Double-wheel self-crushing wear-resistant device of hammer crusher

A hammer crusher and double-wheel technology, applied in grain processing, etc., can solve the problems of high mechanical strength, high energy consumption, and high labor intensity, and achieve the effects of reducing impact and wear, increasing service life, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

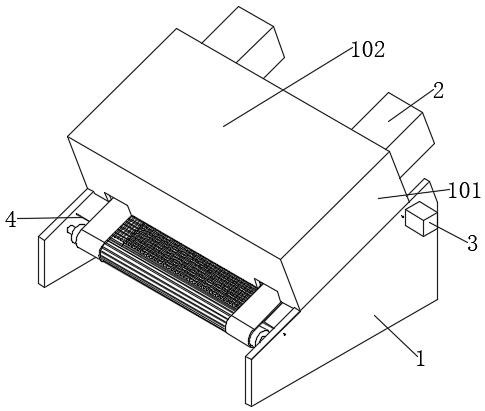

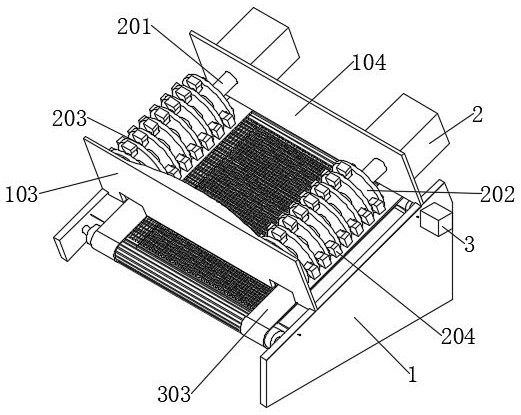

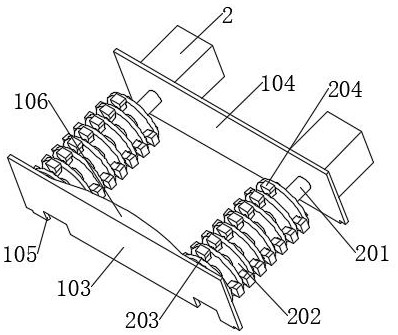

[0029] combined with Figure 1~10 A double-wheel self-crushing and wear-resistant device for a hammer crusher, including two support plates 1, both of which are rigid plates with inclined upper surfaces, and the middle parts of the upper surfaces of the two support plates 1 are fixed Side plate 101 is arranged, the upper end of two side plates 101 is fixed with top plate 102, and the front end of side plate 101 and top plate 102 is fixed with front side plate 103, and the rear end of side plate 101 and top plate 102 is fixed with rear side plate 104, and front side The front side of the plate 103 is symmetrically provided with feed troughs 105, and the feed troughs 105 are used for materials to enter and be crushed. Large particle materials can be moved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com