Thermoplastic elastomer of hydropolymer and method for preparing same

A technology of thermoplastic elastomers and hydrogenated polymers, applied in the field of elastomers, can solve the problems of high-altitude operations, sensitive shearing, slow cooling speed, etc., achieve strong ultraviolet shielding effect, enhance toughness and strength, and improve tensile strength. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

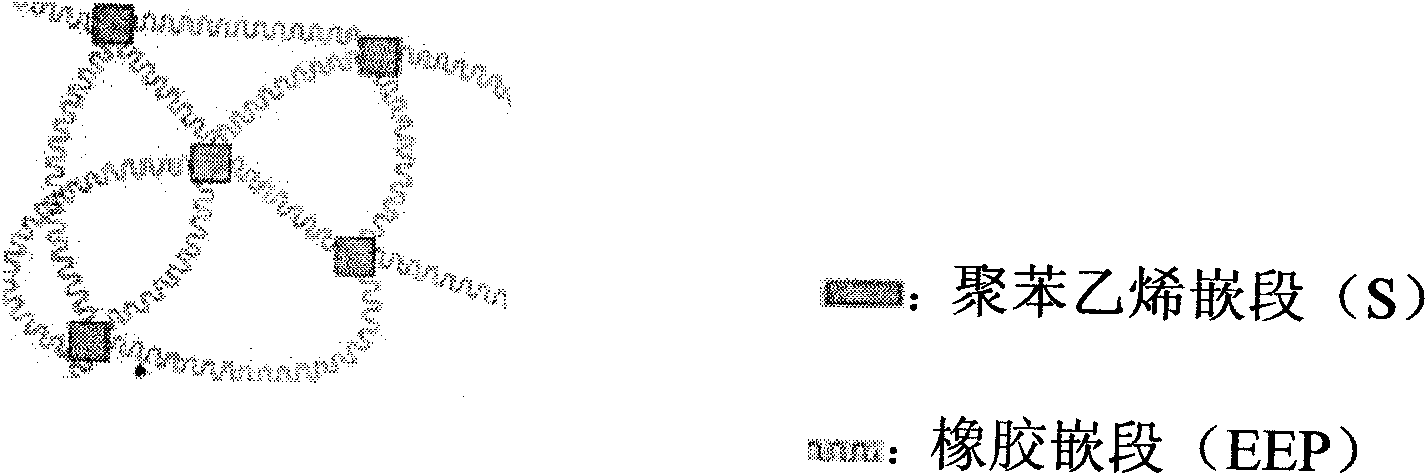

Image

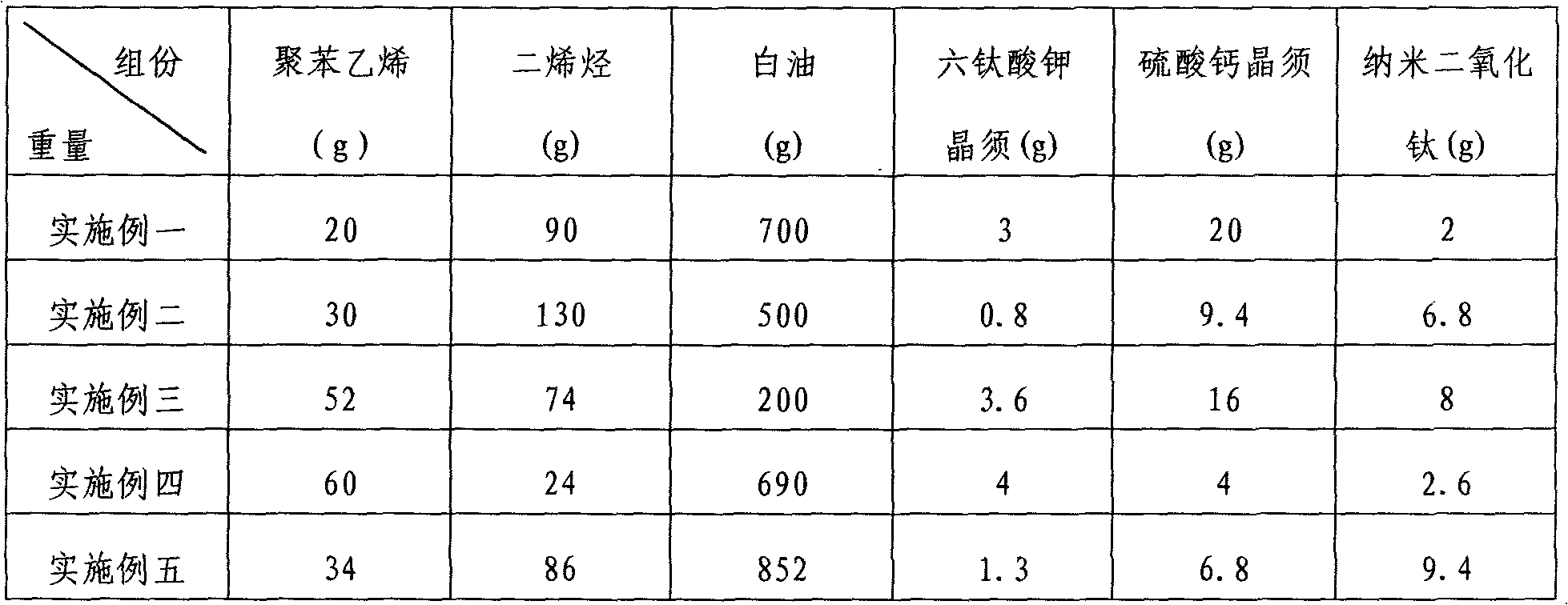

Examples

Embodiment Construction

[0033]

[0034] Preparation:

[0035] In the first embodiment above,

[0036](1) Take three 250ml three-necked bottles and one 1000ml absorption bottle and flush into nitrogen through vacuum baking, pipette 100ml cycloethane respectively for the three three-necked bottles, and then take two of them (one and two bottlenecks) ) respectively add 13.5g styrene with a syringe, take the first one and add 0.5mmol diglyme, add 2.4ml (about 1.77mmol) of butyllithium initiator with a concentration of 0.73mol / L at 60 degrees Celsius to polymerize, and the time is 0.5h, take the third one and add 30ml of isoprene, 50ml of butadiene, take 20g of propylene, add 1.5ml of butyllithium initiator with a concentration of 0.73mol / L at 60 degrees Celsius to polymerize for 0.5h.

[0037] Pipette pipette 500ml of cyclohexane, absorb 90g of diene, and add 20g of styrene and add it into a 2L kettle together with the above-mentioned active species solution of polystyrene. Stirring was started, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com