Fluidized bed colliding airflow mechanical ultrafine pulverization equipment and method

An ultra-fine pulverizing and fluidized bed technology, applied in grain processing and other directions, can solve the problems of small pulverizing area, heat generation, low working efficiency, etc., and achieve the effect of increasing pulverizing area, reducing heat production, and improving pulverizing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

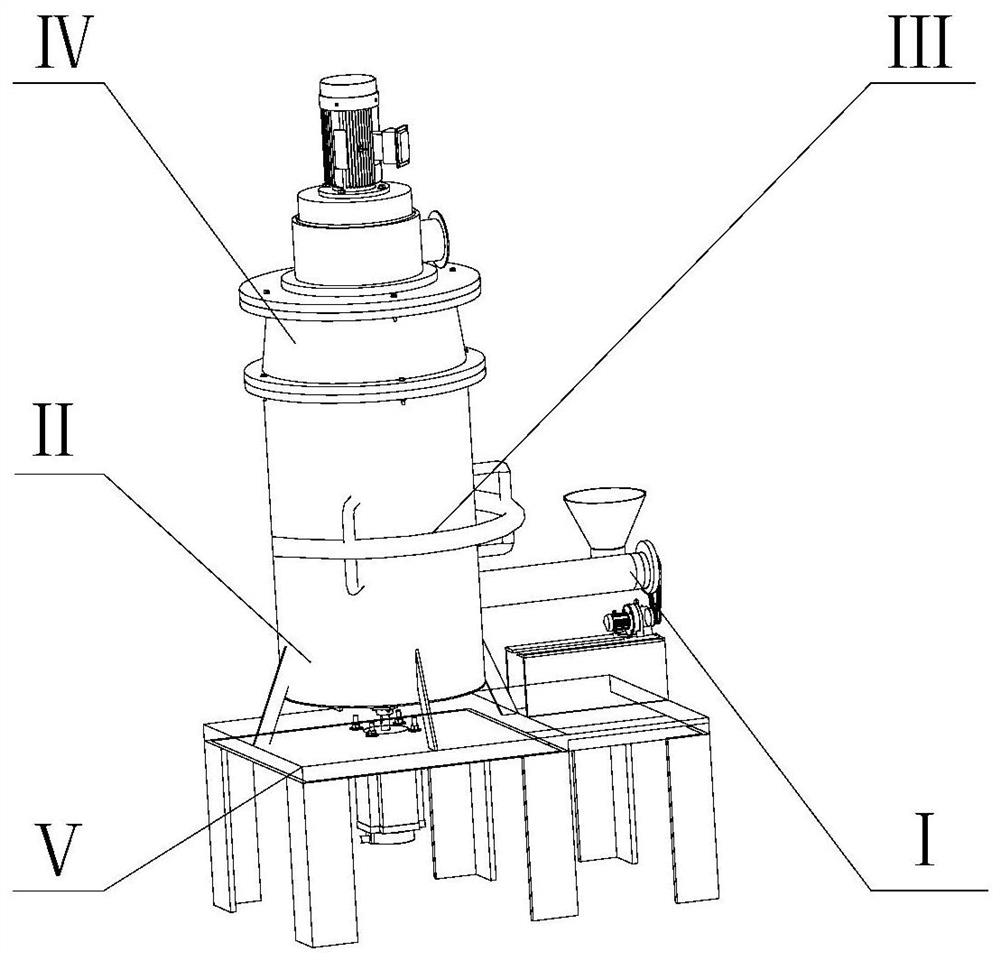

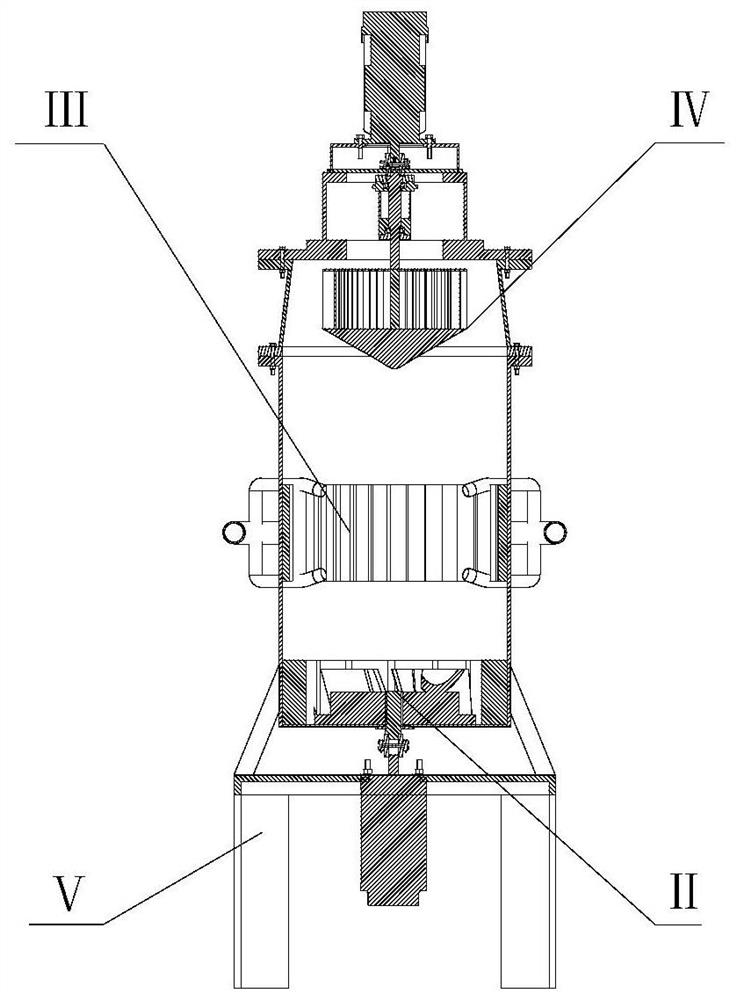

[0075] Attached below figure 1 - attached Figure 14 A further description of a fluidized bed collision type airflow mechanical ultrafine pulverization equipment disclosed in this embodiment; in this embodiment, peanut shells are used as materials for illustration, but in other embodiments, it is not limited to this , can also process other materials, such as ginseng and so on.

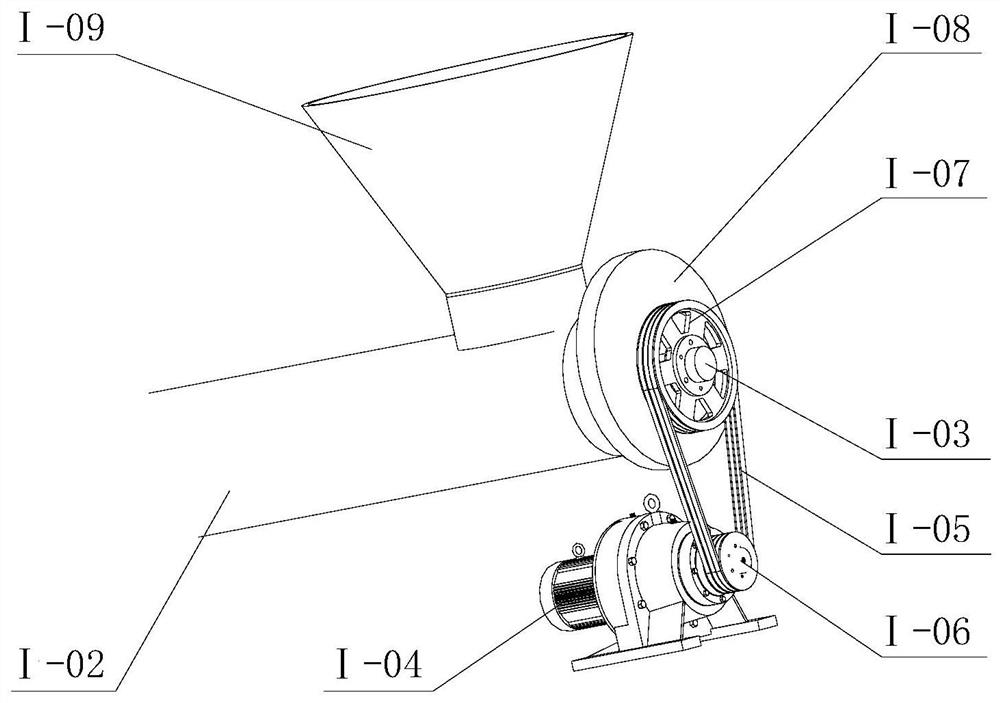

[0076] Refer to attached figure 1 And attached figure 2 Shown, a kind of fluidized bed colliding airflow mechanical ultrafine pulverization equipment, comprises screw feeding device I, impact type mechanical primary pulverization device II, colliding type airflow secondary pulverization device III, centrifugal turbine classification device IV and Frame V has five parts, the screw feeding device I is set on the side of the impact mechanical primary crushing device II, the centrifugal turbine classification device IV is set above the colliding airflow secondary crushing device, and the colliding air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com