A kind of pipeline type shaft inner wall pouring method

A pipelined, vertical shaft technology, applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of prolonged construction period, inability to climb, difficult to control the accuracy of formwork, etc., to improve construction quality, construction efficiency and construction accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

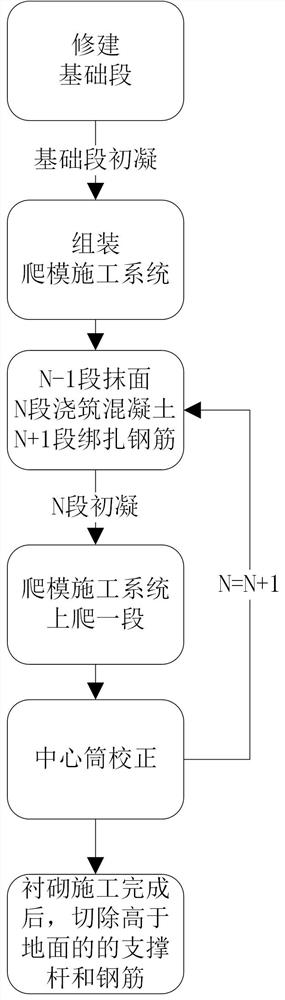

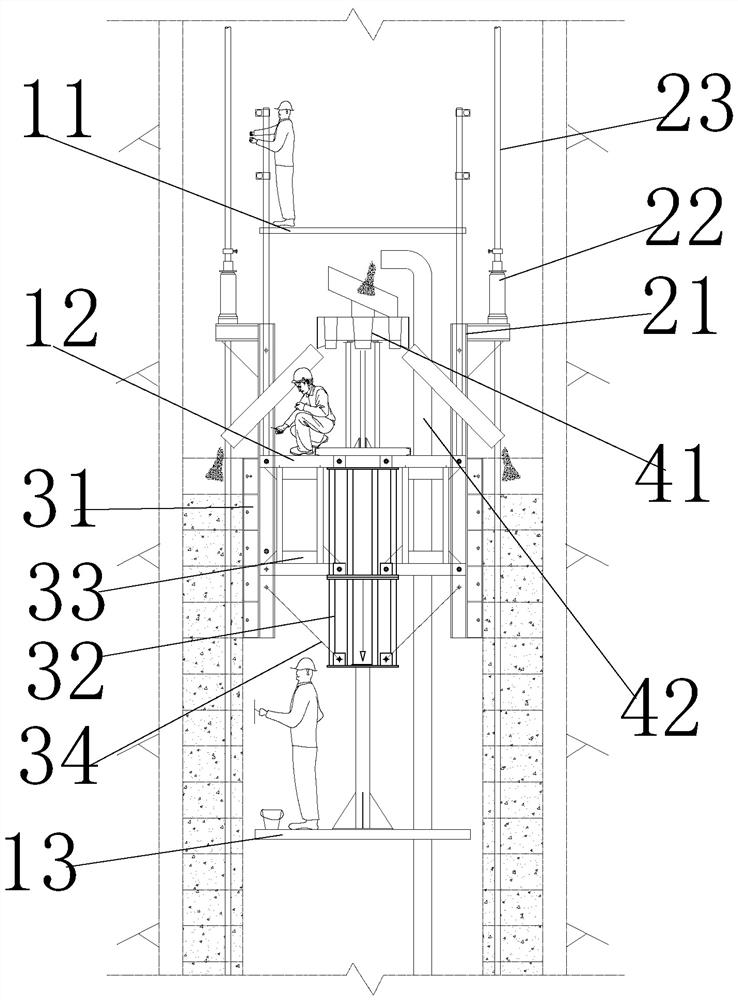

[0046] like figure 1 As shown in the figure, a method for pouring the inner wall of a pipeline type shaft adopts a climbing formwork construction system to construct the shaft lining from bottom to top in the shaft, and includes the following steps:

[0047] Step 1: Divide the shaft lining into multiple construction sections with gradually increasing serial numbers from bottom to top from the beginning, and the first construction section is recorded as the foundation section; For the diameter tube structure, the height of each construction section with serial number greater than one is the same and less than the height of the variable diameter tube, and is recorded as the air section;

[0048] The construction of the foundation section is completed, and the concrete of the foundation section is poured with the formwork 31 that has not been assembled into the climbing formwork construction system.

[0049] Step 2: After the initial setting of the foundation section, remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com