Patents

Literature

48results about How to "Uniform cross section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

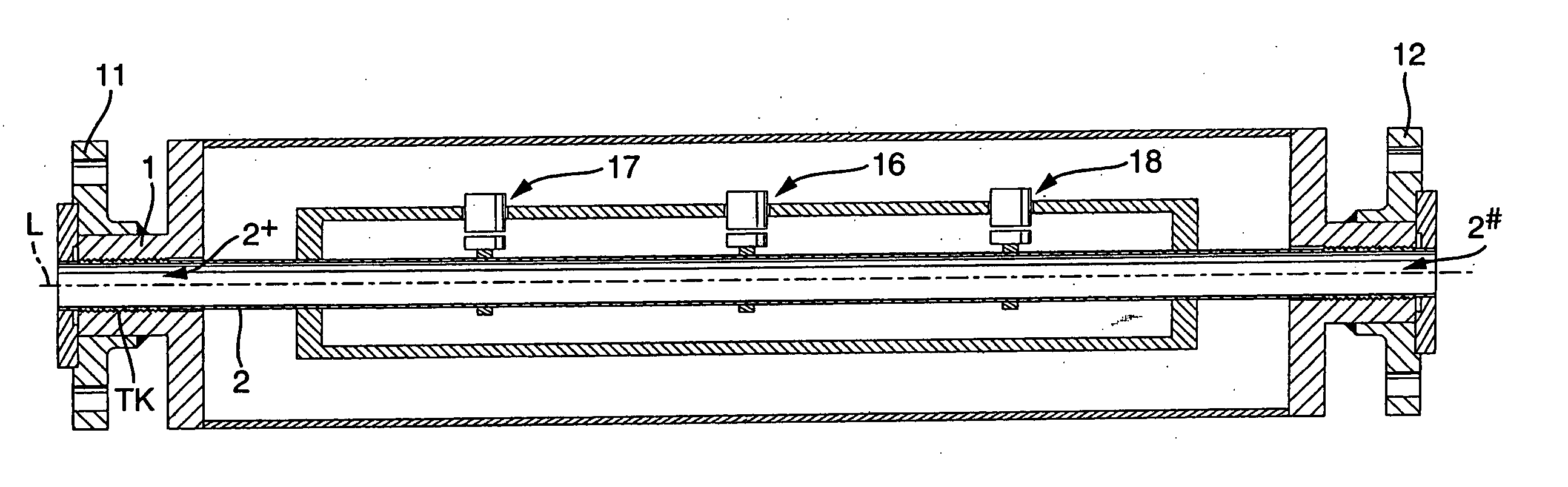

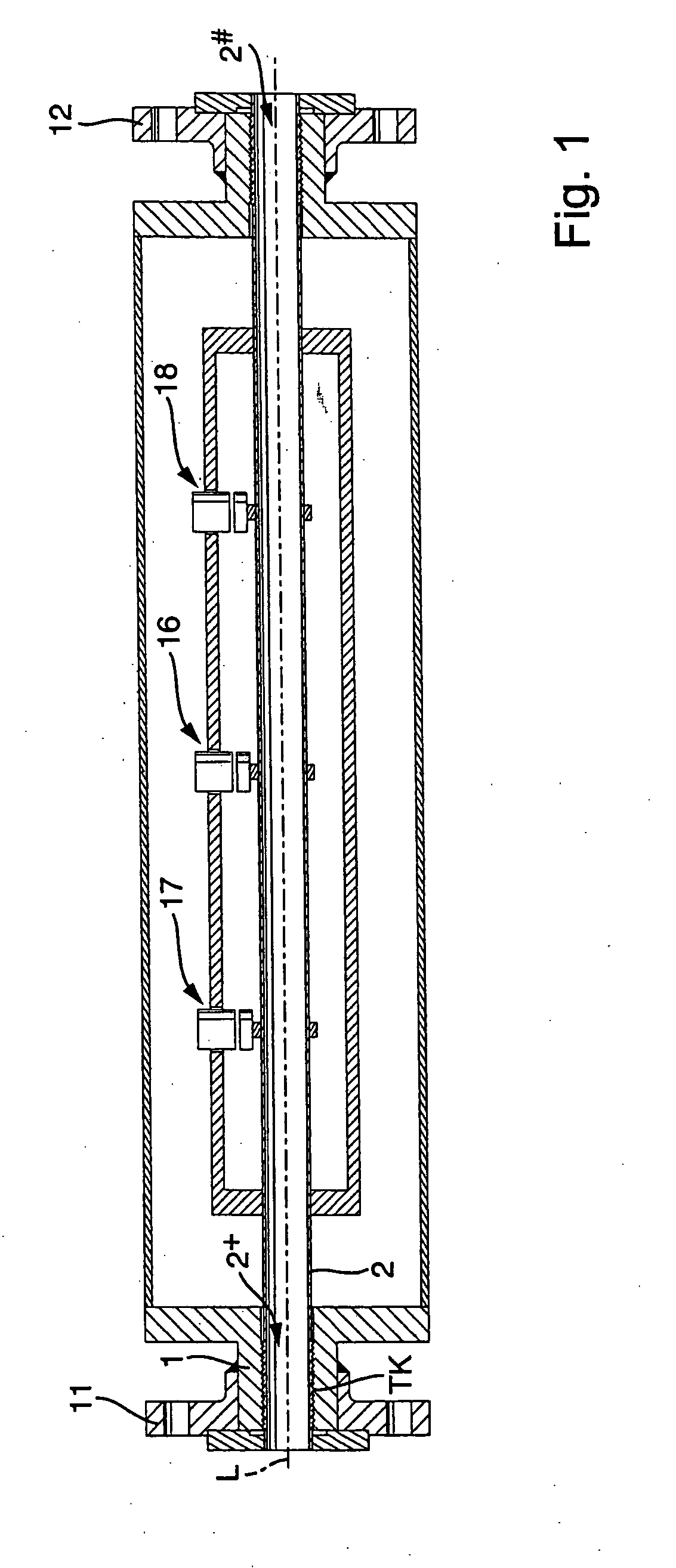

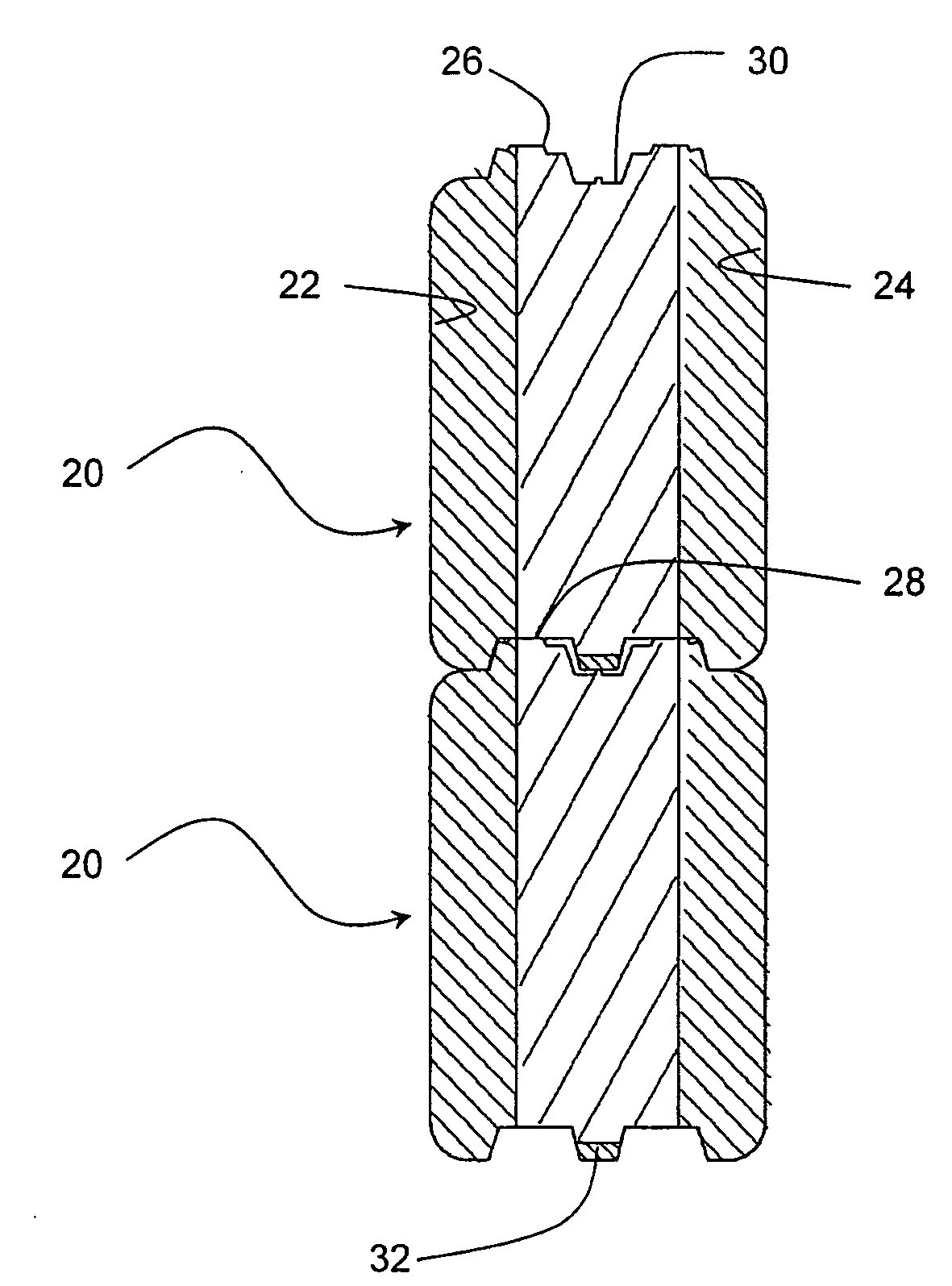

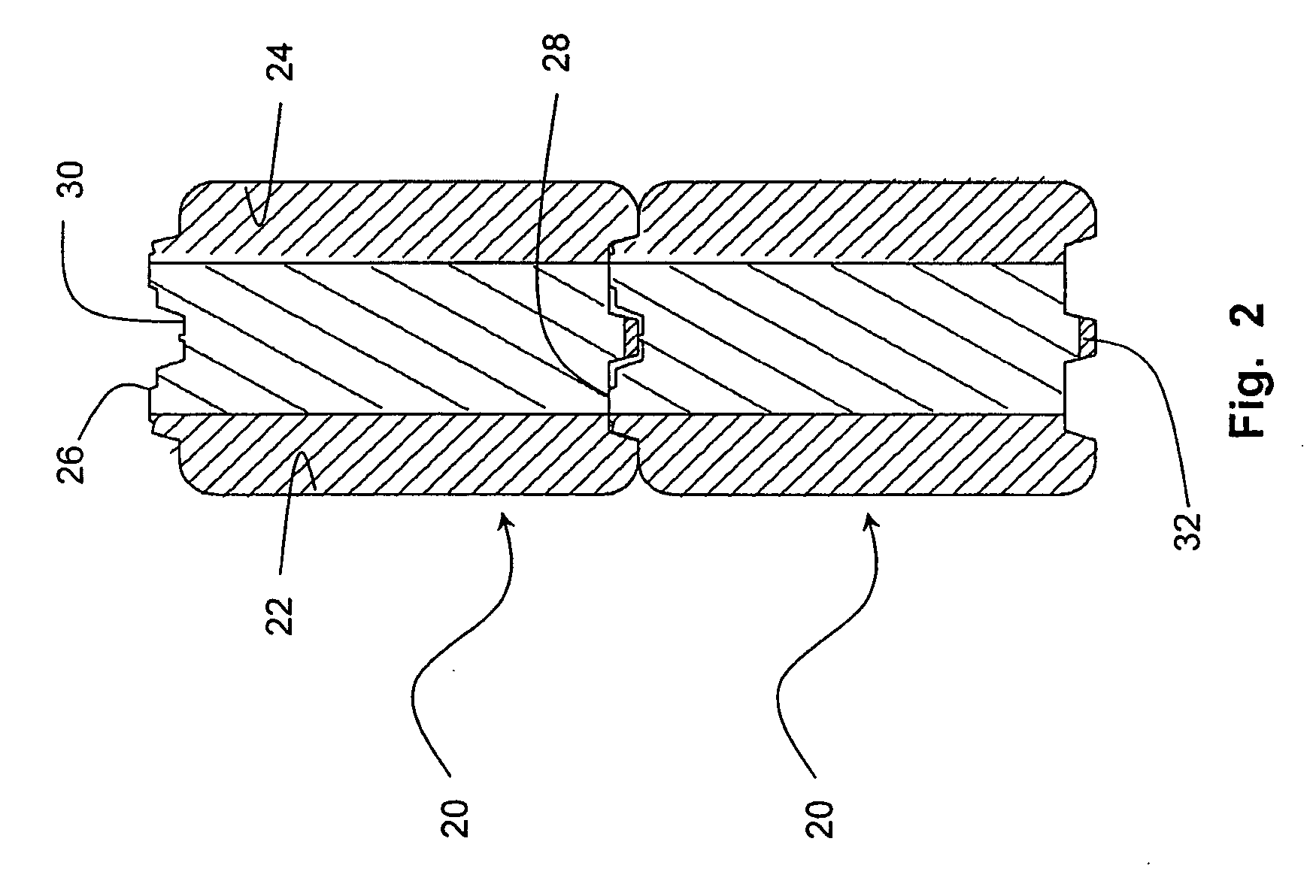

Composite system, method for its manufacture, and measurement pickup using such a composite system

ActiveUS20060083941A1Stable and high-strength and lasting and mechanical connectionIncreased pull-out strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesPig casting plantsEngineeringCompound system

A composite system includes a first component, for instance of metal, and a second component extending at least partly through the first component along an imaginary longitudinal axis of the composite system. The second component contacts, with an at least partially curved, especially cylindrical, outer surface, an inner surface of the first component flushly such that the first component at least sectionally, at least partly, grips around the second component. Joining surfaces of the composite system, which are formed by the mutually contacting surfaces of the two components, are formed in such a manner that the two components exhibit contour portions in the area of these joining surfaces embodied as self-closing, peripheral surfaces. The contour portions fit at least partly into one another, to form a mechanical interference locking effective, at least in part, likewise in the direction of the longitudinal axis. Additionally, the second component, with its outer surface, contacts the inner surface of the first component flushly, such that the two components are mechanically tightly connected together also by means of a frictional locking effective at least partly in the direction of the longitudinal axis. Alternatively, or in supplementation thereof, at least one of the components is subjected at least partly to lastingly elastic, especially mixed plastic-elastic, deformations. The composite system is distinguished by a high pull-out strength, even in the presence of repeatedly arising vibrations in one of the components and is, therefore, especially suited also for use in a vibration-type measurement pickup.

Owner:ENDRESS HAUSER FLOWTEC AG

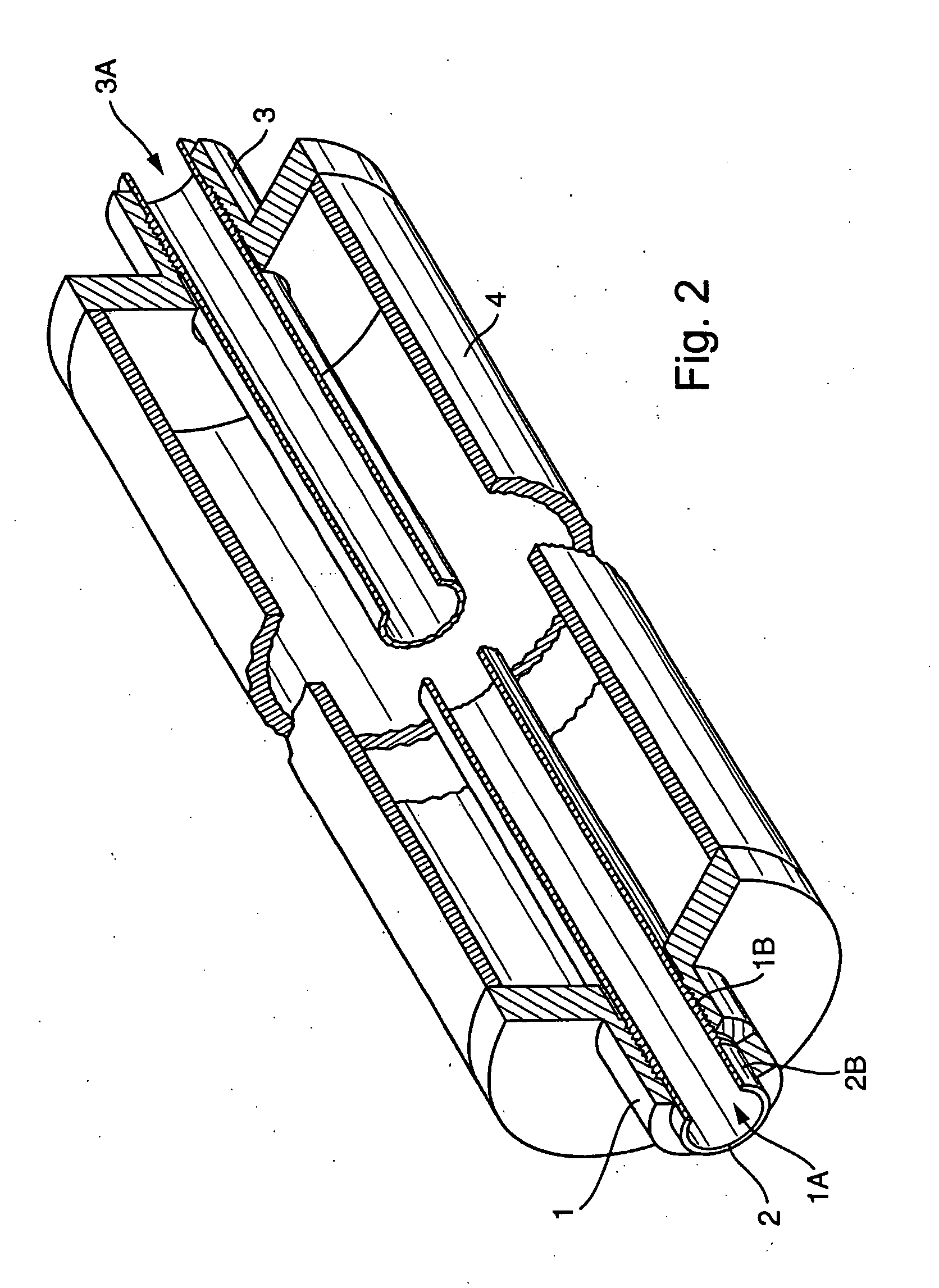

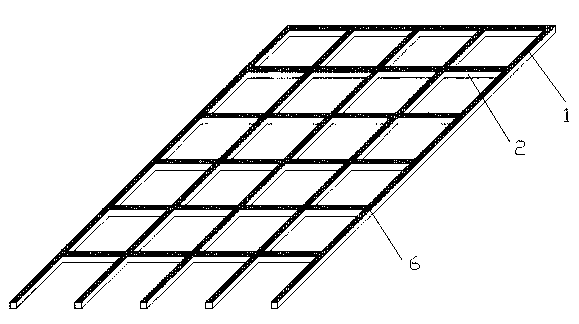

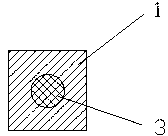

Plane grid rib for structure reinforcement, mould and manufacturing method of plane grid rib

ActiveCN103216041AAvoid crackingNot easy to peel offBuilding repairsBridge erection/assemblyStructural engineeringFibrous composites

The invention discloses a plane grid rib for structure reinforcement. The plane grid rib comprises longitudinal composite ribs and horizontal composite ribs, wherein the longitudinal composite ribs and the horizontal composite ribs are fixedly connected on a same plane to form a plane grid; and the cross sections of the longitudinal and horizontal composite ribs are rectangular. The invention also discloses a mould for manufacturing the plane grid. The mould comprises a male mould and a female mould, wherein the male mould is a first platform; the lower part of the first platform is provided with criss-cross convex ridges; the female mould is a second platform; the upper part of the second platform is provided with criss-cross grooves; and the grooves of the second platform are matched with the convex ridges of the first platform. The invention also discloses a manufacturing method of the plane grid rib. The method comprises the following steps of: 1, manufacturing fibrous composite materials; 2, distributing the fibrous composite materials; and 3, applying pressure to the fibrous composite materials to manufacture the plane grid rib. The plane grid rib disclosed by the invention has the advantages of regularity in section and high tensile strength and elastic modulus.

Owner:江苏绿材谷新材料科技发展有限公司 +2

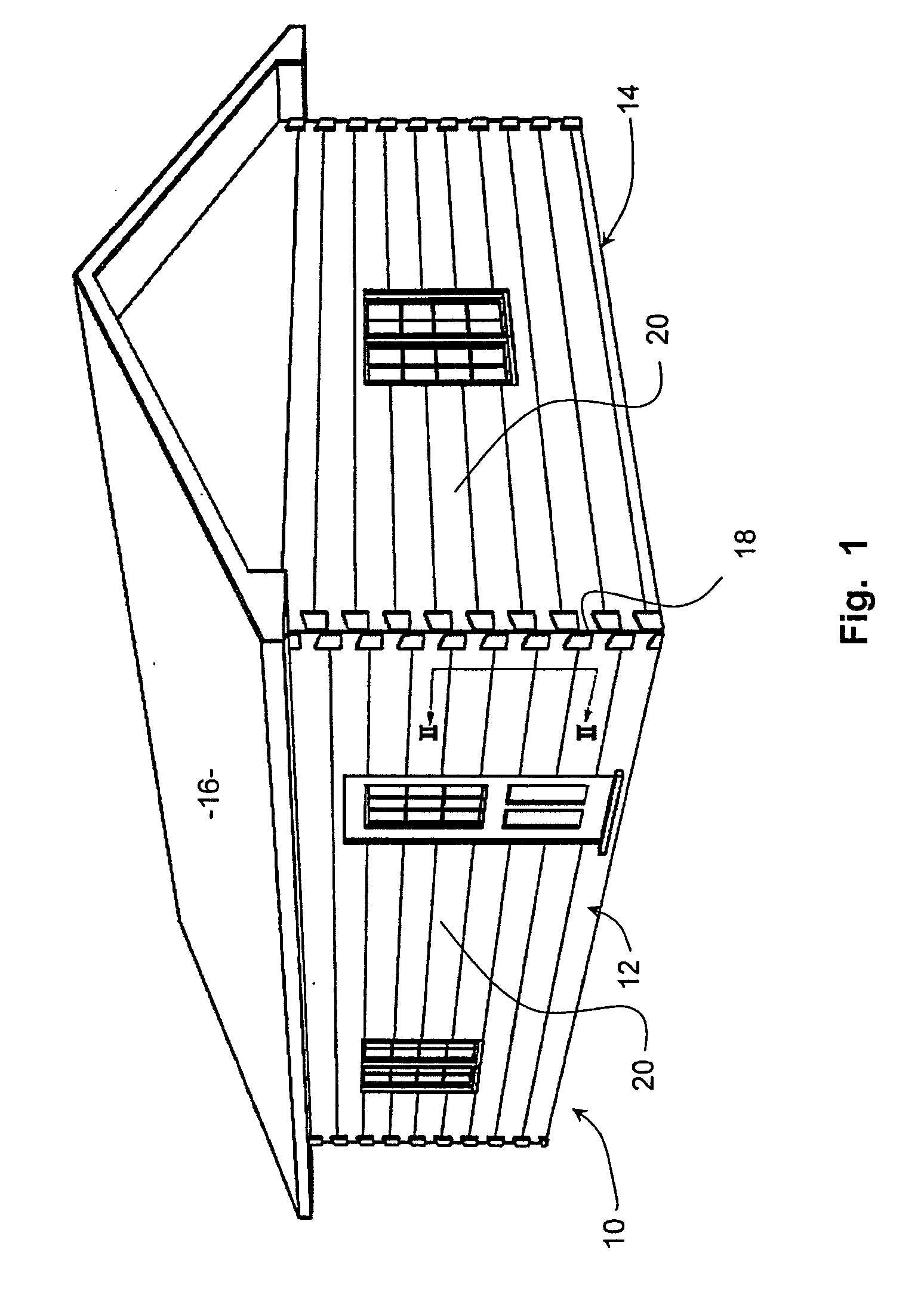

Insulated log homes

InactiveUS20100043323A1Great thermal efficiencyUniform cross sectionWallsPretreated surfacesThermal ratingElectrical and Electronics engineering

A log for a log home has a plurality of pockets formed within the body of the log. The pockets are filled with foam to enhance the thermal rating of the log.

Owner:WRIGHTMAN RONALD A

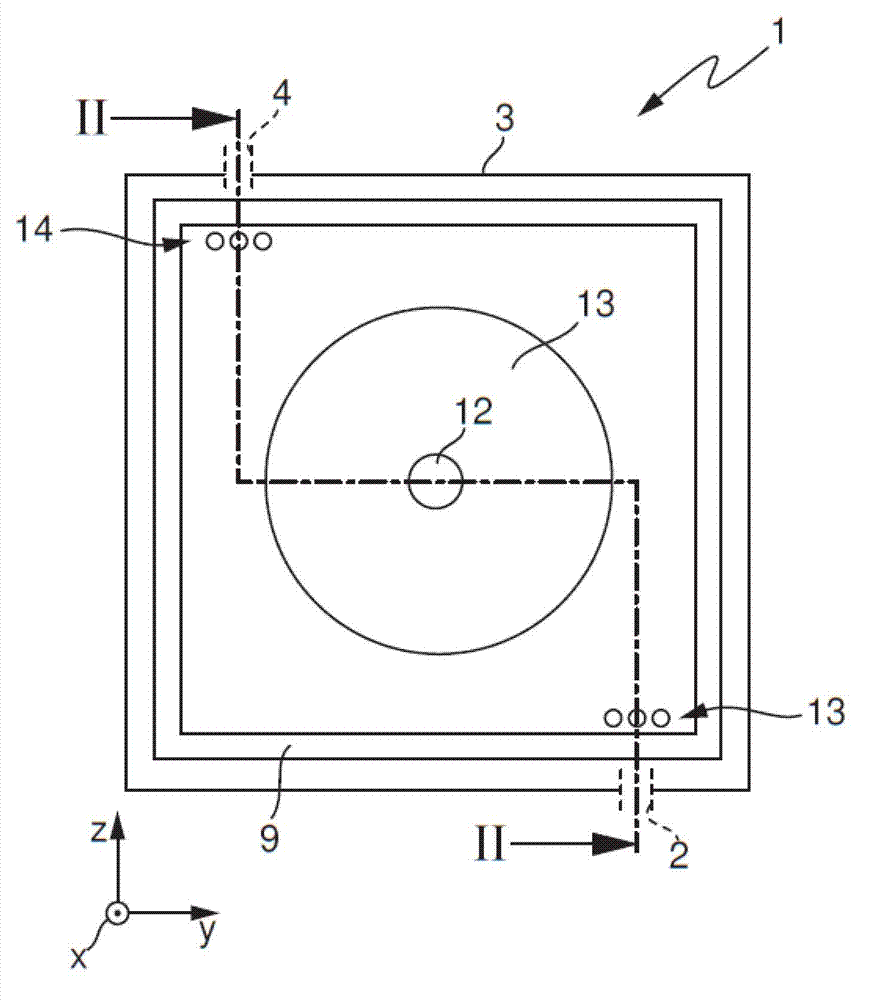

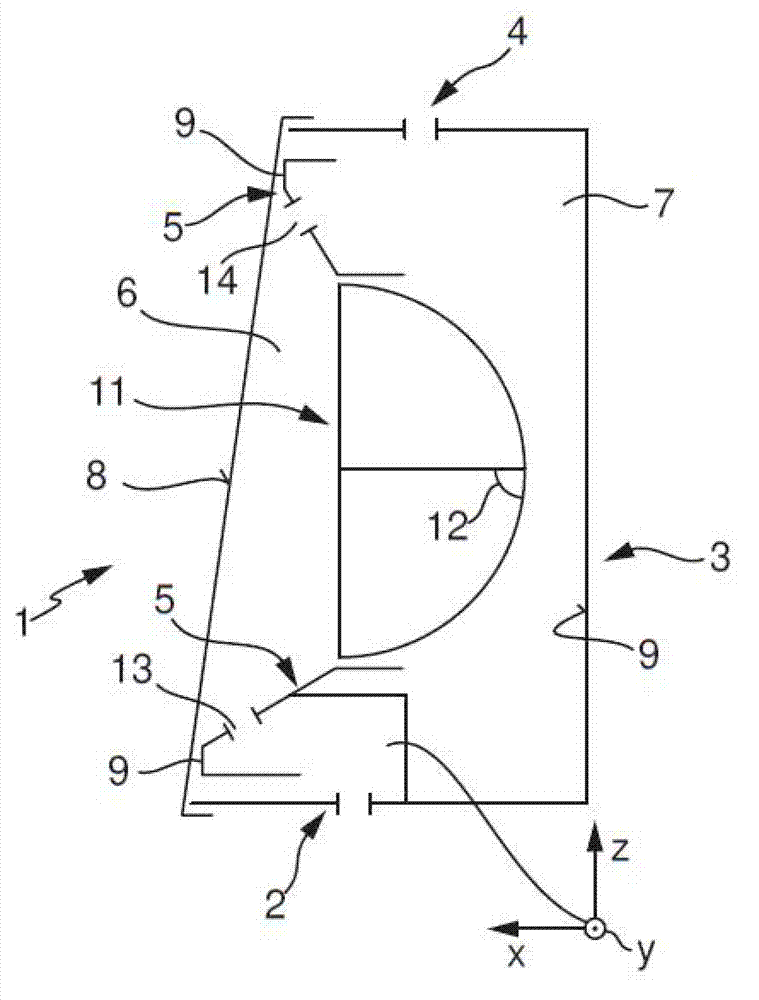

Headlamp with means for air guidance within the headlamp housing

ActiveCN103175083AHigh intrinsic rigidityUniform cross sectionGas-tight/water-tight arrangementsSignalling/lighting devicesGuide tubeHeadlamp

The headlight (1) has a housing (3) having a light exit opening, and a transparent cover plate (8) for covering the light exit opening. The ventilation opening (2) and vent (4) are arranged in the housing. The housing is provided with a hollow structure containing air inlet (13), air outlet (14) and a dimensionally stable pipe section arranged between air inlet and air outlet. The hollow structure is configured to guide the air stream flowing from ventilation opening to the vent within the housing.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

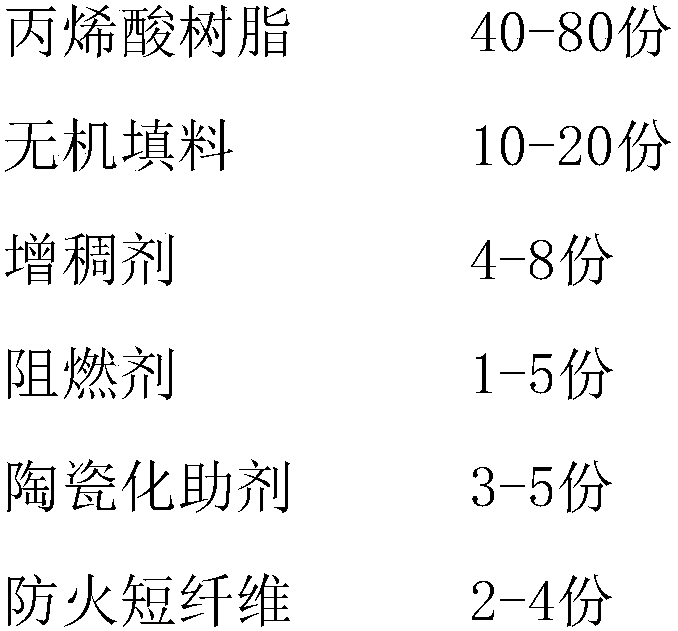

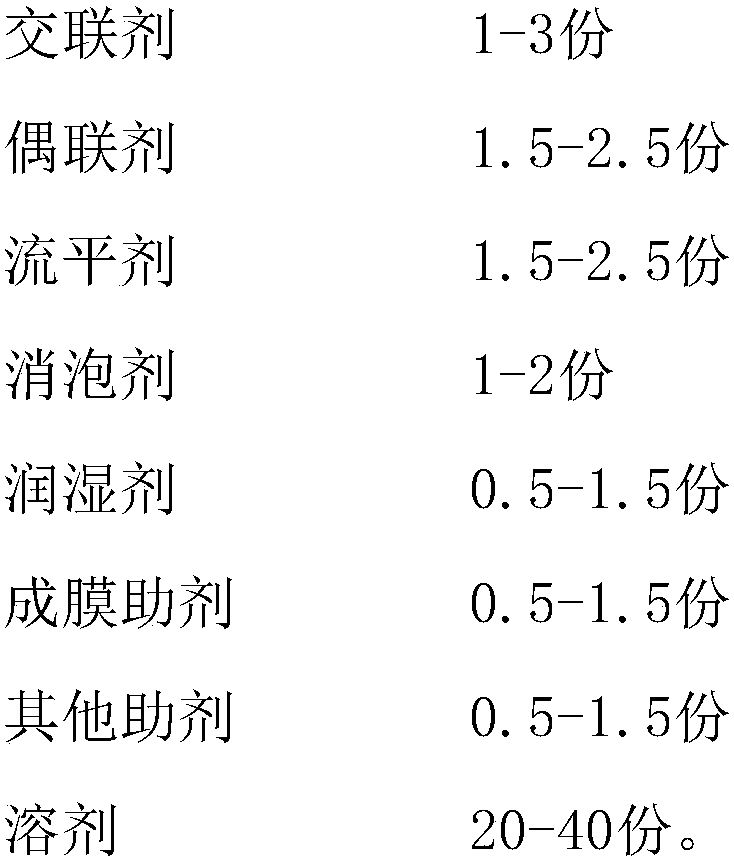

High temperature-resistant fireproof coating and preparation method thereof

ActiveCN108504257AGood weather resistanceImprove performance such as salt spray resistanceFireproof paintsEpoxy resin coatingsFiberAcrylic resin

The invention relates to the technical field of coatings, in particular to a high temperature-resistant fireproof coating and a preparation method thereof. The high temperature-resistant fireproof coating is prepared from the following raw materials in parts by weight: acrylic resin, inorganic filler, a thickener, a flame-retardant agent, a ceramic additive, fireproof short fibers, a crosslinkingagent, a coupling agent, a flatting agent, a defoaming agent, a wetting agent, a film forming additive, other additives and solvents. The high temperature-resistant fireproof coating has the advantages that high temperature can be endured, the flame-retardant property is good, the propagation of fire condition is well blocked, and the fireproof property is excellent; the effect of resisting long-time impact by 1100 DEG C hydrocarbon high-temperature fire hazard is realized; the weather-resistant property and waterproof property are realized, the shrinkage is avoided, the coating strength is high, and the surface is flat.

Owner:GUANGDONG ZHICHENG CHEM +1

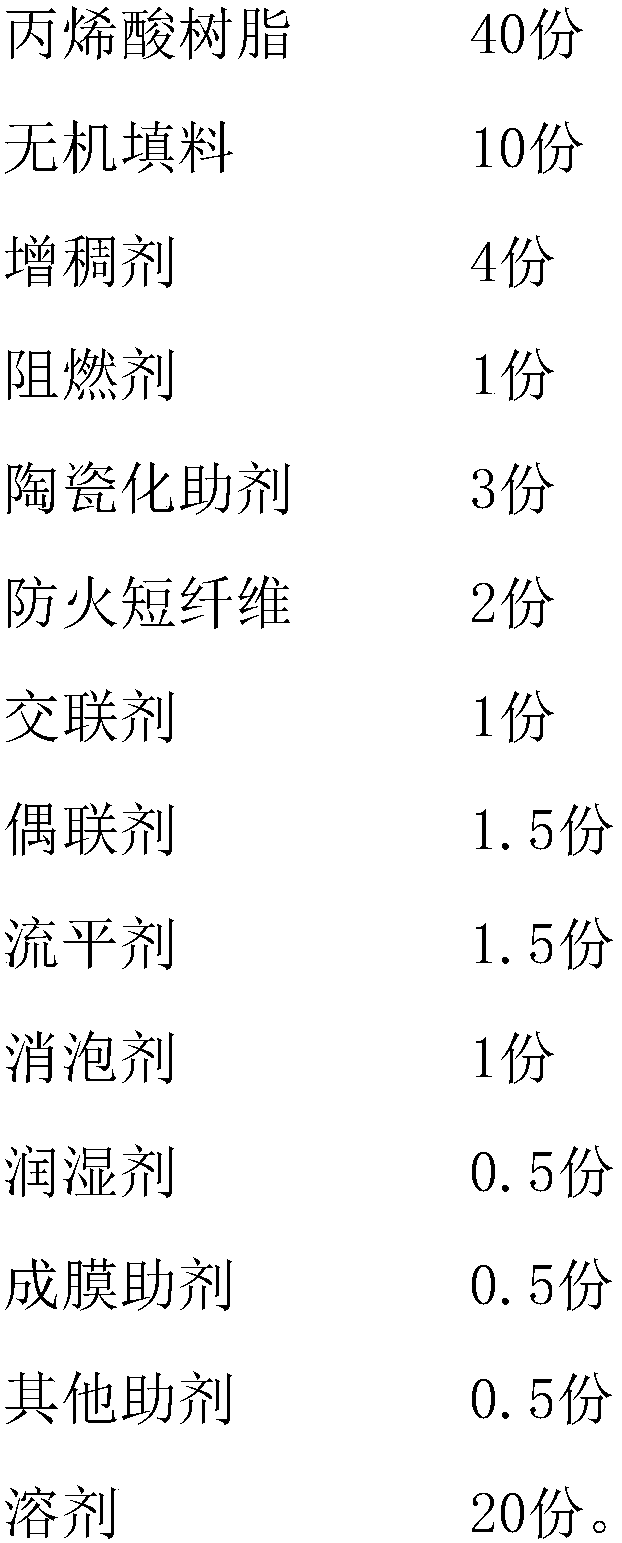

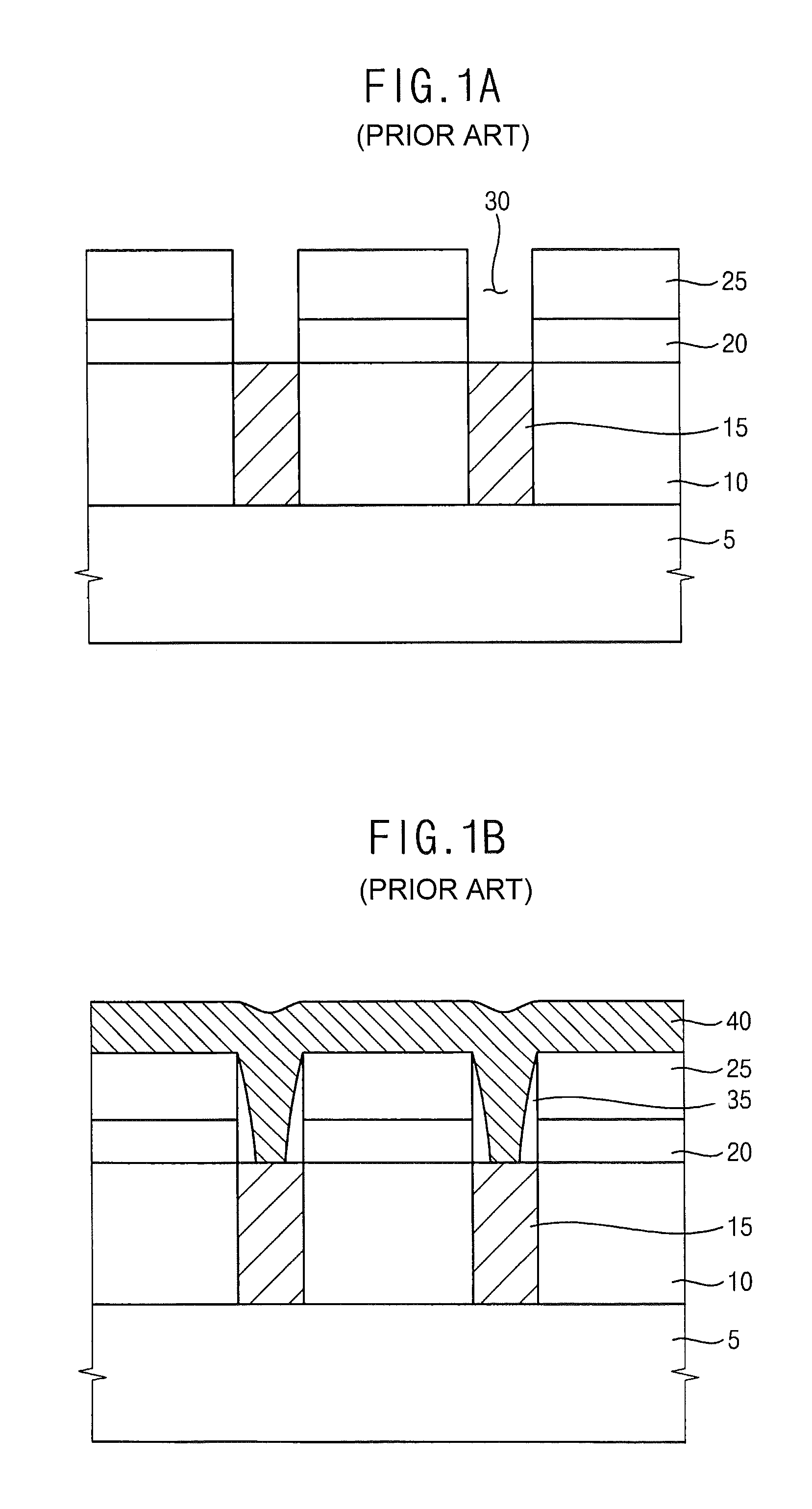

Methods of manufacturing variable resistance non-volatile memory devices including a uniformly narrow contact layer

InactiveUS8039372B2Uniform cross-sectionUniform heightSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringContact layer

A phase changeable memory device is manufactured by forming at least one insulating layer on a substrate. A preliminary first electrode is formed on the insulating layer. The preliminary first electrode is partially etched to form a first electrode electrically connected to the substrate. After the preliminary first electrode is formed, both sidewalls of the preliminary first electrode are partially etched isotropically to form a first electrode having a uniform width and height. A phase changeable material layer pattern and a second electrode are subsequently formed on the first electrode. Related devices also are described.

Owner:SAMSUNG ELECTRONICS CO LTD

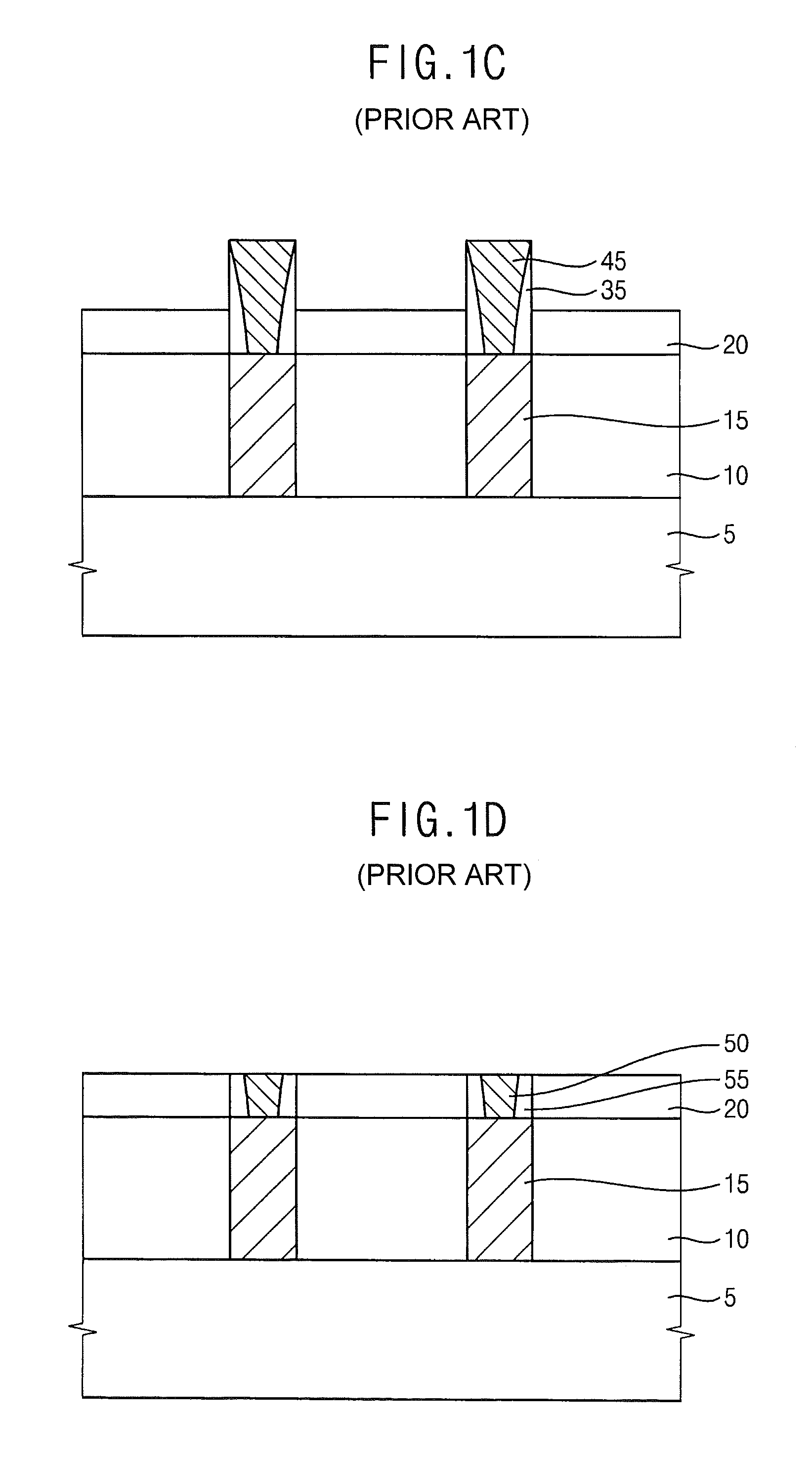

Styrene-butadiene rubber composite material for high-performance tire and preparation method thereof

InactiveCN103865133AImprove mixing uniformityImprove flame retardant performanceSpecial tyresPolymer scienceMooney viscosity

The invention discloses a styrene-butadiene rubber composite material for a high-performance tire. The styrene-butadiene rubber composite material comprises the following raw materials in parts by weight: 80-100 parts of powdered styrene-butadiene rubber, 8-13 parts of nano-loess powder, 15-20 parts of hydroxyl-terminated liquid styrene-butadiene rubber, 5-7 parts of montmorillonite, 13-20 parts of aluminum hydroxide, 18-23 parts of calcium sulfate whisker, 8-12 parts of furnace carbon black, 0.6-0.98 part of sulfur, 0.7-0.92 part of promotor, 0.23-0.5 part of 1,3-diphenylguanidine, 1-3 parts of zinc oxide, 1.5-2.4 parts of stearic acid and 2-3 parts of titanate coupling agent, wherein the content of styrene in the powdered styrene-butadiene rubber is 25-30%, and the Mooney viscosity of the powdered styrene-butadiene rubber (ML1+4, 100 DEG C) is 52-57; the content of styrene in the hydroxyl-terminated liquid styrene-butadiene rubber is 23.4-26.5%, and the viscosity of the hydroxyl-terminated liquid styrene-butadiene rubber is 14.4-16.2Pa.s. The invention also discloses a preparation method of the styrene-butadiene rubber composite material for the high-performance tire.

Owner:ANHUI SHENGDONG CHEM

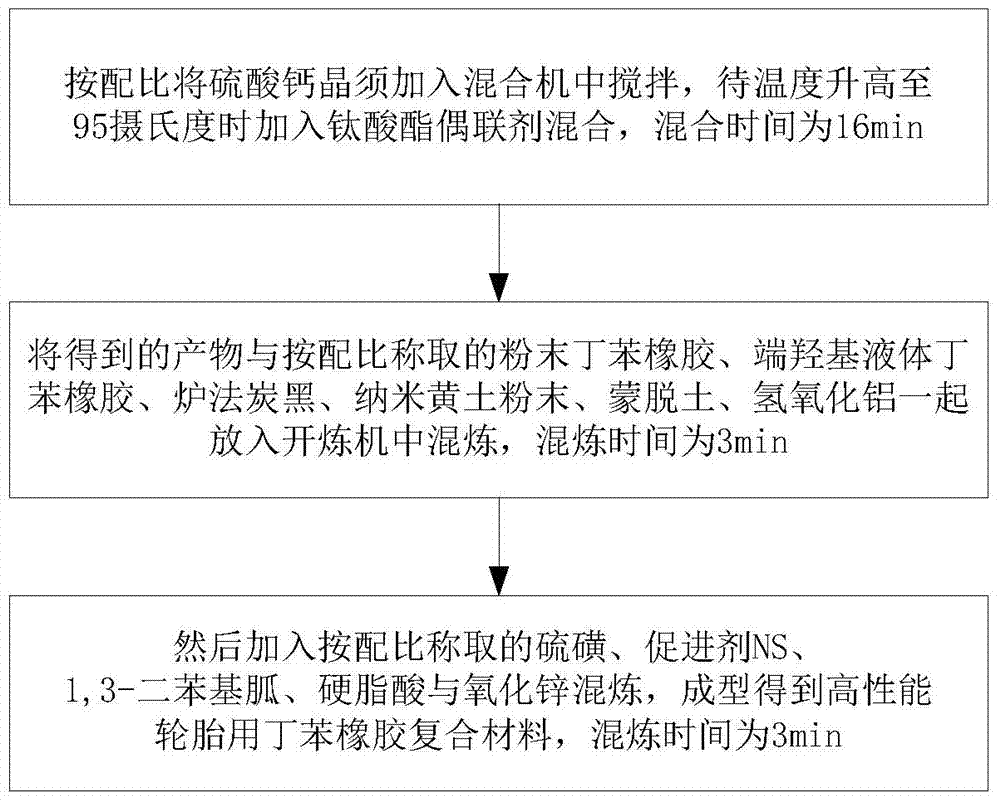

Phenolic foam external wall thermal insulation material and preparation method thereof

InactiveCN106009493AGood toughening effectGood flame retardant and heat resistancePhenol formaldehyde resinCalcium

The invention provides a phenolic foam external wall thermal insulation material and a preparation method thereof. The phenolic foam external wall thermal insulation material comprises the following raw materials by weight: 60-70 parts of resol, 4-8 parts of calcium sulfate whisker, 3-6 parts of a surfactant, 5-10 parts of a foaming agent, 10-15 parts of a curing agent and 3-6 parts of a toughening agent, which is a mixture formed by nano aluminum hydroxide and graphite oxide in an alcohol acid salt solution. The preparation method comprises the steps of: 1) mixing the resol, calcium sulfate whisker and the toughening agent evenly at 40-60DEG C to obtain a mixture A; and 2) mixing the mixture A, the surfactant and the foaming agent evenly, quickly pouring the mixture into a pre-heated mold to perform foaming, and conducting curing. The thermal insulation plate has high strength and oxygen index, and low thermal conductivity coefficient.

Owner:合肥广能新材料科技有限公司

Sheathing material for modified cables and preparation method thereof

InactiveCN104629127AImprove toughnessLow costRubber insulatorsInsulated cablesStearic acidMechanical engineering

The invention discloses a sheathing material for modified cables and a preparation method thereof. The sheathing material comprises the following raw materials in parts by weight: 50-80 parts of styrene butadiene rubber powder, 20-30 parts of zinc oxide whisker, 30-40 parts of organic silicon rubber, 10-15 parts of montmorillonite, 20-30 parts of modified short stapled cotton, 15-30 parts of calcium sulfate whisker, 20-30 parts of furnace black, 1-3 parts of sulfur, 1-1.5 parts of promoter TMTD, 1-3 parts of 1,3-diphenyl guanidine, 1-3 parts of zinc oxide, 1-2.5 parts of stearic acid and 1-3 parts of titanate coupling agent; the sheathing material disclosed by the invention is high in stress bearing strength, strong in toughness, good in thermal stability, environmental friendly and low in cost.

Owner:ANHUI GUOHUA CABLE GROUP

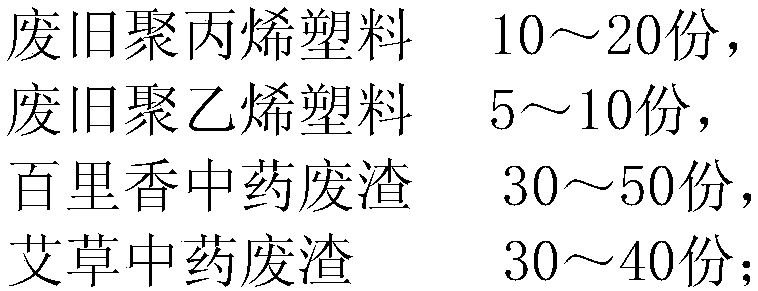

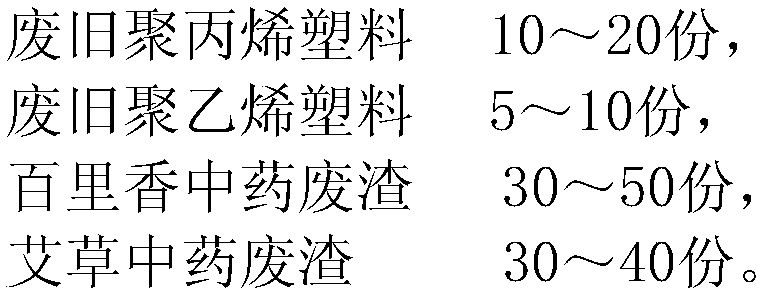

Environment-friendly composite board

The invention discloses an environment-friendly composite board which comprises the following raw materials in parts by weight: 10-15 parts of waste and old polypropylene plastics, 10-15 parts of waste and old polyvinyl plastics, 30-50 parts of waste residues of thyme traditional Chinese medicine and 30-45 parts of waste residues of wormwood traditional Chinese medicine. The environment-friendly composite board is obtained by mixing the raw materials and performing plastic extruding and rolling on the mixed raw materials. The composite board is mainly used for a supporting template and a wallbody template when concrete is poured in construction, and the waste residues of the thyme traditional Chinese medicine and the waste residues of the wormwood traditional Chinese medicine are added into ingredients, so that the composite board has aromatic odor of plants and also has better antibacterial property and sterilizing effect, the composite board is prevented from being mildewed, the radioactivity of the composite board is reduced, and bodies of production workers and installers of the composite board can be protected; the composite board is low in cost of the raw materials, the pollution to the environment caused by the waste residues of the traditional Chinese medicines and the waste and old plastics is reduced, and the 'high-value' utilization of the waste residues of the traditional Chinese medicines and the waste and old plastics are achieved. Additionally, an environment-friendly construction material is added for the construction, so that the composite material has better ecological benefits and economic benefits.

Owner:GUIZHOU UNIV

Calcium sulfate modified ethylene-vinyl acetate copolymer and preparation method of calcium sulfate modified ethylene-vinyl acetate copolymer

ActiveCN102219954AHigh tensile strengthDimensionally stablePigment treatment with non-polymer organic compoundsSulfateEthylene

The invention relates to a calcium sulfate modified ethylene-vinyl acetate copolymer and a preparation method of the calcium sulfate modified ethylene-vinyl acetate copolymer. The calcium sulfate modified ethylene-vinyl acetate copolymer is prepared by the following raw materials according to parts by weight: 55-75 parts of ethylene-vinyl acetate copolymer, 10-30 parts of calcium sulfate and 10-30 parts of titanate coupling agents. The invention also comprises a preparation method of the calcium sulfate modified ethylene-vinyl acetate copolymer. The calcium sulfate modified ethylene-vinyl acetate copolymer has high tensile strength, is not easy to adsorb water, and has stable size, therefore, the calcium sulfate modified ethylene-vinyl acetate copolymer is particularly suitable for producing a transport packing material, a electronics shell, a life tool, a car instrument panel and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

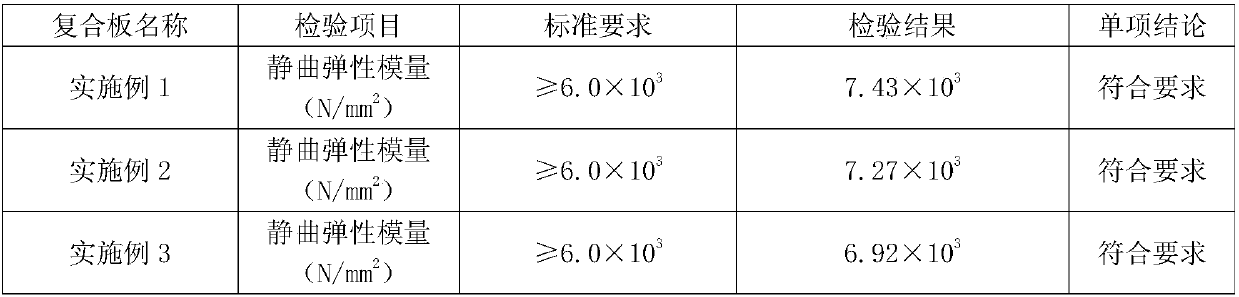

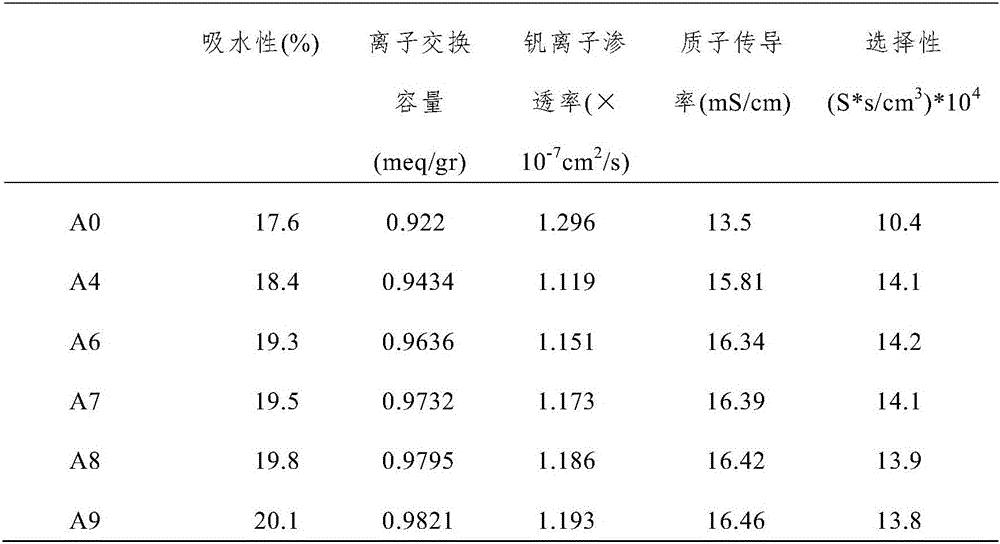

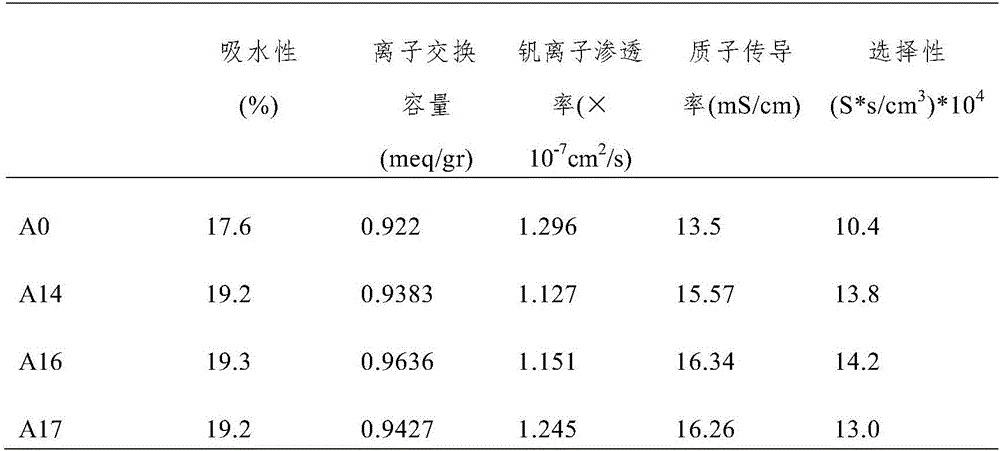

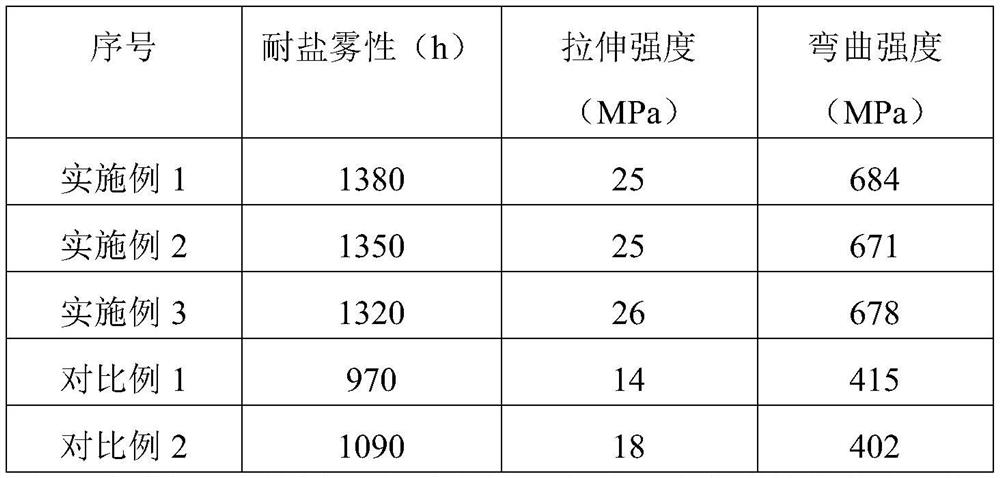

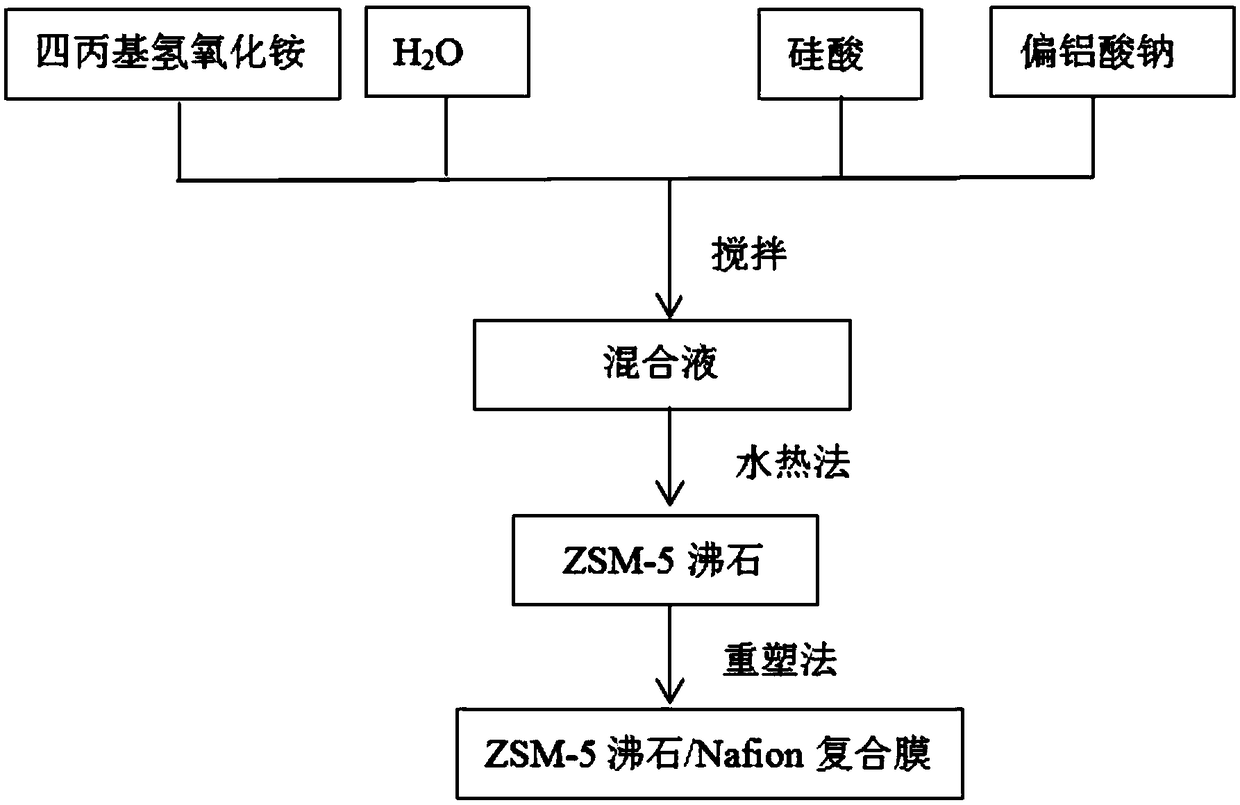

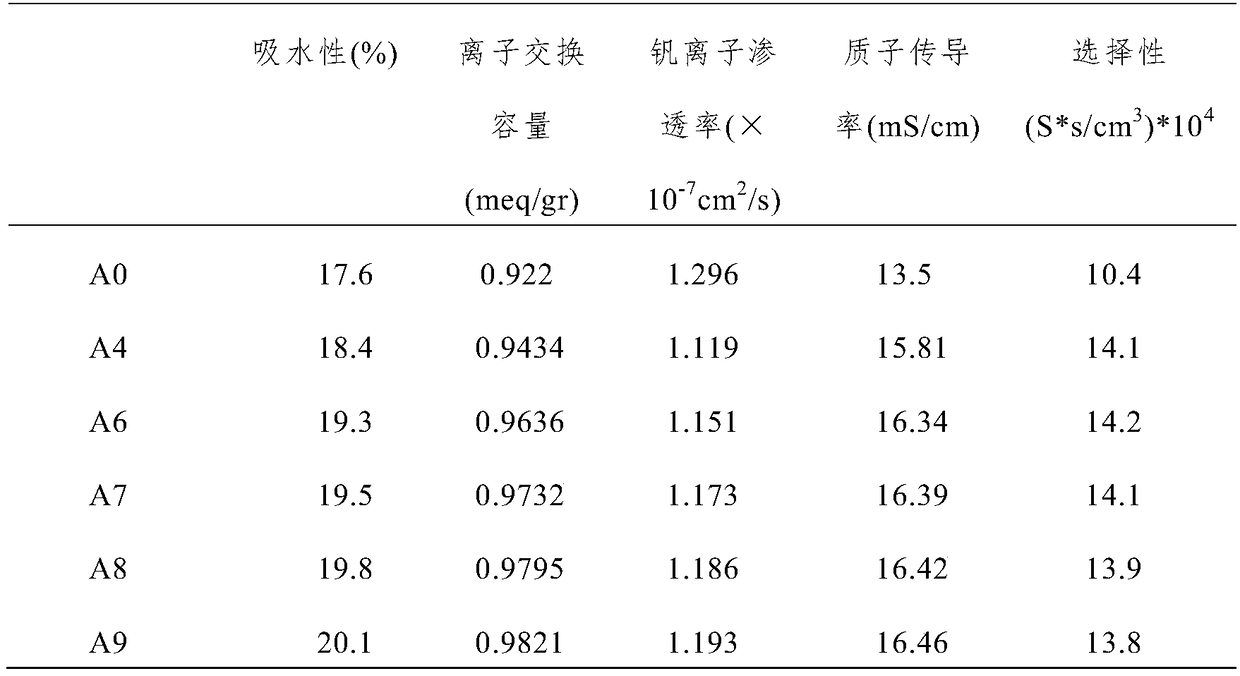

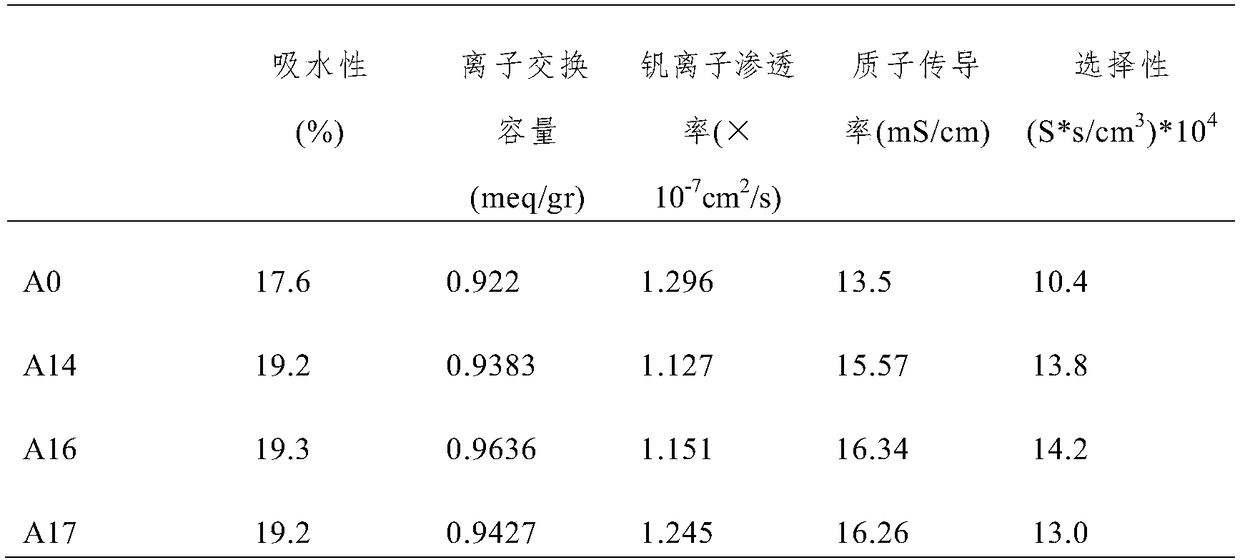

Modification method of proton exchange membrane for all-vanadium redox flow battery

InactiveCN106784917AImprove bindingImprove permeabilityRegenerative fuel cellsSilicic acidIon exchange

The invention relates to a modification method of a proton exchange membrane for an all-vanadium redox flow battery, relating to the technical field of batteries. The modification method comprises the following steps: S1, preparation of submicron order ZSM-5 type zeolite: evenly mixing deionized water, tetrapropylammonium hydroxide, silicic acid and sodium metaaluminate, performing a hydrothermal synthesis method to the mixed solution, and then performing centrifugal cleaning and drying, so as to prepare the submicron order ZSM-5 type zeolite; and S2, preparation of a composite proton exchange membrane: preparing the composite proton exchange membrane from the submicron order ZSM-5 type zeolite obtained in the step 1 and a proton exchange membrane solution. The water-absorbing property, ion exchange capacity, proton conductivity and vanadium ion permeability of the composite proton exchange membrane prepared by adopting the modification method are superior to those of an unmodified proton exchange membrane. Compared with the unmodified proton exchange membrane, the vanadium ion permeability of the composite proton exchange membrane is reduced by 11%, and the proton conductivity is improved by 20%.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

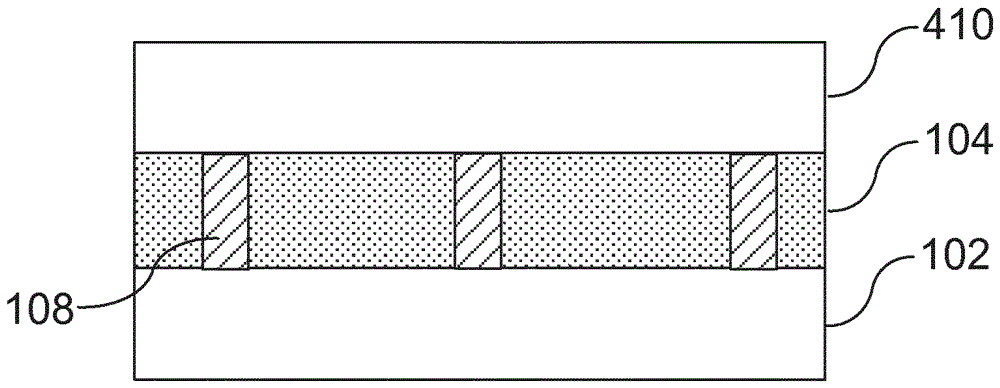

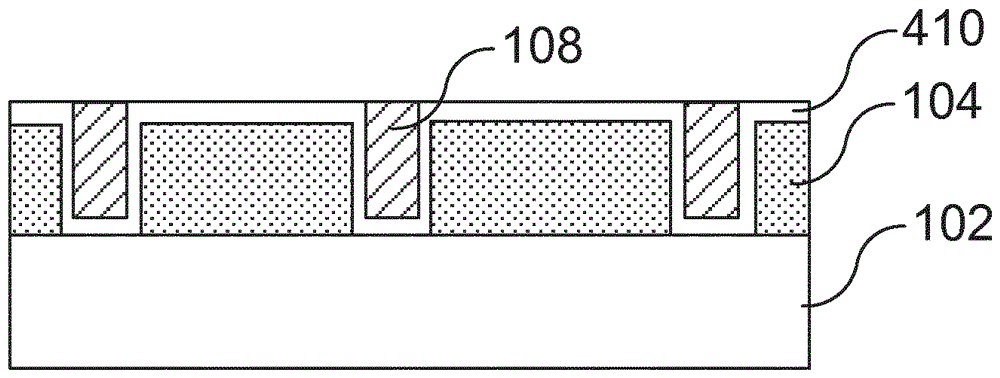

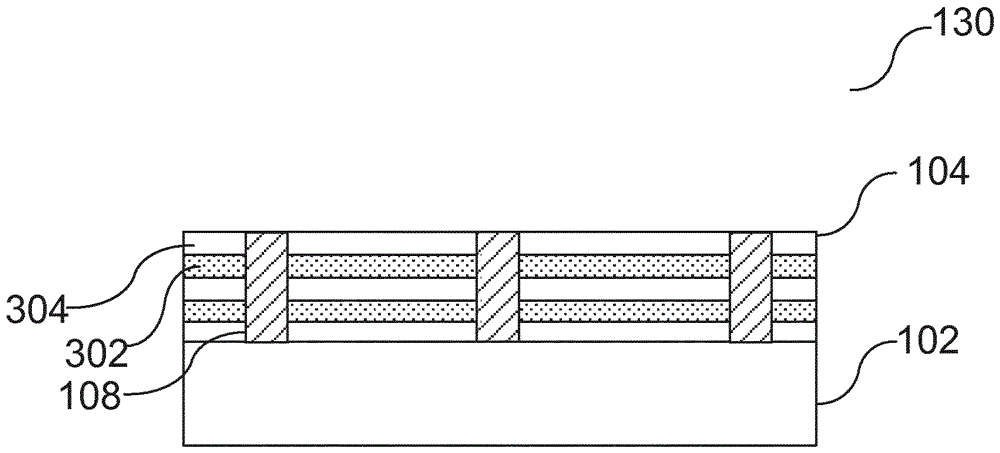

Lighting device, method for producing lighting device

InactiveCN106537631AAchieve current distributionUniform cross sectionSolid-state devicesSemiconductor/solid-state device manufacturingBusbarEffect light

In various exemplary embodiments, a lighting device (100) is provided, and the lighting device (100) comprises: a substrate (130) having a carrier (102), a first electrical busbar (108-1) on or above the carrier (102); a second electrical busbar (108-2) on or above the carrier (102); an optically functional structure (104) on or above the carrier (102), wherein the optically functional structure (104) is formed between the first electrical busbar (108-1) and the second electrical busbar (108-2); and an organic functional layer structure (412) on or above the substrate (130), wherein the organic functional layer structure (412) is designed for converting an electric current into electromagnetic radiation; and a second electrode (414) on or above the organic functional layer structure (412); wherein the optically functional structure (104) is designed in such a way that the beam path of the electromagnetic radiation through the substrate (130) and / or the spectrum of the electromagnetic radiation are / is variable.

Owner:OSRAM OLED

Calcium sulfate modified polylactic acid material and preparation method thereof

The invention discloses a calcium sulfate modified polylactic acid material and a preparation method thereof. The calcium sulfate modified polylactic acid material is prepared from the following raw materials in part by weight: 65 to 85 parts of polylactic acid, 5 to 20 parts of calcium sulfate, and 5 to 30 parts of vinyl triethoxysilane serving as a coupling agent. The invention also discloses the preparation method for the calcium sulfate modified polylactic acid material. The calcium sulfate modified polylactic acid material has high impact strength, good water resistance and good dimensional stability, and is particularly suitable for manufacturing biomedical products, packing products, living articles, electronic appliance shells, automobile instrument panels and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

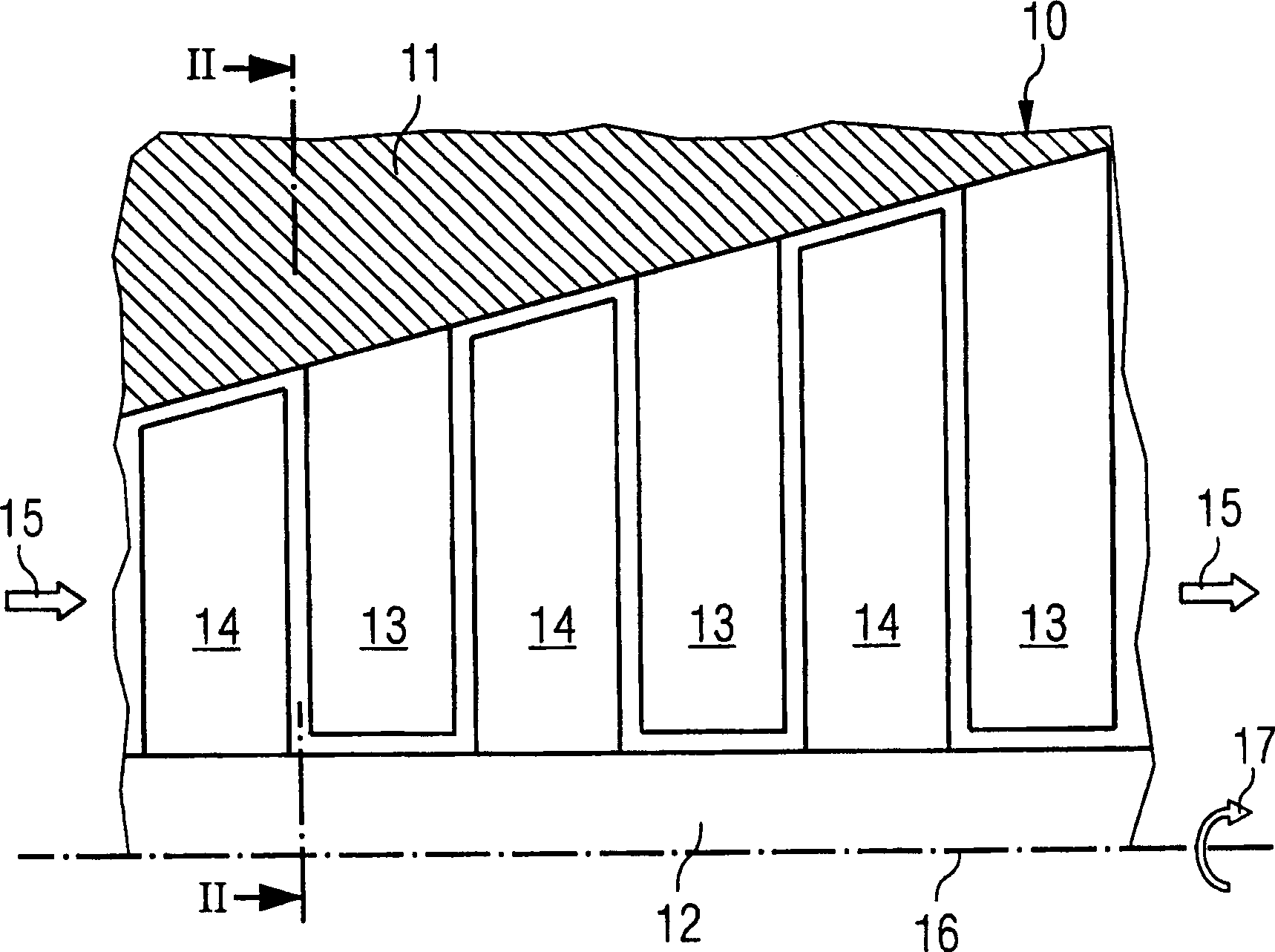

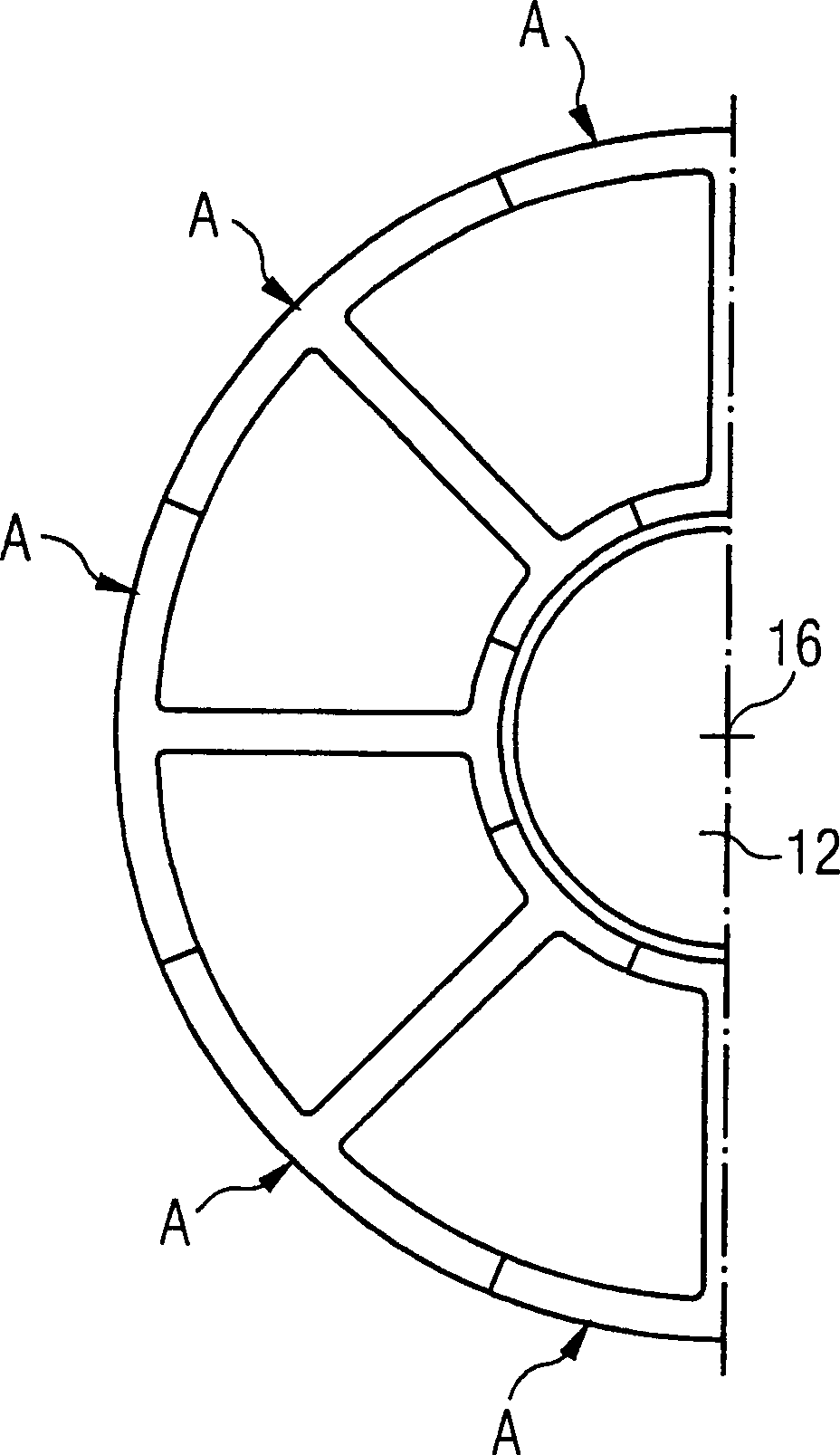

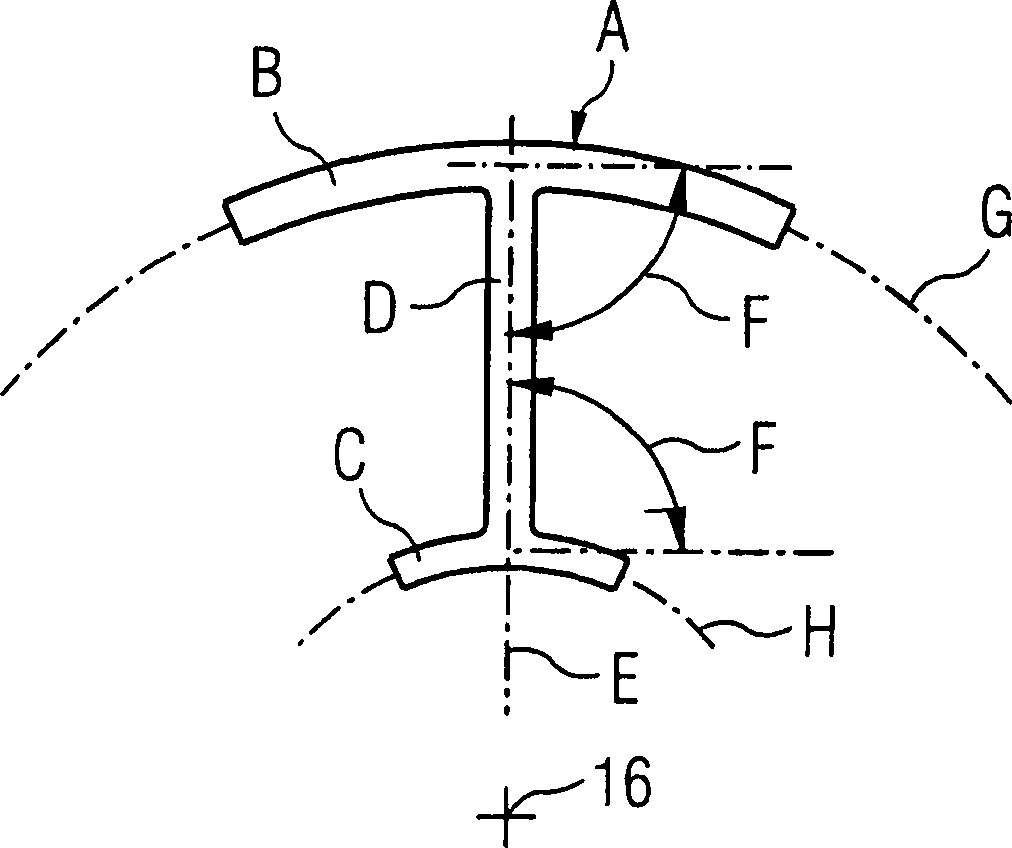

Turbine propeller and turbine engine

InactiveCN1379165ACover gapUniform cross sectionBlade accessoriesFoundry mouldsPropellerTurbine blade

The invention relates to a turbine blade, in particular for a gas turbine (10), having a blade airfoil (20) and at least one platform for fastening to an upperly arranged component (11, 12) (18, 19). According to the invention, each platform (18, 19) forms an obtuse angle (22, 23) with the longitudinal axis (21) of the blade airfoil (20). Through this structural design, it becomes easy to manufacture the turbine blade as a single crystal.

Owner:SIEMENS AG

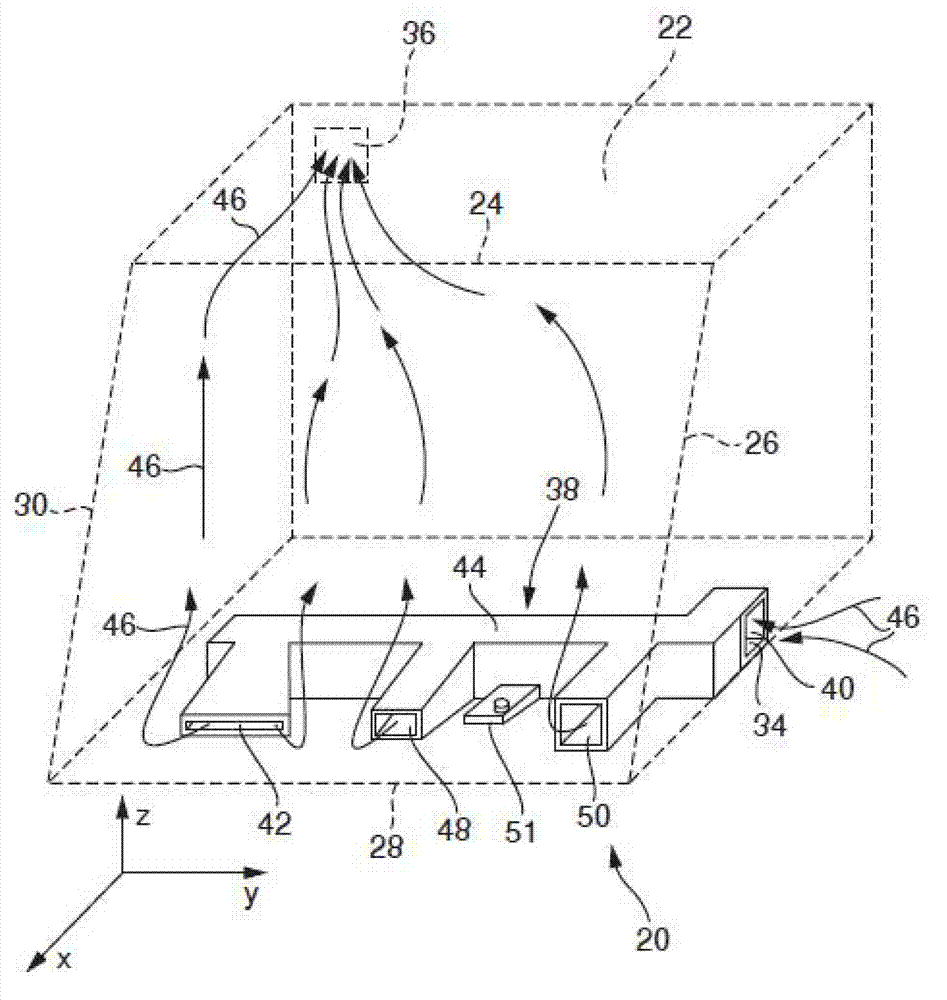

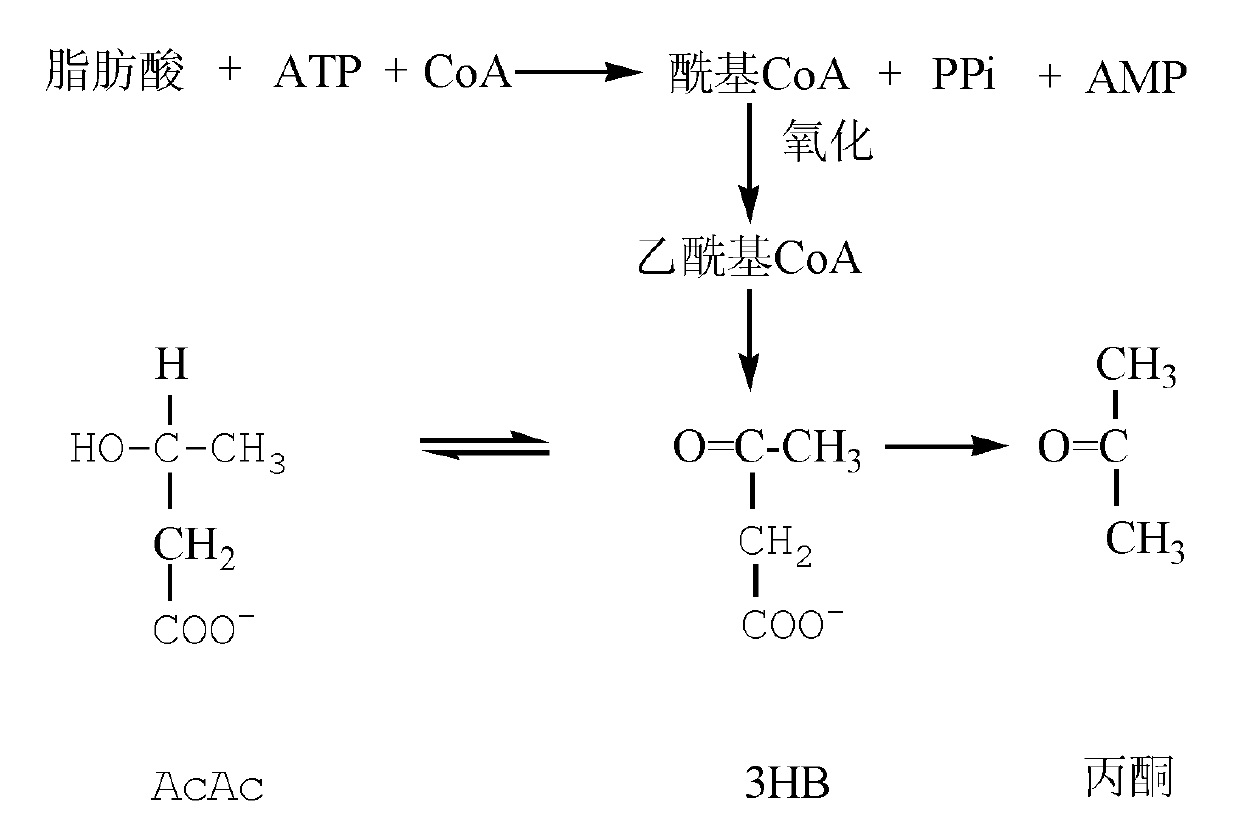

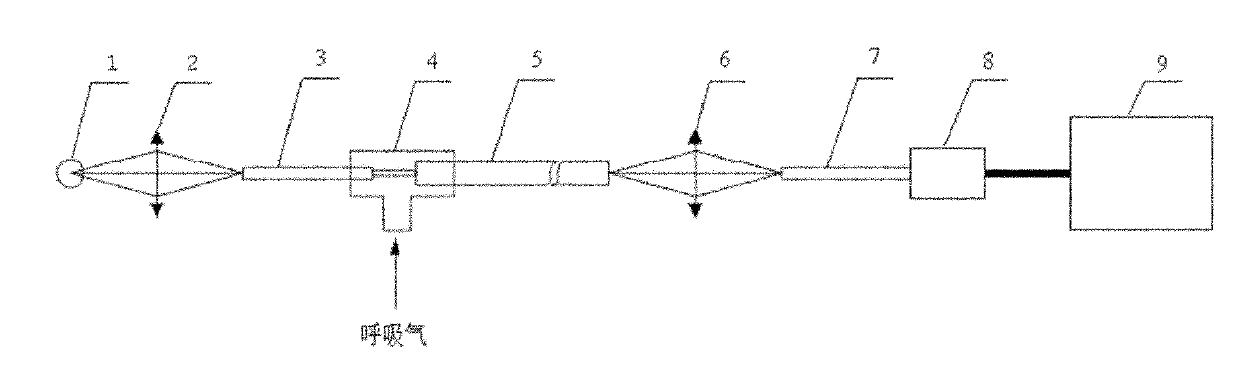

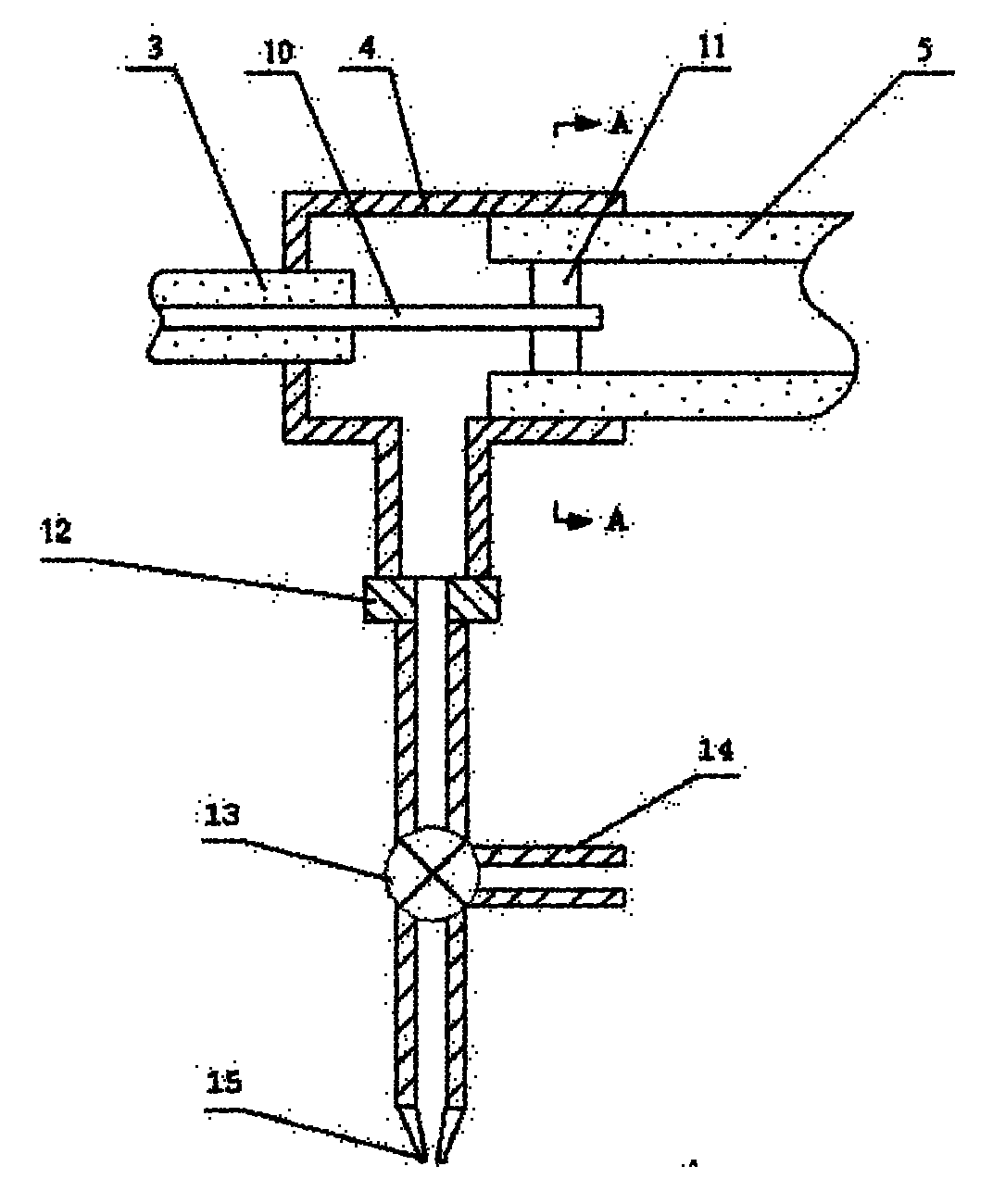

Method for measuring acetone in respiratory gas and implementation device thereof

ActiveCN102175634BSmall attenuationSmall sizeColor/spectral properties measurementsComputerized systemHealth examination

The invention discloses a method for measuring acetone in respiratory gas and an implementation device thereof, wherein a collected respiratory gas sample is injected into the absorption pool of a respiratory gas acetone measuring device; the measuring light is guided into the absorption pool of the respiratory gas acetone measuring device; the measured light absorption spectrum which transmits out of the respiratory gas sample passing through the absorption pool is measured by a light measurer; and the measured absorption spectrum of the respiratory gas sample is compared with the absorptionspectrum containing an acetone gas mixture with the known concentration through a computer system, thereby obtaining the content of the acetone in the respiratory gas sample. In the invention, the content of the acetone in the respiratory gas can be accurately and rapidly measured; the finish and disclosure of the acetone content measurement are the significant progress of a respiratory gas acetone measuring technique; and the progress of the respiratory gas acetone measuring technique is greatly boosted. According to the relation between the content of the acetone in the respiratory gas of ahuman body and diabetes, the method and device provided by the invention can be used for diagnosing the diabetes and can be widely used for the daily health examination of the diabetes and the rapid clinic screening of the diabetes.

Owner:SICHUAN UNIV

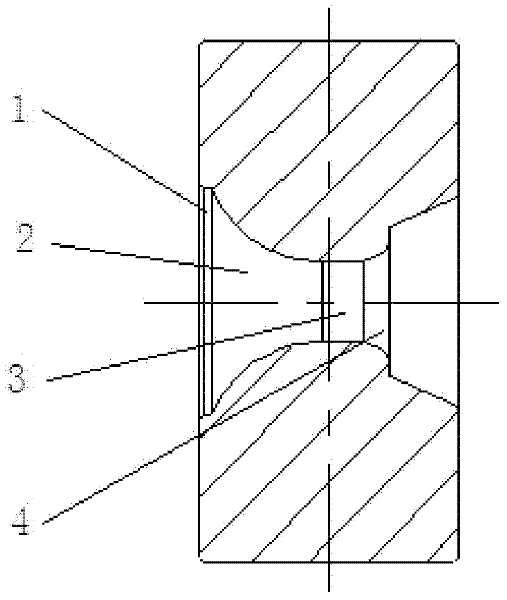

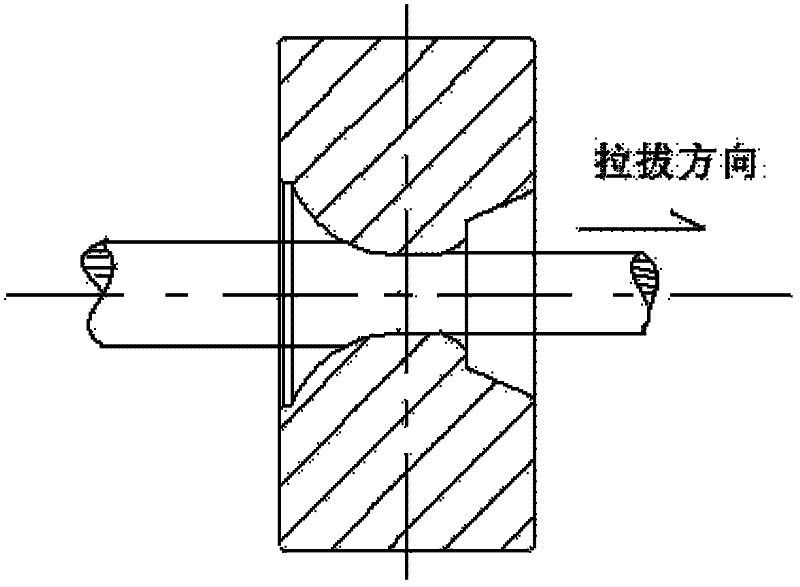

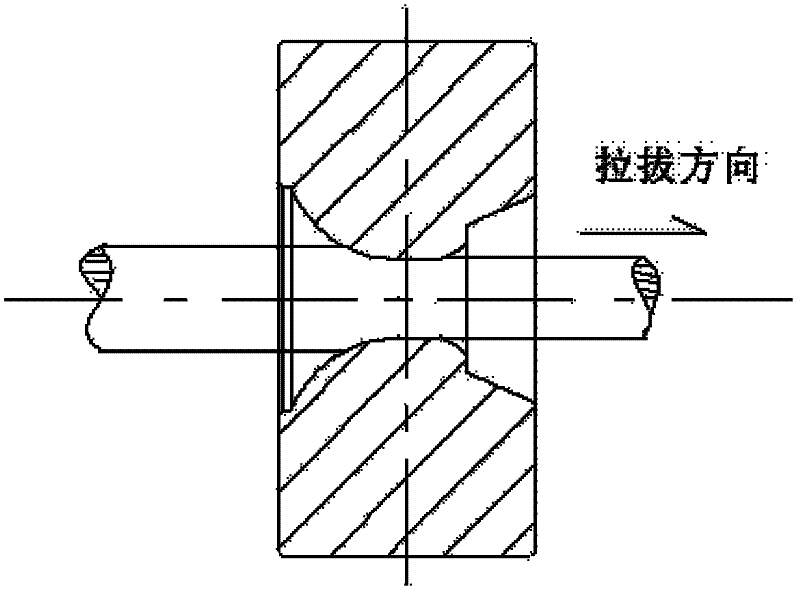

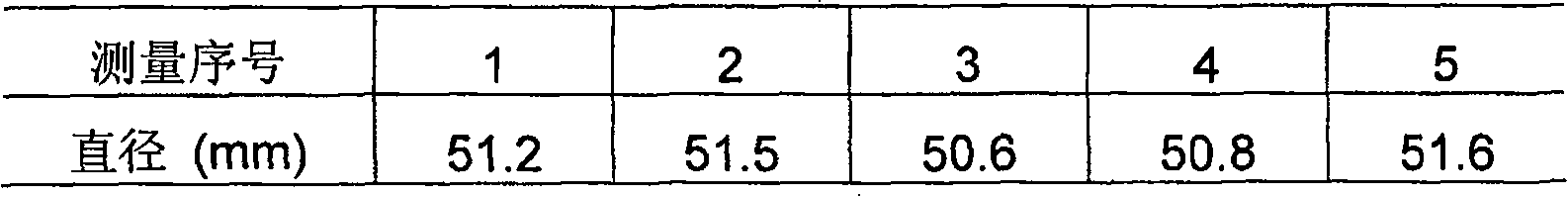

Method for drawing aluminum conductor

InactiveCN102412021AUniform cross sectionFlat surfaceSingle bars/rods/wires/strips conductorsCable/conductor manufactureElectrical conductorOvality

The invention relates to a method for drawing an aluminum conductor. In the method, a mode for compacting the aluminum conductor by the conventional voltage division pressing die is replaced by a mode for drawing a compacted aluminum conductor by a drawing die; and the method for drawing the aluminum conductor comprises the following steps that: the aluminum conductor to be drawn enters a drawing inlet area (1), then sequentially passes through a working area (2), a sizing area (3) and an outlet area (4) under the action of external force, and then is drawn out of the outlet area (4) so as to form the compacted aluminum conductor. The compacted aluminum conductor which is drawn by the method has controllable ovality and a smooth surface, and a safe, and stable medium-voltage cable conductor which has long service life can be provided for a cable core for transmitting medium-voltage current.

Owner:ANHUI LAND GRP

Rubber material with long service life and good mechanical properties

The present invention discloses a rubber material with a long service life and good mechanical properties. Raw materials of the rubber material comprise in parts by weight: 60 to 75 parts of chloroprene rubber, 25 to 32 parts of ethylene-propylene-diene rubber, 1.5 to 2.3 parts of a titanate coupling agent, 1 to 2 parts of sulfur, 0.8 to 1.5 parts of accelerant 4010NA, 1.5 to 2.5 of dibenzothiazole disulfide, 1 to 1.8 parts of zinc oxide, 24 to 28 parts of ultrafine talc powder, 32 to 40 parts of modified bentonite, 18 to 23 parts of silicon carbide whisker, 15 to 30 parts of nano zinc oxide, 32 to 38 parts of furnace carbon black, 1 to 2 parts of calcium stearate, 1 to 2 parts of microcrystalline wax, 1.5 to 2 parts of antioxidant A, 1 to 2 parts of antioxidant D, and 1.5 to 2.3 parts of stearate. The rubber material provided by the present invention is excellent in mechanical properties and long in service life.

Owner:合肥市再德高分子材料有限公司

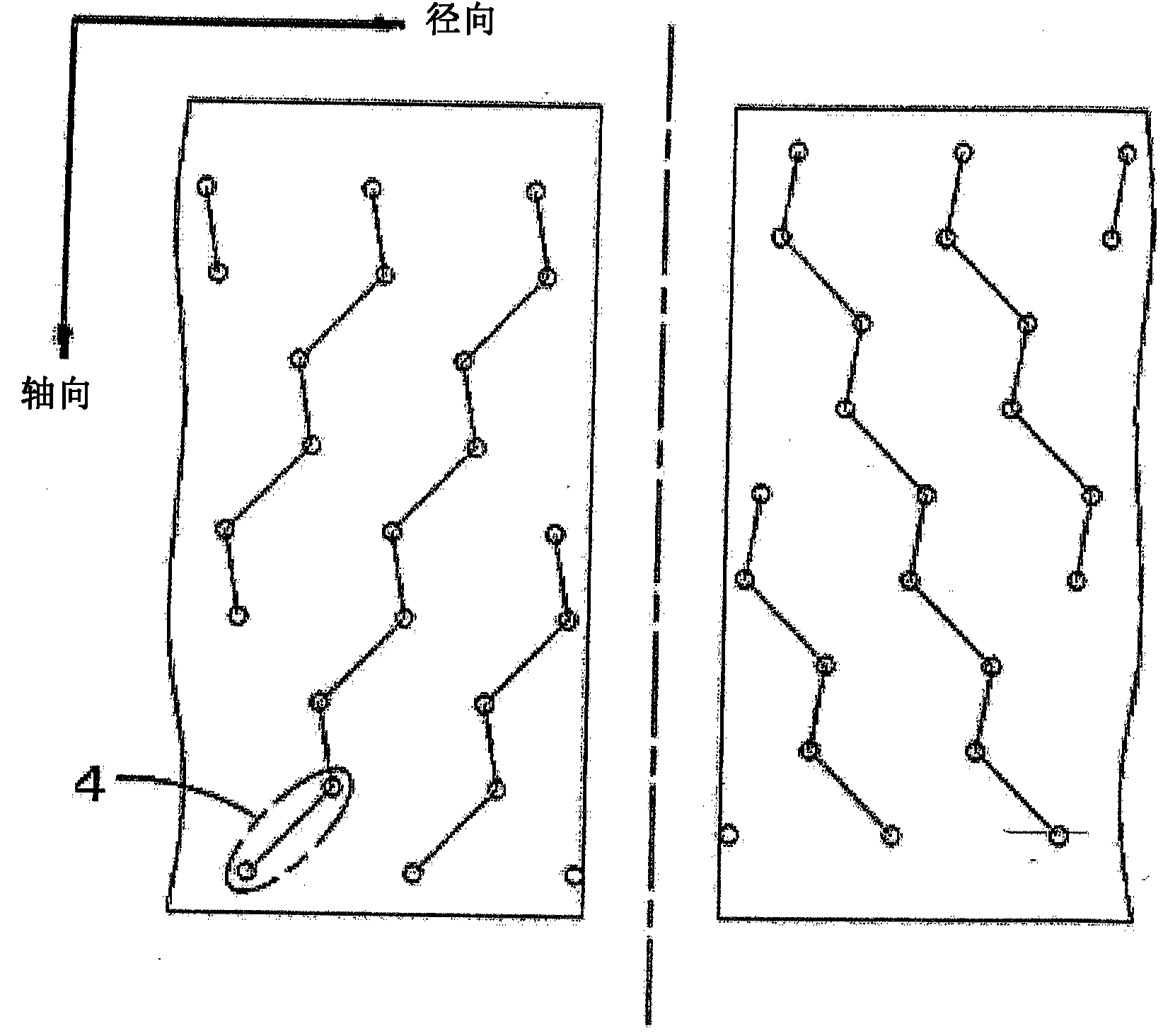

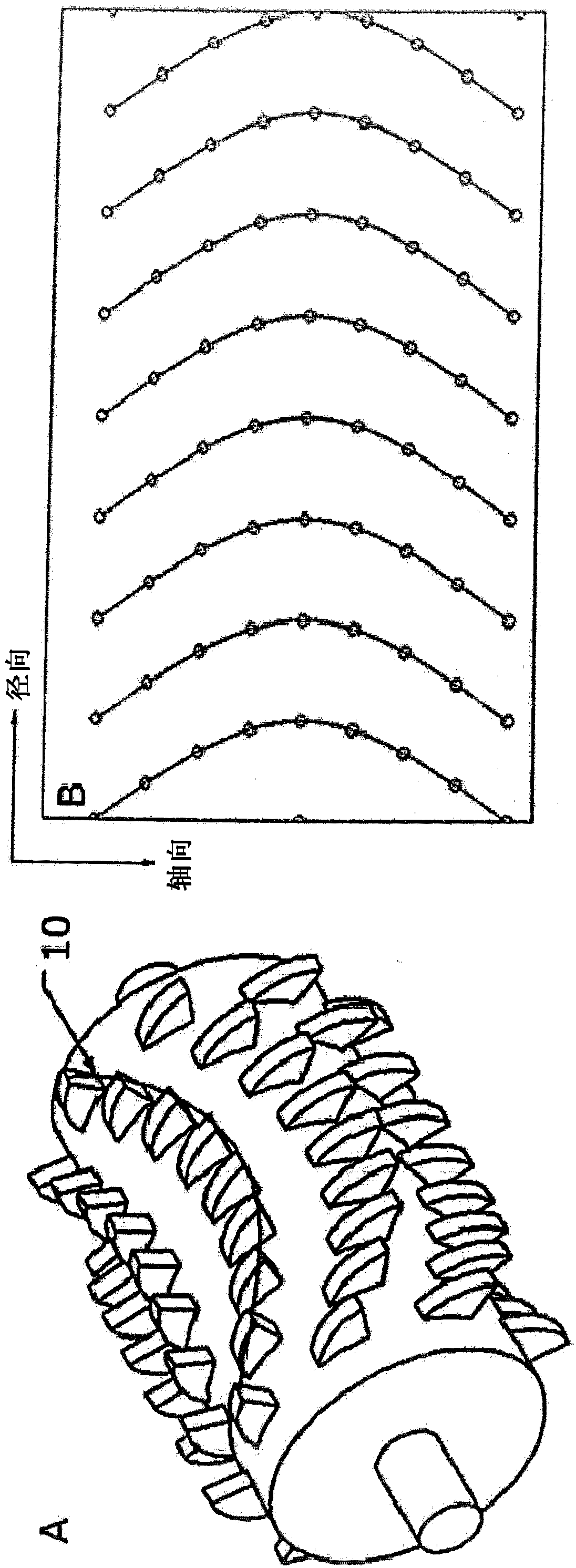

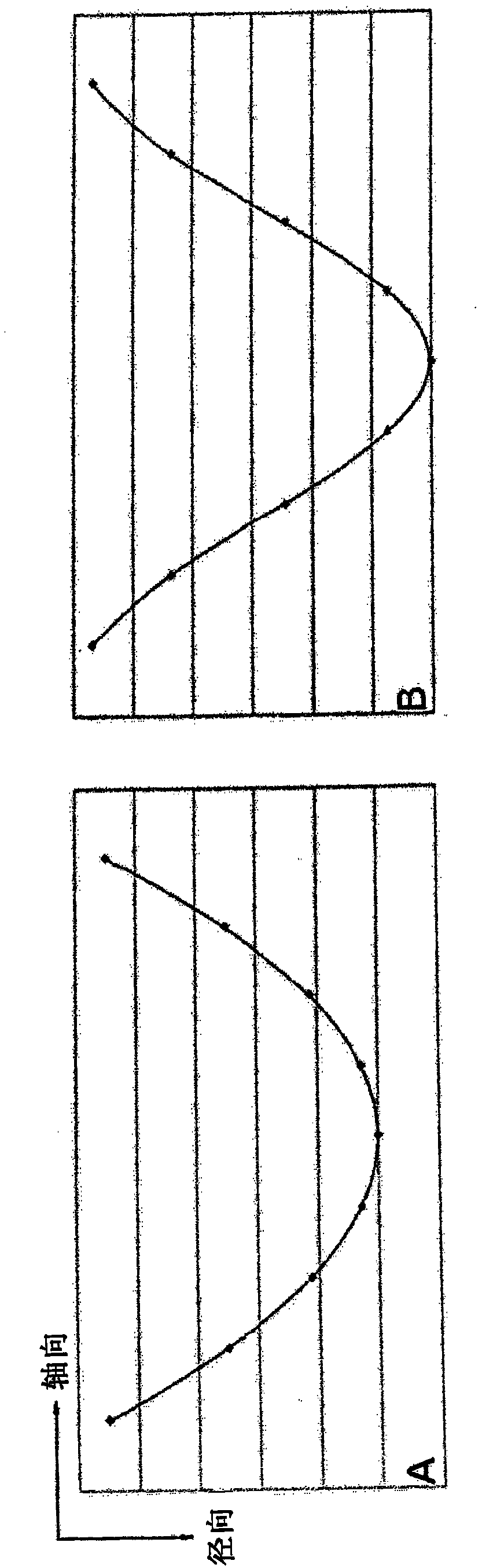

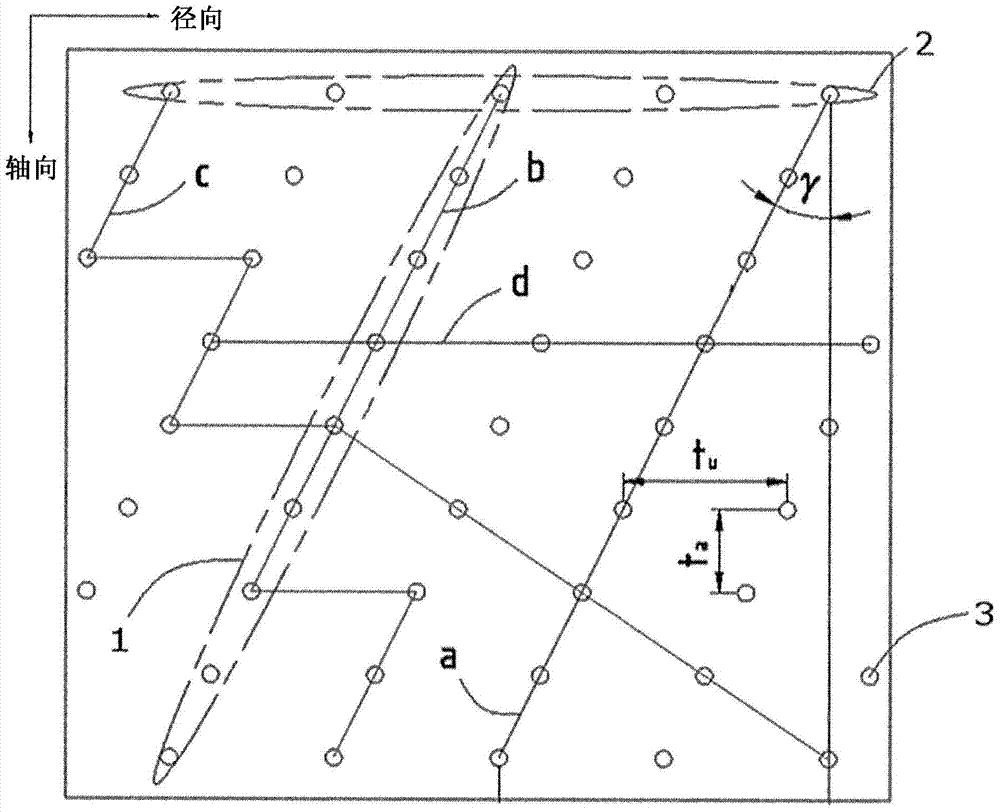

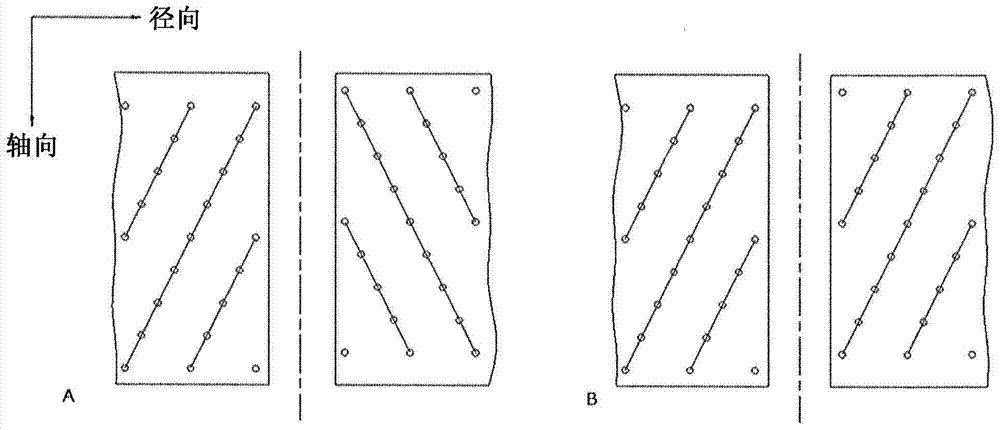

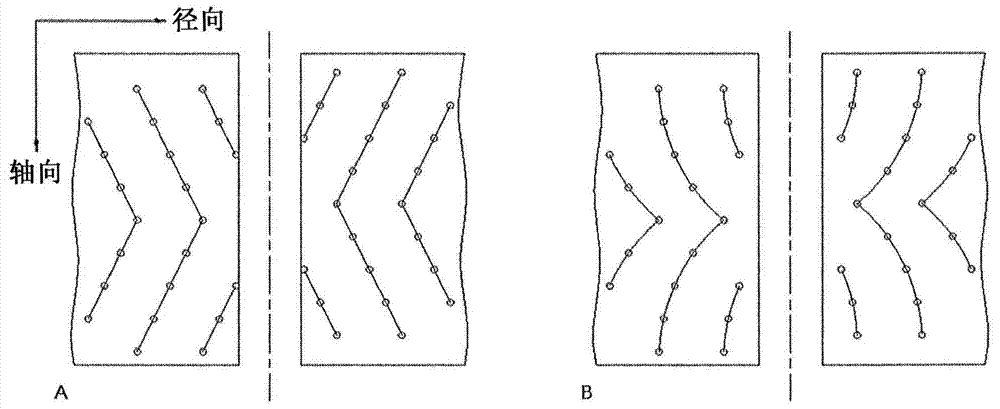

Arc-shaped and polygonal crushing tooth arrangement in rotor crushers and roller crushers

A crushing tooth arrangement for roller crushers or rotor crushers with improved draw-in, discharge, throughput, crushing and / or wear behavior is provided. The crushing tooth arrangement has rows of teeth of the rollers or rotors that do not have any points of discontinuity and have opposing offset angle courses in the axial direction. Forces are exerted, on the material to be crushed or bulk material fed in, which generate an axial mass flow, which homogenizes an inhomogeneous material distribution fed in along the rollers or rotors. Furthermore, a crushing tooth arrangement is provided, in which the rows of teeth each comprise at least three tooth subgroups arranged in an axially aligned manner each with at least two crushing teeth. The tooth subgroups are offset in an arrow-shaped manner and the rows of teeth are arranged opposing one another. This crushing tooth arrangement is especially suitable for crushing large chunks of material.

Owner:TAKRAF

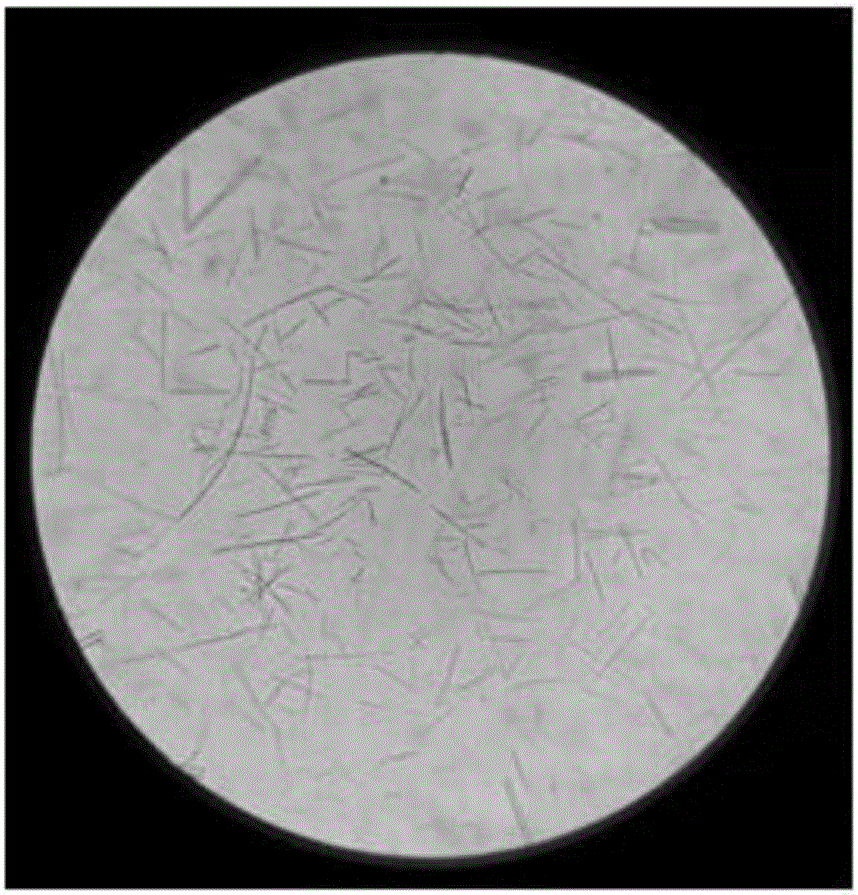

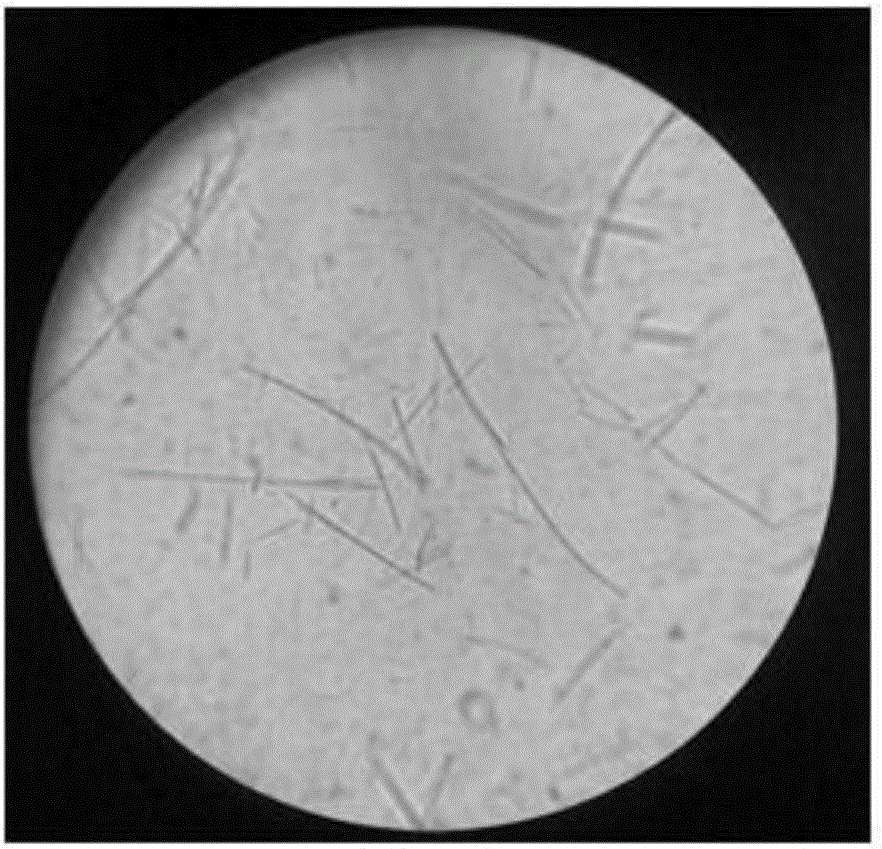

Filter aid for refined filtration of sodium aluminate solution and production and use method of filter aid

ActiveCN106732324AReduce solubilityUniform cross sectionOther chemical processesCalcium/strontium/barium sulfatesFiltrationSodium aluminate

The invention belongs to the technical field of production of aluminum oxide and particularly relates to a filter aid for refined filtration of a sodium aluminate solution and a production and use method of the filter aid. The filter aid for refined filtration of the sodium aluminate solution is alpha-phase calcium sulfate whisker, and the weight content of CaSO4 in the alpha-phase calcium sulfate whisker is greater than or equal to 98 percent. The preparation method comprises the following steps: oxidizing coal-fired power plant or sulfide-containing mineral sintering flue gas desulphurization byproduct, carrying out hydrothermal synthesis reaction and then calcining, wherein the average diameter of the whisker is 0.2 to 4mu m, and the average length-diameter ratio is 30 to 150. The particle size distribution and the dissolving property of the filter aid disclosed by the invention both can meet the requirements of serving as a sodium aluminate filter aid; moreover, the filter aid also has the advantages of good performance and low cost, and is suitable for popularization and application in the production process of the aluminum oxide.

Owner:湖南诺兰蒂尔环保科技有限公司

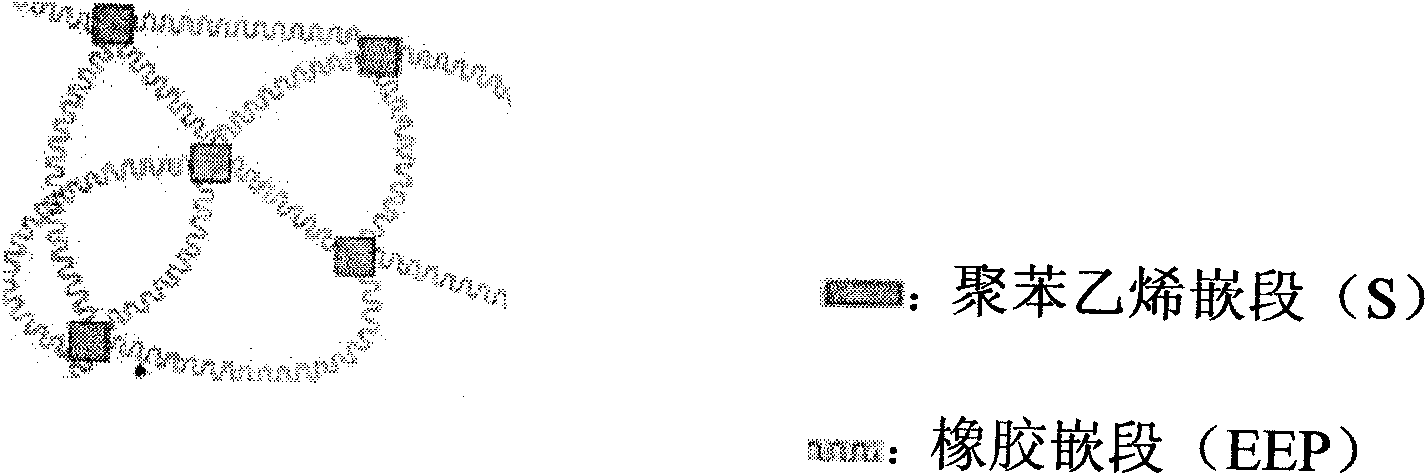

Thermoplastic elastomer of hydropolymer and method for preparing same

The invention relates to a thermoplastic elastomer of hydropolymer and a method for preparing the same. The thermoplastic elastomer is mainly applied to aerospace sealing and sealing and shockproof protectors in the fields of electronics, electric power, energy, communication and the like. For the thermoplastic elastomer, the polymer molecular weight is between 100,000 and 500,000, the S-EEP-S three-block structure is adopted, wherein S is a polystyrene section, EEP is an alkadiene section, the melting-contact point is more than or equal to 230 DEG C, the tearing strength is between 40 and 70Ma, the breaking elongation is between 1,500 and 1,900 percent, and the deformation rate is less than or equal to 2 percent; the elastomer can resist acid, alkali and temperature, the temperature resistant range is that the high temperature is 80 DEG C, and the low temperature is 40 DEG C below zero; moreover, the elastomer can shield ultraviolet rays, the anti-ageing capability is 10 years, and the toughness and the strength ISO37 are 10 times of 3MPa.

Owner:河北星河通信技术有限公司

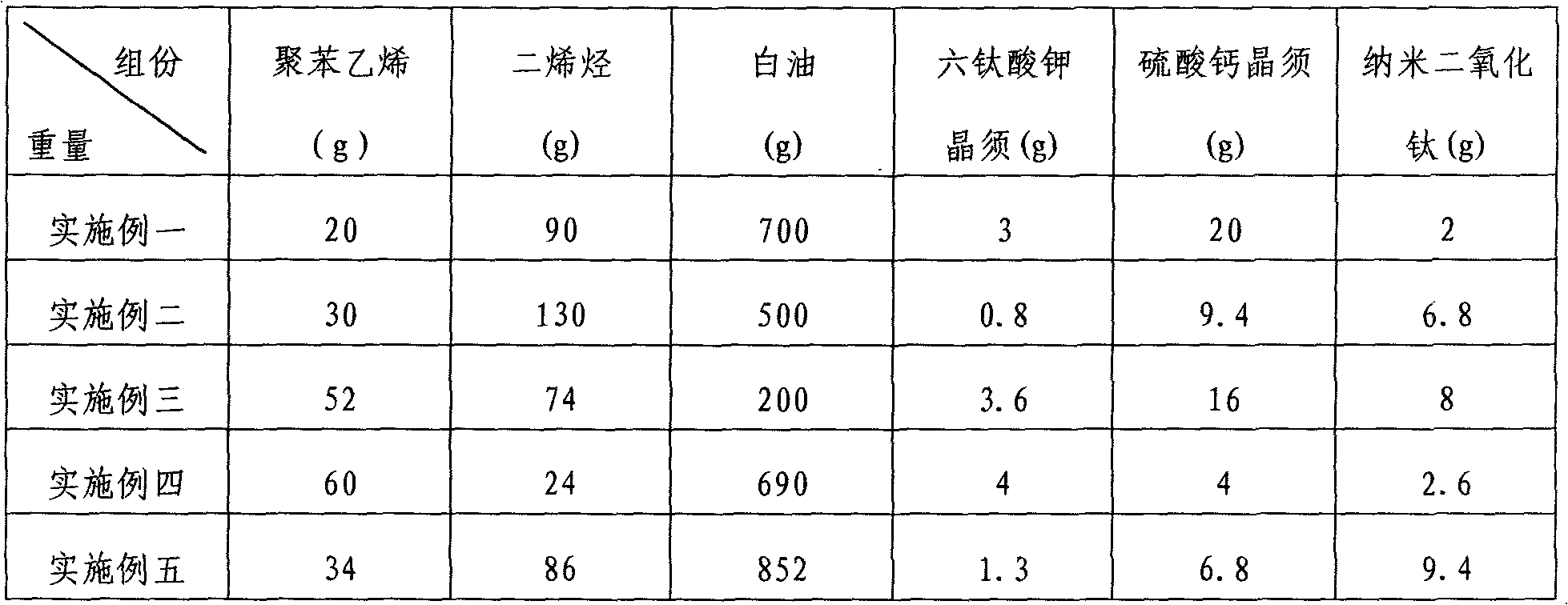

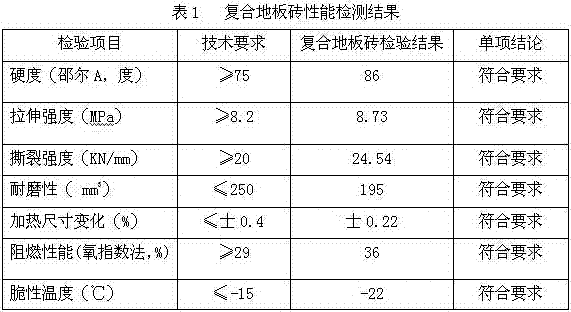

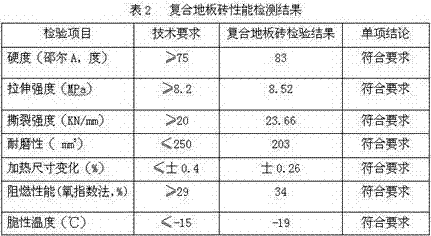

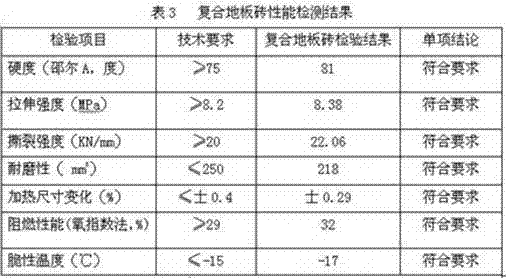

A modified aluminum borate whisker and its composite floor tile made of waste plastic

The invention discloses a modified aluminum borate whisker, which is composed of 0.5-2wt% coupling agent, 1.5-4wt% liquid paraffin and 95%-98wt% aluminum borate whisker, which is produced according to the following steps: a. Stir the coupling agent and liquid paraffin with a mixer for 3 to 4 minutes at 20°C to obtain a coupling agent dilution; b. Add aluminum borate whiskers to a high-speed mixer, heat and stir, and add the coupling agent at 80°C agent diluent, mixed for 5 to 10 minutes to obtain modified aluminum borate whiskers; the composite floor tiles made of it and waste plastics are made of the following raw materials in parts by weight: 20 to 40 parts of waste polyethylene plastics, 20 to 40 parts of waste polypropylene 20-50 parts of plastic, 30-50 parts of modified aluminum borate whiskers. The invention changes the surface properties of the aluminum borate whiskers from hydrophilic to lipophilic, greatly improves the blending compatibility and combination with waste polyethylene and polypropylene, and has good market prospects.

Owner:GUIZHOU UNIV

Corrosion-resistant PE composite material for septic tank and preparation method of corrosion-resistant PE composite material

PendingCN112608549AUniform cross sectionConsolidation fastLinear low-density polyethyleneAntioxidant

The invention discloses a corrosion-resistant PE composite material for a septic tank and a preparation method of the corrosion-resistant PE composite material. The corrosion-resistant PE composite material for the septic tank comprises the following components in parts by weight: 40-50 parts of linear low-density polyethylene, 15-20 parts of polyethylene glycol gel powder, 1-3 parts of a plasticizer, 1-3 parts of a lubricant and 1-3 parts of an antioxidant. The corrosion-resistant PE composite material for the septic tank has good corrosion resistance, can resist corrosion of various chemical media, especially acid, alkali, salt and oil, and is high in environmental adaptability, the preparation method is simple and easy to operate, and the corrosion-resistant PE composite material has good market prospects.

Owner:FUJIAN RESINTECH PLASTICS

Method for manufacturing magnesium boride superconductive belt material

InactiveCN102034575BImprove compactnessIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesDiamond-like carbonArgon atmosphere

The invention provides a method for manufacturing a magnesium boride superconductive belt material. The method comprises the following steps: A, uniformly distributing amorphous boron on a conductive substrate by adopting a coating method to form an amorphous boron layer with thickness of between 0.1 and 2.0mm; B, covering a magnesium or magnesium alloy flake with thickness of between 0.1 and 2.0mm on the boron layer, and rolling to form a magnesium-boron-substrate combination; C, putting the combination in the step B in a thermal treatment furnace, under the protection of argon atmosphere, heating to the temperature of between 550 and 800 DEG C, preserving the temperature for 0.1 to 3 hours, and cooling; D, coating metal, metallic oxide, silicon carbide or diamond like carbon film on thecombination which is treated in the step C to serve as a protective layer to form a composite body; and E, cutting the composite body in the step D into long belts. The MgB2 superconductive belt prepared by the method has the advantages of good compactness and grain connection, high critical current density, uniform current density distribution and high fatigue life, and is suitable for commercial application. The method is simple, and is suitable for industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of modification method of proton exchange membrane for all-vanadium redox flow battery

InactiveCN106784917BImprove bindingImprove permeabilityRegenerative fuel cellsSilicic acidIon exchange

The invention relates to a modification method of a proton exchange membrane for an all-vanadium redox flow battery, relating to the technical field of batteries. The modification method comprises the following steps: S1, preparation of submicron order ZSM-5 type zeolite: evenly mixing deionized water, tetrapropylammonium hydroxide, silicic acid and sodium metaaluminate, performing a hydrothermal synthesis method to the mixed solution, and then performing centrifugal cleaning and drying, so as to prepare the submicron order ZSM-5 type zeolite; and S2, preparation of a composite proton exchange membrane: preparing the composite proton exchange membrane from the submicron order ZSM-5 type zeolite obtained in the step 1 and a proton exchange membrane solution. The water-absorbing property, ion exchange capacity, proton conductivity and vanadium ion permeability of the composite proton exchange membrane prepared by adopting the modification method are superior to those of an unmodified proton exchange membrane. Compared with the unmodified proton exchange membrane, the vanadium ion permeability of the composite proton exchange membrane is reduced by 11%, and the proton conductivity is improved by 20%.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

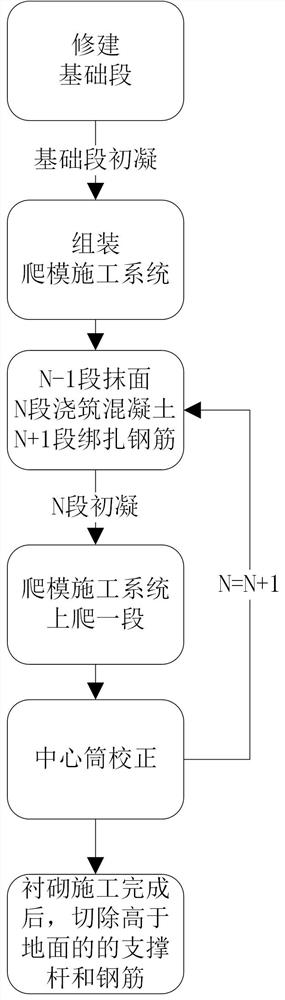

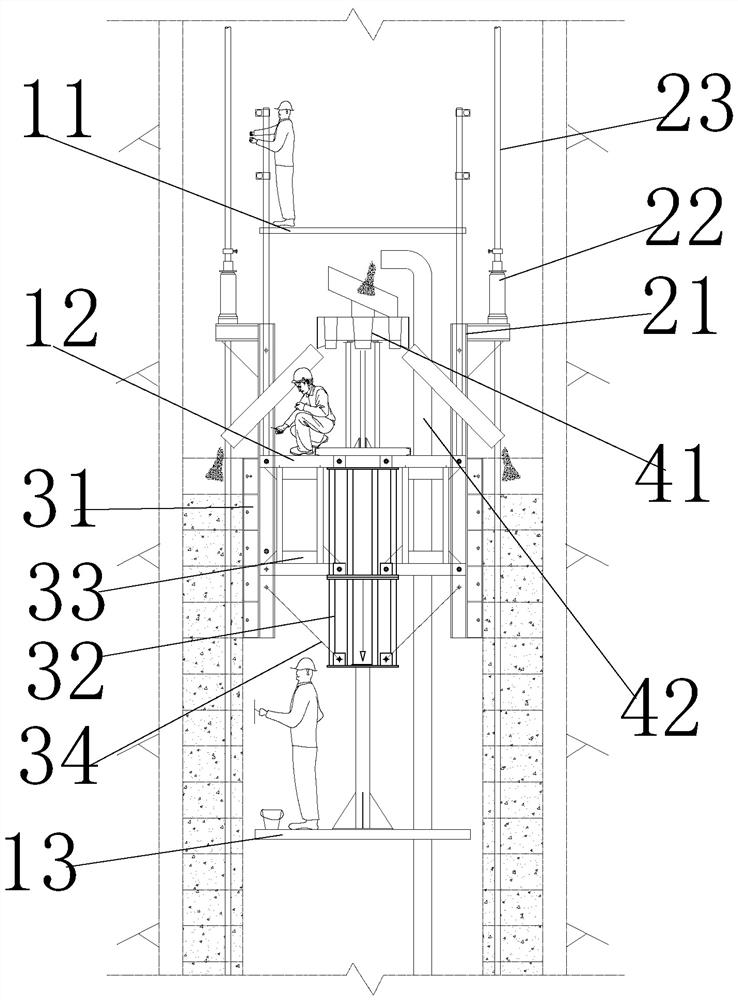

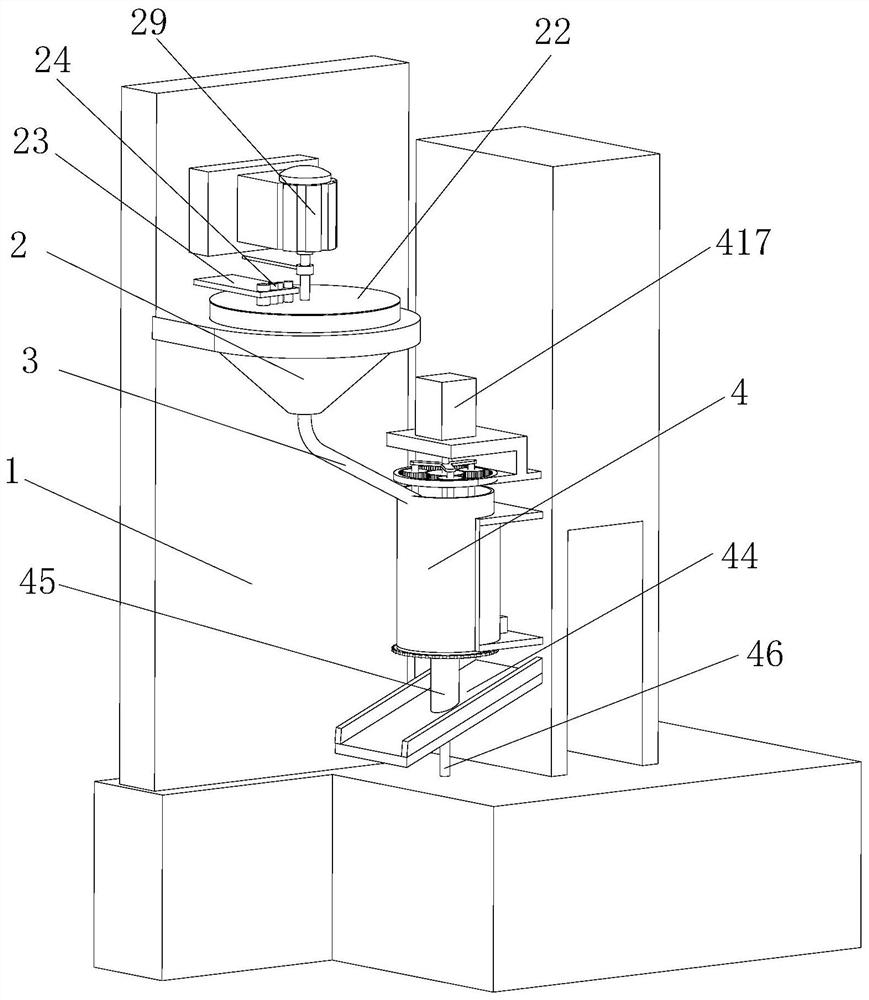

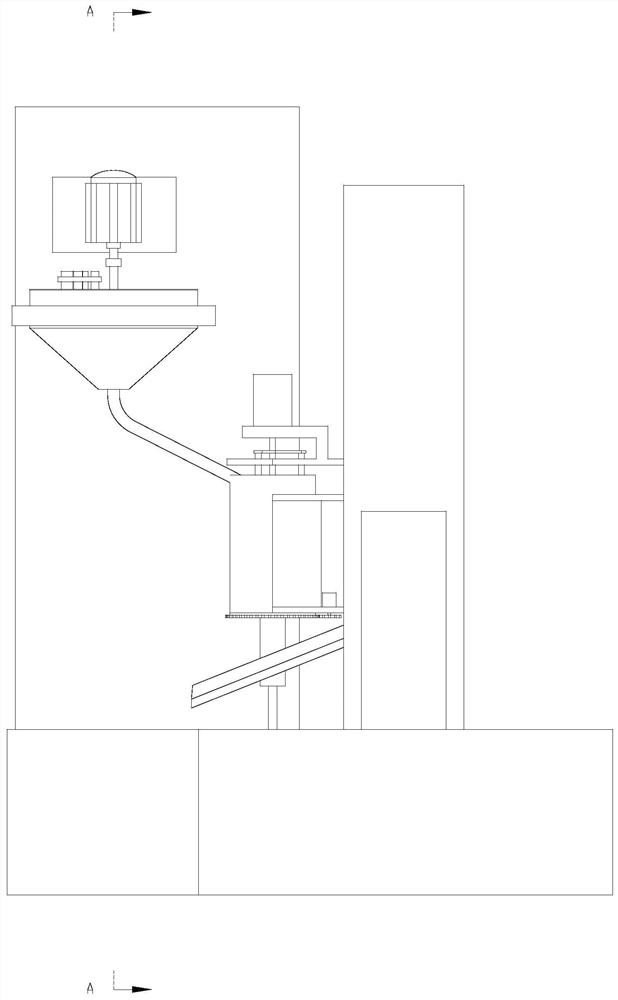

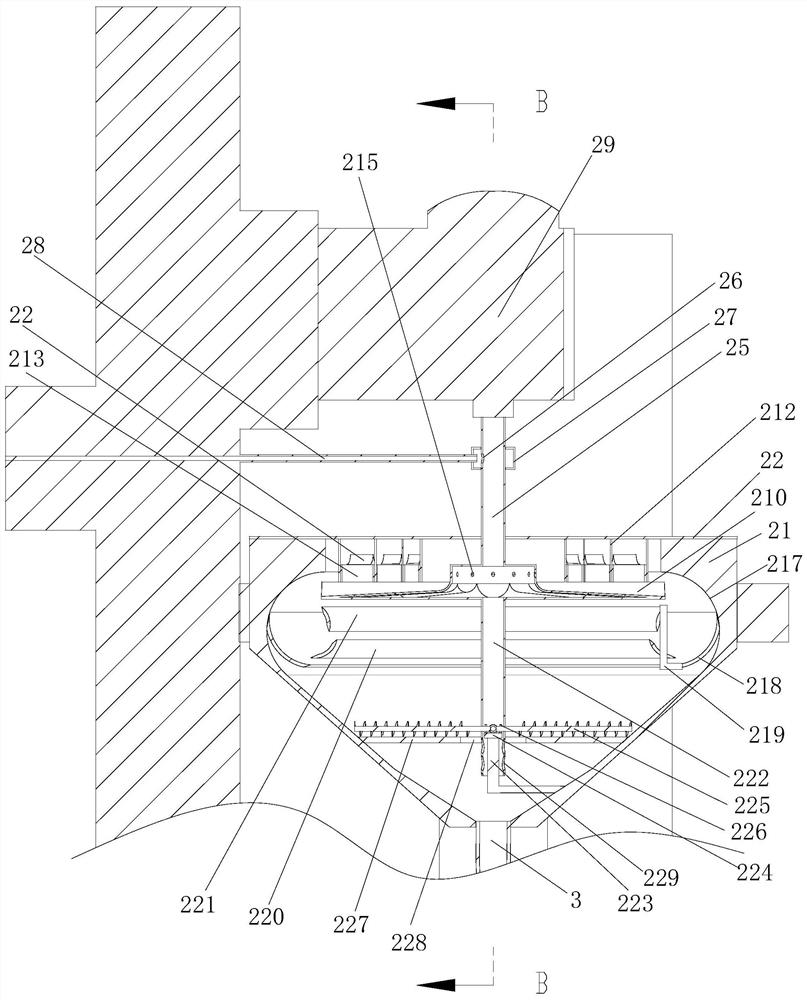

A kind of pipeline type shaft inner wall pouring method

ActiveCN114526078BImprove construction efficiencyShorten the construction periodHydro energy generationShaft liningClassical mechanicsJackscrew

The invention relates to the technical field of shaft lining, and discloses a pipeline-type shaft inner wall pouring method, which is used for bottom-up construction of the shaft lining in the shaft; The construction system integrates the construction equipment and working platform required for the construction of shaft lining according to the construction sequence, and allows multiple processes to be constructed at the same time, which significantly shortens the construction period; the whole system is supported by through-core jacks and support rods, which is different from the traditional climbing formwork system. In contrast, without relying on the load-bearing of the concrete structure, the currently poured concrete can climb after the initial setting, and the formwork is supported by the elastic central cylinder, and the formwork is enclosed into a variable-diameter cylinder structure with upper thickness and lower thickness, so that climbing does not need to retreat. The mold can be carried out smoothly; the laser leveling device and the locker ensure that the top elevations of each lifting frame are consistent during climbing, and the tensioning connector ensures that after each climbing is completed, the center cylinder and the shaft are coaxial, so that the construction accuracy is extremely high.

Owner:BEIJING NO 3 CONSTR ENG

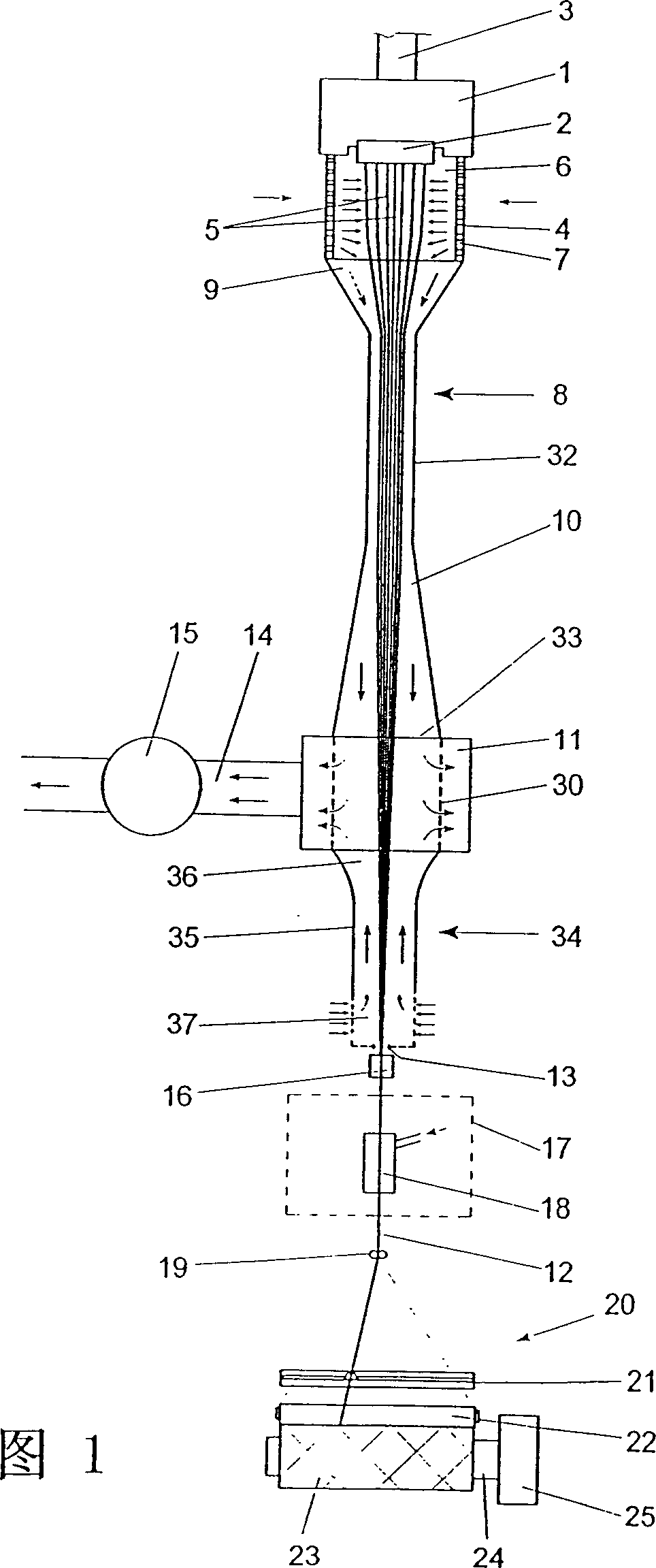

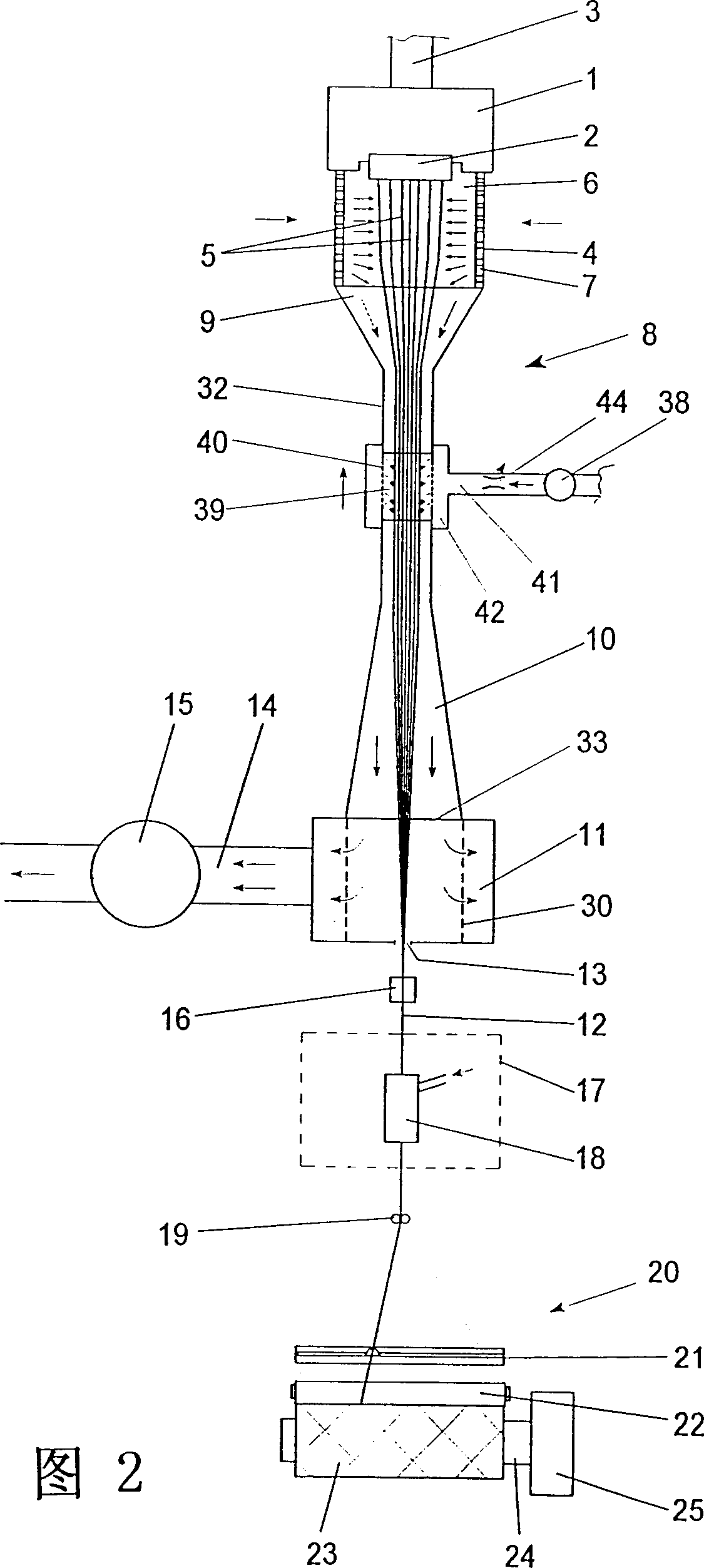

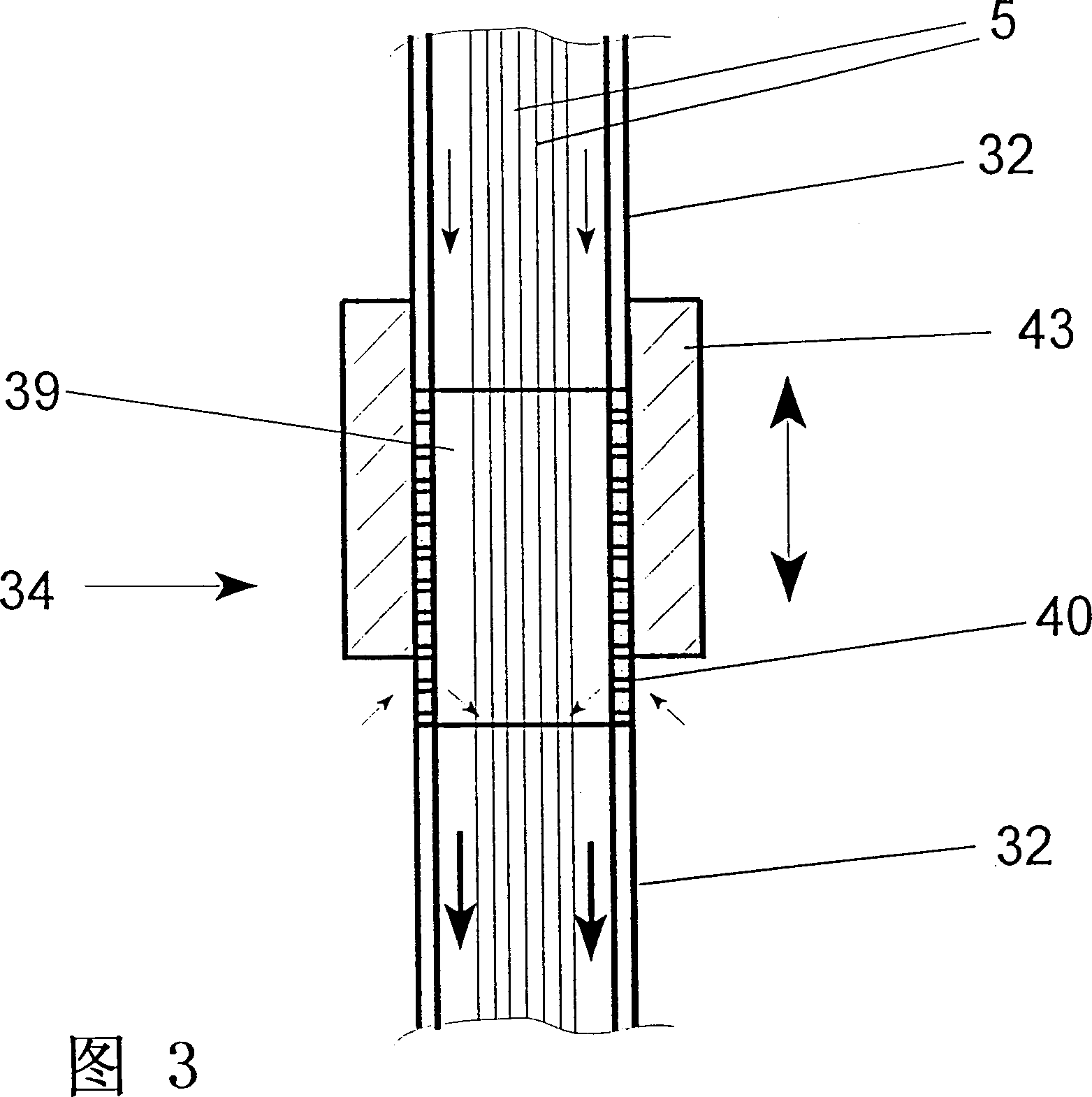

Spinning device and method for spinning synthetic thread

InactiveCN1117186CUniform cross sectionHigh spinning reliabilityArtificial thread manufacturing machinesFilament/thread formingYarnEngineering

A melt spinning apparatus for spinning a synthetic yarn, wherein the yarn is formed by combining a plurality of filaments and wound to a package by means of a takeup device downstream of the spinning apparatus. Downstream of the spinneret, an inlet cylinder with a gas-permeable wall and a cooling tube are arranged. The cooling tube connects to a suction device such that an air stream forms in the cooling tube in the direction of the advancing yarn. This air stream assists the advance of the filaments and leads to a delayed cooling. To ensure adequate cooling of the filaments within the cooling zone, an air supply device is provided for generating an additional cooling air stream which flows in the axial direction of the cooling tube for cooling the filaments downstream of the inlet to the cooling tube.

Owner:SAURER GMBH & CO KG

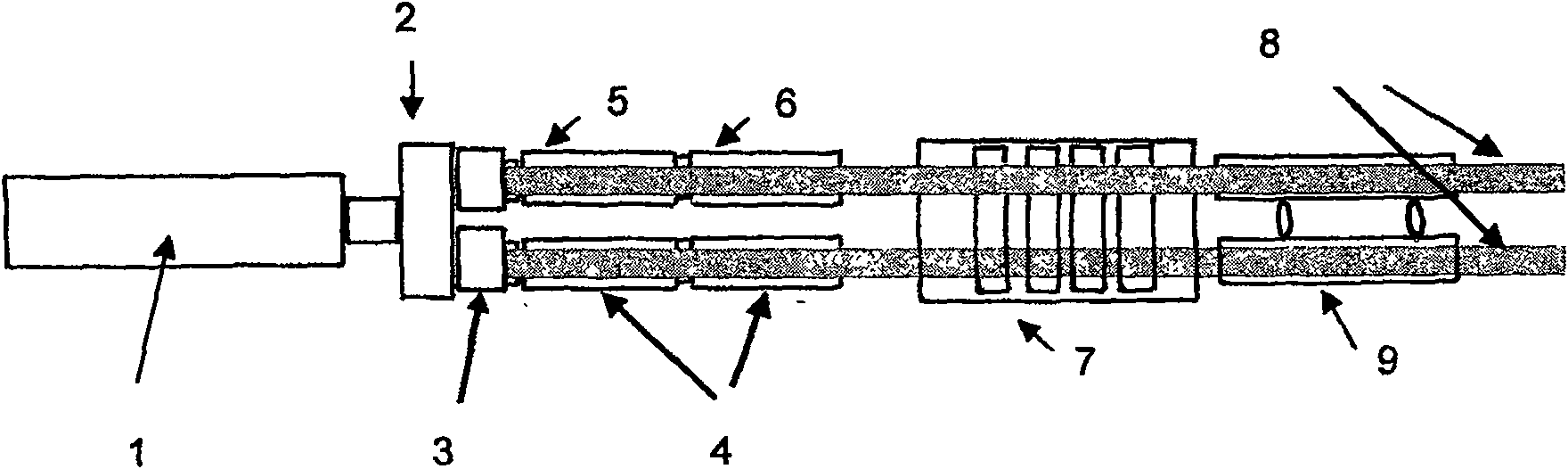

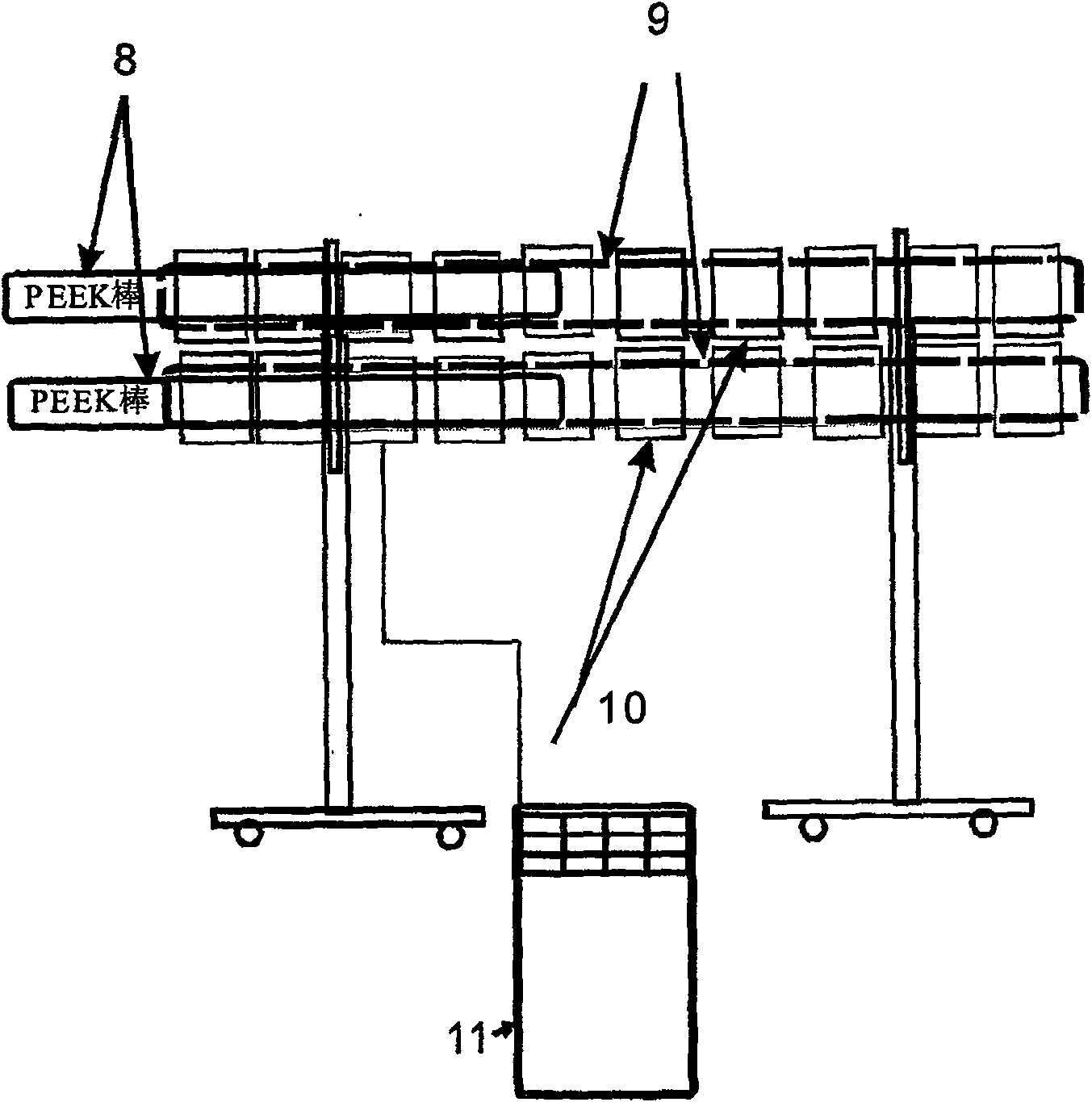

A method for preparing poly(ether-ether-ketone) rod bar

The invention pertains to the plastic product and the profile field thereof, and in particular relates to a method to prepare a PEEK bar by means of extrusion molding. PEEK is put into the feed hopper of an extruder, and is fused to plasticize in the extruder barrel below the degree of 360-400 DEG C, so as to form PEEK melt, which is extruded out by the nose and rod dies. Under the role of back pressure rods with constantly reverse pressure, the melt enters into and permeates the Rod Dies, and then enters into the sizing sets linking with the Rod Dies; The melt goes on formation of products by echelon cooling gradually in the sizing sets, thus the PEEK bar is made. Then the bar is treated by the way of echelon annealing in a tube-type annealing furnace, at last the good crystallized PEEK bar with excellent size stability and against bending is obtained. The PEEK bar produced by the invention is used to the fields of aerospace, electronic and electrical engineering, cars, chemicals, as well as machine, etc., and is used to process all kinds of parts and products needed in these fields.

Owner:长春吉大特塑工程研究有限公司

Asphalt mixture for airport road construction and preparation method thereof

PendingCN112551949APlay a filling roleGood compatibilityIn situ pavingsRoads maintainenceArchitectural engineeringGlass microsphere

The invention discloses an asphalt mixture for airport road construction, which comprises the following components in parts by weight: 110 parts of matrix asphalt, 25 parts of sulfur, 900 parts of basalt, 100 parts of tall oil, 6 parts of hollow glass microspheres, 15 parts of polytetrafluoroethylene fibers, 15 parts of nano silicon dioxide and 35 parts of a wear-resistant agent.

Owner:浙江浙飞机场工程有限公司

A system of crushing teeth on the peripheral surface of the two rollers or the rotor of a roller crusher or rotor crusher

ActiveCN104117402BUniform cross sectionEvenly loadedGrain treatmentsInhomogeneous materialEngineering

A crushing tooth arrangement for roller crushers or rotor crushers with improved draw-in, discharge, throughput, crushing and / or wear behavior is provided. The crushing tooth arrangement has rows of teeth of the rollers or rotors that do not have any points of discontinuity and have opposing offset angle courses in the axial direction. Forces are exerted, on the material to be crushed or bulk material fed in, which generate an axial mass flow, which homogenizes an inhomogeneous material distribution fed in along the rollers or rotors. Furthermore, a crushing tooth arrangement is provided, in which the rows of teeth each comprise at least three tooth subgroups arranged in an axially aligned manner each with at least two crushing teeth. The tooth subgroups are offset in an arrow-shaped manner and the rows of teeth are arranged opposing one another. This crushing tooth arrangement is especially suitable for crushing large chunks of material.

Owner:TAKRAF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com