Method for preparing CuO/ZnO/Al*O* catalyst

A technology of catalyst and precipitant, which is applied in the field of preparing CuO/ZnO/Al2O3 catalyst by hypergravity precipitation method, can solve the problems of inability to realize continuous operation, uneven catalyst grain size, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare a 1.3mol / L sodium carbonate solution, wherein sodium carbonate is an analytically pure reagent. The 1.3mol / L sodium carbonate solution is placed in the storage tank. [Cu(NO 3 ) 2 ]+[Zn(NO 3 ) 2 ]+[Al(NO 3 ) 3 ] The concentration of the mixed solution is 1.5mol / L, while [Cu(NO 3 ) 2 ] / [Zn(NO 3 ) 2 ] / [Al(NO 3 ) 3 ] for 3 / 7 / 1. The Cu(NO 3 ) 2 , Zn(NO 3 ) 2 and Al(NO 3 ) 3 The mixed solution is placed in a storage tank.

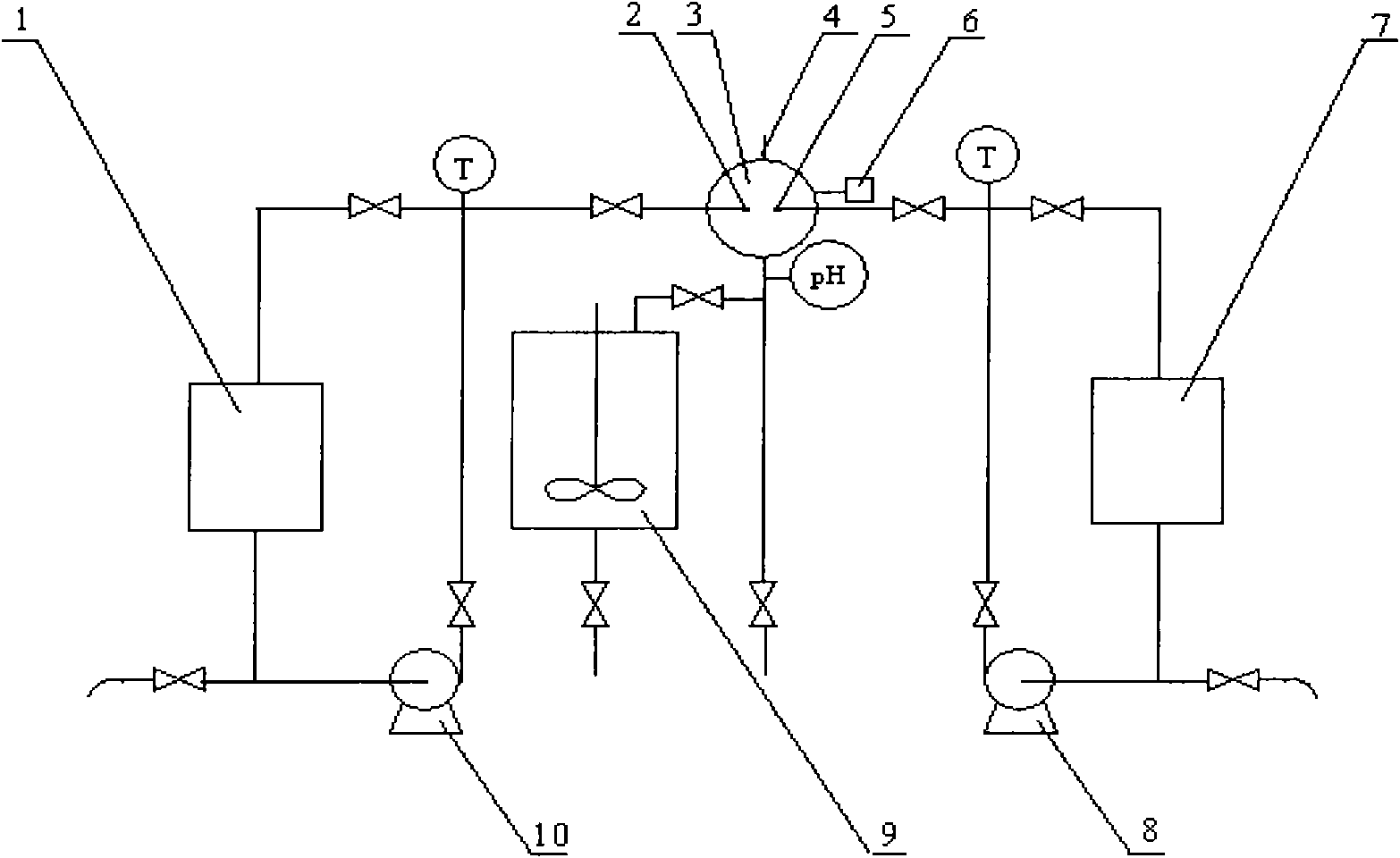

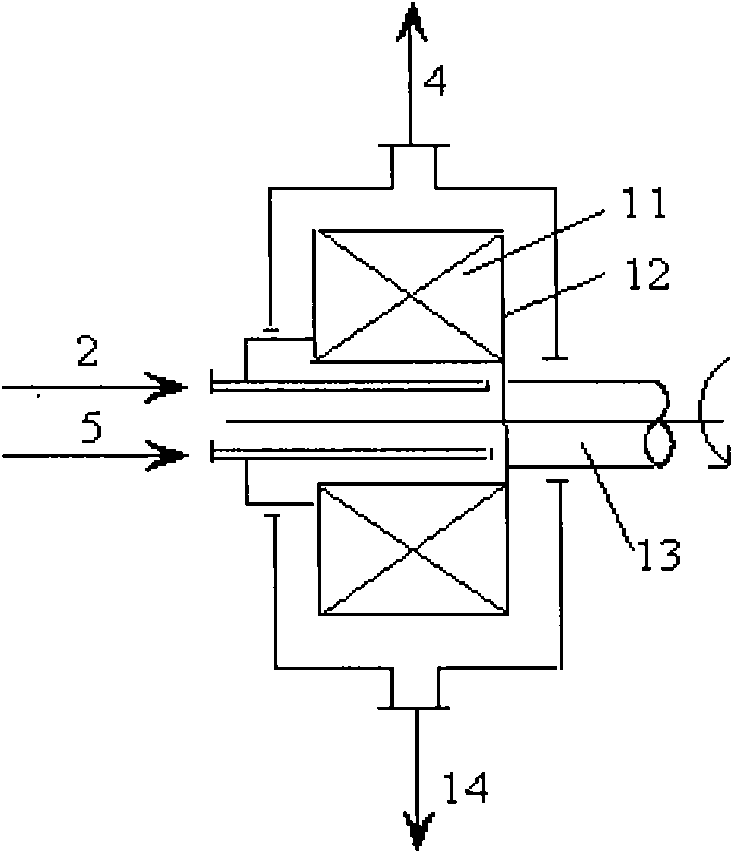

[0038] Turn on the water pump, preheat the hypergravity reactor, and adjust the circulating water temperature to 80°C. After the temperature of the two raw material solutions reached 80°C and the supergravity reactor was started, the Cu(NO 3 ) 2 , Zn(NO 3 ) 2 and Al(NO 3 ) 3 The mixed solution is pumped out from the storage tank 1 through the peristaltic pump, and the flow rate of the solution is controlled by adjusting the speed of the peristaltic pump. The metered mixed solution enters the rotary bed through the liquid in...

Embodiment 2

[0042] Change following conditions, other conditions are with embodiment 1.

[0043] The rotor speeds of the high gravity reactor were 200r / min, 400r / min, 700r / min, and 1300r / min, respectively, and the average particle sizes of CuO in the obtained catalysts were 10.8nm, 11.1nm, 9.3nm, and 11.6nm, respectively.

Embodiment 3

[0045] This example is to illustrate the effect of changing the flow rate of the precipitating agent, that is, adjusting the pH value of the reaction mixture on the product performance.

[0046] Change following conditions, other conditions are with embodiment 1. The flow rate of sodium carbonate solution was changed to 27.0L / h, 28.8L / h, 31.5L / h, 33.0L / h, and the average particle diameters of CuO in the obtained catalyst were 8.2nm, 9.1nm, 10.0nm, 10.7nm respectively.

[0047] According to the method of the present invention, since the reaction is carried out in the high-gravity rotating bed, the mass transfer process between the liquid and the liquid is greatly strengthened, so that the present invention prepares CuO / ZnO / Al 2 o 3 The reaction of the catalyst is completed instantly, and particles with small particle size and uniform distribution of components can be produced.

[0048] Further, the raw materials of the process are easy to obtain, the reaction time is short, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com