Method for preparing nano barium sulfate with controllable particle size distribution

A nano-barium sulfate and particle size distribution technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of small overall structure of the reactor and difficulty in large-scale industrial application, so as to prevent further growth of crystal nuclei and crystal grains The effect of small diameter and narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step A: Weigh 317g BaCl 2 2H 2 O and 218g of Na 2 SO 4 , Dissolved in deionized water, respectively made into a solution with a concentration of 1.3M and a volume of 1L.

[0031] Step B: Adjust the gap width of the fully back-mixed liquid membrane reactor to 0.3 mm, and the rotational speed to 1000 rpm, and simultaneously feed the two solutions into the fully back-mixed liquid film reactor at a feeding rate of 210 ml / min to perform a nucleation reaction.

[0032] Step C: Collect the suspension slurry from the reactor outlet and centrifuge wash with deionized water until the aqueous phase is free of Cl - exist. The resulting filter cake was dried in an oven at 70°C for 12 hours to obtain nano BaSO 4 .

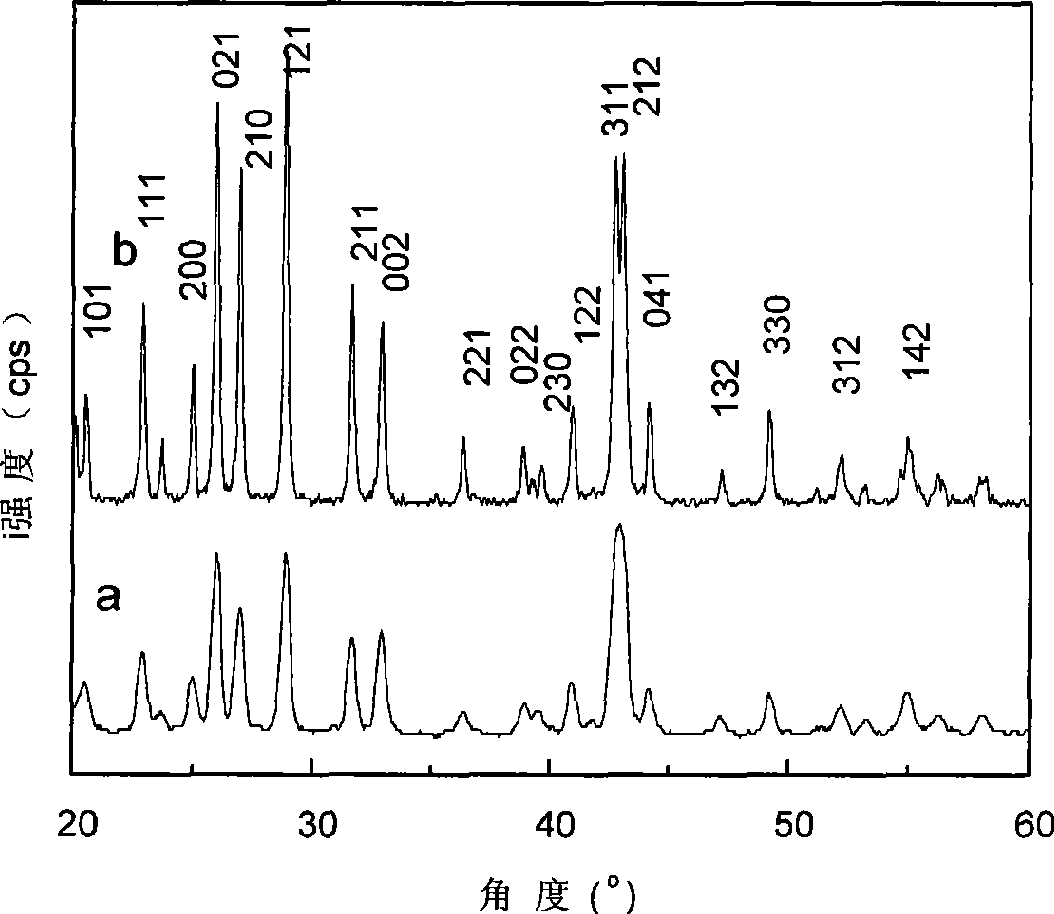

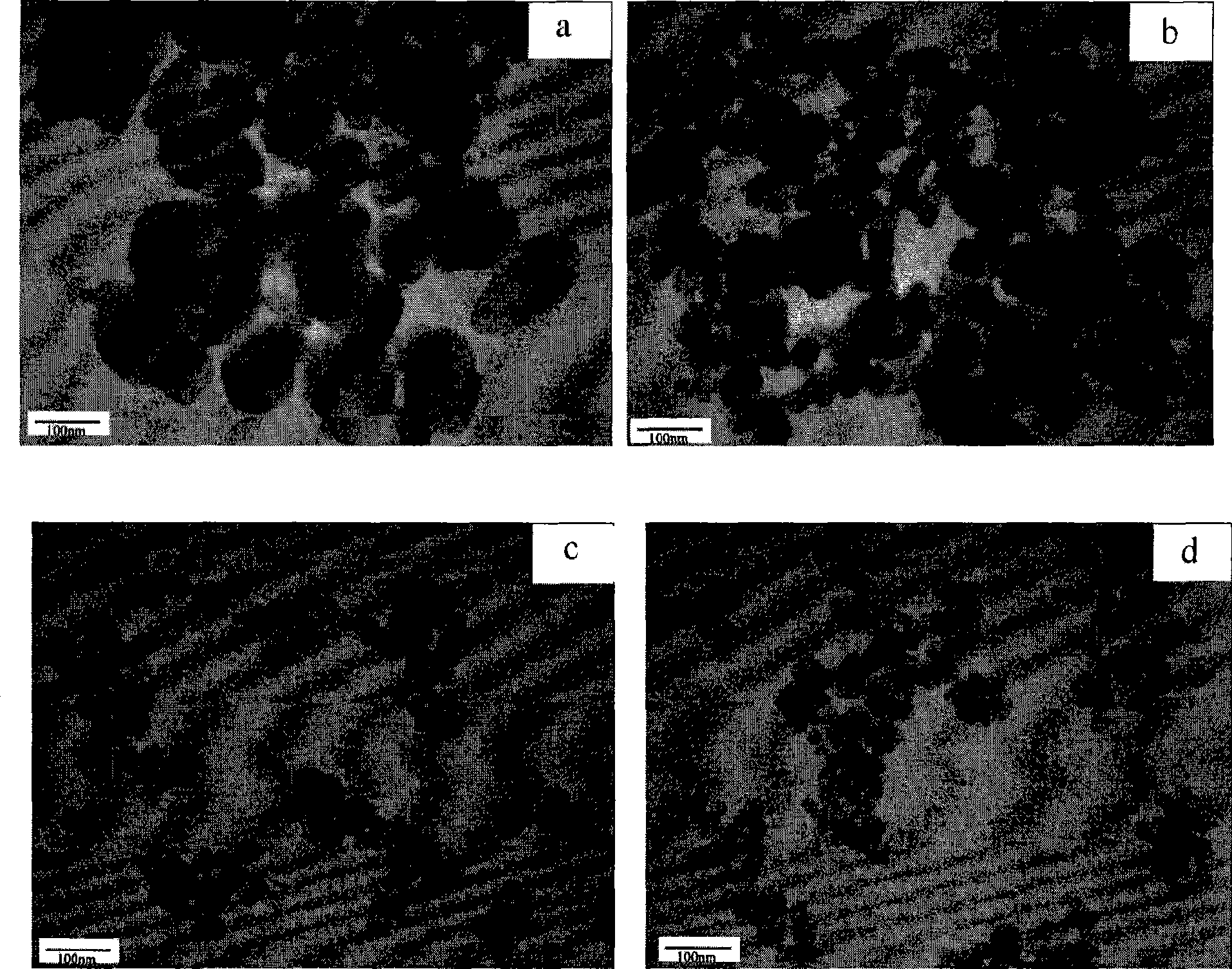

[0033] Prepared BaSO 4 After TEM characterization, see figure 2 a, The measured average particle size is 120nm.

Embodiment 2

[0035] Step A: take 8.5g of Ba(NO 3 ) 2 , dissolved in deionized water to form a solution with a concentration of 0.0425M and a volume of 1L, measure 4.25g of concentrated sulfuric acid with a concentration of 98%, dissolve it in deionized water, and prepare a solution with a concentration of 0.0425M and a volume of 1L.

[0036] Step B: Adjust the gap width of the fully back-mixed liquid membrane reactor to 0.3 mm, and the rotational speed to 1000 rpm, and simultaneously add the two solutions into the fully back-mixed liquid film reactor at a speed of 210 ml / min to perform a nucleation reaction.

[0037] Step C: Collect the suspended slurry from the outlet of the reactor and centrifugally wash it with deionized water until pH=7. The resulting filter cake was dried in an oven at 60°C for 14 hours to obtain nano BaSO 4 .

[0038] Prepared BaSO 4 After TEM characterization, the measured average particle size is 80nm.

Embodiment 3

[0040] In Example 1, other preparation conditions were kept unchanged, and in step B, the rotational speed of the reactor was adjusted to 2000 rpm, and the feeding speed of the peristaltic pump was increased to 250 ml / min. The resulting BaSO 4 After TEM characterization, see figure 2 b, the measured average particle diameter is 61 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com