Environment-friendly composite board

A composite board, an environmentally friendly technology, applied in the field of composite boards for construction, can solve problems such as environmental pollution and waste of resources, and achieve the effects of low cost, pollution reduction, good antibacterial and bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

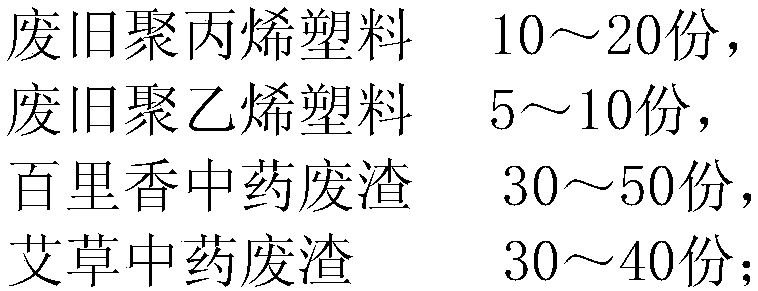

Method used

Image

Examples

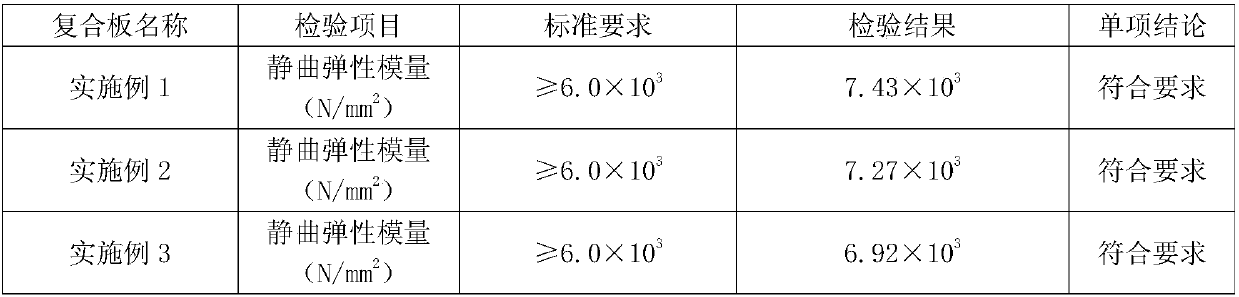

Embodiment 1

[0040] An environment-friendly composite board is made by the following steps:

[0041] a. Separately clean 100Kg of waste polypropylene and 50Kg of waste polyethylene plastics, dry them, crush them to less than 8mm, and mix them uniformly to obtain product A;

[0042] b. Wash and dry 300Kg thyme traditional Chinese medicine waste residue and 300Kg wormwood traditional Chinese medicine waste residue to be below 4mm, and mix them uniformly to obtain product B;

[0043] c. Mix product A and product B evenly and send them to the feed port of the screw extruder, and extrude at a screw speed of 70r / min and a barrel temperature of 175°C to obtain product C;

[0044] d. After calendering product C under a pressure condition of 4.8 MPa by a sheeting roller and two cooling rollers, the finished product is obtained by heating and leveling, cooling by arranging rollers, and trimming and shearing.

Embodiment 2

[0046] An environment-friendly composite board is made by the following steps:

[0047] a. Separately wash 150Kg of waste polypropylene and 80Kg of waste polyethylene plastics, dry them, crush them to less than 8mm, and mix them uniformly to obtain product A;

[0048] b. Wash and dry 400Kg thyme traditional Chinese medicine waste residue and 350Kg wormwood traditional Chinese medicine waste residue to be below 4mm, and mix uniformly to obtain product B;

[0049] c. Mix product A and product B evenly and send them to the feed port of the screw extruder, and extrude at a screw speed of 70r / min and a barrel temperature of 175°C to obtain product C;

[0050] d. After calendering product C under a pressure condition of 4.8 MPa by a sheeting roller and two cooling rollers, the finished product is obtained by heating and leveling, cooling by arranging rollers, and trimming and shearing.

Embodiment 3

[0052] An environment-friendly composite board is made by the following steps:

[0053] a. 200Kg of waste polypropylene and 100Kg of waste polyethylene plastics are sorted, cleaned, dried, crushed to less than 8mm, and mixed uniformly to obtain product A;

[0054] b. Wash and dry 500Kg of thyme traditional Chinese medicine waste residue and 400Kg of mugwort Chinese medicine waste residue to below 4mm, and mix uniformly to obtain product B;

[0055] c. Mix product A and product B evenly and send them to the feed port of the screw extruder, and extrude at a screw speed of 70r / min and a barrel temperature of 175°C to obtain product C;

[0056] d. After calendering product C under a pressure condition of 4.8 MPa by a sheeting roller and two cooling rollers, the finished product is obtained by heating and leveling, cooling by arranging rollers, and trimming and shearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com