Novel micro-fluidic chip forming die and method

A technology of microfluidic chips and forming molds, applied in the field of micromachining, can solve the problems of long heating and cooling time of thermal conductivity materials, limitations in the wide application of polymer hot embossing technology, and the inability of polymers to completely fill the cavity. The effect of simplifying molding equipment, shortening process cycle and easy filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

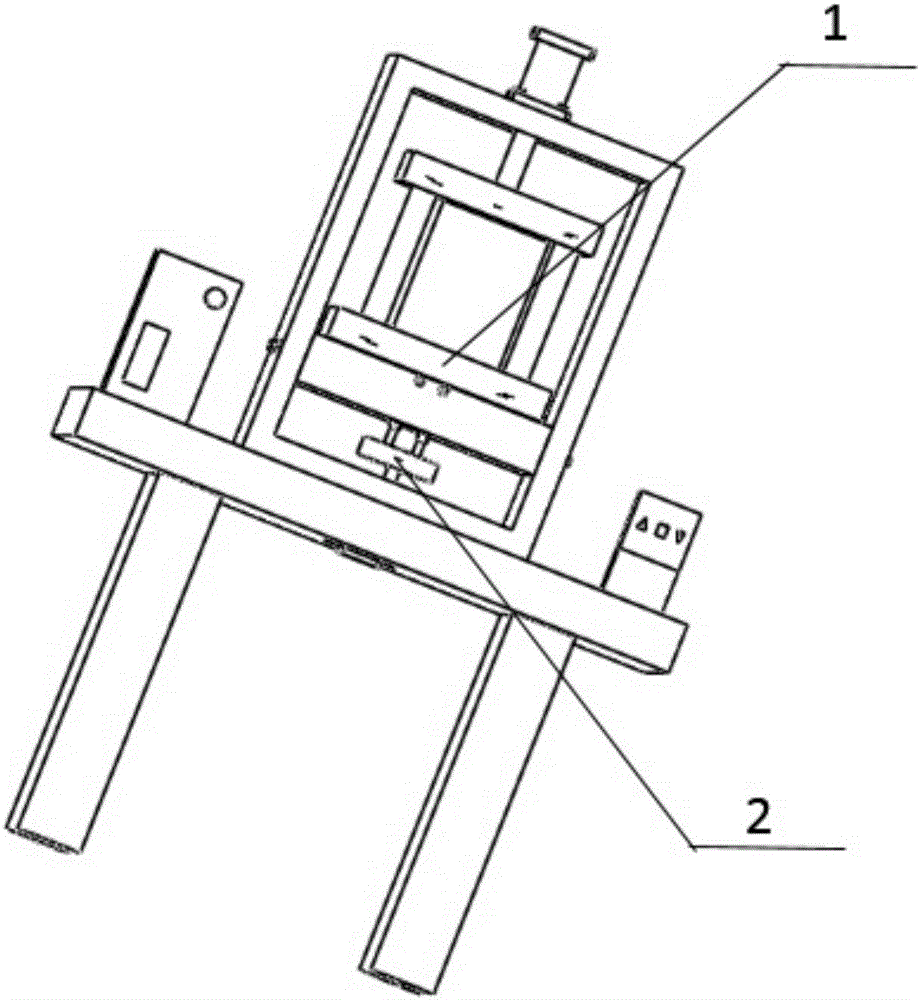

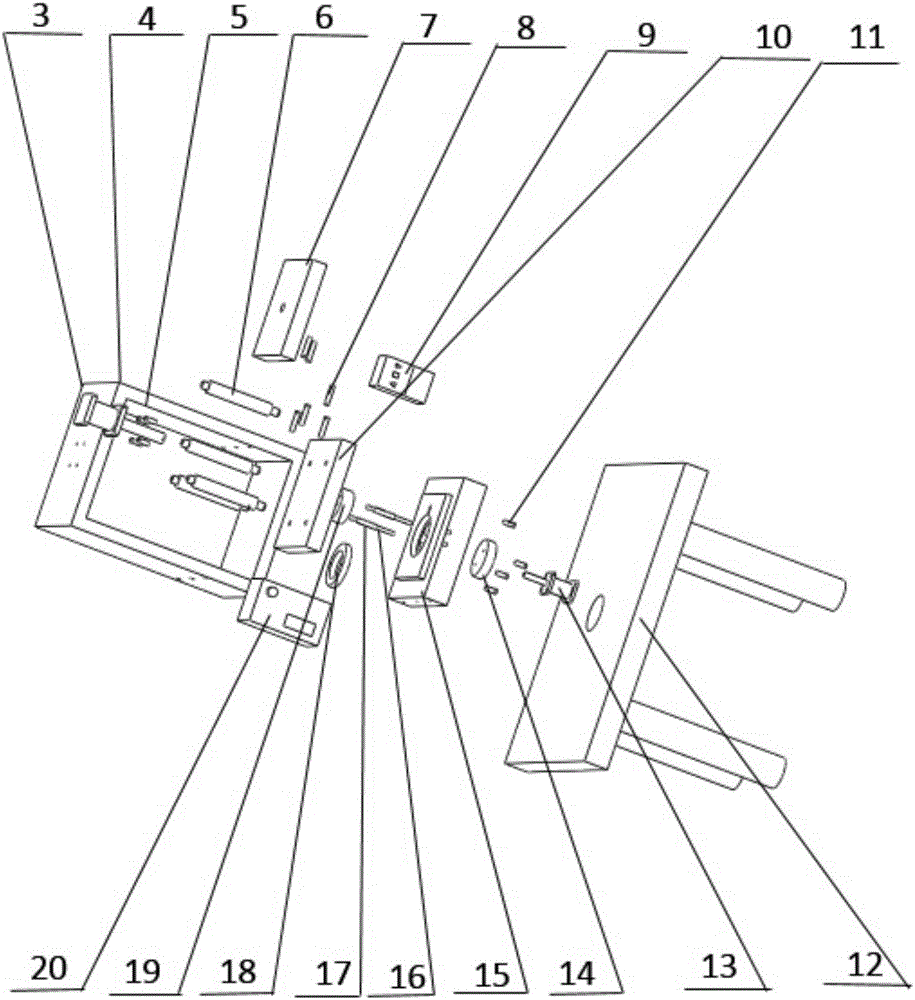

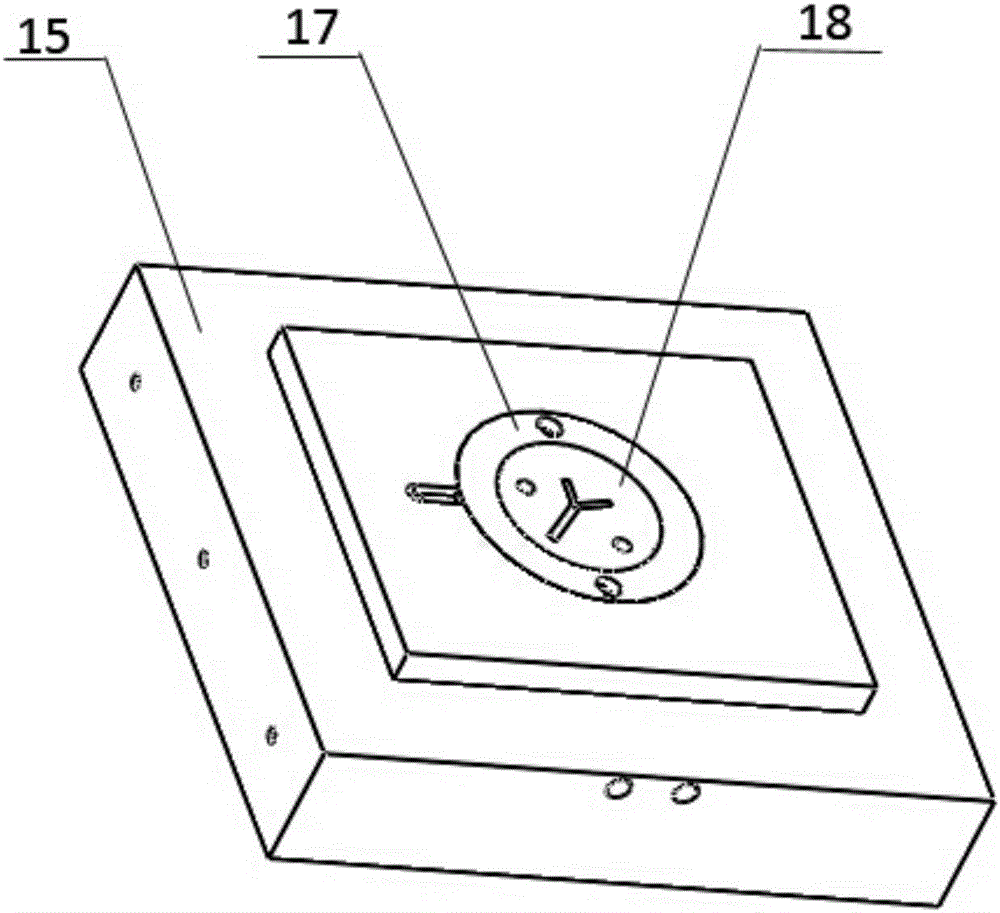

[0024] A novel microfluidic chip molding die of the present invention such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the mold mainly includes: forming component 1, stripping component 2, mold clamping cylinder 3, fixing bracket 4, M5X15 hex head bolts 5 and 11, guide post 6, guide post connecting plate 7, M5X30 hex head bolt 8, Temperature controller 9, movable template 10, table 12, top mold cylinder 13, ejector pin push plate 14, mold core fixing block 15, ejector pin 16, spring sleeve 17, copper pressure block 18, mold core 19, DC power supply 20. Wherein the molding assembly 1 includes: mold core fixing block 15, mold core 19, copper pressing block 18, the mold core 19 is embedded in the lower half of the mold core fixing block 15, and the copper pressing block 18 is placed in the mold core fixing block 15 inside the mold core The upper part of the upper part of the mold core is compressed; the stripping assembly 2 includes: a top mold cylinder 13, a pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com