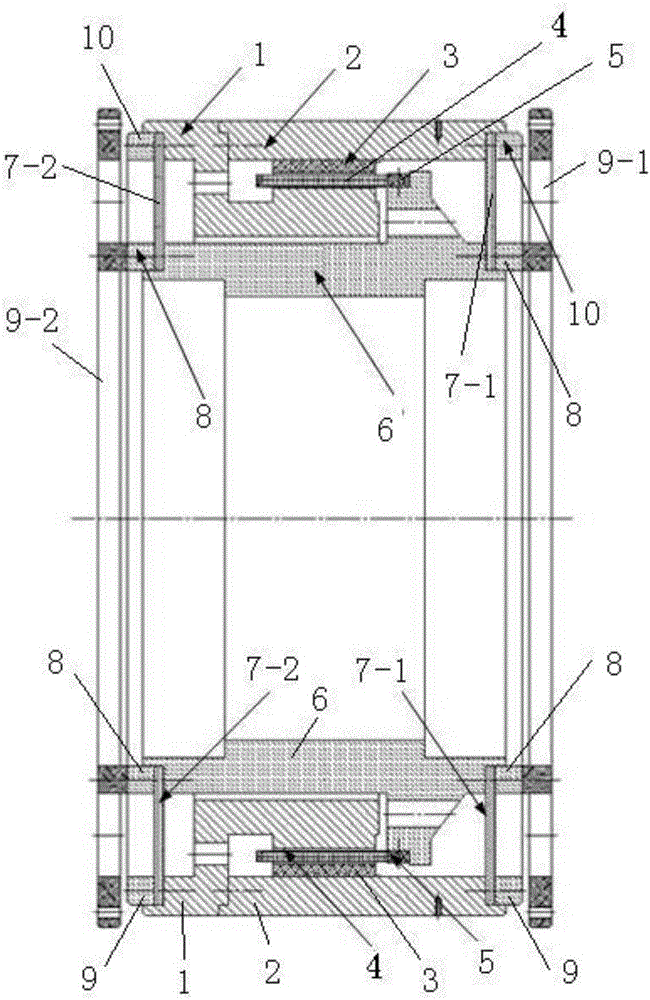

[0030] see figure 1 and figure 2 , a marine electromagnetic actuator, comprising an annular magnetic steel support body 2 and an annular magnetizer 1; the cross section of the magnetizer 1 is U-shaped, and the heights of the two ends of the U-shaped magnetizer are inconsistent; one end of the magnetizer 1 is connected to the magnetic The steel support body 2 is connected, and the other end of the magnetizer 1 and the magnetic steel support body 2 are successively provided with a coil frame 5 and a permanent magnet 3, and the permanent magnet 3 is fixedly connected with the magnetic steel support body 2; the coil frame 5 is wound with Coil 4, there is a gap between the coil 4 and the permanent magnet 3; the coil skeleton 5 is connected to the force transmission frame 6; the permanent magnet 3 is spliced by a plurality of permanent magnet units, and the whole is ring-shaped, placed on the magnetizer 1 and the magnetic steel Between the support body 2; multiple permanent magn...

Embodiment 2

[0036] Embodiment 2 is different from Embodiment 1 in that there are two permanent magnets, which are arranged on both sides of the actuator; each permanent magnet is spliced by multiple permanent magnet units, and is an arc structure; each A permanent magnet corresponds to a coil and a coil bobbin.

Embodiment 3

[0037] Embodiment 3 is different from Embodiment 1 in that there are multiple permanent magnets, the permanent magnets are uniformly distributed in the circumferential direction, and there are gaps between adjacent permanent magnets. The permanent magnets are evenly arranged along the circumferential direction to ensure more uniform magnetism and further enhance the actuator's operating force; the use of multiple permanent magnets can better control the curvature of the magnetic steel and ensure that it fits better with other structures. When a certain permanent magnet fails, it only needs to be replaced, and the operation is very convenient.

[0038] The invention has the advantages of compact structure, high rigidity, small structural flux leakage, and the uniform distribution of permanent magnets along the circumferential direction can enhance the output force; the permanent magnet adopts a multi-piece splicing method, which can make its magnetism more uniform and convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com