Concentric ring type cross current type hypergravity field swinging bed device

A high-gravity field and rotating bed technology, which is applied to the concentric circle cross-flow type high-gravity field rotating bed device, desorption, reaction process, and heat exchange fields, can solve unsuitable gas-liquid heat and mass transfer occasions and insufficient mass transfer efficiency High, not suitable for large flow and other problems, to achieve the effect of high gas-liquid mass transfer efficiency, simple structure, and small equipment pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

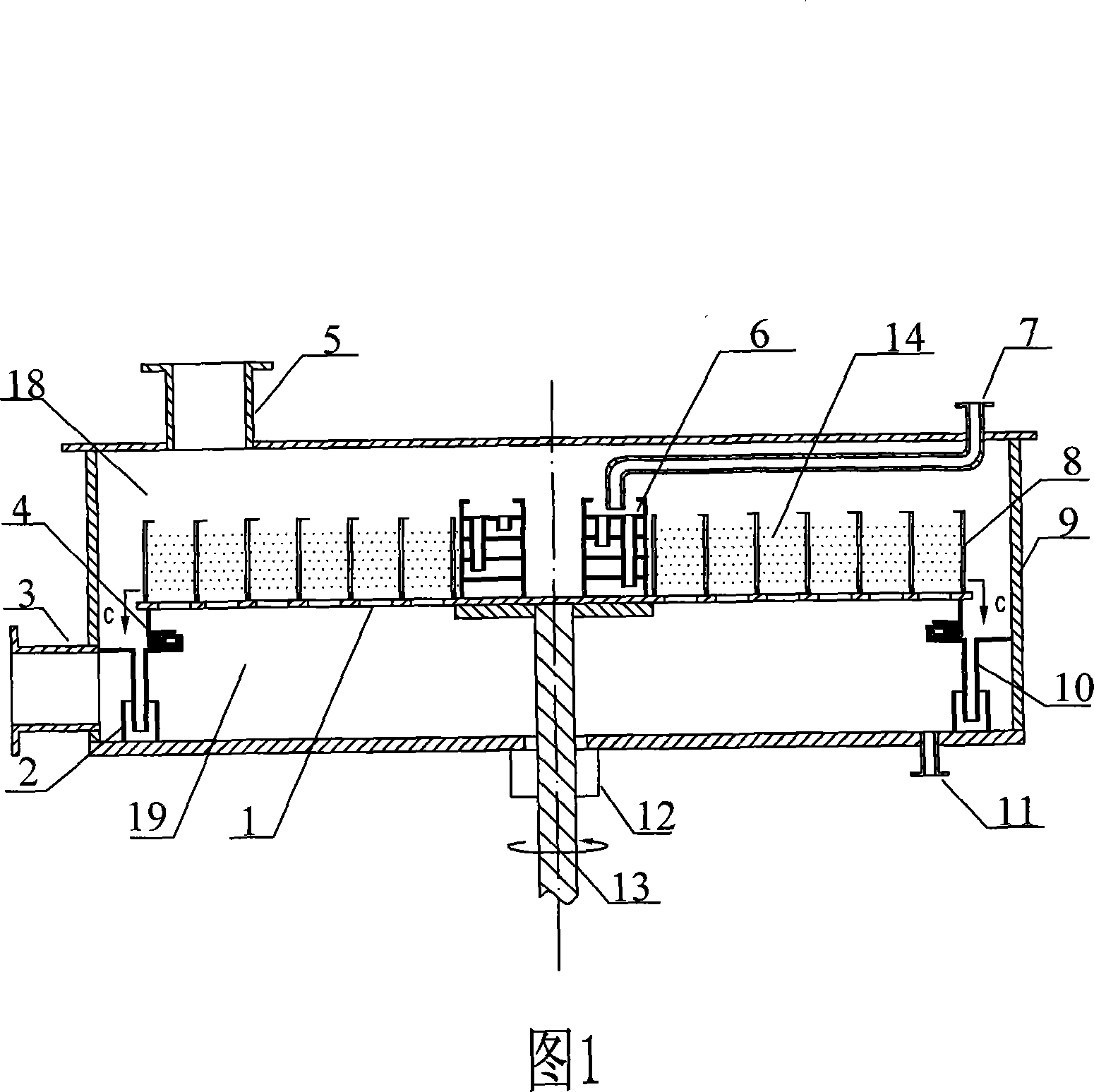

[0019] Embodiment 1: When used for desorption, the structure of the device is shown in Figure 1. The medium a is gas, and the medium c is liquid. The gas enters the inner cavity of the shell 9 from the inlet pipe 3 of the medium a, passes through the rotating disk 1, and is discharged through the outlet pipe 5 of the medium b after cross-flow contact with the medium c; the raw material is discharged from the inlet pipe 7 of the medium c After entering the liquid redistributor 6 for initial distribution, it enters the inner ring of the concentric ring 8, is thrown out by the high-speed rotating concentric ring 8 radially, and is crushed into small liquid droplets that contact the gas multiple times in cross-flow for transmission. The substance is finally discharged from the guide pipe 10 through the outlet pipe 11 of the medium d.

[0020] In the present invention, since the liquid is thrown out from the center by the rotor, it is pulverized into small liquid droplets by the co...

Embodiment 2

[0021] Embodiment 2: When used for heat exchange, the structure of the device is shown in Figure 1. The medium a is gas, and the medium c is liquid. The gas enters the inner cavity of the shell 9 from the inlet pipe 3 of the medium a, passes through the rotating disk 1, and is discharged through the outlet pipe 5 of the medium b after cross-flow contact with the medium c; the liquid is discharged from the inlet pipe 7 of the medium c After entering the liquid redistributor 6 for initial distribution, it enters the inner ring of the concentric ring 8, and is thrown out by the high-speed rotating concentric ring 8 radially, and is crushed into small liquid droplets that contact the gas multiple times in cross-flow for exchange. The heat is finally discharged from the guide pipe 10 through the outlet pipe 11 of the medium d.

[0022] In the present invention, since the liquid is thrown out from the center by the rotor, it is crushed into small liquid droplets by the concentric ci...

Embodiment 3

[0023] Embodiment 3: When the product used in the single-step gas-liquid chemical reaction is liquid or liquid and gas, the structure of the device is shown in Figure 1. Medium a is a gaseous reaction raw material, medium c is a liquid reaction raw material, the gaseous reaction raw material enters the inner cavity of the shell 9 from the inlet pipe 3 of medium a, passes through the rotating disk 1, and performs a cross-flow contact reaction with the liquid reaction raw material medium c, and the generated gas reacts The product is discharged through the medium b outlet pipe 5; the liquid reaction raw material enters the liquid redistributor 6 from the medium c inlet pipe 7 for initial distribution, and then enters the inner ring of the concentric ring 8, and is rotated by the high-speed concentric ring 8 along the radial direction. Throw it out, crush it into small liquid droplets and contact with the gas multiple times in cross-flow for reaction, mass transfer and heat transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com