Turbine propeller and turbine engine

A technology for turbines, turbine blades, applied in the direction of supporting elements of blades, mechanical equipment, engine elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

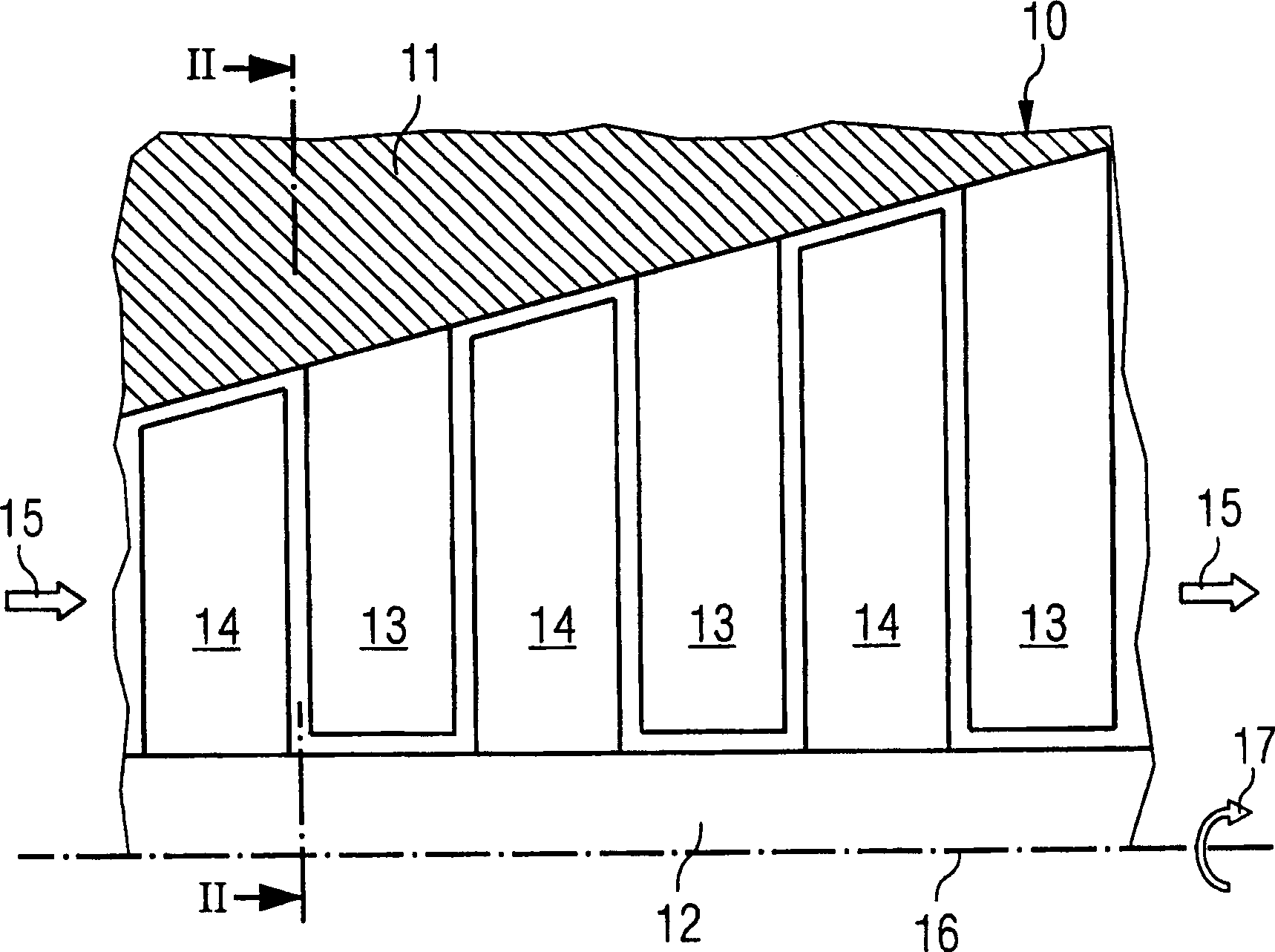

[0024] figure 1 A schematic longitudinal section of a gas turbine 10 with a housing 11 and a rotor 12 is shown. The casing 11 has stationary blades 13 and the rotor 12 has moving blades 14 . The hot flue gases pass through the gas turbine 10 in the direction of arrow 15 , causing the rotor 12 to rotate about an axis of rotation 16 in the direction of arrow 17 .

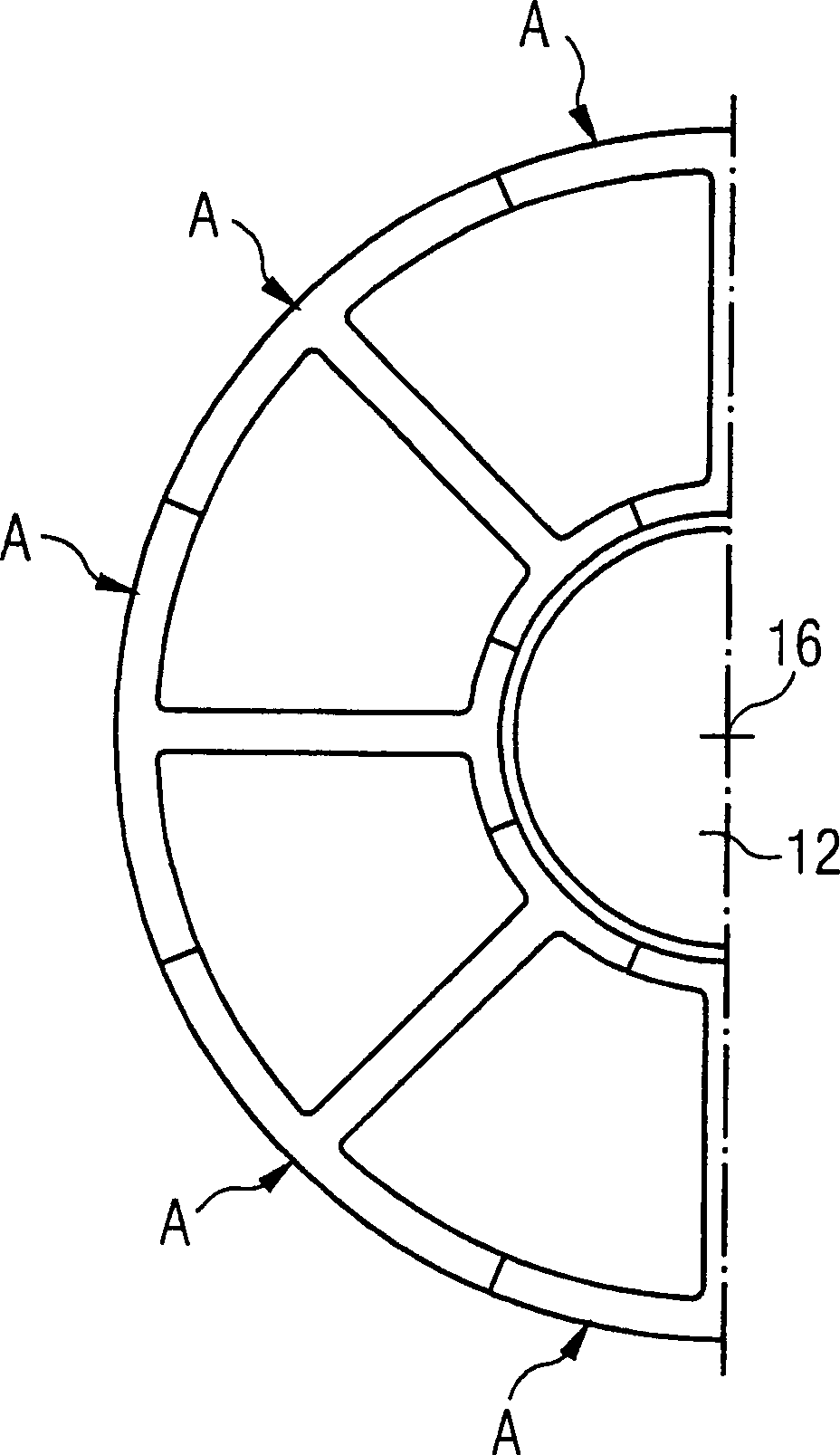

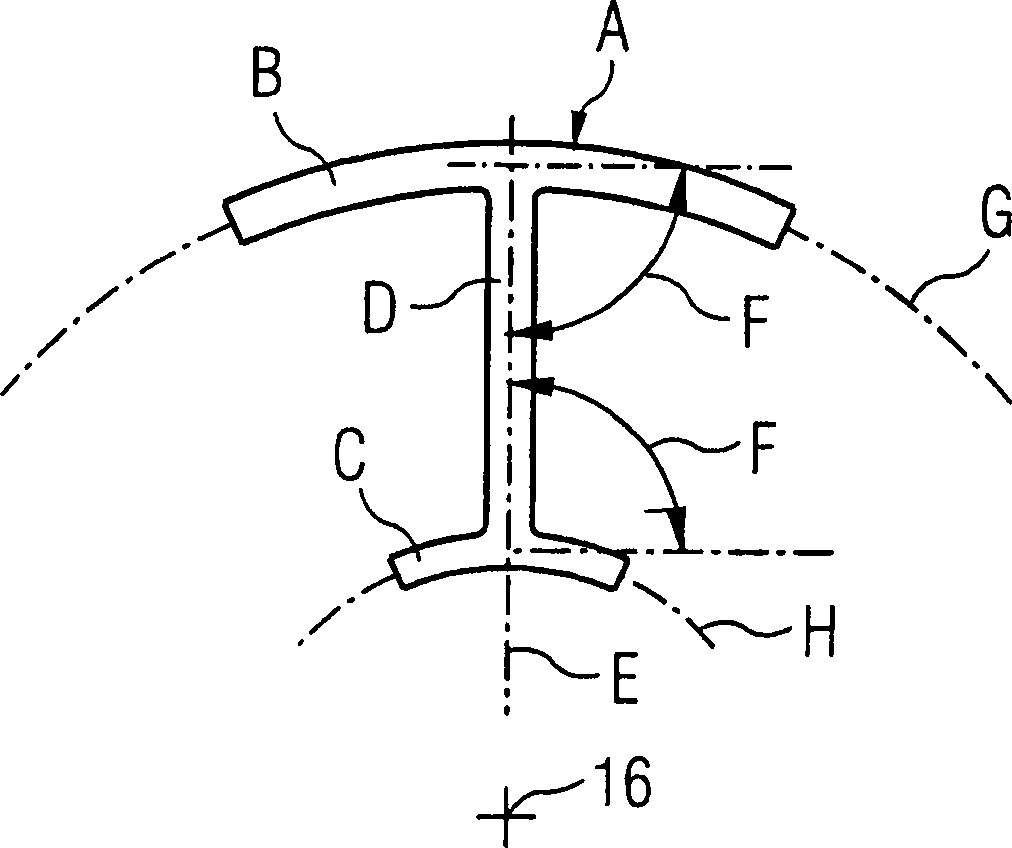

[0025] Figures 2 to 4 A design according to the prior art is shown. especially in figure 2 and image 3 As shown in , a plurality of stator blades A are arranged uniformly on the circumference of the gas turbine 10 . Each stationary blade A has a bottom plate B for fixing on the casing 11 and covering the gap between the two stationary blades A, a top plate C and a blade airfoil D between them. The longitudinal axis E of the blade profile passes through the axis of rotation 16 of the rotor 12 . Each base and top plate B, C protrudes from the blade airfoil D at a right angle F. For convenience of description,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com