A system of crushing teeth on the peripheral surface of the two rollers or the rotor of a roller crusher or rotor crusher

A roller crusher and rotor type technology is applied in the field of the crushing tooth system on the two rollers of the roller crusher or the rotor crusher or on the peripheral surface of the rotor, and can solve the problem that the radial connecting line is not named. , to achieve the effect of reduced tooth wear, long service life and high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

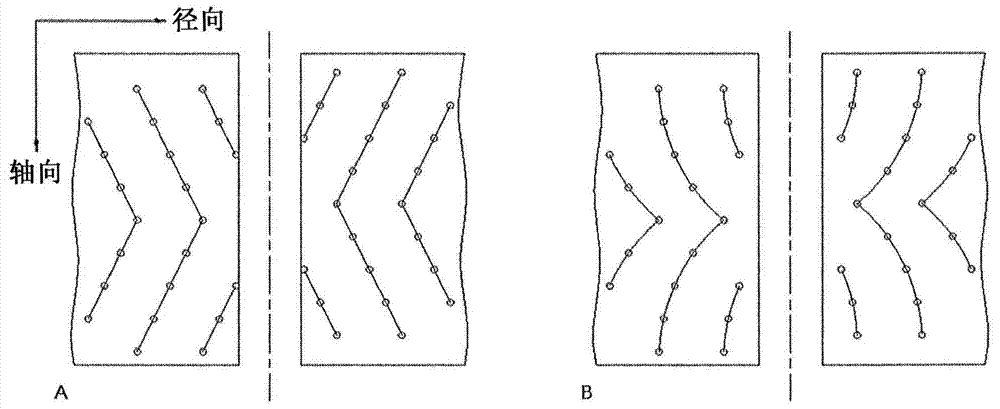

[0052] exist Figure 7The exemplary illustrated arched configuration in includes construction lines with polynomial functions of permutations of the second (A) and third (B). Advantageously, this arched formation is represented by polynomial functions arranged arbitrarily, since these polynomial functions are always continuously differentiable and do not contain discontinuities as in the case of an arrowhead formation at the tip of the arrow .

[0053] exist Figure 8 The arched configuration with eccentric (A) and concentric (B) arch segments pointing towards the crushing gap or pointing away from the crushing gap is shown in . In the case of arching in the direction of the crushing gap, the material is conducted towards the edge of the rotor / roller (eccentrically), otherwise towards the center (concentrically).

[0054] It is also possible to switch a plurality of arches in a row of teeth in undulating succession in the manner of multiple arches.

[0055] A crushing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com