An organically encapsulated magnetic nanoparticle composite bone scaffold and its preparation method

A magnetic nanoparticle and magnetic nanoparticle technology, applied in the field of material manufacturing, can solve the problems of cell response limitation, lack of osteoinductivity, poor hydrophobicity, etc., and achieve the effect of improving mechanical properties, enhancing mechanical properties, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Nano-Fe 3 o 4 (Particle size is 20nm) / Add to the mixed solution containing 50mL of absolute ethanol and 50mL of deionized water, ultrasonically disperse for 30 minutes, transfer the solution to a magnetic stirrer, pass through nitrogen protection, when the temperature rises to 80°C, Add 5 mL of oleic acid and stir at 80°C for 1 hour. After the temperature is cooled to room temperature, wash with distilled water three times to remove excess oleic acid and obtain oleic acid-modified Fe 3 o 4 Powder (o-Fe 3 o 4 ).

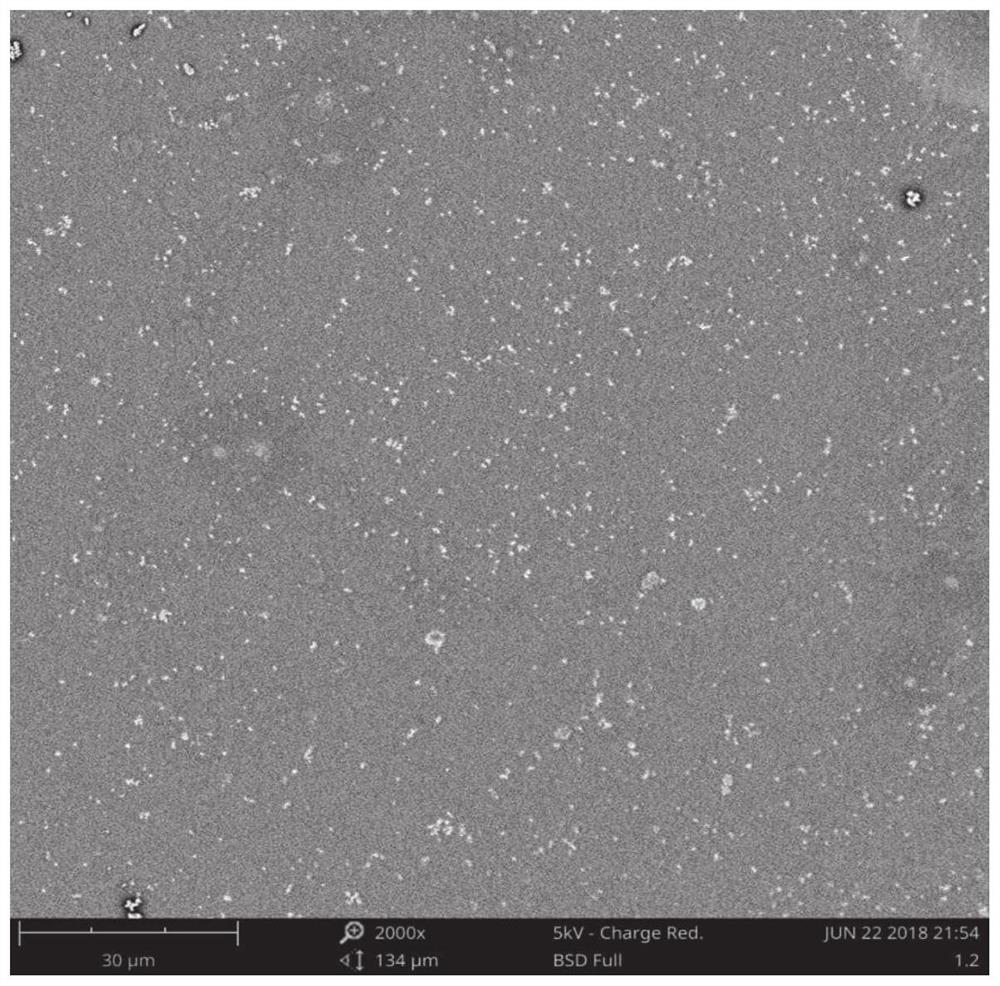

[0052] (2) Pre-weighed dry o-Fe 3 o 4 The powder is in 20 times the volume of chloroform, and the suspension is added to 4wt.% PEEK (purity is 99.9%, particle size is 20 μm) / chloroform solution to obtain o-Fe 3 o 4 A mixture with a content of 2.5wt.% (o-Fe 3 o 4 powder and PEEK powder mass ratio 0.025:0.975), the composite powder was further ultrasonicated for 1 hour, and finally the mixed powder was dried in a vacuum oven at room temperature for ...

Embodiment 2

[0056] Compared with Example 1, the difference is that the amount of magnetic nanoparticles in the bone scaffold is reduced:

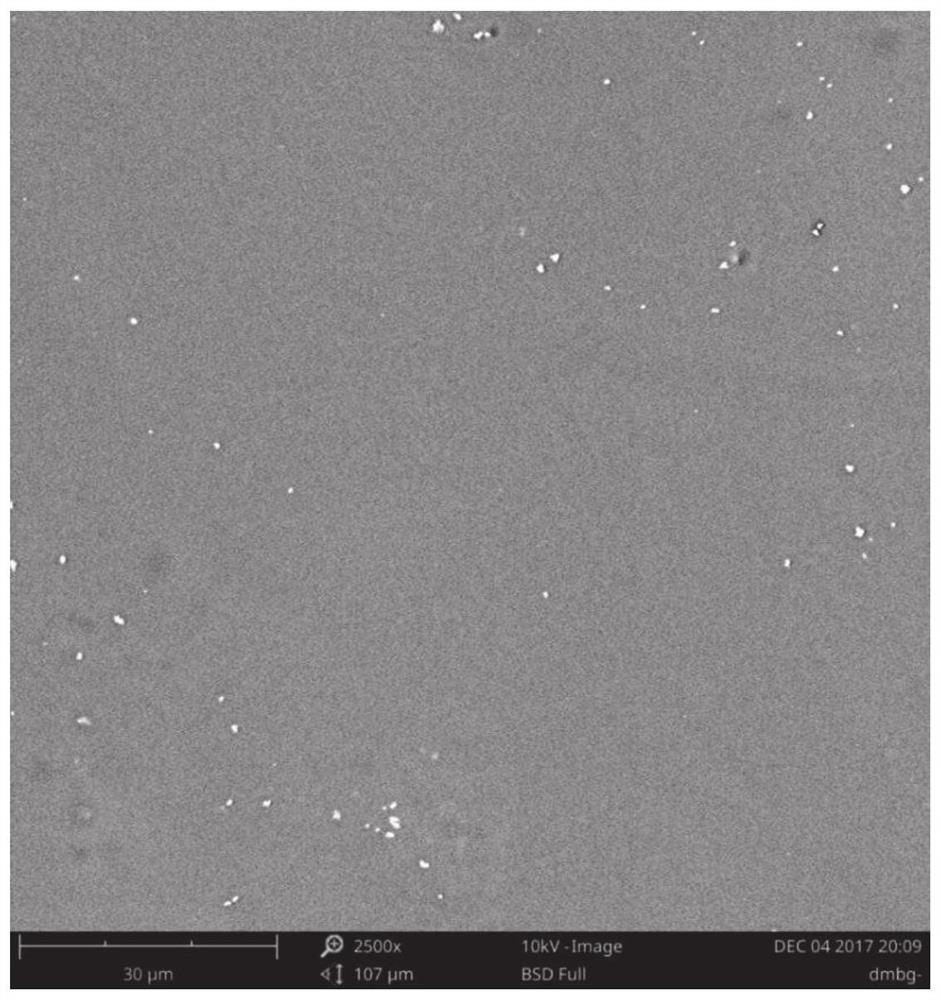

[0057] (1) Nano-Fe 3 o 4 (Particle size is 2nm) / Add to the mixed solution containing 50mL of absolute ethanol and 50mL of deionized water, ultrasonically disperse for 30 minutes, transfer the solution to a magnetic stirrer, pass through nitrogen protection, when the temperature rises to 80°C, Add 5 mL of oleic acid and stir at 80°C for 1 hour. After the temperature is cooled to room temperature, wash with distilled water three times to remove excess oleic acid and obtain oleic acid-modified Fe 3 o 4 Powder (o-Fe 3 o 4 ).

[0058] (2) Pre-weighed dry o-Fe 3 o 4 The powder is in 20 times the volume of chloroform, and the suspension is added to 4wt.% PEEK (purity is 99.9%, particle size is 20 μm) / chloroform solution to obtain o-Fe 3 o 4 The content of 0.5wt.% mixture (o-Fe 3 o 4 powder and PEEK powder mass ratio 0.005:0.995), the composite powd...

Embodiment 3

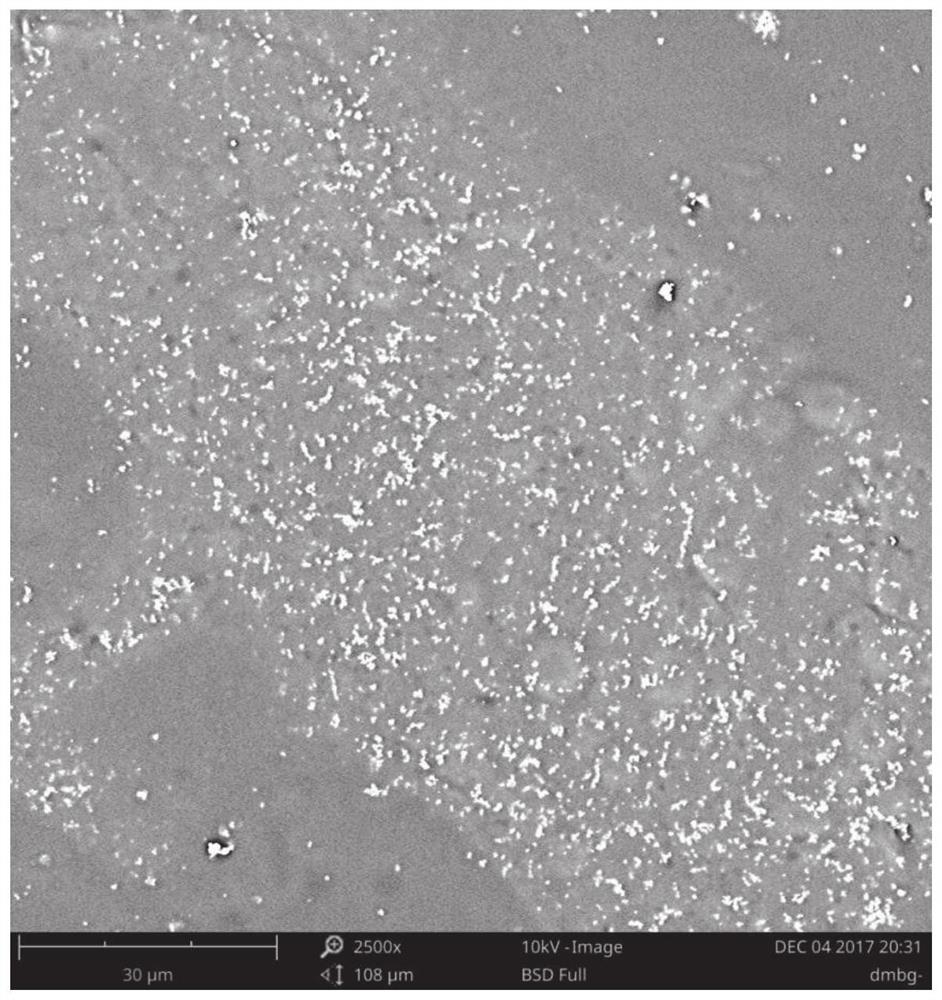

[0062] All the other conditions are consistent with Example 1, the difference is that o-Fe 3 o 4 The content of the mixture is 12wt.% (o-Fe 3 o 4 Powder and PEEK powder mass ratio 0.12:0.88).

[0063] Microstructural tests found that 12wt% Fe 3 o 4 Dispersed in the PEEK matrix, the agglomeration phenomenon is serious. Mechanical properties tests found that PEEK / Fe 3 o 4 The tensile strength of the scaffold is 66MPa and the compressive strength is 52MPa. The MTT test found that the 12wt% composite scaffold proliferated by 87% relative to the cathode control group. Compared with Example 1, the mechanical properties are poor because the Fe after oleic acid modification 3 o 4 The content is more than that of Example 1, serious agglomeration occurs, and the strengthening effect is limited. More magnetic nanoparticles promote cell proliferation, thus exhibiting a higher cell proliferation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com